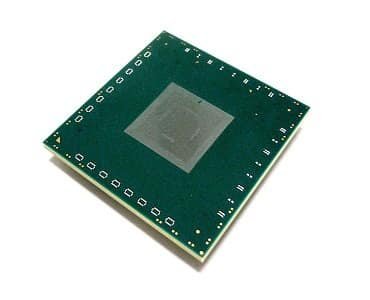

IC Substrates PCB Manufacturing

Powering Your Semiconductor Innovations with Precision

JHYPCB delivers high-density, high-performance IC substrates PCBs from our advanced facilities in China. With decades of expertise, we provide reliable solutions for semiconductors, consumer electronics, and more, from rapid prototyping to turnkey assembly. Need tailored support? Reach us at sales@pcbjhy.com.

Why IC Substrates Matter for Your Projects

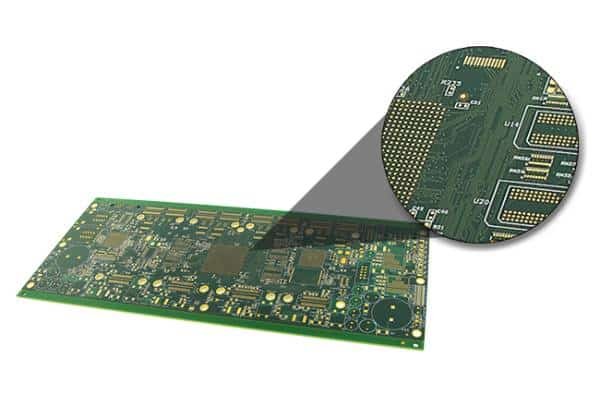

IC substrates PCBs are the backbone of modern electronics, enabling compact, high-performance devices that power today’s innovations. At JHYPCB, we understand the critical role these advanced substrates play in your projects. Designed for superior signal integrity and thermal management, IC substrates support the miniaturization and efficiency demands of industries like semiconductors, telecommunications, and consumer electronics.

Here’s why IC substrates are essential:

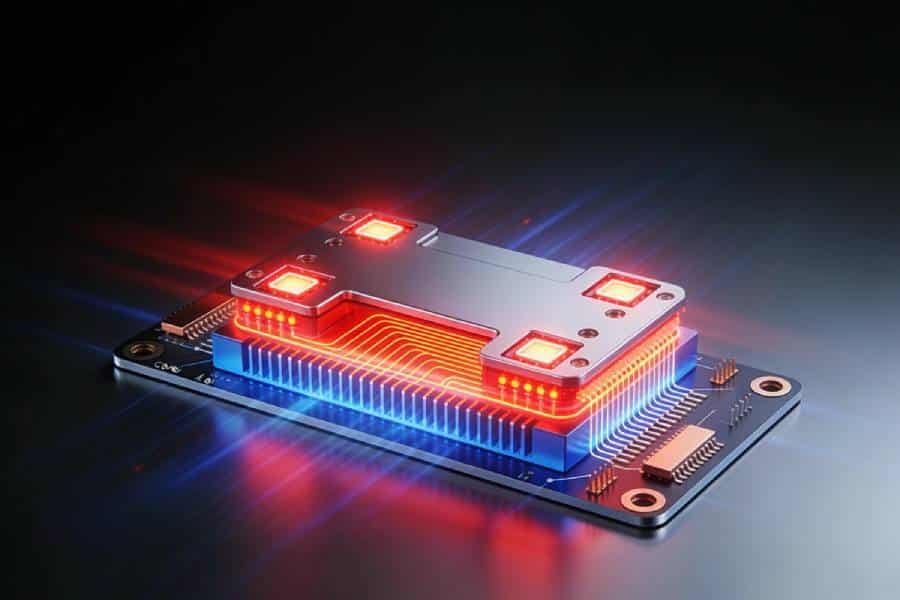

Reliable Thermal Management

Reliable thermal management ensure durability and performance under demanding conditions.

For a deeper understanding of IC substrates, explore our blog post, “What is IC Substrates?” To discuss your project needs, contact us at sales@pcbjhy.com for expert IC substrate manufacturing services in China.

