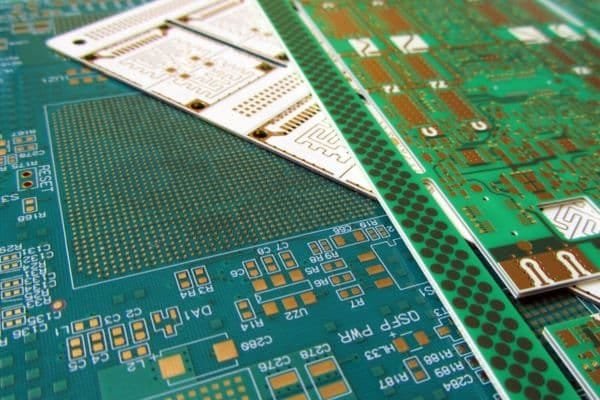

Multilayer PCB Prototyping & Manufacturing Services

Explore multilayer PCBs: their structure, benefits, and applications. Trust JHYPCB for fast, high-quality manufacturing and prototyping services.

Multilayer PCBs are essential for complex electronics, offering enhanced performance for modern applications. At JHYPCB, we provide fast, reliable multilayer PCB manufacturing and prototyping services. Learn more about their benefits and our capabilities below!

Multilayer PCBs Complete Guide

- What is Multilayer PCB?

- What are the benefits of multilayer PCBs?

- What Are The Multilayer PCB Applications?

- How many layers are there in multilayer PCB?

- Why Is There Any Need for Multilayer PCBs?

- Multilayer PCB Manufacturing Process

- Multilayer PCB Manufacturing Capabilities

- Multilayer PCB Manufacturer in China

- Multilayer PCB FAQs

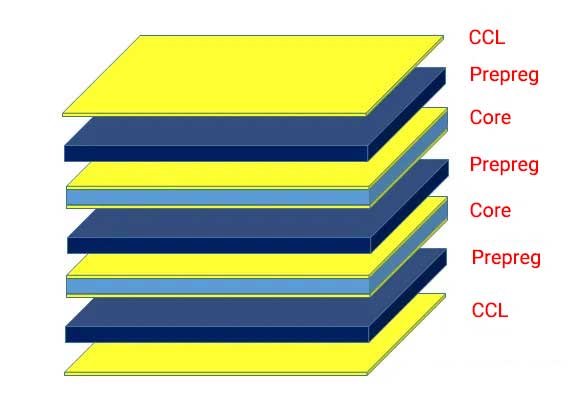

What is a Multilayer PCB?

A multilayer PCB features three or more copper layers, unlike single-layer PCBs with just one. Components are placed on the outer surface layers, while inner layers manage wiring and connections, enabling compact and efficient circuit designs.

Diagram: Multilayer PCB structure showing outer and inner layers.

Benefits of Multilayer PCBs

Multilayer PCBs offer key advantages for modern electronics:

- Compact Size: Minimize space with a reduced form factor, ideal for small devices.

- Lightweight Design: Lighter boards simplify integration into portable products.

- Enhanced Durability: Multiple layers ensure long-term reliability under stress.

- Greater Flexibility: Adaptable for complex circuit layouts and applications.

- Improved EMI Shielding: Reduce interference for better signal integrity.

Discover how these benefits apply to your project—explore applications.

Multilayer PCB Applications

Multilayer PCBs power advanced technology across industries:

- Computers: Enable high-speed processing in compact motherboards.

- Medical Equipment: Support precision in diagnostic devices like MRI machines.

- Satellite Systems: Ensure reliable communication in space applications.

- Wearable Devices: Fit complex circuits into small, flexible designs.

- Defense: Provide durability for rugged military electronics.

- Aerospace: Enhance performance in navigation and control systems.

- Telecommunication: Boost signal integrity in 5G infrastructure.

Ready to apply multilayer PCBs to your industry? Request a Quote.

How Many Layers in a Multilayer PCB?

Multilayer PCBs range from 4 to over 100 layers, depending on complexity:

- 4-6 Layers: Ideal for consumer electronics like smartphones.

- 8-12 Layers: Used in advanced devices like medical equipment.

- Up to 100 Layers: Support high-density applications like aerospace systems.

