Affordable PCB Prototypes & Assembly by JHYPCB

Discover high-quality, low-cost PCB fabrication and assembly services from China’s trusted manufacturer. From 2-layer to multilayer and flexible PCBs, we deliver fast, reliable solutions tailored to your needs.

Why Choose JHYPCB for Low-Cost PCB Prototypes?

At JHYPCB, we combine affordability with uncompromising quality. As a leading PCB manufacturer in China, we offer:

- Cost-Effective Solutions: Low-cost PCB prototypes starting at $10, with no hidden fees.

- Fast Turnaround: 24-hour delivery for 2-layer PCB prototypes and quick-turn options for multilayer boards.

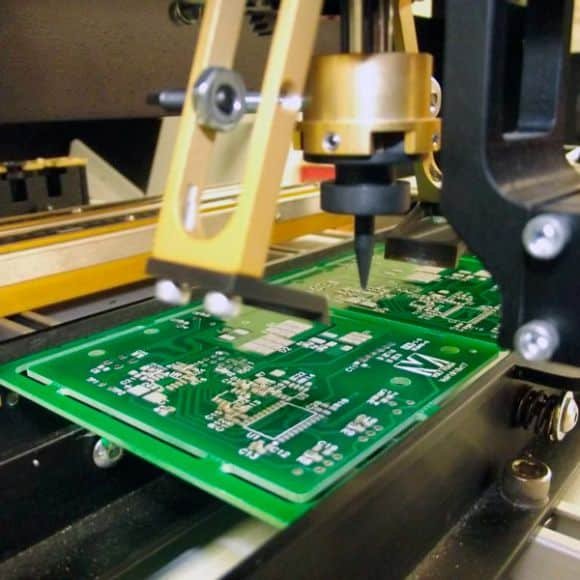

- High Reliability: Rigorous testing (e.g., flying probe tests) ensures IPC-compliant boards.

- Global Shipping: Affordable, flexible shipping options to customers worldwide.

- Expert Support: Dedicated engineers provide design and manufacturing guidance to reduce costs.

Whether you’re a researcher, student, or engineer, JHYPCB delivers tailored PCB solutions at competitive prices.

What Impacts PCB Manufacturing Costs?

PCB fabrication costs typically range from $10 to $50, depending on several factors. Understanding these can help you optimize your design for affordability:

| Factor | Impact on Cost |

|---|---|

| Board Size | Larger boards require more materials, increasing costs. |

| Material Type | Standard FR4 is cost-effective; high-Tg or high-frequency materials cost more. |

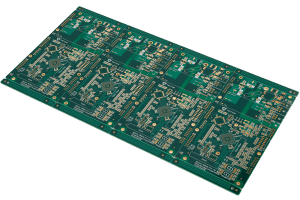

| Layer Count | Multilayer PCBs (e.g., 4-layer, 8-layer) involve complex processes, raising costs. |

| Copper Thickness | Thicker copper increases material and processing costs. |

| Order Quantity | Prototypes are pricier per unit; bulk orders reduce costs. |

| Turnaround Time | Faster delivery (e.g., 24-hour turnaround) incurs premium fees. |

| Design Complexity | Intricate designs (e.g., HDI, impedance control) require advanced manufacturing. |

Tips to Save Costs:

- Minimize board size and layer count.

- Opt for standard materials like FR4.

- Plan for longer lead times to avoid rush fees.

Learn More About Cost Optimization

Our Low-Cost PCB Fabrication and Assembly Services

JHYPCB offers a full range of PCB solutions tailored to your needs, from prototypes to mass production:

