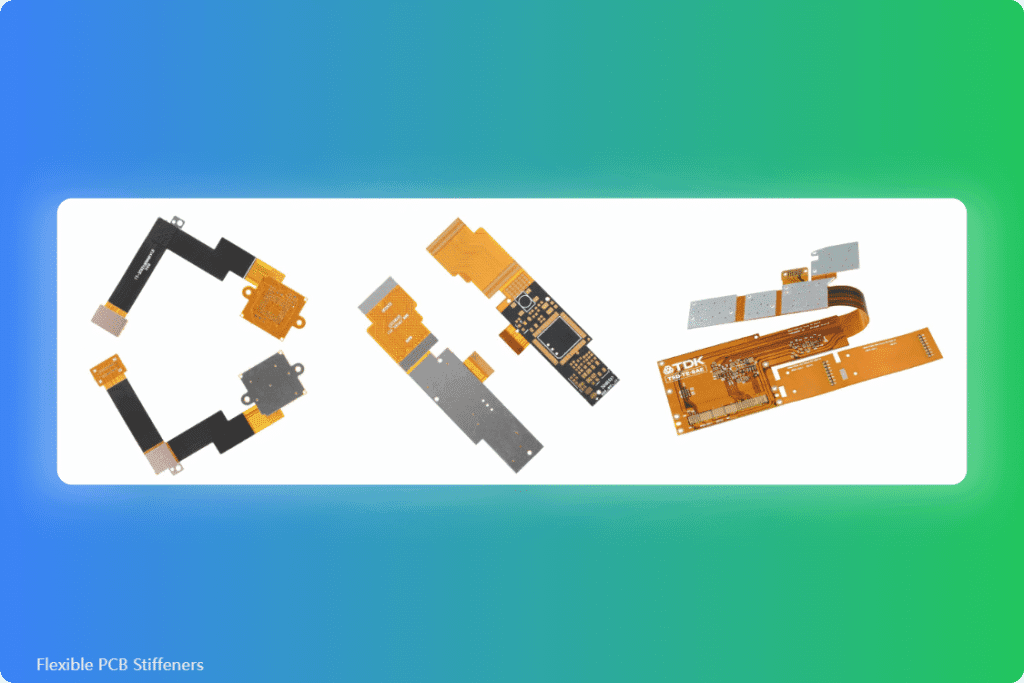

Flexible PCBs enable compact, adaptable designs in modern electronics, from foldable smartphones to aerospace control systems. Their polyimide-based flexibility supports innovative form factors, but excessive bending risks damaging components, cracking solder joints, or misaligning connectors. Flexible PCB stiffeners address these challenges by providing targeted mechanical support, balancing flexibility with rigidity to ensure durability and performance.

Unlike the PCB’s electrical layers, PCB stiffeners are non-conductive components, typically made from FR4, polyimide (PI), or metals like stainless steel or aluminum. They reinforce specific areas, enabling high-density component mounting, reliable ZIF connector performance, and compliance with standards like IPC-2223. This comprehensive guide explores the definition, materials, applications, and benefits of flexible PCB stiffeners, offering insights for engineers, designers, and manufacturers. Read on to discover how stiffeners can elevate your PCB design, streamline production, and meet industry demands.

Table of Contents

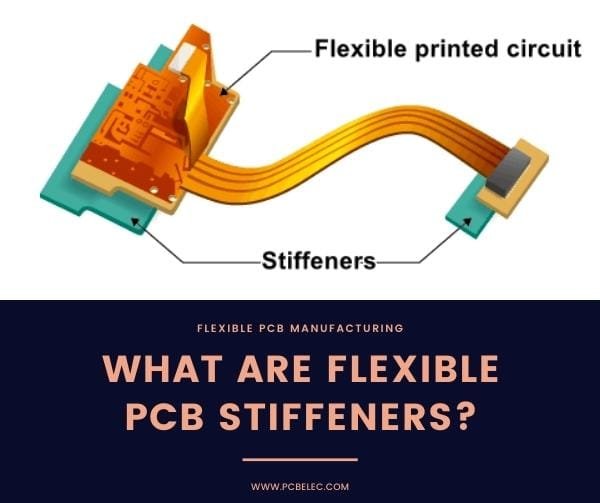

What Are Flexible PCB Stiffeners?