JHYPCB’s IC Substrates Manufacturing Capabilities

At JHYPCB, we leverage advanced technology and decades of expertise to deliver high-quality IC substrates PCBs that power cutting-edge electronics. Our state-of-the-art facilities in China ensure precision, reliability, and efficiency, meeting the demands of industries like semiconductors, telecommunications, and automotive.

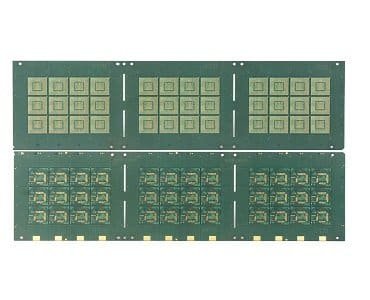

Types of IC Substrates We Provide

We offer a diverse range of IC substrates to support your project requirements:

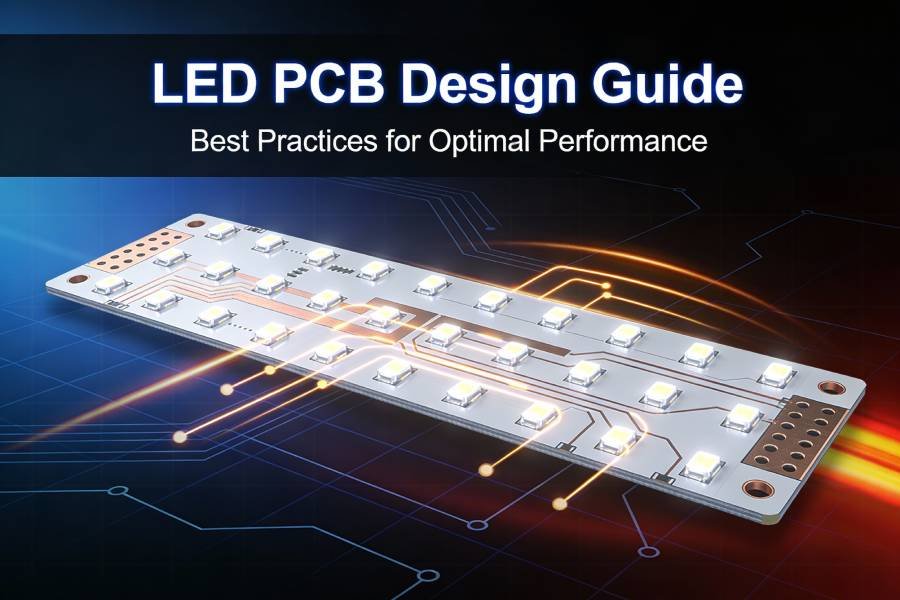

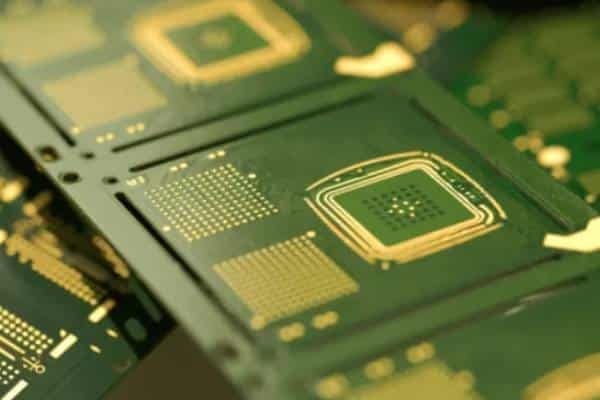

Rigid IC Substrates

Ideal for high-density semiconductor packaging with robust performance.

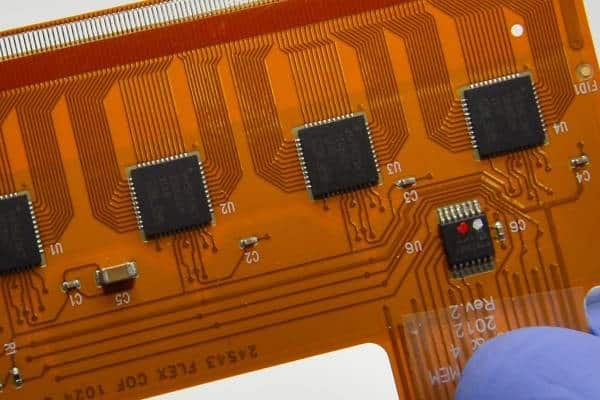

Flexible IC Substrates

Perfect for compact, bendable electronics in consumer devices.

