Prototype PCB Assembly Service – Fast, Reliable & Turnkey

Fast prototype PCB assembly with no minimum order quantity, flexible turnkey options, and engineering support to help you validate designs quickly.

Turn your PCB design into fully assembled prototype boards in days, not weeks. JHYPCB provides dedicated prototype PCB assembly services in China, combining PCB fabrication, component sourcing, SMT/THT assembly, and testing into one streamlined workflow. Whether you need a single proof-of-concept board or a small batch pilot run, we help you move faster with less risk.

Why Engineers Choose Our Prototype PCB Assembly

Four core advantages that make our prototype PCB assembly service faster, easier, and more reliable for your development projects.

Fast Turnaround Time

No MOQ, Built for Prototypes

Turnkey or Flexible Sourcing

Engineering Support & Quality

What Is Prototype PCB Assembly?

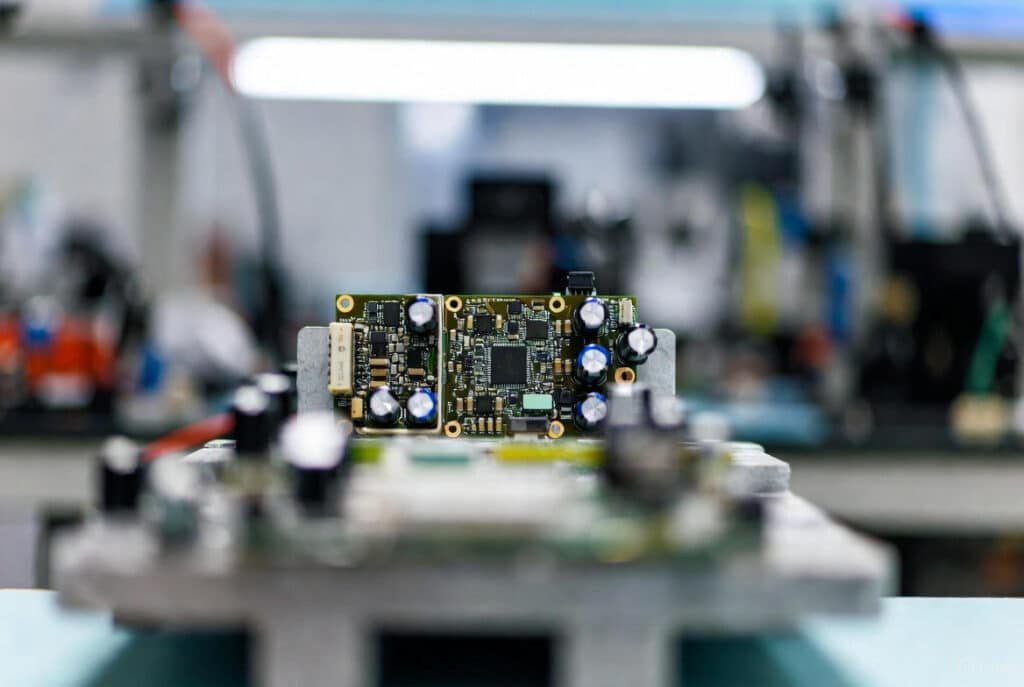

Prototype PCB assembly is the low-volume assembly of printed circuit boards with components, used to test and refine a design before mass production. It gives you a realistic view of how your circuit will perform, making it easier to debug issues, optimize layouts, and verify functionality.

Instead of committing to thousands of boards, prototype PCB assembly lets you build a small number of fully assembled PCBs for validation and iteration. This approach reduces overall project risk and helps you bring better products to market faster.

Who Is This Service For?

Prototype PCB assembly from JHYPCB is designed for teams and individuals who need fast, reliable hardware validation:

- R&D and engineering teams developing new electronic products

- Startups building proof-of-concept and investor demo units

- OEMs running engineering builds and pilot batches

- Companies preparing EMC, safety, and certification samples

- Designers and consultants who need quick, small-batch assemblies

If you have a PCB design that needs to be assembled and tested quickly, this service is built for you.

Why Choose JHYPCB for Prototype PCB Assembly?

Choosing a partner for prototype PCB assembly is about more than just price. You need speed, reliability, and engineering support.

Capabilities at a Glance

JHYPCB’s capabilities are built to support a wide range of prototype PCB assembly requirements.

If you have specific technical limits (e.g., minimum track/spacing, fine-pitch BGA), our engineering team can confirm feasibility before production.

Turnkey & Flexible Sourcing Options

Every project has different needs. JHYPCB offers flexible sourcing models for prototype PCB assembly:

Full turnkey prototype PCB assembly

JHYPCB handles PCB fabrication, component procurement, assembly, and testing. You provide files and specifications; we deliver assembled boards.

Partial turnkey prototype PCB assembly

Responsibility is shared. You may supply key or custom components, while JHYPCB sources standard parts and handles all manufacturing steps.