Flexible PCB stiffeners are non-electrical components applied to flexible circuit boards or rigid-flex PCBs to enhance mechanical stability without altering electrical functionality. Made from materials like FR4, polyimide, or metals, stiffeners counteract the inherent pliability of polyimide substrates, which can lead to stress-induced failures in dynamic or high-density applications.

The primary role of a PCB stiffener is to reinforce specific PCB regions, ensuring structural integrity under mechanical or environmental stress. For instance, in a foldable smartphone, a PI stiffener behind a ZIF connector maintains precise thickness (e.g., 50 µm), ensuring reliable connections despite repeated flexing. In automotive radar systems, an aluminum stiffener dissipates heat from power components, reducing thermal stress by up to 15% (per IPC studies).

Stiffeners address several challenges:

- Preventing Excessive Bending: Limit flexing to protect solder joints, reducing failure rates by 20% in dynamic applications.

- Supporting Components: Provide a rigid surface for Surface Mount Technology (SMT) and Plated-Through Hole (PTH) parts.

- Ensuring Connector Compatibility: Achieve exact thickness for ZIF connectors, critical in medical wearables.

- Facilitating Assembly: Enable automated pick-and-place processes, improving yield.

By integrating stiffeners, designers can optimize flexible PCB reliability, making them indispensable for industries like consumer electronics, aerospace, and medical devices.

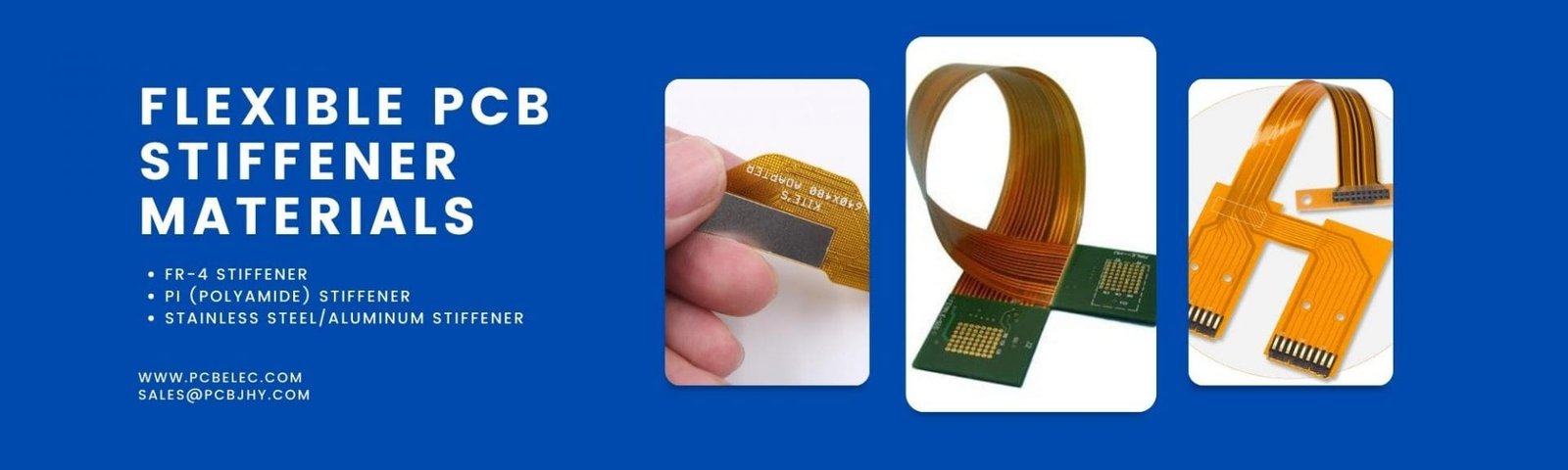

Types of Flexible PCB Stiffener Materials

Selecting the right PCB stiffener material is critical for balancing performance, cost, and application requirements. The three primary materials—FR4, polyimide (PI), and stainless steel/aluminum—offer distinct properties, tailored to specific use cases.

FR4 Stiffener

- Properties: Water-resistant, rigid, high dielectric strength.

- Applications: Surface Mount Technology (SMT) and Plated-Through Hole (PTH) component support, general-purpose reinforcement.

- Thickness Range: 0.08 mm (0.003″) to 3.18 mm (0.125″).

- Pros: Cost-effective, widely available, suitable for most rigid-flex PCBs.