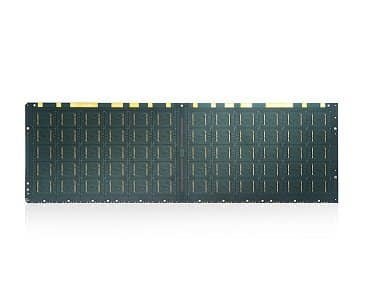

HDI IC Substrates

Designed for advanced applications requiring fine pitch and miniaturization.

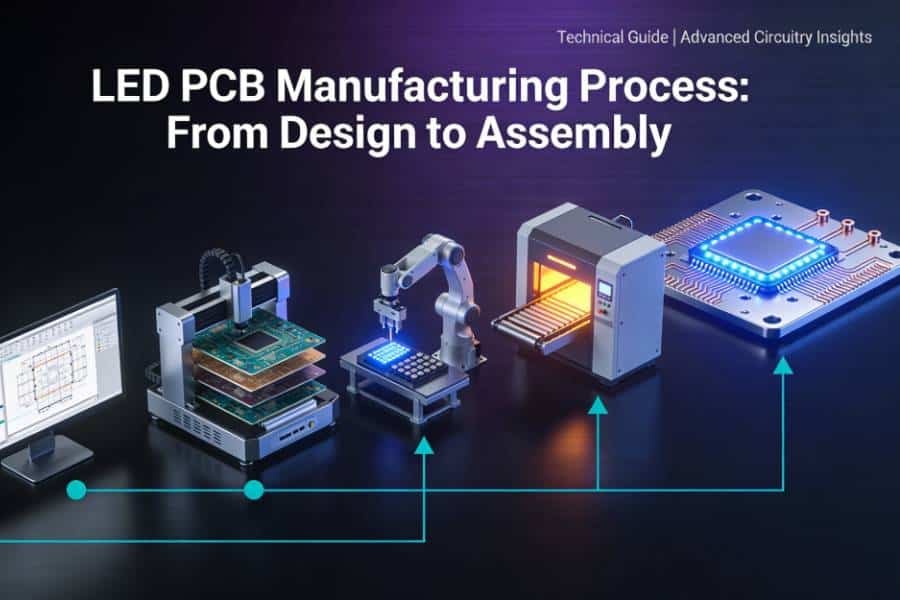

Advanced Manufacturing Technologies

Our production processes set industry standards for IC substrate manufacturing services in China:

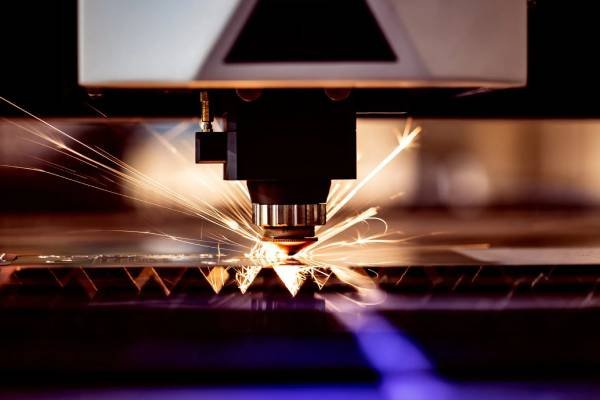

Laser Drilling

Ensures precise microvias for high-density interconnects.

Fine Line Etching

Achieves intricate circuit patterns for superior signal integrity.

Rigorous Quality Control

ISO-certified processes guarantee consistent, defect-free substrates.

Solutions Tailored to Your Needs

From rapid prototyping to high-volume production, JHYPCB supports your project with comprehensive services, including component sourcing and turnkey IC substrate PCB assembly. Our expert team ensures fast turnaround and uncompromised quality. Have specific requirements? Contact us at sales@pcbjhy.com.