Consigned prototype PCB assembly

You provide all components, and we focus on SMT/THT assembly and testing according to your process requirements.

These options give you control over supply chain, cost, and lead time.

Benefits of Prototype PCB Assembly with JHYPCB

Working with JHYPCB for prototype PCB assembly helps you validate designs faster, reduce risk, and control costs while maintaining high quality standards.

Faster Design Validation

Shorten your development cycle with fast prototype PCB assembly, so you can quickly test real hardware, gather feedback, and move to the next design iteration without long waiting times.

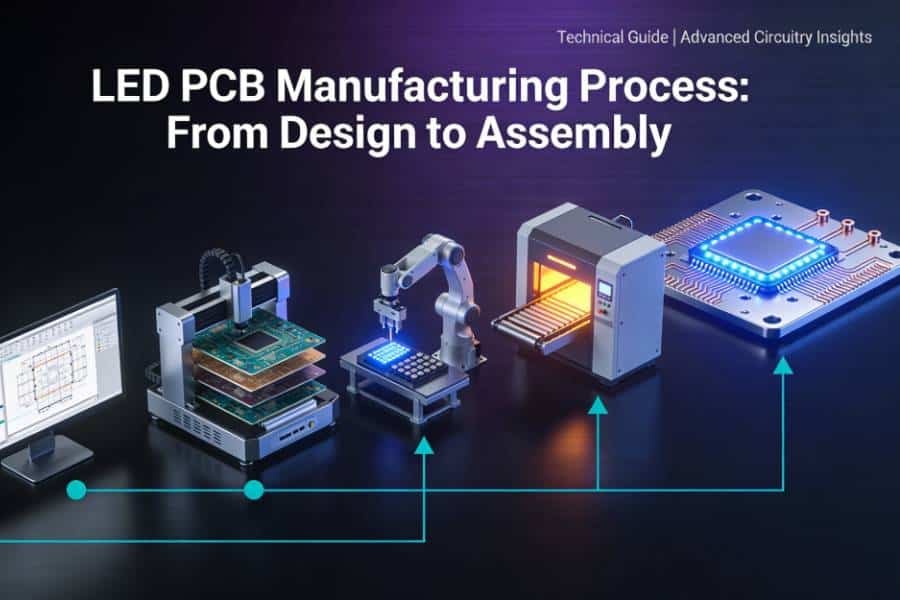

Our Prototype PCB Assembly Process

A clear, efficient process keeps projects on schedule and reduces surprises.

Request and file submission

You send Gerber, BOM, Pick & Place, and any assembly drawings through the quote form or email.

Engineering review and quotation

Our engineers review your files for completeness and manufacturability, then provide a detailed, itemized quotation.

Order confirmation and planning

Once you approve the quote, we confirm schedules, sourcing responsibilities, and any special requirements.

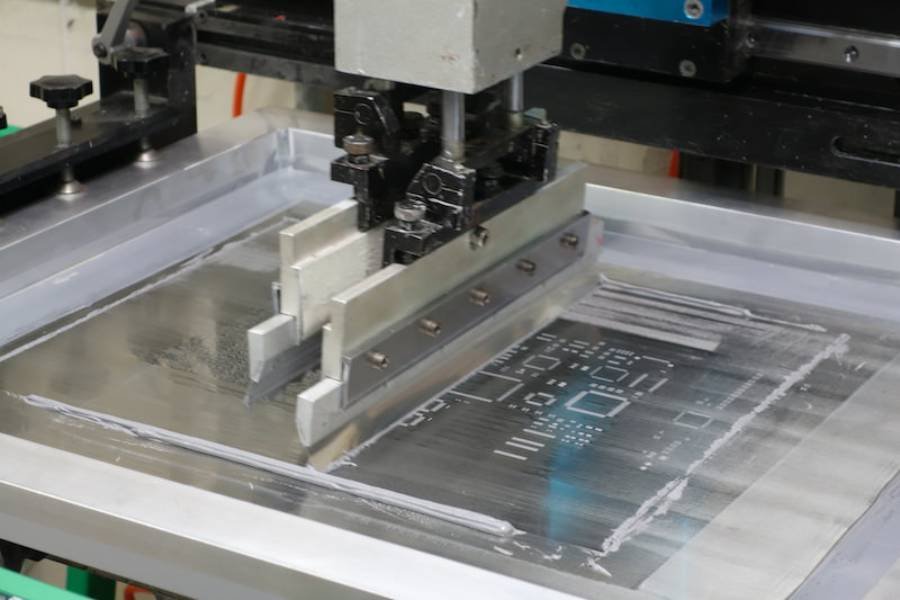

PCB fabrication and component sourcing

Prototype PCBs are manufactured, and components are sourced from trusted distributors according to your BOM.