- Cons: Limited heat dissipation, less flexible for ultra-thin designs.

Example: In a consumer electronics device like a smartwatch, an FR4 stiffener supports SMT components, ensuring a flat surface for reliable soldering.

Polyimide (PI) Stiffener

The PI stiffener, made from polyimide, is a high-performance material prized for its thermal and mechanical properties. It is commonly used in applications requiring precise thickness, such as ZIF connectors.

- Properties: High insulation, temperature resistance (-200°C to 300°C), low dielectric loss (0.004-0.007).

- Applications: ZIF connector support, high-reliability devices (e.g., aerospace, medical).

- Thickness Range: 25 µm (0.001″), 50 µm (0.002″), 75 µm (0.003″), 125 µm (0.005″).

- Pros: Lightweight, flexible thickness options, ideal for compact designs.

- Cons: Higher cost than FR4, less rigid for heavy components.

Example: In a medical wearable, a PI stiffener behind a ZIF connector ensures reliable connections despite repeated flexing.

Stainless Steel or Aluminum Stiffener

Stainless steel (e.g., 303 grade) and aluminum stiffeners are used when high strength or heat dissipation is required. These metal options are more expensive but excel in demanding environments.

- Properties: High strength, excellent heat dissipation (aluminum), corrosion resistance (stainless steel).

- Applications: Heat-sensitive applications, crimping, or space-constrained designs.

- Thickness Range: 0.1 mm (4 mil) to 0.45 mm (18 mil).

- Pros: Superior durability, ideal for thermal management.

- Cons: Higher cost, increased weight.

Example: In an aerospace radar system, an aluminum stiffener supports high-power components while dissipating heat.

Material Comparison Table

Material | Cost | Strength | Heat Dissipation | Key Applications |

|---|---|---|---|---|

FR4 | Low | High | Moderate | SMT/PTH support, general use |

Polyimide (PI) | Medium | Moderate | Low | ZIF connectors, high-reliability |

Stainless Steel/Aluminum | High | Very High | High | Heat dissipation, crimping |

Choosing the Right Stiffener Material

Selecting a PCB stiffener material depends on your design’s requirements—cost, thickness, thermal needs, or application environment. For cost-sensitive consumer electronics, FR4 is often sufficient. For high-performance or compact designs, PI or metal stiffeners may be necessary.

Why Use Flexible PCB Stiffeners?

Flexible PCB stiffeners are essential for enhancing the reliability and functionality of flexible circuit boards and rigid-flex PCBs. By adding mechanical support to specific areas, stiffeners address critical challenges in PCB design and manufacturing, ensuring durability and performance in demanding applications. This section explores the key benefits of using PCB stiffeners and why they are a must-have for modern electronics.

Enhancing PCB Durability

Flexible PCBs, made from materials like polyimide, are prone to excessive bending, which can stress solder joints and damage components. Flexible PCB stiffeners prevent this by:

- Reducing Mechanical Stress: Stiffeners limit flexing in critical areas, protecting solder joints from cracking during repeated bending.

- Extending Lifespan: By minimizing wear and tear, stiffeners ensure PCB durability, especially in dynamic applications like foldable smartphones or automotive sensors.

- Maintaining Structural Integrity: They keep the board stable, preventing warping or deformation under component weight.

Example: In an automotive radar system, an FR4 stiffener reinforces the PCB to withstand vibrations, ensuring long-term reliability.

Supporting Components and Connectors

Heavy or complex components, such as Surface Mount Technology (SMT) or Plated-Through Hole (PTH) parts, require a rigid surface for stable mounting. PCB stiffeners provide:

- Stable Mounting Surfaces: A flat, rigid area ensures precise component placement and secure soldering.

- ZIF Connector Compatibility: Stiffeners, often polyimide, add the necessary thickness for ZIF connector support, ensuring reliable connections.

- High-Density Design Support: They enable dense component layouts without compromising the board’s flexibility.

Example: In a medical wearable device, a PI stiffener supports a ZIF connector, allowing repeated connections without damaging the PCB.

Simplifying Assembly and Handling

During manufacturing, flexible PCB stiffeners streamline automated processes like pick-and-place or reflow soldering by:

- Improving Handling: Stiffeners create flat, stable surfaces, making it easier for robotic systems to handle the PCB.

- Reducing Assembly Errors: A rigid section minimizes flexing during soldering, ensuring consistent quality.

