Table of Contents

Flexible printed circuit boards (Flex PCBs) are powering the future of electronics in 2025, enabling compact, durable, and dynamic designs across industries. With the global Flex PCB market projected to grow by 11.5% in 2025 (Source: Comprehensive Market Research), their flexibility, lightweight design, and resilience drive innovation in wearables, medical devices, automotive systems, IoT, green energy, and beyond. Discover how flex circuits are transforming technology and how JHYPCB’s expertise delivers tailored solutions.

Why Choose Flex PCBs? Key Technical Advantages

Feature | Flex PCB | Rigid PCB |

|---|---|---|

Thickness | 0.1mm or less | 0.8mm+ |

Bend Radius | <0.5mm | Not flexible |

Weight | Up to 70% lighter | Heavier |

Durability | 200,000+ flex cycles | Limited |

Temperature Range | -40°C to 200°C | -20°C to 120°C |

Flex PCBs, built on polyimide substrates, offer high thermal stability, signal integrity at 10 GHz+, and biocompatibility, making them ideal for dynamic, compact applications.

Flexible PCBs in Wearable Technology

Technical Advantages

With thicknesses as low as 0.08mm and bend radii below 0.5mm, flex PCBs enable skin-like wearables with high-speed signal transmission for sensors and displays.

Key Applications

- Smartwatches: Apple Watch Series 11 integrates flex PCBs for OLED displays and ECG sensors.

- Fitness Trackers: Fitbit Sense 2 uses flex circuits for lightweight heart rate monitoring.

- AR Headsets: Meta Orion leverages flex PCBs for curved optics integration.

Case Study: JHYPCB’s Wearable Innovation

JHYPCB designed a 0.08mm flex PCB for a fitness tracker, reducing weight by 15% and boosting battery life by 10%. Our rapid prototyping cut development time by 30%.

Future Trends

In 2025, flex PCBs will enable smart fabrics with integrated health sensors, revolutionizing wearable diagnostics.

Flexible PCBs in Consumer Electronics

Technical Advantages

Flex PCBs support high-density interconnects in 1mm² spaces, enduring 100,000+ bend cycles for foldable devices.

Key Applications

- Foldable Smartphones: Samsung Galaxy Z Fold 8 uses flex PCBs for reliable hinge connectivity.

- Convertible Laptops: Lenovo Yoga 9i leverages flex circuits for seamless mode transitions.

Future Trends

Rollable displays and holographic interfaces will rely on flex PCBs for ultra-thin, dynamic designs in 2025.

Flexible PCBs in Medical Devices

Technical Advantages

Biocompatible flex PCBs withstand bodily fluids and temperatures up to 150°C, enduring 1M+ flex cycles for implantable devices. Their low dielectric constant (Dk < 3.5) ensures reliable signal transmission in compact designs.

Key Applications

- Hearing Aids: Phonak Audéo uses flex PCBs for compact audio processing, fitting within the ear canal.

- Endoscopes: Flex circuits integrate 4K imaging sensors in minimally invasive tools, enabling precise diagnostics.

- Pacemakers: Biocompatible flex PCBs ensure long-term reliability inside the body.

Case Study: JHYPCB’s Medical Breakthrough

JHYPCB developed a biocompatible flex PCB for a next-gen insulin pump, reducing device size by 20% and improving patient comfort. Our ISO 13485-certified process ensured compliance with stringent medical standards, with the flex PCB passing 1,000-hour immersion tests in simulated bodily fluids.

Design Challenges

Designing flex PCBs for medical applications involves overcoming challenges like signal integrity, thermal management, and biocompatibility. For instance, implantable devices require substrates with low dielectric loss (Dk < 3.5) to minimize signal attenuation at 1 GHz. JHYPCB’s advanced polyimide-based flex PCBs undergo finite element analysis (FEA) to optimize bend radii (<0.5mm) and ensure reliability under dynamic conditions. Our rigorous testing, including accelerated aging and fluid immersion, guarantees performance for critical applications like pacemakers and neural implants.