Learn more about stack-up and thickness.

Types of Multilayer PCBs

Discover the variety of multilayer PCBs designed to meet diverse project demands, each with unique properties and real-world applications

Features a solid FR4 structure, perfect for stable, high-performance circuits.

Example: Drives the core processing unit in gaming consoles.

Utilizes polyimide for bendable, space-saving designs.

Example: Powers the flexible screens in foldable smartphones.

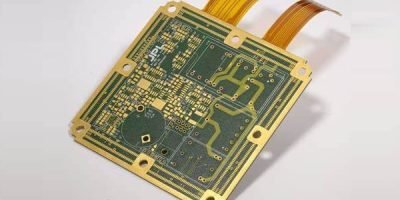

Combines rigid and flexible layers for hybrid durability and flexibility.

Example: Enables compact connectors in aerospace avionics.

High-Density Interconnect design with fine lines for advanced miniaturization.

Example: Supports the dense circuitry in 5G smartphones.

Incorporates a metal base (e.g., aluminum) for enhanced heat management.

Example: Optimizes thermal control in high-power LED displays.

Why Choose Multilayer PCBs?

Single-layer and double-layer PCBs struggle with complex designs due to limited space and connectivity. They require more room for wiring, often leading to bulky products, and rely on jumpers, making intricate circuits challenging to implement.

See how multilayer PCBs solve these challenges—explore their benefits.

Single-layer vs Multilayer PCB Comparison Table

| Aspect | Single/Double-Layer PCB | Multilayer PCB |

|---|---|---|

| Space Efficiency | Bulky, limited space for complex designs | Compact, efficient for high-density circuits |

| Connectivity | Requires jumpers, challenging for intricate circuits | Streamlined via inner layers, supports complexity |

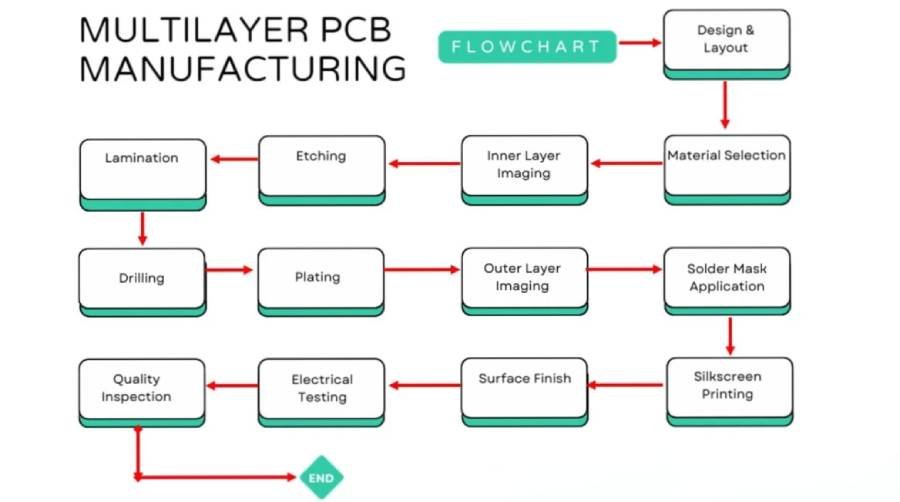

Multilayer PCB Manufacturing Process

Explore the step-by-step process of manufacturing multilayer PCBs, ensuring precision and quality at every stage.

Diagram showing the multilayer PCB manufacturing process, from design and layout to quality inspection.

Steps in Multilayer PCB Manufacturing

| Step# | Process | Description |

|---|---|---|

| 1. | Design and Layout | Develop PCB layout using CAD software to define circuit patterns and layers. |

| 2. | Material Selection | Select materials like FR4 for rigid boards or polyimide for flexible PCBs, based on project needs. |

| 3. | Inner Layer Imaging | Use photoresist and UV light to transfer circuit patterns onto inner layers. |

| 4. | Etching | Remove excess copper with chemicals to form precise circuit paths. |