- Supporting Panelization: Extended stiffeners (e.g., FR4) maintain array alignment in production, reducing costs.

Example: In consumer electronics like smartwatches, stiffeners simplify automated assembly, boosting production efficiency.

Meeting Industry Standards

In high-reliability sectors like aerospace, medical, and military, flexible PCB stiffeners ensure compliance with strict standards (e.g., IPC-2223). They help:

- Achieve Precise Specifications: Stiffeners meet thickness and rigidity requirements for specialized connectors or components.

- Enhance Reliability: By reducing stress and supporting robust designs, they ensure performance in harsh environments.

Wondering when to use stiffeners in your flexible PCB designs? The next section explores specific scenarios where they are indispensable.

When Are Stiffeners Needed for Flexible PCBs?

Flexible PCB stiffeners are not always required, but they are critical in specific scenarios where flexible circuit boards or rigid-flex PCBs face mechanical or functional challenges. By adding rigidity to targeted areas, stiffeners ensure reliability, support complex designs, and meet industry standards. This section outlines key situations where PCB stiffeners are essential, helping you determine when to incorporate them into your flexible PCB designs.

High-Density Component Mounting

When Surface Mount Technology (SMT) or Plated-Through Hole (PTH) components are mounted on a flexible PCB, their weight can stress the flexible material, risking damage or misalignment. PCB stiffeners are needed to:

- Provide a rigid, flat surface for precise component placement and soldering.

- Distribute component weight to prevent bending or deformation.

- Protect solder joints from stress during dynamic flexing.

Example: In a foldable smartphone, an FR4 stiffener supports a high-density SMT chipset, ensuring stability despite repeated folding.

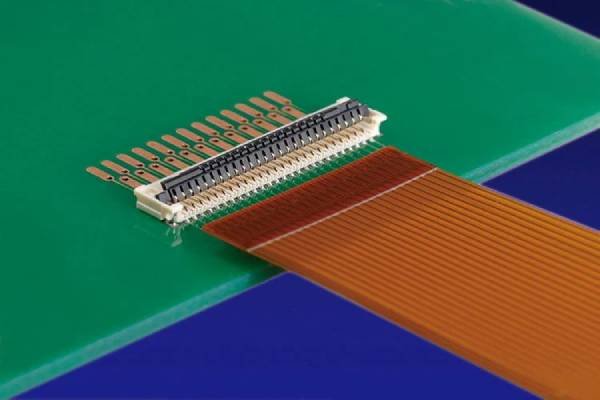

ZIF Connector Applications

Zero Insertion Force (ZIF) connectors require precise thickness and rigidity for reliable connections, especially in applications with frequent insertions. ZIF connector stiffeners, typically polyimide (PI), are used to:

- Achieve the exact thickness required by ZIF specifications.

- Minimize stress on connection pads during repeated insertions.

- Ensure consistent electrical performance in compact designs.

Example: In a medical diagnostic device, a PI stiffener reinforces a ZIF connector, enabling reliable data transmission in a portable unit.

Dynamic or High-Stress Environments

In applications where the PCB undergoes frequent bending or vibration, excessive flexing can compromise reliability. Flexible PCB stiffeners are needed to:

- Restrict bending in critical areas, reducing mechanical stress.

- Enhance durability in harsh environments, such as automotive or aerospace systems.

- Maintain structural integrity under thermal or vibrational loads.

Example: In an aerospace satellite, a stainless steel stiffener stabilizes a flexible PCB, protecting components during launch vibrations.

Automated Assembly Processes

During automated manufacturing, flexible PCBs can be difficult to handle due to their pliability. PCB stiffeners facilitate:

- Stable handling in pick-and-place or reflow soldering processes.

- Alignment in panelized production, reducing assembly errors.

- Cost savings by replacing SMT carriers with stiffener-reinforced panels.

Example: In consumer electronics like wireless earbuds, FR4 stiffeners simplify automated assembly, improving production yield.

Meeting Industry Specifications

High-reliability sectors like medical, military, and aerospace often require strict compliance with standards (e.g., IPC-2223). Flexible PCB stiffeners help:

- Meet thickness or rigidity requirements for specialized components or connectors.

- Ensure performance in extreme conditions, such as high temperatures or humidity.

Curious about how to apply PCB stiffeners effectively? The next section explores methods like PSA and thermal bonding to optimize your designs.

