Quick Turn Flex Circuits Manufacturer in China – JHYPCB

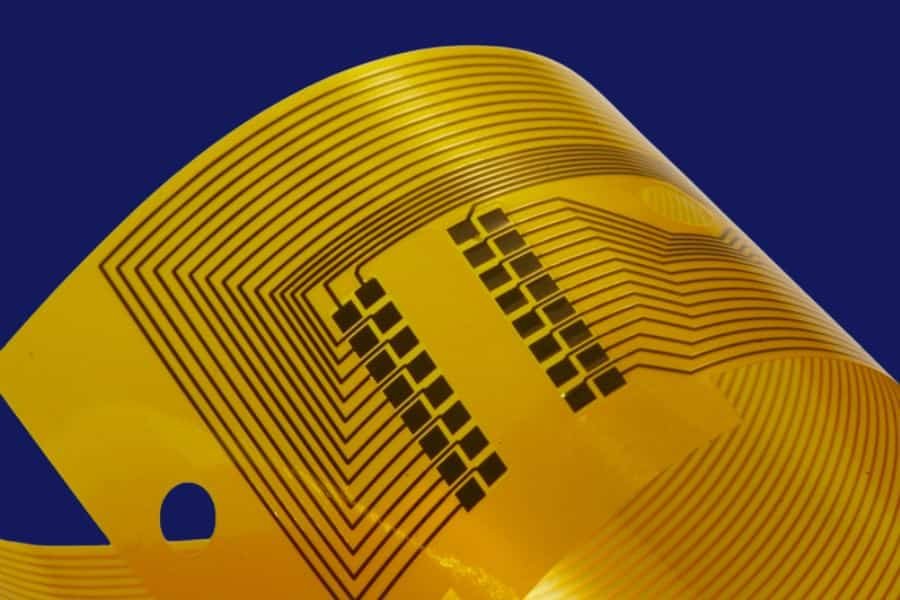

Flexible PCB Prototype & Flex PCB Prototyping Service

JHYPCB provides flexible PCB prototype and low volume flex PCB prototyping services for engineers and buyers developing new electronic products.