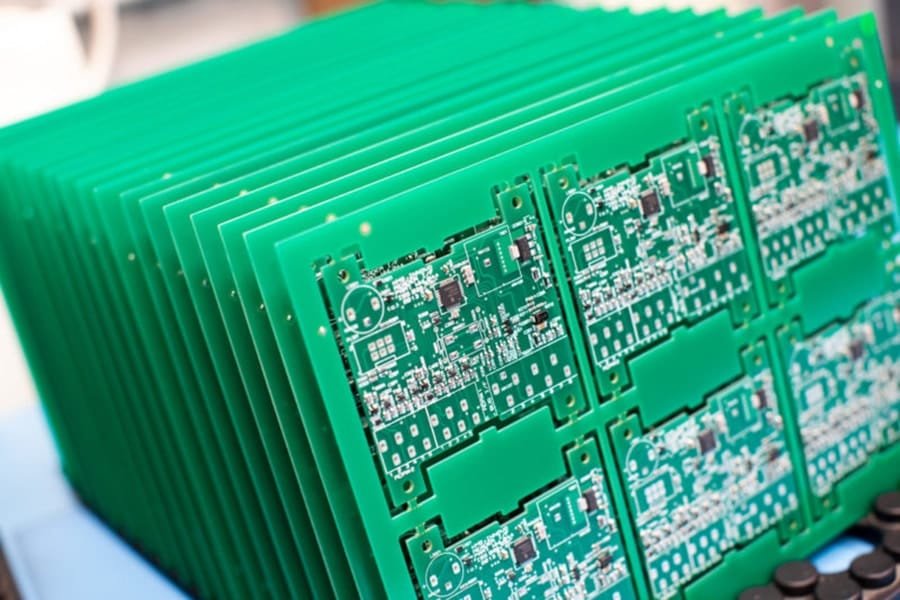

Low-Cost 2-Layer PCB Prototypes

- Ideal for simple designs and rapid prototyping.

- 24-hour turnaround available for urgent projects.

- Starting at $10 for small-batch orders.