Future Trends

In 2025, flex PCBs will enable smart implants with real-time health monitoring, such as glucose sensors integrated with IoT for remote patient care.

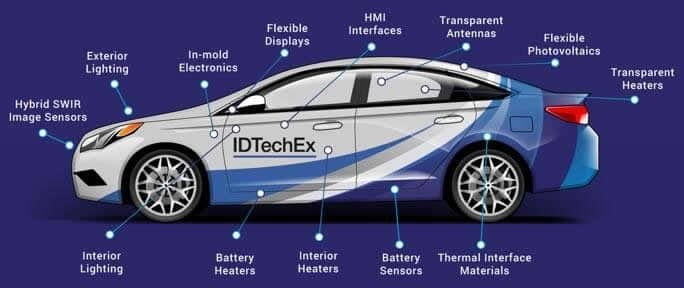

Flexible PCBs in Automotive Electronics

Technical Advantages

Flex PCBs endure 20G vibrations and -40°C to 150°C temperatures, reducing vehicle weight by 10%.

Key Applications

- Dynamic Components: Flex circuits connect electronics in sunroofs and seats.

- Airbag Systems: Flex PCBs ensure reliability during rapid deployment.

- EV Battery Management: Tesla Model S Plaid uses flex PCBs for efficient battery systems.

Future Trends

In 2025, flex PCBs will enable curved displays and sensor arrays for autonomous vehicles.

Flexible PCBs in Aerospace and Defense

Technical Advantages

Flex PCBs operate at 200°C and 50G forces, with EMI shielding for mission-critical reliability.

Key Applications

- Aerospace: Boeing 787 navigation systems use flex PCBs for vibration resistance.

- Defense: Night-vision goggles leverage flex circuits for lightweight designs.

Future Trends

Flex PCBs will support lightweight drones and lunar rovers in 2025’s space exploration boom.

Flexible PCBs in the Internet of Things (IoT)

Technical Advantages

Flex PCBs enable low-power, compact IoT devices, withstanding moisture and vibrations.

Key Applications

- Smart Home: Amazon Echo Dot uses flex PCBs for cylindrical designs.

- Industrial IoT: Flex circuits in sensors endure harsh environments.

- Wearable IoT: Smart jewelry integrates flex PCBs for discreet monitoring.

Future Trends

In 2025, flex PCBs will power smart city sensors, enabling seamless urban connectivity.

Flexible PCBs in Green Energy

Technical Advantages

Flex PCBs conform to curved surfaces, resisting UV and temperature fluctuations for renewable energy.

Key Applications

- Flexible Solar Panels: Flex PCBs enable lightweight, curved solar modules.

- Wind Turbine Sensors: Flex circuits monitor blade conditions in harsh environments.

Future Trends

Flex PCBs will support thin-film batteries and hybrid solar systems in 2025’s green energy surge.

Emerging Applications of Flexible PCBs

Robotics

Flex PCBs enable intricate robotic limbs, integrating sensors and actuators across movable joints for natural movement. For example, JHYPCB’s multi-layer flex circuits support high-density sensor arrays in humanoid robots, withstanding 200,000+ flex cycles.

Flexible Displays

Rollable smartphones and e-readers rely on flex PCBs for dynamic functionality. In 2025, flex circuits will enable foldable displays with 0.1mm thickness, supporting 4K resolution and 120 Hz refresh rates.

6G and Brain-Computer Interfaces

Flex PCBs are pivotal for 6G communication, supporting antennas operating at 100 GHz with minimal signal loss. In brain-computer interfaces (BCIs), flex PCBs enable neural implants with biocompatible, ultra-thin designs. For instance, JHYPCB’s 0.05mm-thick flex circuits integrate 128-channel electrode arrays for BCIs, achieving signal fidelity under 1% loss after 1,000 hours of operation. Our design process addresses challenges like electromagnetic interference (EMI) and thermal dissipation, using advanced shielding and low-loss materials (Dk < 3.2). These innovations position flex PCBs as the backbone of neurotechnology and high-speed connectivity in 2025.