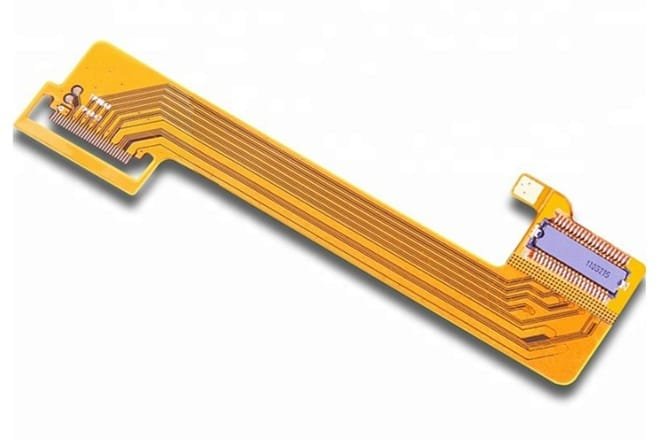

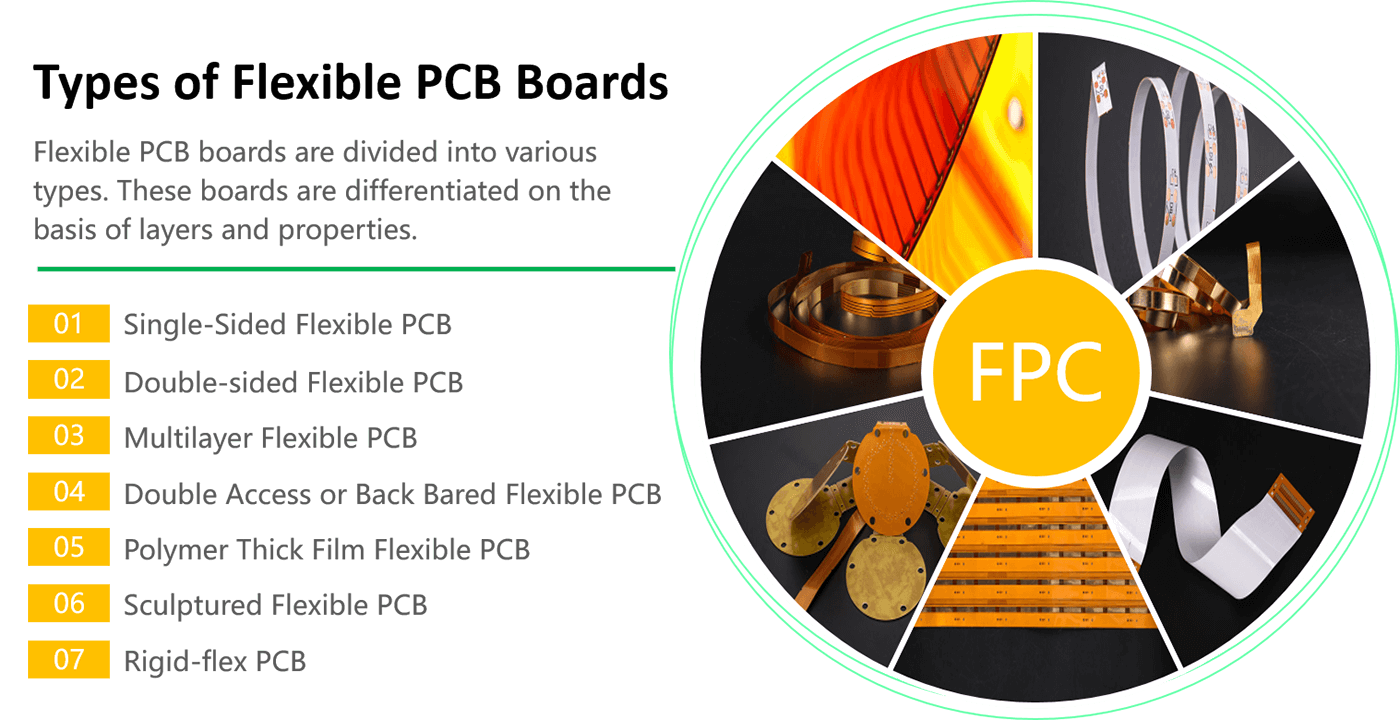

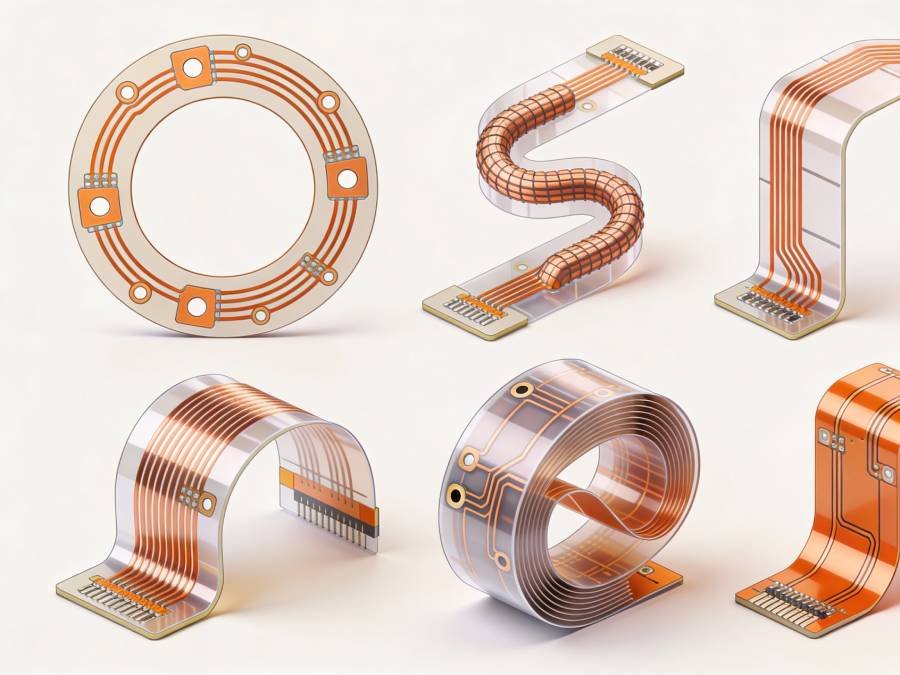

As a China quick turn flex circuits manufacturer, we support single-sided, double-sided and multilayer flex PCB prototypes, as well as rigid-flex PCB prototypes.