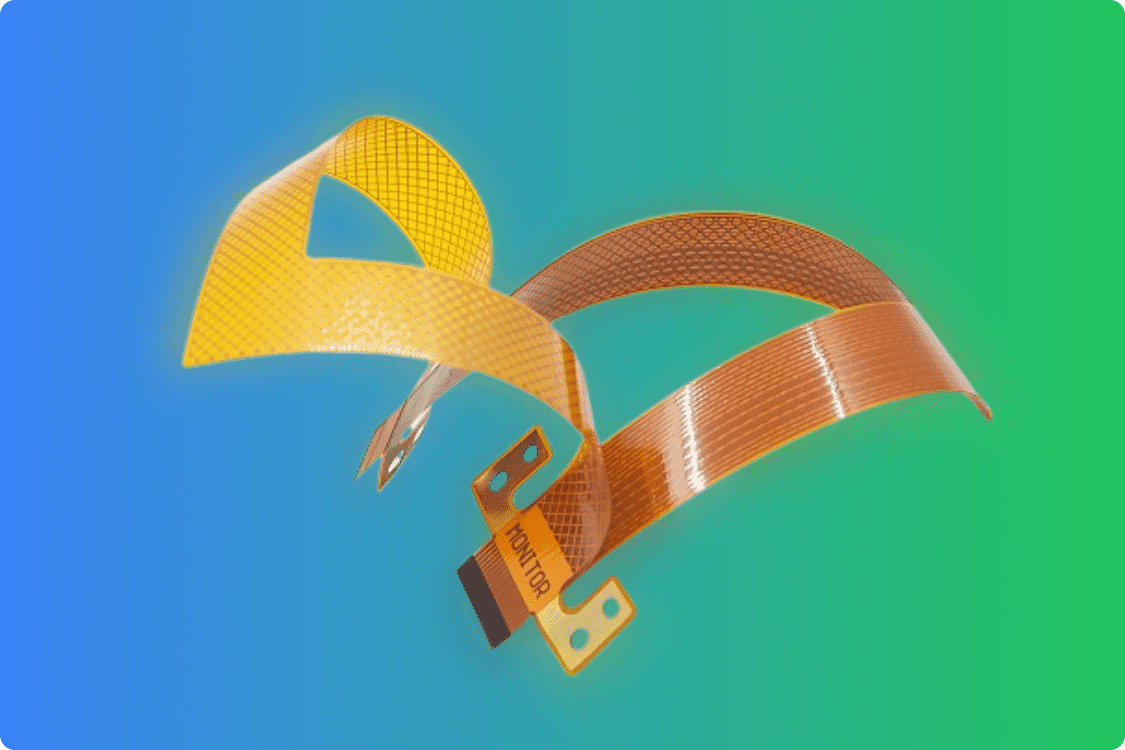

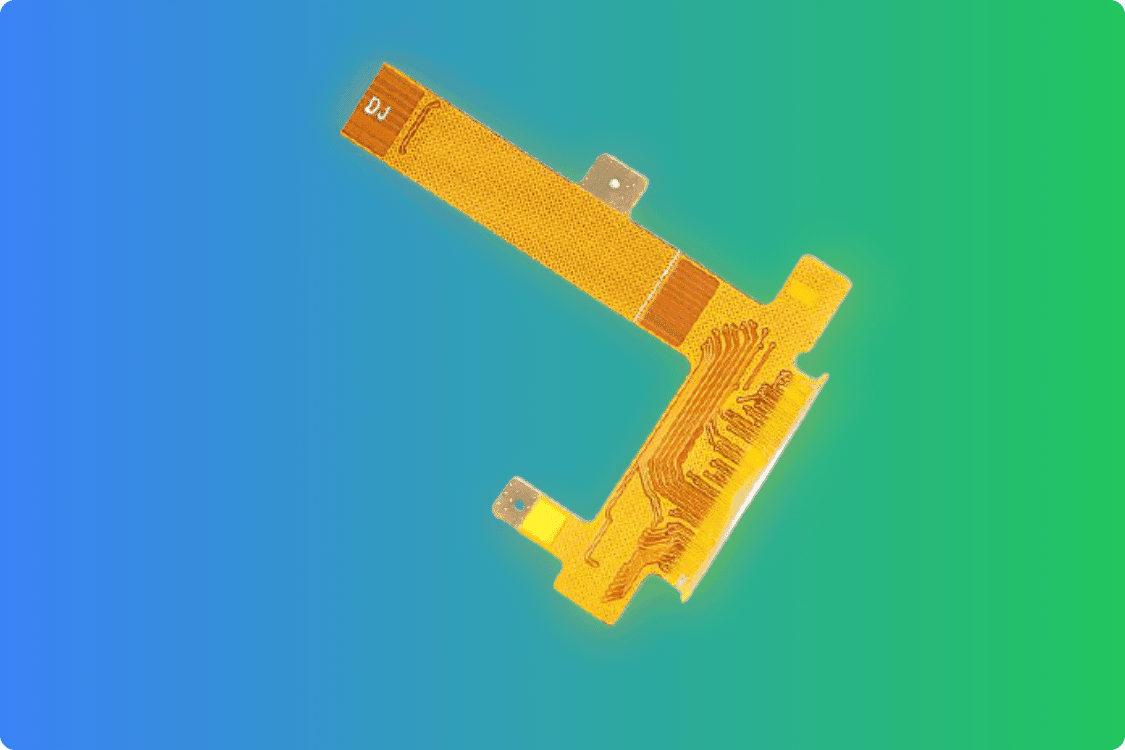

Flexible and Rigid-Flex PCB Prototypes

- Single-layer to 12-layer flexible and rigid-flex PCBs.

- Perfect for compact, lightweight, or durable applications.

- Competitive pricing with fast delivery.

- Low-cost SMT, THT, and turnkey assembly.

- No minimum order quantity for small-batch projects.

- Component sourcing and stencil services included.

Send your Gerber files to sales@pcbjhy.com for a free quote within 24 hours.

How to Get a Low-Cost PCB Quote

Requesting a quote from JHYPCB is simple and fast:

- Submit Your Files: Upload your Gerber RS-274X files via our online form or email sales@pcbjhy.com.

- Review by Experts: Our engineers evaluate your design for manufacturability and cost optimization.

- Receive Your Quote: Get a detailed quote within 24 hours, including lead time and pricing.

- Start Production: Approve the quote to begin fabrication with our quality assurance guarantee.

Special Offer: Students, researchers, and hobbyists enjoy exclusive discounts on PCB prototypes.

10 Tips to Reduce PCB Manufacturing Costs

Optimize your PCB design and order process to save money without sacrificing quality:

- Minimize Board Size: Smaller boards use less material, lowering costs.

- Extend Lead Times: Allow longer delivery times to avoid rush fees.

- Simplify Design Complexity: Reduce intricate features like HDI or impedance control.

- Choose Standard Materials: Opt for FR4 over high-Tg or specialty materials.

- Reduce Layer Count: Use fewer layers for simpler designs (e.g., 2-layer vs. 4-layer).

- Standardize Thickness: Stick to 1.6mm thickness to avoid a 15% cost increase per 0.4mm.

- Optimize Panelization: Combine small orders for cost-efficient production.

- Select Cost-Effective Finishes: Choose HASL over ENIG for budget-friendly surface finishes.

- Order in Bulk: Larger quantities reduce per-unit costs.

- Partner with JHYPCB: Our engineers provide free design reviews to optimize costs.