How to Apply Flexible PCB Stiffeners

Applying flexible PCB stiffeners correctly is crucial for enhancing the durability and functionality of flexible circuit boards and rigid-flex PCBs. Stiffeners are attached to specific areas of the PCB to provide mechanical support, using two primary methods: Pressure Sensitive Adhesive (PSA) and thermal bonding. This section explores these methods, their advantages, disadvantages, and best-use scenarios to help you optimize your PCB stiffener application process.

Pressure Sensitive Adhesive (PSA)

PSA stiffeners are applied by pressing the stiffener material (e.g., FR4 or polyimide) onto the PCB with an adhesive backing, similar to applying a sticker. This method is simple and widely used for cost-sensitive applications.

- Advantages:

- Easy to apply, requiring minimal equipment or expertise.

- Cost-effective, ideal for prototypes or low-budget projects.

- Removable, allowing adjustments during testing or assembly.

- Disadvantages:

- Less durable bonding, unsuitable for high-stress or dynamic environments.

- May peel under extreme conditions like high heat or humidity.

- Applications: Consumer electronics, such as smartwatches, where temporary or low-cost reinforcement is needed.

Example: In a wearable fitness tracker, a PSA stiffener (FR4) supports a low-density SMT component area, enabling quick assembly without specialized tools.

Thermal Bonding

Thermal bonding involves applying heat and pressure to bond the stiffener (e.g., PI or metal) to the PCB using acrylic or epoxy adhesives. This method creates a permanent, robust connection suited for high-reliability applications.

- Advantages:

- Strong, permanent bond, ideal for harsh environments (e.g., aerospace, military).

- High resistance to heat, vibration, and mechanical stress.

- Supports demanding designs with frequent flexing or heavy components.

- Disadvantages:

- Higher cost due to specialized equipment and materials.

- Non-removable, limiting flexibility for design changes.

- Applications: Medical devices or automotive systems requiring long-term reliability.

Example: In an aerospace control unit, a thermally bonded aluminum stiffener supports high-power components, ensuring stability under extreme temperatures.

Comparison of Application Methods

| Method | Cost | Bond Strength | Ease of Use | Best Applications |

|---|---|---|---|---|

| PSA | Low | Moderate | High | Consumer electronics, prototypes |

| Thermal Bonding | High | Strong | Low | Aerospace, medical, military |

Best Practices for Applying Stiffeners

To ensure optimal flexible PCB assembly:

- Choose the Right Method: Use PSA for cost-sensitive or temporary needs; opt for thermal bonding in high-reliability designs.

- Align with Design Specs: Ensure the stiffener material and thickness match connector or component requirements (e.g., ZIF specifications).

- Test for Compatibility: Verify adhesive compatibility with the PCB material to avoid delamination.

How does the choice of stiffener thickness impact performance? The next section explores PCB stiffener thickness and specifications for various applications.

Stiffener Thickness and Specifications for Flexible PCBs

The thickness of flexible PCB stiffeners is a critical factor in ensuring the performance, reliability, and compatibility of flexible circuit boards and rigid-flex PCBs. Whether using FR4, polyimide (PI), or stainless steel/aluminum, selecting the right PCB stiffener thickness impacts component support, connector compatibility, and overall design success. This section explores standard thickness ranges, their applications, and key considerations for choosing the optimal specifications.

FR4 Stiffener Thickness

FR4 stiffeners, made from flame-retardant woven fiberglass, are popular for their affordability and strength. Their thickness typically ranges from:

- Standard Range: 0.08 mm (0.003″) to 3.18 mm (0.125″).

- Applications: Supporting Surface Mount Technology (SMT) and Plated-Through Hole (PTH) components in consumer electronics or general-purpose designs.

- Considerations: Thicker FR4 (e.g., 1.5 mm) is ideal for heavy components, while thinner options (e.g., 0.08 mm) suit lightweight designs.

Example: In a tablet PC, a 1.0 mm FR4 stiffener supports a high-density SMT chipset, ensuring a stable soldering surface.

Polyimide (PI) Stiffener Thickness

PI stiffeners are lightweight and precise, making them ideal for ZIF connector thickness requirements in high-reliability applications. Available thicknesses include:

- Standard Range: 25 µm (0.001″), 50 µm (0.002″), 75 µm (0.003″), 125 µm (0.005″).