Our team offers DFM support for your flex PCB prototyping projects, helping you reduce risks and move to mass production faster.

Response within 24 hours for most flex PCB prototyping inquiries.

Why Choose Our Flexible PCB Prototype Service

Use this section to explain why engineers and buyers choose JHYPCB for flexible PCB prototype and flex PCB prototyping projects.

We focus on quick turn flex circuits, low volume flex PCB prototypes, and custom flexible PCB solutions supported by an experienced engineering team.

Low Volume Flex PCB Prototypes

Our flexible PCB prototype service is ideal for low volume and small batch flex PCB builds, from one-off samples to pilot runs.

You can verify your design and flex performance before committing to mass production.

DFM Support for Flex PCB Prototyping

JHYPCB engineers review your Gerber files and stack-up to provide DFM recommendations for flex circuits and rigid-flex PCB prototypes.

We help you avoid common flex PCB issues in bend areas, coverlay openings, and stiffener design.

WHAT WE DO

Flexible PCB Prototype

& Flex PCB Prototyping Service

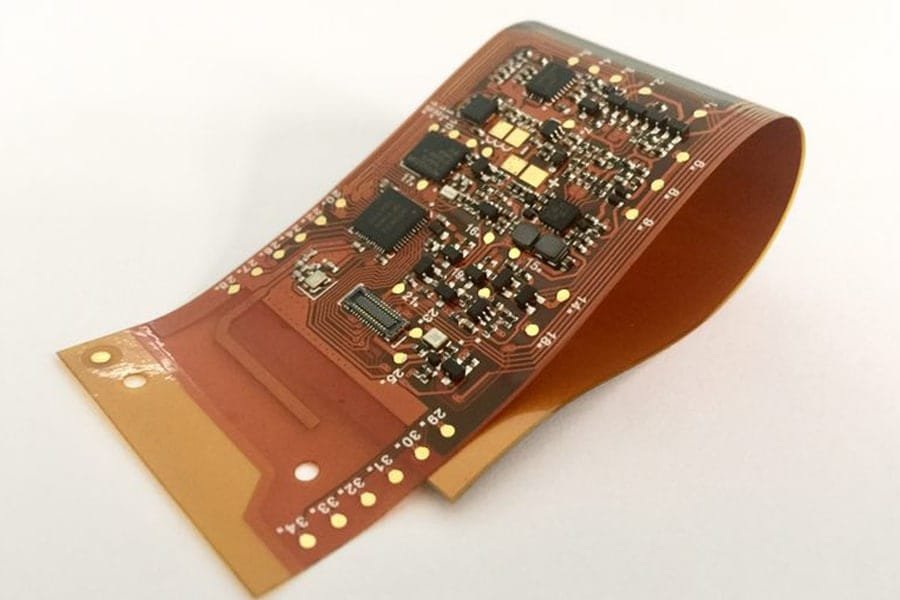

Our flexible PCB prototype and flex PCB prototyping service is designed for engineers and buyers who need reliable flex circuits in small quantities for design verification, functional testing, and pre-production builds.

We focus on low volume flex PCB prototypes and flex circuit board prototyping service, helping you identify design issues early and reduce risks before mass production.

What We Offer for Flex PCB Prototyping

Who Our Flexible PCB Prototype Service Is For

This flexible PCB prototype service is ideal for hardware startups, OEMs and design houses working on wearable devices, medical electronics, automotive modules, industrial control systems and consumer products.