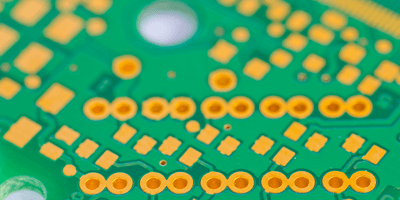

| 5. | Lamination | Bond copper layers and insulating prepreg under heat and pressure for durability. |

| 6. | Drilling | Drill vias to enable electrical connections between layers. |

| 7. | Plating | Electroplate vias to create conductive paths, ensuring layer connectivity. |

| 8. | Outer Layer Imaging | Apply imaging and etching to outer layers for final circuit patterns. |

| 9. | Solder Mask Application | Add a protective solder mask to prevent short circuits and corrosion. |

| 10. | Silkscreen Printing | Print labels and markings for component identification. |

| 11. | Surface Finish | Apply a surface finish (e.g., HASL, ENIG) to protect exposed copper pads. |

| 12. | Electrical Testing | Test for electrical faults like open circuits or shorts to ensure functionality. |

| 13. | Quality Inspection | Conduct visual and automated inspections to verify precision and quality. |

Learn more about how to build a multilayer PCB.

JHYPCB Multilayer PCB Manufacturing Capabilities

With years of expertise, JHYPCB delivers high-quality multilayer PCBs, supporting complex projects across industries with advanced manufacturing capabilities.

| Feature | Specifications |

|---|---|

| Layer Capacity | Rigid multilayer PCBs: Up to 30 layers Flexible multilayer PCBs: Up to 10 layers Rigid-Flex multilayer PCBs: Up to 8 layers |

| Materials | Rigid: FR4, High Tg, High-frequency Flexible: Polyimide Rigid-Flex: Polyimide |

| Board Thickness | Rigid: 0.4–6.0 mm Flexible: 0.1–0.8 mm Rigid-Flex: 0.25–2.0 mm |

| Solder Mask | Options like green, white, and blue for circuit protection |

| Surface Finish | HASL Lead-Free, Immersion Gold/Silver/Tin, Hard Gold for durability and conductivity |

| Testing Methods | Impedance Control, Solderability, Thermal Shock, Flying Probe, Automated Optical Inspection for quality assurance |

Learn more about our PCB manufacturing capabilities.

Why Choose JHYPCB for Multilayer PCB Manufacturing?

Based in China, JHYPCB brings over a decade of expertise to deliver high-quality multilayer PCBs, ensuring precision, speed, and cost-efficiency for every project.

- Proven Expertise

With over 10 years in the industry, JHYPCB ensures your multilayer PCBs meet stringent quality standards, backed by extensive experience across diverse applications. - Design for Manufacturability (DFM) Checks

Our team reviews your Gerber files to identify potential issues early, minimizing errors and reducing production costs for a seamless manufacturing process. - Advanced Technology and Scalability

Using cutting-edge equipment, we offer scalable solutions—from rapid prototypes to high-volume production—ensuring consistency and precision for every order. - Fast Delivery

Enjoy short lead times, with prototypes delivered as fast as 48 hours, helping you meet tight project deadlines without compromising quality.

Multilayer PCB FAQs

Find answers to common questions about multilayer PCBs and JHYPCB’s services:

Costs depend on layer count, design complexity, and order quantity. JHYPCB’s DFM checks optimize your design to minimize expenses—request a quote for a detailed estimate.

Multilayer PCBs can use single-point grounding for low-frequency circuits, multi-point grounding for high-frequency signals, or a mixed approach for balanced performance.

Look for experience, quality assurance, and fast delivery. JHYPCB offers over 10 years of expertise, advanced testing, and prototypes in as fast as 48 hours.

JHYPCB serves industries like telecommunications, aerospace, medical, and consumer electronics, delivering tailored solutions for each sector.

Submit your Gerber files through our online portal, specify your requirements, and request a quote. Our team will guide you through the process.

We provide post-production support, including quality troubleshooting and technical assistance, to ensure your project’s success.

Have more questions? Contact Us for personalized support or learn more FAQs.

JHYPCB’s Multilayer PCB Ordering Process

JHYPCB simplifies ordering multilayer PCBs with a streamlined process:

- Submit Your Design: Upload your Gerber files via our online portal.

- Get a Quote: Receive a fast, customized quote with DFM feedback to optimize costs.

- Production & Support: Enjoy rapid prototyping (as fast as 48 hours) and ongoing assistance.