Applications of Our IC Substrates PCBs

IC substrates PCBs from JHYPCB power a wide range of industries, enabling high-performance, compact electronics that drive innovation. Our advanced manufacturing ensures reliable, high-density substrates that meet the rigorous demands of modern applications. From AI chips to medical devices, we deliver solutions that enhance performance and reliability.

Key applications include:

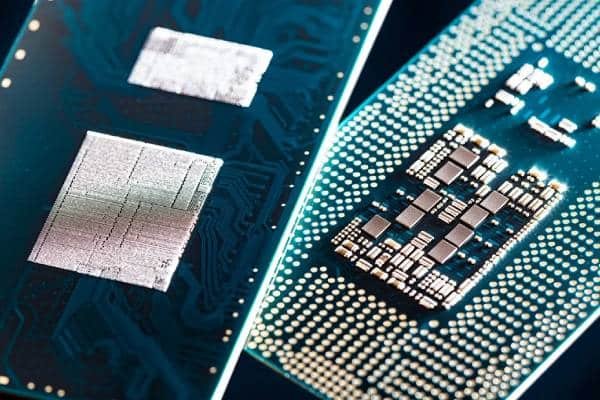

- Semiconductors: Our IC substrates support high-speed data processing in AI chips and microprocessors, ensuring superior signal integrity.

- Consumer Electronics: Enable sleek, efficient designs for smartphones, wearables, and IoT devices with compact, high-density substrates.

- Telecommunications: Power 5G infrastructure and networking equipment with robust, high-frequency IC substrates.

- Automotive: Support advanced driver-assistance systems (ADAS) and electric vehicle electronics with durable, thermally efficient substrates.

- Medical Devices: Ensure precision and reliability in diagnostic equipment and wearable health monitors.

Discover how JHYPCB’s IC substrate manufacturing for semiconductors and beyond can elevate your project. Ready to explore? Contact sales@pcbjhy.com.

Why Partner with JHYPCB for IC Substrates?

Selecting the right manufacturer for your IC substrates PCBs ensures project success. At JHYPCB, we lead in IC substrate manufacturing services in China, combining advanced technology with a proven track record. Our commitment to quality and efficiency empowers industries like semiconductors and telecommunications to achieve superior performance.

Here’s why JHYPCB is your trusted partner:

Choose JHYPCB to power your IC substrate projects with precision. Have questions? Contact sales@pcbjhy.com.

Frequently Asked Questions (FAQs)

Discover answers to common questions about JHYPCB’s IC substrates PCB manufacturing services. For further details, contact us at sales@pcbjhy.com.

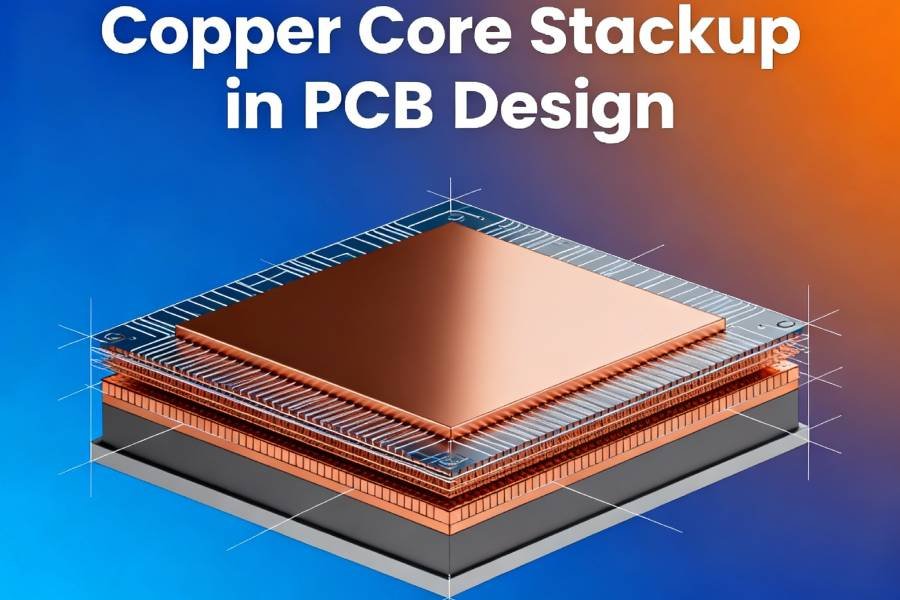

What is an IC substrate and its primary function?