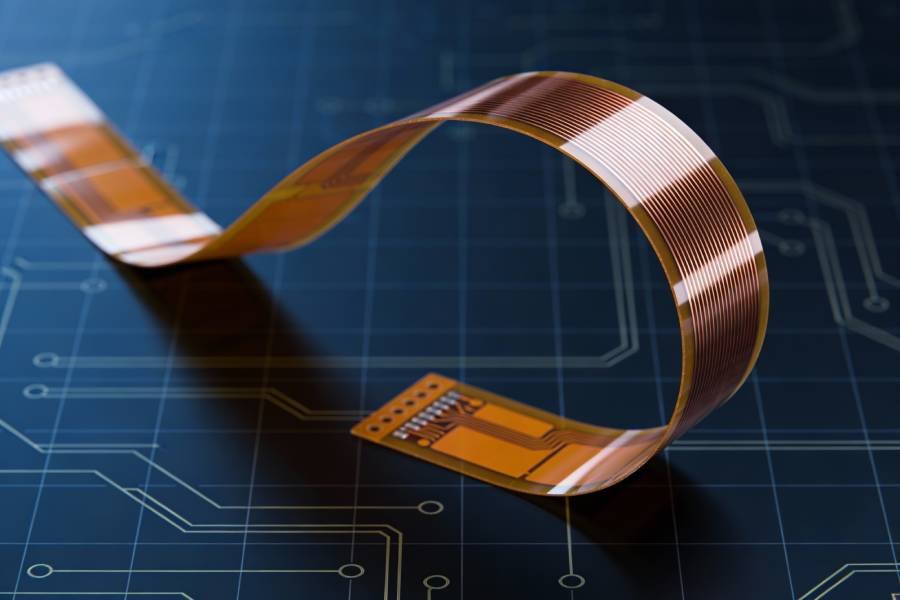

It is especially suitable when you need quick feedback from real flex circuits in bending environments, tight spaces or dynamic applications before committing to large volume flex PCB manufacturing.

Typical Flexible PCB Prototype Use Cases

Quick Turn Flex Circuits & Fast Turn Flex PCB

When speed matters, our quick turn flex circuits and fast turn flex PCB services help you get working prototypes on your bench in days, not weeks.

We align our flexible PCB prototype production, material purchasing and engineering review to support tighter lead times for urgent projects and iterative design cycles.

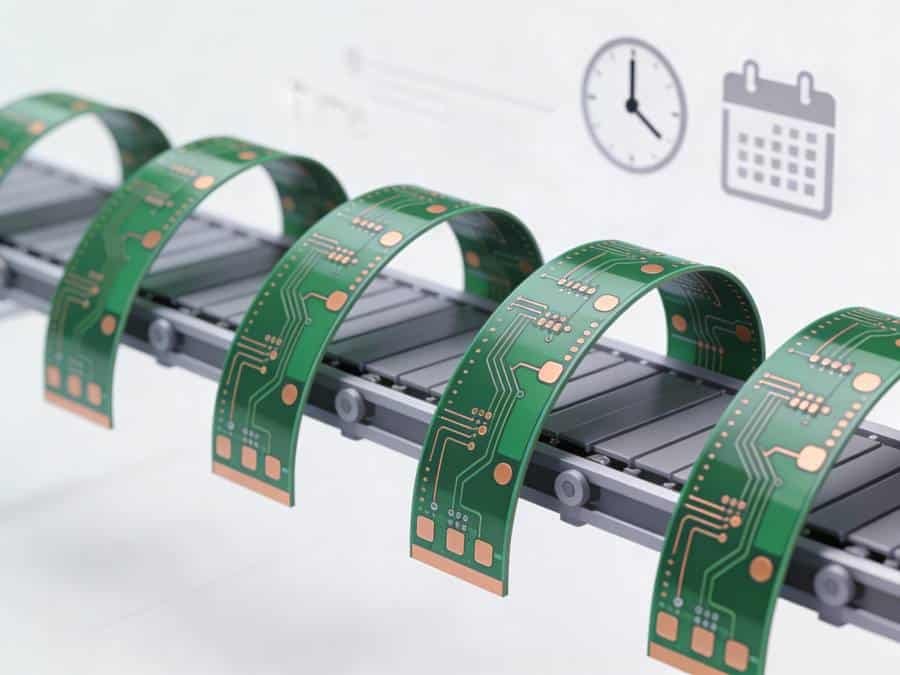

Typical Lead Times for Flexible PCB Prototypes

For most flexible PCB prototype builds, our standard lead times range from 1 to 3 working days depending on layer count, materials and special requirements.

Quick turn flex PCB options are available for qualified designs, where we prioritize engineering review and flex PCB manufacturing slots to meet your schedule.

- Quick turn flex circuits for urgent engineering builds and line-down situations.

- Fast turn rigid-flex PCB prototypes when you need both bending areas and rigid sections in one assembly.

- Flexible PCB quick turn service for design validation, demos, and pre-production testing.

When to Choose Quick Turn Flex PCB Prototyping

Quick turn flex PCB prototyping is ideal when project timelines are tight and you need real flex circuits to validate your design before committing to volume production.

