Fast Turnaround PCB Prototype Services from Certified Manufacturer

Quick turn PCB prototyping, custom solutions for startups and enterprises.

ISO-certified, rapid delivery, and global support – upload your design for a free DFM check!

– As fast as 24-hour build and delivery

– No minimum quantity

– Serving: IoT, automotive, medical, consumer electronics

Why JHYPCB: Rapid PCB Prototyping for Every Need

Ultra-Fast Turnaround

Boards delivered as quickly as 24 hours, meeting urgent project timelines and helping you accelerate product development without delays.

Comprehensive Capabilities

We support rigid, flex, rigid-flex, high-frequency, and special material PCBs, covering a wide range of application scenarios.

No Minimum Order Requirement

Order any quantity from a single board to full production—perfect for prototypes and small batches.

Expert Engineering Support

Get free DFM checks and instant technical support from our experienced engineers at every project stage.

Competitive Pricing

Factory-direct pricing ensures cost-effective solutions for every budget, with transparent quotes and no hidden fees.

Design Data Security & IP Protection

We treat your design files confidentially, offer NDA on request, and safeguard your intellectual property with strict internal controls and secure systems.

What is a PCB prototype?

A PCB prototype is just like a test board that is used for testing purposes. During PCB designing(Learn more about: PCB Design Guidelines, PCB Design Software Free Download), you may need to change many things and come up with different designs and dozens of alterations. So, you never know whether your PCB is perfect for mass production or not. Therefore, a PCB prototype board is made for testing. A few PCB prototype boards are made to test your design according to the desired results. If you have achieved what you wanted, then it’s perfect. Otherwise, you will need to redesign and order another PCB prototype. You need to make sure that your PCB is working correctly before starting bulk production. A prototype PCB may lack some features, but it is very close to the standard PCB. You will get a complete idea of your design; therefore, it is an essential step.

Highly Reliable Double-sided/Multi-layer PCB Prototype China Manufacturer

JHYPCB PCB prototype fabrication capabilities

What can we do for your PCB prototype?

as you know, JHYPCB is a leading fast PCB prototype manufacturer in China; our PCB prototype fabrication service is available to global clients. We can provide any kind of simple-to-complex prototype PCBs with or without special requirements.

Check out our circuit board prototype capabilities in the following list:

- Rigid PCBs

- Flexible circuits

- Rigid-Flex PCBs

- IMS PCBs or metal core PCBs): 1-4 layers, aluminum base, copper base, or ceramic base

- HDI boards: laser drilling micro vias, blind and buried vias, till any layer interconnect

- Special substrates: Rogers, Isola, Dupont, Nelco, Panasonic, etc.

Heavy copper: 1-15oz - Gold Plating: Hard or soft gold with selective or full body plating

Blind and burid vias, microvias - Surface finish: Immersion gold, Immersion silver, Immersion Tin

- Controlled impedance: Single-ended, differential pairs, hatch impedance

PCB Prototype Capabilities & Tech Specs

PCB Manufacturing Specifications

| Feature | Options/Details |

|---|---|

| Layers | 1–32 |

| Material | FR-4, Rogers, Aluminum, CEM-1, High TG |

| Board Thickness | 0.2–3.2mm |

| Min Trace/Space | 3mil/3mil |

| Min Hole Size | 0.15mm |

| Impedance Control | Supported, ±10% accuracy |

| Surface Finishes | HASL, ENIG, OSP, Immersion Gold/Silver/Tin |

| Mask Colors | Green, Black, Blue, White, Yellow, Red |

| Max Board Size | 600mm × 1200mm |

| Add-ons | V-cut, gold fingers, selective plating |

| Testing | 100% E-test for all boards |

| Lead Time | 24h, 48h, 3d, 5d, 7d |

Pricing & Lead Time Details

Our PCB prototype pricing is transparent and competitive, tailored to your project’s specifications. Fast turnaround options and volume discounts are available to meet your development timeline and budget.

Example Pricing

| PCB Type | Starting Price (USD) | Estimated Lead Time |

|---|---|---|

| Single-layer Prototype | $10 | 3–5 days |

| 4-layer PCB | $25 | 4–7 days |

| High-frequency/Rogers PCB | $40 | 6–10 days |

| Express Service | +20% surcharge | as fast as 24–48 hours |

Prices vary based on board size, layer count, material, finish, and special requirements.