An IC substrate is a specialized base, typically silicon or ceramic, that connects integrated circuits to PCBs, providing electrical connectivity and mechanical support.

What materials are used in JHYPCB’s IC substrates?

We use ultra-thin copper foils, epoxy resins, polyimides, and ceramics, selected for superior electrical properties and thermal stability, ensuring durability in demanding applications.

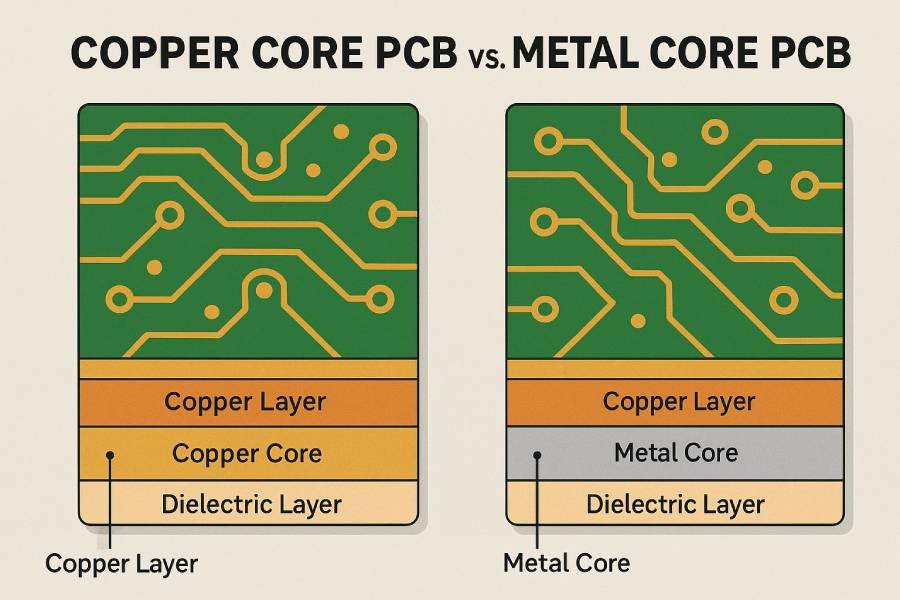

How do IC substrates differ from traditional PCBs?

IC substrates feature finer interconnects and advanced materials like ceramics for semiconductor packaging, unlike PCBs, which connect multiple components. See our blog post, “What is IC Substrates.”

Why are IC substrates critical for high-performance devices?

JHYPCB’s IC substrates enable compact, high-density designs with excellent signal integrity and thermal management, vital for smartphones, 5G infrastructure, and automotive electronics.

What are the manufacturing challenges for IC substrates?

Challenges include material selection, precise patterning, surface finishing, yield, and cost.

What is the role of a solder mask in IC substrates?

The solder mask insulates traces, protects against oxidation, and ensures precise soldering.

What are the advantages of using flex substrates?

Flex substrates offer flexibility and lightweight design for compact devices like wearables.

What is the difference between laminate and ceramic IC substrates?

Laminate substrates (e.g., BT resin) are cost-effective, while ceramic substrates (e.g., alumina) offer superior thermal conductivity. JHYPCB supports both for diverse needs.

Start Your IC Substrates Project with JHYPCB

Ready to advance your semiconductor or electronics project? At JHYPCB, we’re here to provide top-tier IC substrates PCB manufacturing services in China, backed by our expertise in high-density designs and reliable assembly. Whether you’re prototyping innovative AI chips or scaling production for consumer devices, our team ensures quality, speed, and performance every step of the way.

Let’s bring your vision to life. Reach out to sales@pcbjhy.com for expert guidance, or request a quote today.