Typical situations include:

- Early-stage product prototypes where you must iterate quickly on flex PCB layouts.

- Customer demos, investor samples and pilot runs that require fast delivery of flex PCB prototypes.

- Emergency replacements when supply chain issues delay your existing flex PCB supplier.

Flexible PCB Prototype Manufacturing Capabilities

Our flexible PCB prototype manufacturing capabilities cover a wide range of stack-ups, materials and feature sizes, making it easier to bring your flex PCB designs from concept to working prototypes.

These capabilities apply to flexible PCB prototypes, flex circuit board prototypes and selected rigid-flex PCB prototypes in low volume builds.

Typical Flex PCB Prototype Capabilities

| Item | Capability (Typical for Flex PCB Prototypes) |

|---|---|

| Layers | 1–X layers flexible PCB prototypes and rigid-flex PCB prototypes |

| Materials | Polyimide (PI), PET, FR-4 + PI rigid-flex constructions, adhesive-less flex where required |

| Finished Board Thickness | From approx. 0.05 mm up to around 1.6 mm depending on stack-up |

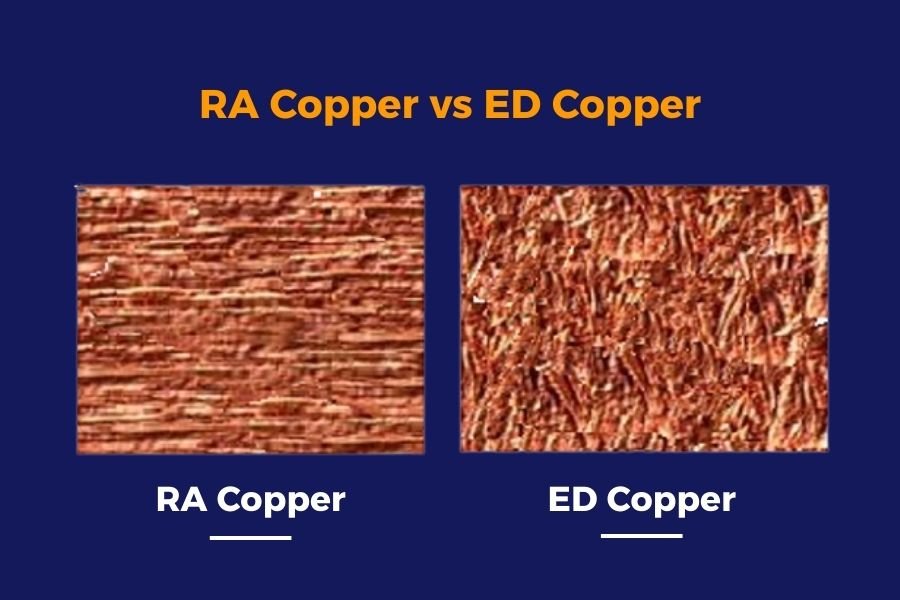

| Copper Thickness | 0.5 oz to 2 oz standard for flex PCB prototypes |

| Minimum Trace / Space | Around 0.075 mm / 0.075 mm (3 mil / 3 mil) for typical flex PCB prototyping; finer features on request |

| Minimum Drill Size (PTH) | Approx. 0.20 mm mechanical drills for prototype builds |

| Maximum Panel Size | Common panel sizes up to roughly 250 mm × 510 mm (adjust to your actual maximum size) |

| Surface Finishes | ENIG (Immersion Gold), Immersion Silver, Immersion Tin, OSP, selective hard gold for contacts |

| Coverlay / Solder Mask Options | PI coverlay, flexible solder mask, controlled openings for pads and bend areas |

| Stiffener Options | PI, FR-4 and stainless steel stiffeners for connector areas and component zones |

| Outline & Profiling | Mechanical routing, punch tooling and laser cutting for complex flex PCB outlines |

| Electrical Testing | 100% electrical test available for flexible PCB prototypes and rigid-flex PCB prototypes |

This capability range is suitable for most flexible PCB prototype and flex circuit board prototyping service requests in wearable, medical, automotive and industrial applications.

If your design pushes limits in minimum trace/space, ultra-thin flex cores or complex rigid-flex stack-ups, our engineering team can review your files and confirm what is feasible for prototype builds.

