High-Precision Laser Cut SMT Stencils for Superior PCB Assembly

JHYPCB delivers industry-leading laser-cut stencils for precise solder paste application, ensuring high-quality SMT assembly.

What Are Laser Cut SMT Stencils?

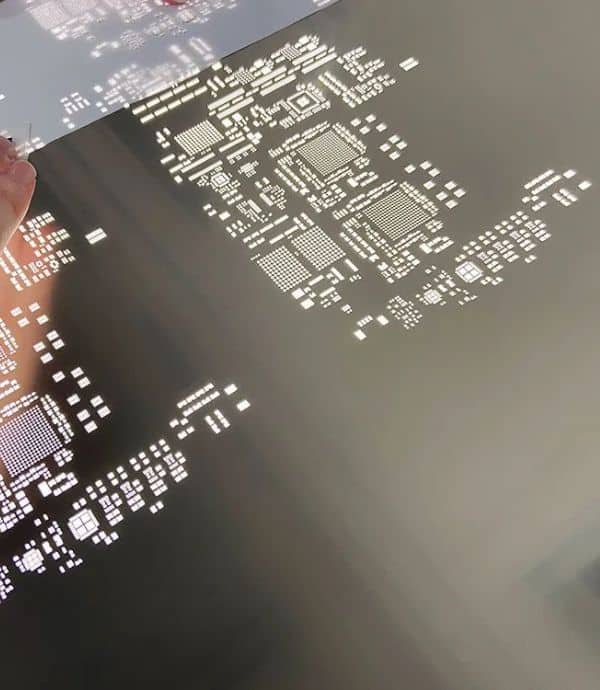

Laser Cut SMT Stencils are precision-engineered tools used in Surface Mount Technology (SMT) assembly to apply solder paste onto PCBs. Made from high-quality stainless steel, these stencils feature intricate openings cut with advanced laser technology, ensuring accurate and consistent solder paste deposition. This precision is critical for achieving reliable electrical connections, especially in modern PCBs with fine-pitch components and high-density layouts.

At JHYPCB, we specialize in manufacturing laser-cut SMT stencils tailored to your specific PCB designs. Our stencils are designed to minimize defects, improve assembly efficiency, and support a wide range of applications, from consumer electronics to aerospace. With our state-of-the-art laser cutting technology and rigorous quality control, we deliver stencils that meet the highest industry standards, helping you achieve flawless PCB assembly. Explore our other stencil solutions, including Step Stencils, Nano-Coating Stencils, and Electroformed Stencils, to find the perfect fit for your project.

Why Choose Laser Cut SMT Stencils for Your PCB Assembly?

Benefits of Laser Cut SMT Stencils

With JHYPCB’s laser-cut SMT stencils, you can achieve reliable, high-quality PCB assembly tailored to your project’s demands.

01

Unmatched Precision

Advanced laser cutting technology ensures precise aperture sizes and smooth edges, ideal for fine-pitch components and high-density PCB designs.

02

Enhanced Durability

Crafted from premium stainless steel, our stencils withstand repeated use, maintaining performance over high-volume production runs.

03

Cost-Effective Production

Laser cutting enables faster manufacturing compared to electroform stencils, reducing costs without compromising quality.

04

Versatile Applications

Suitable for a wide range of PCB designs, from prototypes to complex multilayer boards, supporting diverse SMT assembly needs.

05

Superior Quality Assurance

JHYPCB’s laser-cut stencils minimize solder paste defects, ensuring consistent application and higher assembly yields.

06

Fast Turnaround Time

Our streamlined laser cutting process delivers stencils quickly, helping you meet tight project deadlines with ease.

Ready to Elevate Your PCB Assembly?

Get High-Precision Laser Cut SMT Stencils from JHYPCB

Our Manufacturing Excellence

Precision Laser Cut SMT Stencil Production

JHYPCB delivers high-quality stencils with advanced laser technology.

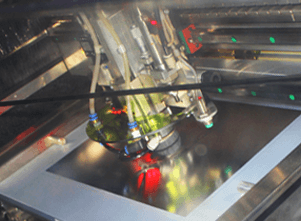

Advanced Laser Cutting

Our state-of-the-art laser cutting machines create precise apertures with smooth edges, tailored to your PCB’s Gerber files. This ensures accurate solder paste application, even for fine-pitch components and high-density layouts.

Premium Materials

We use high-grade stainless steel sheets for durability and compatibility with SMT assembly. These materials resist wear and maintain performance, supporting high-volume production and long-term reliability.