- Applications: ZIF connectors in medical devices, wearables, or aerospace electronics requiring exact thickness compliance.

- Considerations: PI’s thin profile supports compact designs, but uniform thickness is critical to avoid stress points.

Example: In a wearable health monitor, a 50 µm PI stiffener ensures precise ZIF connector alignment, enabling reliable data connections.

Stainless Steel or Aluminum Stiffener Thickness

Stainless steel (e.g., 303 grade) and aluminum stiffeners offer robust support and heat dissipation, with thicknesses ranging from:

- Standard Range: 0.1 mm (4 mil) to 0.45 mm (18 mil).

- Applications: Heat-sensitive or high-stress environments, such as automotive or aerospace systems, where durability is paramount.

- Considerations: Thicker metal stiffeners (e.g., 0.45 mm) are used for heavy components or crimping, but they increase weight and cost.

Example: In an automotive ECU, a 0.3 mm aluminum stiffener dissipates heat from power components, ensuring performance under high temperatures.

Thickness Comparison Table

| Material | Thickness Range | Key Applications | Best For |

|---|---|---|---|

| FR4 | 0.08 mm–3.18 mm (0.003″–0.125″) | SMT/PTH support | Cost-effective, general use |

| Polyimide (PI) | 25 µm–125 µm (0.001″–0.005″) | ZIF connectors | High-precision, compact designs |

| Stainless Steel/Aluminum | 0.1 mm–0.45 mm (4–18 mil) | Heat dissipation, crimping | High-stress, thermal management |

Choosing the Right Stiffener Thickness

Selecting the optimal PCB stiffener thickness depends on:

- Design Requirements: Match thickness to connector specs (e.g., ZIF) or component weight.

- Application Environment: Thicker stiffeners for harsh conditions (e.g., aerospace); thinner for compact devices (e.g., wearables).

- Uniformity: Ensure consistent thickness to prevent stress or bending issues.

- Cost Constraints: Balance performance with budget, as thicker or metal stiffeners increase costs.

Custom thicknesses are available but require careful testing to meet standards like IPC-2223. Want to know how thickness impacts PCB reliability? The next section explores how stiffeners enhance performance.

Can Stiffeners Improve Flexible PCB Performance?

Flexible PCB stiffeners play a vital role in enhancing the performance of flexible circuit boards and rigid-flex PCBs. By providing targeted mechanical support, stiffeners improve PCB reliability, extend lifespan, and ensure functionality in demanding applications. This section explores how PCB stiffeners boost performance through stress reduction, connector compatibility, and robust design support, making them indispensable for modern electronics.

Reducing Mechanical Stress

Excessive bending in flexible PCBs can lead to solder joint failures or component damage, compromising performance. PCB stiffeners address this by:

- Minimizing Flex-Induced Stress: Stiffeners restrict bending in critical areas, protecting solder joints and components from mechanical strain.

- Increasing Bend Radius: By reinforcing specific sections, stiffeners reduce sharp bends, lowering stress at flex-to-rigid transitions.

- Enhancing Durability: Reduced stress extends the PCB’s operational life, especially in dynamic applications.

Example: In a foldable smartphone, an FR4 stiffener prevents solder joint cracks in the hinge area, ensuring reliable performance over thousands of folds.

Improving Connector Reliability

ZIF connector performance and other connection systems depend on precise thickness and rigidity. Flexible PCB stiffeners enhance this by:

- Ensuring Thickness Compliance: Polyimide (PI) stiffeners meet exact ZIF specifications, reducing connection failures.

- Stabilizing Connector Pads: Stiffeners prevent pad wear during repeated insertions, maintaining signal integrity.

- Supporting High-Frequency Signals: By reducing flexing, stiffeners minimize signal interference in high-speed applications.

Example: In a medical imaging device, a PI stiffener supports a ZIF connector, ensuring consistent data transmission for critical diagnostics.

Supporting Complex Designs

High-density or heavy components require a stable platform that flexible PCBs alone cannot provide. PCB stiffeners enable:

- Robust Component Mounting: A rigid surface supports Surface Mount Technology (SMT) and Plated-Through Hole (PTH) components, preventing misalignment.

- High-Density Layouts: Stiffeners allow dense component arrangements without compromising flexibility elsewhere.

- Compliance with Standards: Stiffeners meet rigorous requirements (e.g., IPC-2223) for aerospace or military applications.