Applications for Flexible PCB Prototypes

Flexible PCB prototypes are used across many industries where compact size, low weight and dynamic bending are important.

Our flexible PCB prototype and rigid-flex PCB prototype services support applications from wearable and medical devices to automotive electronics and industrial control systems.

Wearable Devices & Consumer Electronics

Our flexible PCB prototypes help you validate comfort, bending performance and reliability before launching high-volume wearable products.

Medical Devices & Health Monitoring

We support flex PCB prototypes and rigid-flex PCB prototypes for applications that require small size, high reliability and consistent performance in demanding environments.

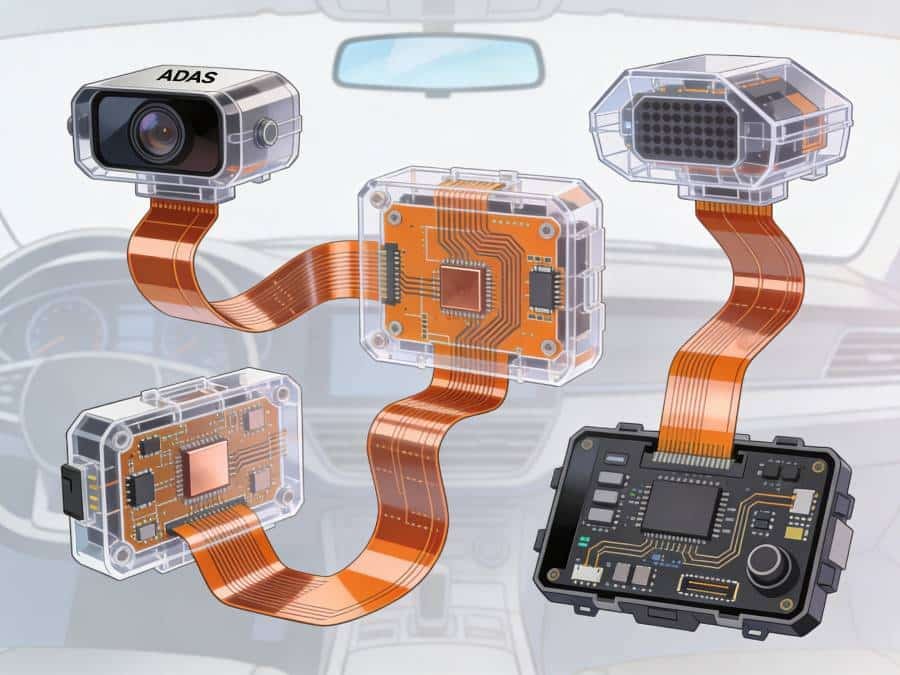

Automotive Electronics & Rigid-Flex Modules

Our flexible PCB prototype and rigid-flex PCB prototype capabilities help you evaluate designs that must withstand vibration, temperature cycling and space constraints in vehicles.