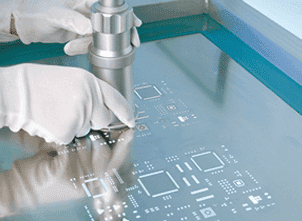

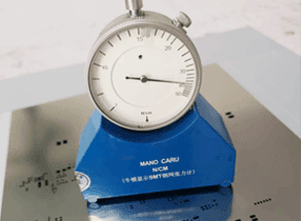

Rigorous Quality Control

Every stencil undergoes comprehensive inspections, including dimensional accuracy and surface quality checks, to meet IPC-7525 standards. This ensures defect-free performance and consistent results for your PCB assembly.

Our Manufacturing Capabilities for Laser Cut SMT Stencils

JHYPCB leverages a fleet of 22 laser machines and advanced nano technology to produce high-precision SMT stencils. Our capabilities ensure precise cutting, enhanced durability, and fast delivery, meeting your PCB assembly needs with superior quality.

| Item | Process Capability |

|---|---|

| Processing Method | Laser Cutting |

| Minimum Opening | >0.08mm |

| Cutting Tolerance | ±0.003mm |

| Sheet Thickness | Common Thickness: 0.1, 0.12, 0.15, 0.18, 0.2mm Special Thickness: 0.08, 0.06, 0.25, 0.3mm |

| Data Format | Gerber, PCB |

| Polishing Process | Electro-polishing, Etching Polishing, Grinding Polishing |

| Nano Process | Vacuum Coating, Reduces Solder Paste Adhesion, Improves SMT Yield |

| Steel Mesh Model | 304HTA |

| Machine Scale | 22 Laser Machines |

| Delivery Time | 6 Hours to 2 Days (Depending on Order Status) |

Available Frame Sizes for Laser Cut SMT Stencils

JHYPCB offers a diverse selection of frame sizes for laser-cut SMT stencils, accommodating various PCB assembly setups. Choose from standard, eco-friendly, or frameless options to match your specific requirements, ensuring compatibility and precision for your projects.

| Frame Size (Width × Length, cm) | Inner Size (Width × Length, cm) |

|---|---|

| 37 × 47 | 19 × 29 |

| 30 × 40 | 14 × 24 |

| 42 × 52 | 24 × 34 |

| 45 × 55 | 27 × 37 |

| 58.4 × 58.4 | 38 × 38 |

| 55 × 65 | 34 × 44 |

| 73.6 × 73.6 | 50 × 50 |

| 28 × 38 (No Aluminum Frame) | 20 × 36 |

| 28 × 38 (No Aluminum Frame) | 26 × 30 |

| 40 × 60 | 22 × 40 |

| 40 × 80 | 22 × 60 |

| 40 × 100 | 22 × 76 |

| 40 × 120 | 22 × 100 |

| 40 × 140 | 22 × 120 |

| 50 × 70 | 32 × 50 |

| 50 × 80 | 32 × 60 |

| 50 × 100 | 32 × 80 |

| 50 × 120 | 32 × 100 |

| 50 × 140 | 32 × 120 |

| 50 × 150 | 32 × 130 |

| 37 × 47 (Eco-Friendly Simple Model) | 19 × 29 |

| 30 × 40 (Eco-Friendly Simple Model) | 14 × 24 |

| 32 × 42 (No Aluminum Frame) | 24 × 40 |

| 32 × 42 (No Aluminum Frame) | 30 × 34 |

| 46 × 46 (No Aluminum Frame) | 38 × 43 |

| 60 × 60 (No Aluminum Frame) | 52 × 56 |

Why Choose JHYPCB for Laser Cut SMT Stencils?

Partner with JHYPCB for laser-cut SMT stencils that combine precision, quality, and exceptional service, tailored to your PCB assembly needs.

FAQ

Frequently Asked Questions About Laser Cut SMT Stencils

What is a laser-cut SMT stencil?

A laser-cut SMT stencil is a stainless steel sheet with precisely cut apertures, created using laser technology, to apply solder paste accurately during Surface Mount Technology (SMT) PCB assembly.

What are the advantages of laser-cut stencils over other types?

Laser-cut stencils offer superior precision, smooth aperture edges, and cost-effective production. They are ideal for fine-pitch components and high-density PCBs, with faster turnaround times compared to electroform stencils.

Can JHYPCB customize laser-cut SMT stencils?

Yes, JHYPCB offers fully customizable stencils, including thickness (0.08mm to 0.2mm), aperture design, frame types, and fiducial markings, tailored to your PCB design and assembly requirements.

How long does it take to receive a laser-cut SMT stencil from JHYPCB?

Production and delivery times depend on your location and order specifications. Typically, JHYPCB offers fast turnaround, with global shipping in 3-7 business days. Contact us for a precise quote.