Example: In an aerospace navigation system, a stainless steel stiffener supports high-power components, ensuring performance under extreme conditions.

Enhancing Assembly Efficiency

Stiffeners streamline manufacturing, indirectly boosting PCB performance by:

- Facilitating Automated Assembly: Flat, rigid areas simplify pick-and-place and soldering processes, reducing errors.

- Improving Yield Rates: Stable surfaces ensure consistent assembly quality, minimizing defects.

Example: In wireless earbuds, FR4 stiffeners enable precise SMT assembly, enhancing production reliability and performance.

Why It Matters

By reducing stress, improving connector reliability, supporting complex designs, and aiding assembly, flexible PCB stiffeners significantly enhance PCB reliability and longevity. These benefits are critical in high-stakes industries like medical, automotive, and aerospace, where performance is non-negotiable. Want to avoid common pitfalls when using stiffeners? The next section covers mistakes to steer clear of in your designs.

Common Mistakes to Avoid When Using Flexible PCB Stiffeners

While flexible PCB stiffeners enhance the reliability and functionality of flexible circuit boards and rigid-flex PCBs, improper use can lead to design failures, increased costs, or reduced performance. Avoiding PCB stiffener mistakes is crucial for optimizing your PCB design. This section highlights common errors in selecting and applying PCB stiffeners, along with practical tips to ensure success.

Choosing the Wrong Stiffener Material

Selecting an inappropriate material for your application can compromise performance or increase costs unnecessarily.

- Mistake: Using FR4 for heat-sensitive applications requiring high thermal dissipation or polyimide (PI) for heavy component support.

- Impact: Poor heat management or insufficient rigidity can lead to component failure or PCB deformation.

- Solution: Match the material to the application—use FR4 for cost-effective designs, PI for ZIF connector precision, or stainless steel/aluminum for thermal management.

Example: In an automotive sensor, choosing an FR4 stiffener instead of aluminum led to overheating, causing circuit failure.

Incorrect Stiffener Thickness

Mismatched thickness can disrupt connector compatibility or stress the PCB.

- Mistake: Using a non-uniform or incorrect thickness for ZIF connector requirements or heavy components.

- Impact: Incompatible connectors fail to align, or excessive thickness adds unnecessary weight and cost.

- Solution: Verify thickness against design specs (e.g., 50 µm PI for ZIF connectors, 1.0 mm FR4 for SMT components) and ensure uniformity.

Example: A wearable device with a 25 µm PI stiffener (instead of 50 µm) failed to meet ZIF connector specs, causing unreliable connections.

Improper Bonding Method

The choice between Pressure Sensitive Adhesive (PSA) and thermal bonding affects durability and reliability.

- Mistake: Using PSA in high-reliability applications like aerospace or medical devices.

- Impact: Weak bonding may peel under stress, leading to component detachment or PCB damage.

- Solution: Opt for thermal bonding in harsh environments and PSA for prototypes or low-stress applications.

Example: In a military drone, a PSA-bonded stiffener detached during vibration testing, whereas thermal bonding would have ensured stability.

Overlooking Design Specifications

Ignoring industry standards or design requirements can lead to compliance issues.

- Mistake: Neglecting standards like IPC-2223 for thickness, material, or placement in high-reliability sectors.

- Impact: Non-compliant designs may fail certification or underperform in critical applications.

- Solution: Consult standards and test stiffener placement to meet connector or environmental requirements.

Example: A medical implant PCB failed regulatory approval due to non-compliant stiffener thickness, delaying production.

Best Practices to Avoid Mistakes

To prevent PCB design errors:

- Validate Material Choice: Align material with thermal, mechanical, and cost needs.

- Test Thickness Compatibility: Use prototypes to confirm thickness for connectors or components.

- Choose Appropriate Bonding: Match bonding method to application demands.

- Adhere to Standards: Follow IPC-2223 or relevant guidelines for high-reliability designs.

Ready to finalize your flexible PCB design? The next section summarizes key takeaways and offers actionable steps to implement stiffeners effectively.

FAQs About Flexible PCB Stiffeners

Have questions about flexible PCB stiffeners? This section answers common queries to help you understand their role, materials, and applications in flexible circuit boards and rigid-flex PCBs. Whether you’re designing for consumer electronics or aerospace, these insights will guide your PCB design decisions.

What Is a Flexible PCB Stiffener?