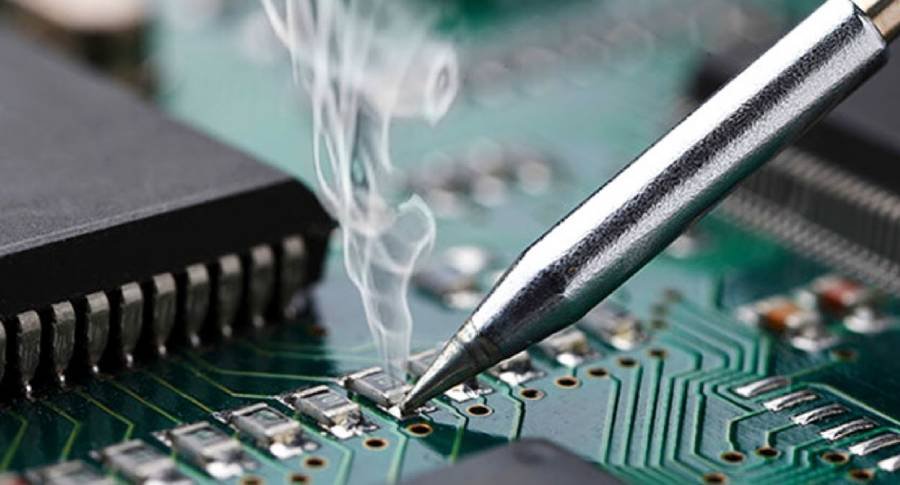

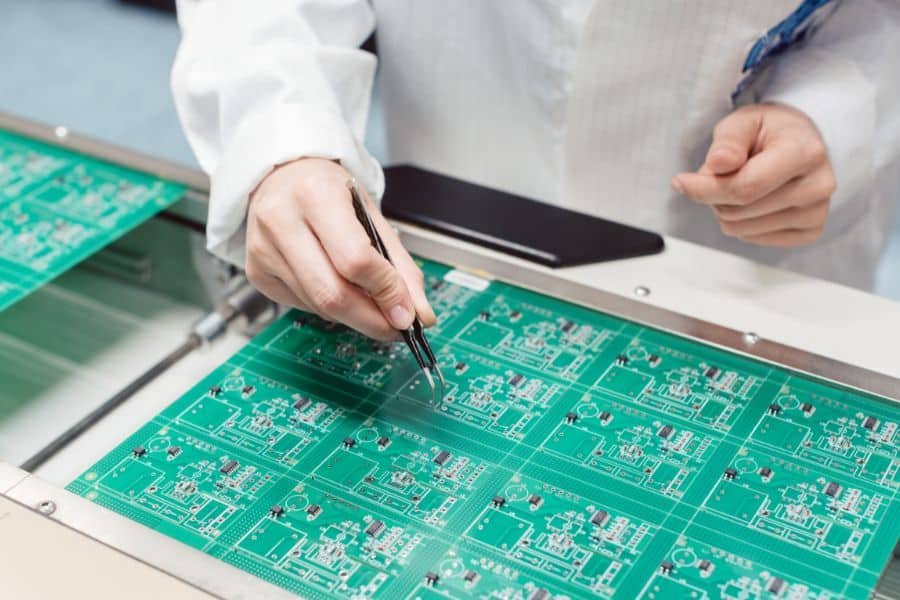

PCB assembly (SMT/THT)

Solder paste is applied, SMT components are placed with automated equipment, and through-hole parts are assembled.