Contact us for a customized quote—volume discounts available!

Lead Time Promise

- Standard prototypes: 3–7 business days

- Express/urgent: as fast as 24–48 hours

- Bulk/complex orders: confirmed upon review

- Real-time order tracking available

FAQ

- Q: What affects my PCB price?

A: Factors include board size, number of layers, selected material, finish, order quantity, and delivery speed. - Q: Can I get a quote before finalizing my design?

A: Yes, submit your preliminary files or requirements for a cost estimate. - Q: How are shipping costs calculated?

A: Based on package weight, destination, and courier selection—details included in your quote.

Fast & Streamlined PCB Prototyping Workflow

How It Works – Fast & Easy PCB Prototyping

1. Upload Your Files

Upload your Gerber files and project details securely through our online platform (NDA available).

2. Free DFM Review & Instant Quote

Our engineers perform a free manufacturability check and you receive an instant, transparent quote.

3. Confirm & Pay

Review your quote, confirm details, and complete payment using your preferred secure method.

4. Production & Quality Check

Your prototype PCBs are produced in our certified facility and 100% tested before shipment.

5. Global Delivery & Tracking

We ship your boards worldwide with real-time tracking; support available every step of the way.

Request a Quotation & File Upload

Upload your Gerber files or project documents for a professional review. Our engineers will carefully assess your requirements and send a personalized quotation by email—usually within 12 hours (business days).

Your files are 100% confidential. NDA available upon request.

How Our Quotation Process Works

- Securely upload your design files—no registration required

- Our engineering team reviews your requirements within 12 hours

- Receive your personalized quotation by email

- Free DFM and manufacturability advice included

- All data protected with industry-grade security

Frequently Asked

- Q: What files do you accept?

A: Gerber (RS-274x), BOM, PDF, EAGLE, Altium, etc. - Q: How long until I receive a quote?

A: Usually within 12 hours on business days. - Q: Will you offer manufacturability advice?

A: Yes, every submission gets a free engineering review.

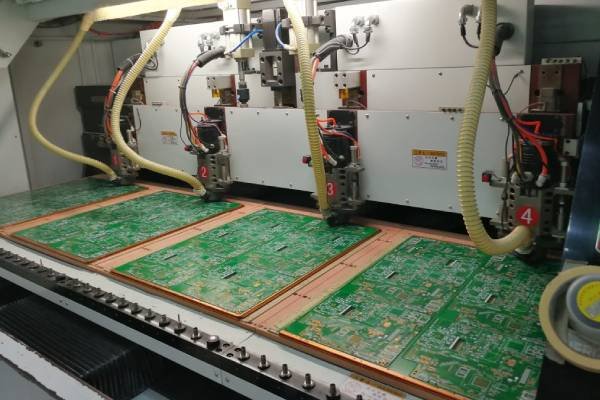

Automatic PCB Board Prototyping Machine

Introduce high-end advanced equipment, build a first-class production line, and escort quality