A PCB stiffener is a non-electrical component added to a flexible PCB to provide mechanical support. It prevents excessive bending, supports components, and ensures compatibility with connectors like ZIF connectors. Stiffeners enhance PCB reliability in applications like smartphones or medical devices.

Which Material Is Best for PCB Stiffeners?

The best PCB stiffener material depends on your needs: FR4 for cost-effective designs, polyimide (PI) for ZIF connector precision, and stainless steel/aluminum for heat dissipation or high strength. For example, PI is ideal for wearables, while aluminum suits automotive systems.

Are PCB Stiffeners Necessary for All Flexible PCBs?

Not always. Flexible PCB stiffeners are needed for high-density components, ZIF connectors, dynamic environments, or automated assembly. For simple, static designs, they may be optional. Evaluate your design’s mechanical and connector requirements to decide.

How Do I Choose the Right Stiffener Thickness?

Select PCB stiffener thickness based on application: 0.08–3.18 mm for FR4 (SMT support), 25–125 µm for PI (ZIF connectors), or 0.1–0.45 mm for metal (thermal management). Ensure uniformity and compliance with standards like IPC-2223.

What’s the Difference Between PSA and Thermal Bonding?

PSA stiffeners are cost-effective and removable, ideal for prototypes or consumer electronics. Thermal bonding offers a strong, permanent bond for high-reliability applications like aerospace. Choose PSA for simplicity, thermal bonding for durability.

How Do PCB Stiffeners Affect Cost?

PCB stiffener cost varies by material and method: FR4 and PSA are low-cost, while PI, metal, or thermal bonding are pricier due to material and processing expenses. Custom thicknesses also increase costs. Consult suppliers for precise quotes.

Conclusion: Why Flexible PCB Stiffeners Matter

Flexible PCB stiffeners are a cornerstone of modern electronics, enabling flexible circuit boards and rigid-flex PCBs to deliver reliability, durability, and performance in demanding applications. From consumer devices like smartphones to critical systems in aerospace and medical fields, stiffeners address key challenges by providing mechanical support, ensuring connector compatibility, and streamlining assembly. By choosing the right materials—FR4, polyimide (PI), or stainless steel/aluminum—and applying them correctly, you can optimize your PCB design for success.

Key Takeaways

- Enhanced Durability: Stiffeners reduce mechanical stress, protecting solder joints and extending PCB reliability in dynamic environments.

- Component and Connector Support: They provide stable surfaces for SMT/PTH components and precise thickness for ZIF connectors.

- Streamlined Manufacturing: Stiffeners simplify automated assembly, improving yield and reducing costs.

- Industry Compliance: Materials and thicknesses align with standards like IPC-2223, ensuring performance in high-stakes applications.

- Avoidable Pitfalls: Proper material, thickness, and bonding choices prevent costly PCB design errors.

Take the Next Step

Ready to elevate your flexible PCB designs? Whether you’re designing for consumer electronics, medical devices, or aerospace systems, PCB stiffeners can make the difference. Explore our resources or consult with experts to ensure your designs meet performance and reliability goals.

Contact us for custom PCB stiffener solutions tailored to your project.

Related Reading

- Knowledge of Flexible Printed Circuit Board Processing Technology

- The terms you have to know related to the manufacture of Flexible PCB

- Complete Introduction of Flexible Circuit Board Materials

- Complete Introduction To Flexible PCB Assembly Process

- What is Flexible PCB Prototype?

- 16 Factors Affecting The Cost And Price of Flexible PCB

- How to Solder On Flex PCB?

- What Are The Advantages And Applications Of Rigid-Flex PCBs?

- What is a PCB Manufacturer? The Definitive Guide

- Custom Flex PCB:Tailored Solutions for Your Applications

- Custom PCB Fabrication in China – Prototyping & Mass Production

- Introduction to Semi-Flex PCBs: Bridging Rigid and Flex PCBs

- Flexible PCB Manufacturing: A Guide to Fabrication and Assembly

- How to Select the Right Flexible PCB Manufacturer for Your Product: A 6-Step Guide

- Layer Stackup in Rigid-Flex PCB

- What Are The Types of Flexible Circuit Boards?

- Flexible PCB Cost: Why It’s More Expensive and How to Reduce It

- What Is Flexible PCB Coverlay (FPC Cover Layer)?

- The Manufacturing Process Of Double-sided Flexible PCB Coverlay