Future Trends

Flex PCBs will drive advancements in soft robotics and wearable BCIs, enabling seamless human-machine integration by 2025.

How to Choose a Flex PCB Supplier

Selecting the right Flex PCB supplier is critical for project success. Key considerations include:

- Quality Certifications: Ensure compliance with ISO 9001, ISO 13485 (medical), or AEC-Q100 (automotive). JHYPCB’s certifications guarantee reliability across industries.

- Customization Capabilities: Look for rapid prototyping and multi-layer flex circuit expertise. JHYPCB offers tailored designs, from single-sided to 12-layer flex PCBs, with turnaround times as low as 48 hours.

- Technical Support: Choose a supplier with in-depth design consultation. JHYPCB’s engineers use FEA and signal integrity analysis to optimize flex PCB performance.

- Lead Time and Scalability: Prioritize suppliers with fast delivery and scalable production. JHYPCB supports prototypes to mass production, meeting tight deadlines.

Contact JHYPCB for a free consultation and see how we deliver customized flex PCB solutions.

FAQ: Flexible Printed Circuit Boards

What are the advantages of Flex PCBs over rigid PCBs?

Flex PCBs are 70% lighter, support <0.5mm bend radii, and endure 200,000+ flex cycles, making them ideal for dynamic, compact applications.

How are Flex PCBs manufactured?

Flex PCB manufacturing involves etching copper traces on polyimide substrates, applying solder masks, and rigorous testing (e.g., IPC-6013 standards). JHYPCB’s automated production ensures precision, with defect rates below 0.5%.

What are the key design challenges for Flex PCBs?

Challenges include thermal management, signal integrity, and bend reliability. For high-frequency applications like 6G antennas, low-loss materials (Dk < 3.5) are critical. JHYPCB uses FEA to optimize bend radii and thermal dissipation, ensuring performance under extreme conditions.

Add Your Heading Text Here

Why choose JHYPCB?

JHYPCB offers rapid prototyping, multi-layer flex circuits, and ISO-certified quality, with design support for complex applications like 6G and medical implants.

Conclusion

In 2025, flexible printed circuit boards are transforming wearables, medical devices, automotive systems, IoT, green energy, and emerging technologies like 6G and BCIs. Their flexibility, durability, and compact design are unmatched. JHYPCB’s advanced manufacturing and customization capabilities empower businesses to lead in this dynamic market.

Ready to innovate with Flex PCBs? Contact JHYPCB for a free consultation.

Related Reading

- What Is Flex PCB Prototyping?

- What Is Flexible PCB Coverlay (FPC Cover Layer)?

- What Are The Advantages And Applications Of Rigid-Flex PCBs?

- Rigid PCB vs Flex PCB: What Is The Difference?

- What Are Flexible PCB Stiffeners?

- Everything You Need To Know About Multilayer Flexible PCB

- Custom Flex PCB:Tailored Solutions for Your Applications

- Introduction to Semi-Flex PCBs: Bridging Rigid and Flex PCBs

- Flexible PCB Manufacturing: A Guide to Fabrication and Assembly

- How to Select the Right Flexible PCB Manufacturer for Your Product: A 6-Step Guide

- Layer Stackup in Rigid-Flex PCB

- What Are The Types of Flexible Circuit Boards?

- Why is Flexible PCB so Expensive?

- The Manufacturing Process Of Double-sided Flexible PCB Coverlay

- How to Solder On Flex PCB?

- Flexible Printed Circuit For Today’s Packaging

- 16 Factors Affecting The Cost And Price of Flexible PCB

- Complete Introduction of Flexible Circuit Board Materials

- Knowledge of Flexible PCB Manufacturing Process Steps

- Knowledge of Plating on Flexible Circuit Board Surface

- Five factors that FPC PCB designers should know about impedance control

- Key Process Flow of Rigid-Fled PCB Production