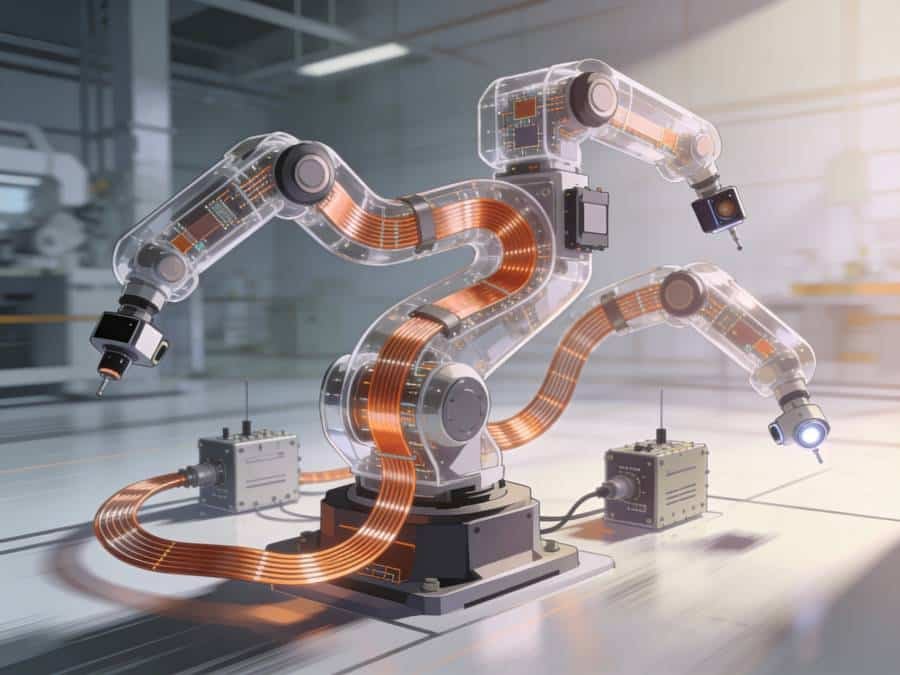

Industrial Control & Robotics

We provide flexible PCB prototypes for static flex-to-install uses and dynamic applications with repeated bending in industrial environments.

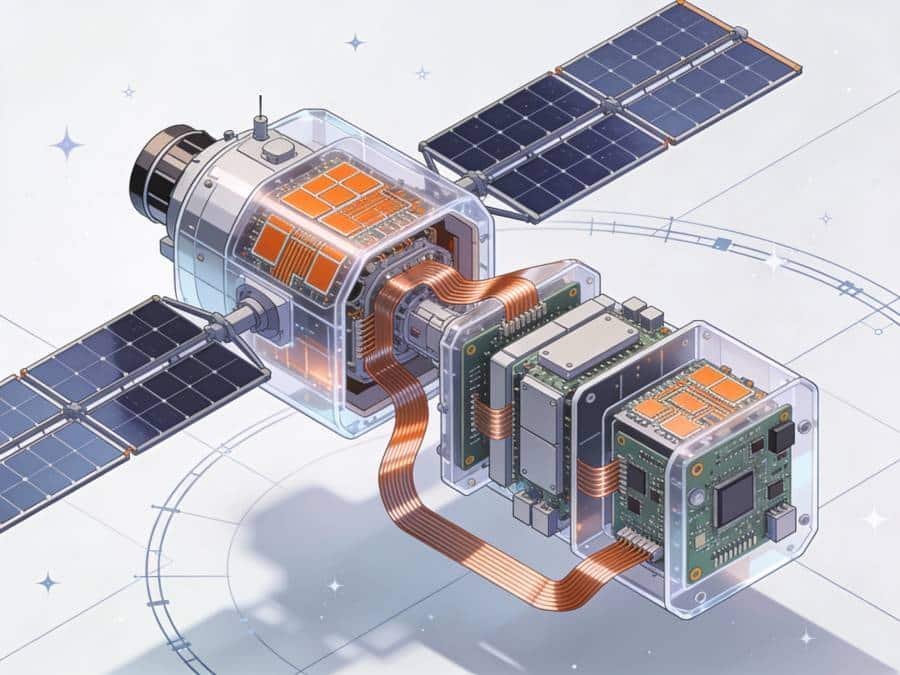

Aerospace, Defense & High-Reliability Systems

Our flex PCB prototyping service supports designs that must balance weight reduction, compact packaging and mechanical robustness.

Custom Flexible PCB Applications

We work with customers to develop flex circuit board prototypes tailored to their specific mechanical and electrical requirements.

Custom Flexible PCB & Rigid-Flex PCB Prototypes from China Manufacturer

As a China flexible PCB manufacturer, JHYPCB provides custom flexible PCB prototypes and rigid-flex PCB prototypes tailored to your specific mechanical and electrical requirements.

We support custom flexible PCB designs with different stack-ups, materials, stiffness levels and connector interfaces, helping you optimize both performance and assembly.