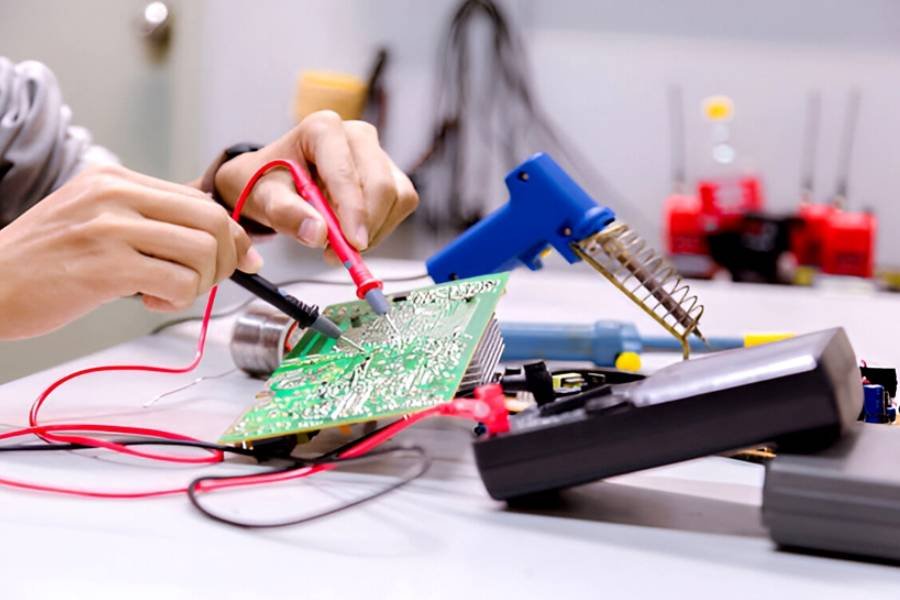

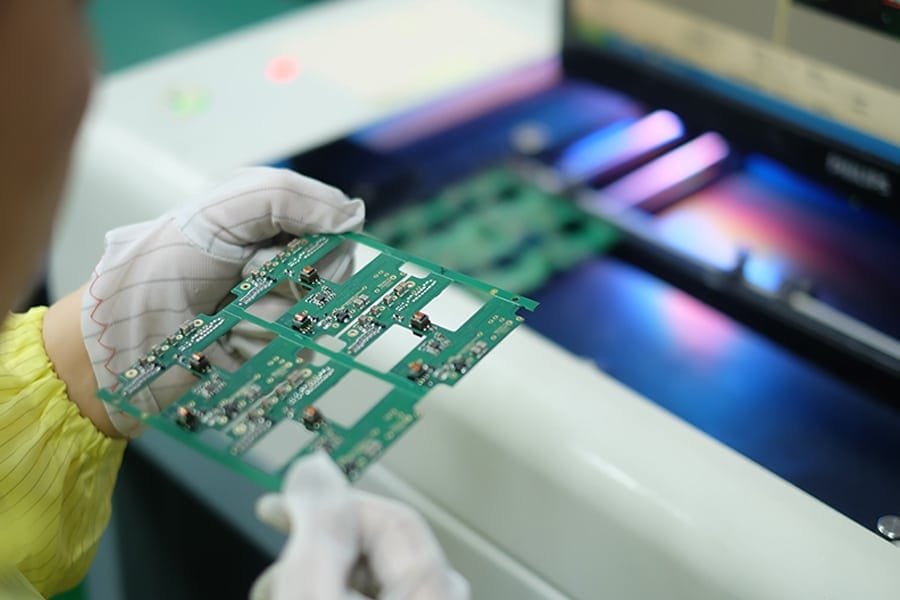

Inspection and testing

AOI, visual inspection, and optional flying probe or functional tests ensure quality and performance.

Packaging and delivery

Assembled boards are packed in ESD-safe materials and shipped to your location using your preferred courier.

Lead Time for Prototype PCB Assembly

Prototype timelines are often tight. Our processes are optimized for speed without sacrificing quality.

Typical lead time ranges:

- PCB fabrication: around 3–10 days for standard prototypes

- Component sourcing: around 2–15 days depending on availability

- Assembly and inspection: around 3–5 days for low-volume builds

Actual lead time depends on design complexity, BOM, and testing requirements. Expedited options may be available for urgent projects—speak with our team to discuss a schedule that fits your deadline.

Time Details of Low Volume Prototype PCB Assembly

Prototype PCB assembly costs are influenced by:

- PCB specifications (layers, materials, finish, panelization)

- Component count, package types, and assembly density

- Testing and inspection requirements

- Quantity of assembled boards

- Shipping destination and method

JHYPCB aims to keep prototype costs competitive while providing professional engineering and manufacturing support, helping you run more iterations within your budget.

You can get an accurate quotation by sending your Gerber, BOM, and Pick & Place files, along with the expected quantity and required lead time.

How to Order Prototype PCB Assembly

Ordering is straightforward and designed to minimize back-and-forth.

Prepare your design data

Submit a quote request

Review and confirm

Production and delivery

Industries & Typical Applications

Prototype PCB assembly from JHYPCB supports a variety of end markets and use cases. This experience helps ensure your prototypes are built with an understanding of different quality standards and regulatory expectations.

FAQs About Prototype PCB Assembly

Prototype PCB assembly is the process of assembling components onto a small batch of PCBs to verify design, function, and manufacturability before mass production.

There is no strict minimum order quantity for prototypes. You can order from one fully assembled board upward.

Yes. We offer full turnkey, partial turnkey, and consigned prototype PCB assembly to match your sourcing and budget preferences.

We generally need Gerber files, BOM, Pick & Place/centroid files, and any assembly drawings or special instructions.

In most cases, you will receive a quotation within 24 hours after submitting complete design data.

Yes. We ship prototype PCB assemblies worldwide and regularly work with customers from different regions.

Ready to Build Your

Prototype PCB Assemblies?

Share your Gerber, BOM, and assembly requirements today to receive a fast, detailed quote for prototype PCB assembly. Our engineers are ready to review your design, provide DFM feedback, and help you turn your ideas into fully assembled, test-ready boards as quickly as possible.