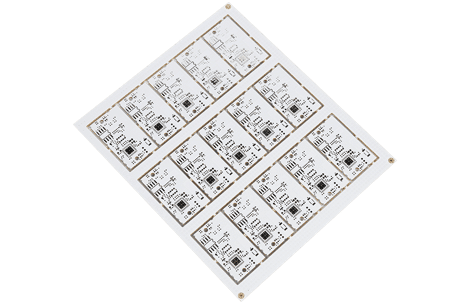

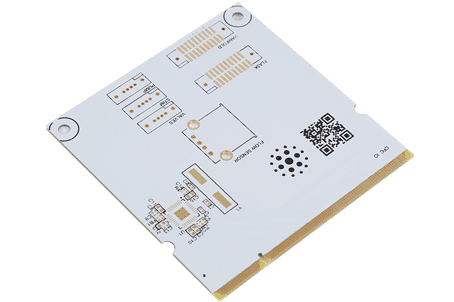

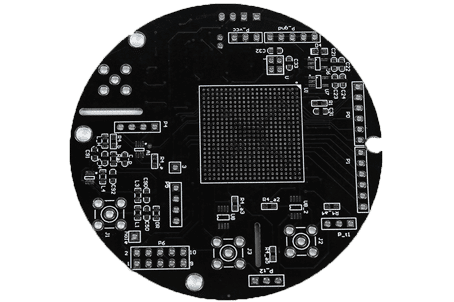

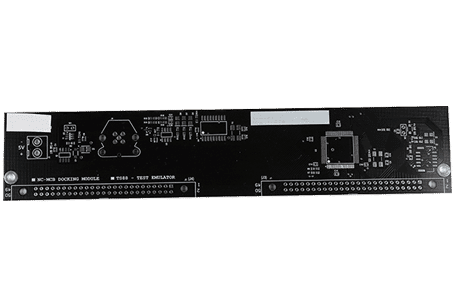

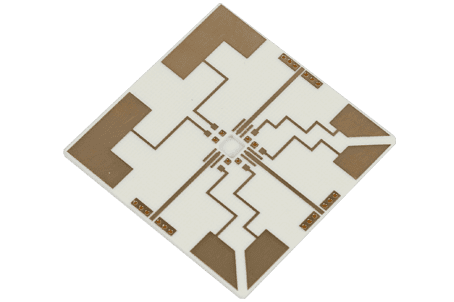

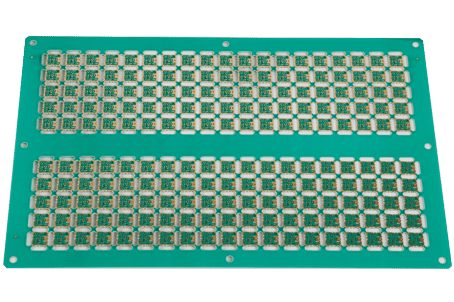

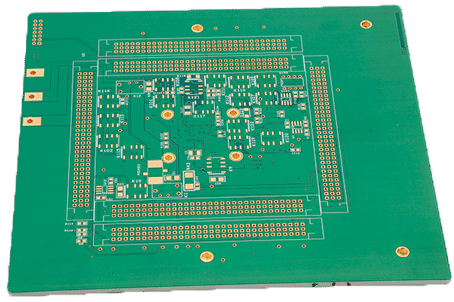

Custom PCB Prototype Boards Show

We are a PCB manufacturer that specializes in PCB prototype and low volume PCB production

1 Layer / Single-sided PCB Prototype

2 Layer / Double-sided PCB Prototype

Large PCB Prototype Board

Ready to Start Your PCB Prototype Project?

Let our expert team help turn your ideas into reality. For personalized support, pricing, and technical advice, please visit our dedicated inquiry page. We offer fast replies, professional engineering guidance, and full project confidentiality for all customers worldwide!

Request a QuoteFrequently Asked Questions (FAQ)

You should provide Gerber files (RS-274x format) and, if possible, a Bill of Materials (BOM) for assembly requests. We also accept design files in formats such as Altium, Eagle, or PDF for initial estimation.

Our engineers review all submissions and typically reply with your custom quotation by email within 12 business hours. Urgent requests are processed with priority.

Yes, we welcome orders starting from just one board—perfect for prototypes, R&D, or product validation.

Pricing depends on board size, layer count, material selection, surface finish, quantity, and turnaround time. Express service and advanced features (e.g., impedance control, gold fingers) may add to cost.

Absolutely. We treat every file with strict confidentiality, offer NDA on request, and have robust data protection measures in place.

Yes, every quotation request receives a free DFM (Design for Manufacturability) review and expert engineering advice to ensure smooth production and best results.

Yes, once production begins, you will receive progress updates and a tracking link for shipment.

Help Resources

- Why Do You Need a PCB Prototype?

- What Are The Requirements To PCB Prototype Manufacturing?

- Prototype PCB Fabrication Service Price in China

- Important Things to Consider While Ordering PCB Prototype Service

- Why is the prototype PCB manufacturing so important?

- The Cheapest PCB Prototype Manufacturer-Your Best Choice

- 6 Tips For Looking For A PCB Prototype Manufacturer

- How To Buy Prototype PCB Boards?

- Low-Cost PCB Prototype Fabrication Service

- Fast Turn And Best Prototype PCB Fabrication Service

- How to Make Low Cost PCB Prototypes