Rigid-Flex PCB Prototypes from China

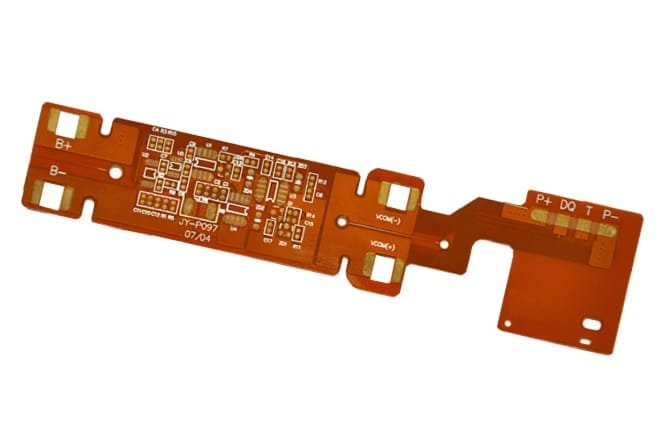

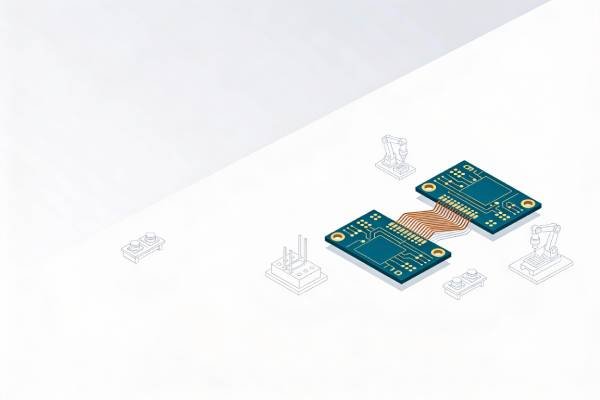

JHYPCB also offers rigid-flex PCB prototypes for applications that combine rigid sections with flexible interconnects in a single structure. This is especially useful when you need to replace wiring harnesses, improve signal integrity or save space in complex assemblies.

Custom Flexible PCB Services

Why Work with a China Flexible PCB Manufacturer

Working with a China flexible PCB manufacturer like JHYPCB allows you to combine custom flexible PCB and rigid-flex PCB prototyping with competitive pricing and a wide selection of materials and processes.

We support international customers with English-speaking engineers, flexible MOQs and logistics options suited for prototype and low volume shipments.

How Our Flex PCB Prototyping Service Works

Our flex PCB prototyping service follows a clear, engineer-friendly workflow so you know exactly what to expect from first contact to receiving your flexible PCB prototypes.

By combining DFM review, controlled flex PCB manufacturing and electrical testing, we help you move from design to working flex circuit prototypes with fewer surprises.

Flexible PCB Prototype FAQ

A flex PCB prototype is a small batch of flexible printed circuit boards used to verify your design, stack-up and manufacturability before committing to mass production.

These flexible PCB prototypes allow you to test fit, bending performance and electrical behavior in real-world conditions.

Flexible PCB prototypes can bend, fold and twist to fit into compact or moving assemblies where rigid PCBs cannot.

They help reduce connectors and wiring harnesses, save space and weight, and improve reliability in dynamic or vibration-prone applications.

We support single-sided, double-sided and multilayer flexible PCB prototypes as well as selected rigid-flex PCB prototypes.

Designs can include different materials, copper weights, stiffeners and coverlay options depending on your application.

To quote a flexible PCB prototype, we typically need your Gerber files, stack-up details, quantity, finished board thickness, copper weight and desired surface finish.

Any information about bend areas, minimum radius, stiffeners and special requirements for rigid-flex PCB prototypes will also help us provide an accurate quote.

Yes, we offer quick turn flex PCB prototyping options for qualified designs and quantities.

Standard lead times depend on layer count and complexity, and we can often provide faster options when your project schedule requires it.

Typical limits include minimum trace/space, minimum drill size, maximum panel size and available materials, which are summarized in our flexible PCB prototype capabilities section.

If your design is close to or beyond standard limits, our engineering team can review it and suggest adjustments for reliable flex PCB prototyping.

Yes, we provide DFM review for flex PCB prototyping, checking items such as bend radius, trace routing in flex areas, coverlay openings and stiffener placement.

This helps reduce the risk of cracks, delamination or premature failures in your flexible PCB prototypes and rigid-flex PCB prototypes.

We can extend from flexible PCB prototype builds to low volume and small production runs using the same or similar process flow.

This makes it easier to go from initial flex PCB prototyping to stable, repeatable manufacturing as your project scales.

Ready to Start

Your Flexible PCB Prototype?

If you are ready to move from design to a working flexible PCB prototype, our team is here to help with quoting, DFM review and quick turn flex PCB prototyping options.

Share your Gerber files and basic requirements, and we will respond with a flexible PCB prototype quote and lead time details.