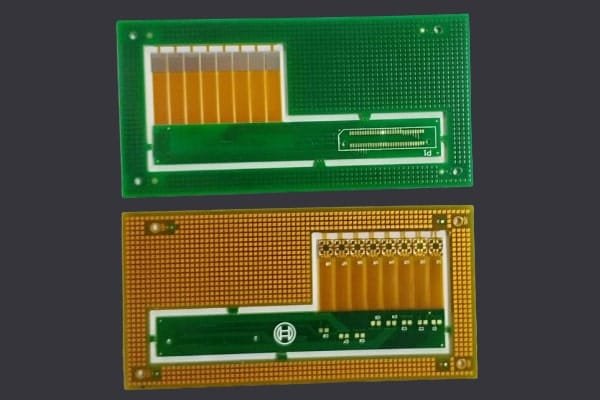

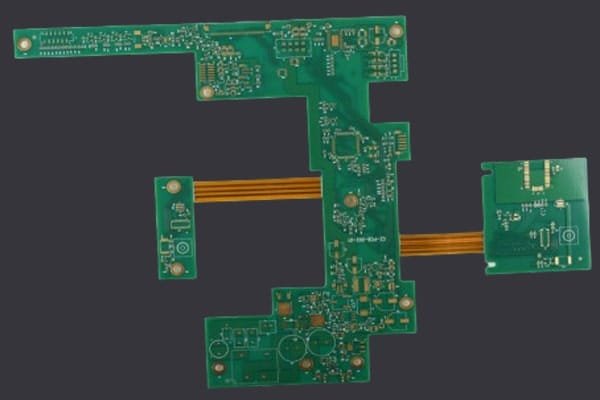

Rigid-Flex PCB Manufacturing & Prototype Services

China rigid-flex PCB manufacturer offering 1–12 layer rigid-flex PCB prototyping, small-to-large volume fabrication, and assembly with fast turnaround and DFM support.

- 1–12 layer rigid-flex PCB, 4/6/8 layer stackup expertise.

- Polyimide + FR4 materials, 2.5mil/2.5mil trace/space, various surface finishes.

- Free DFM check and rigid-flex PCB prototype service, no MOQ.

- ISO/UL/RoHS certified, quick-turn rigid-flex PCB.

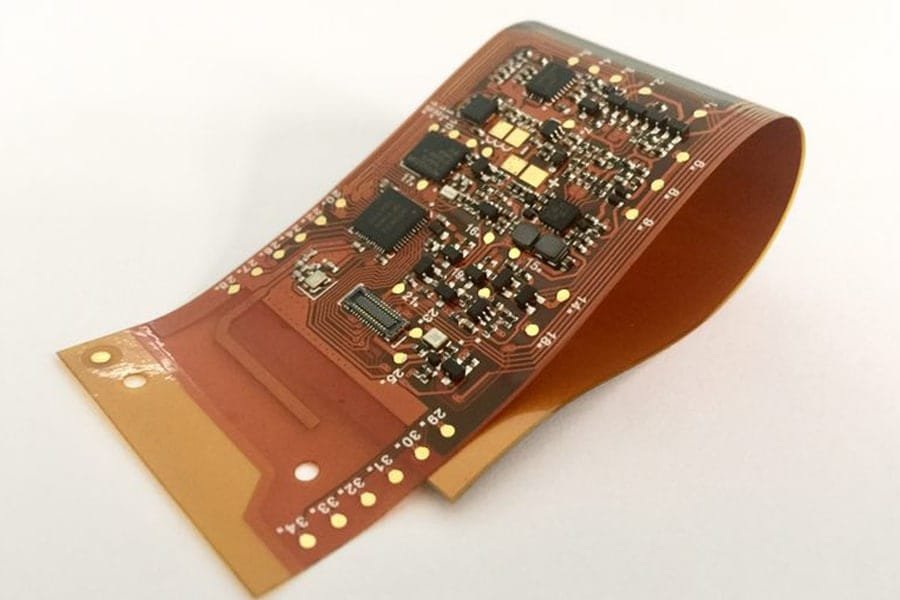

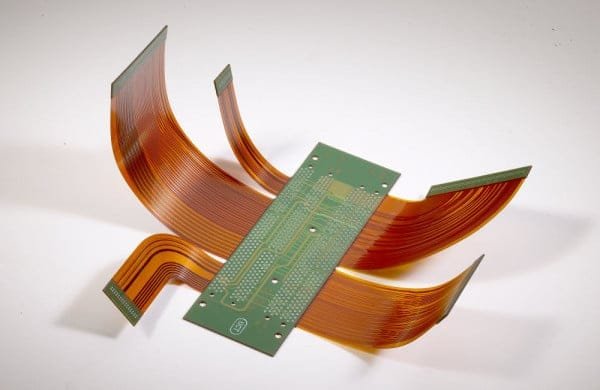

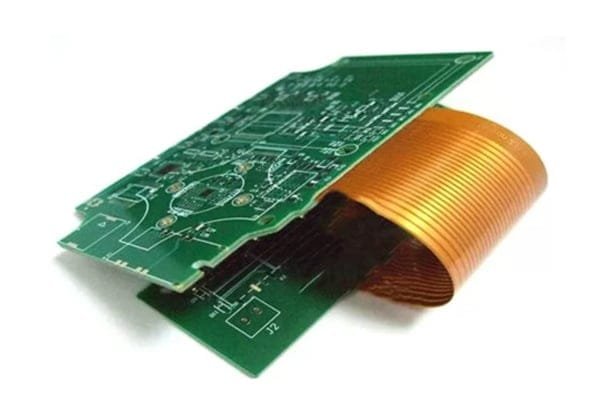

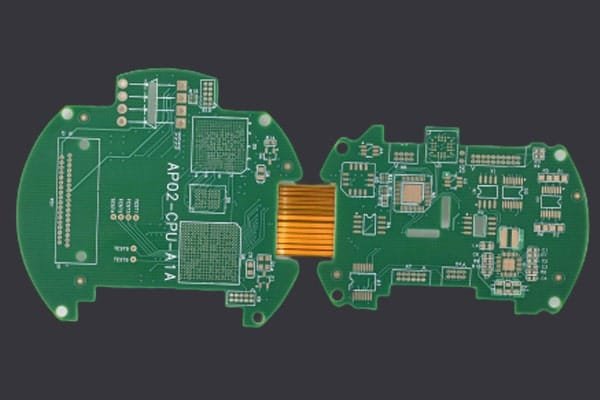

Rigid-Flex PCB, Combine the Best of Both Rigid PCB and Flexible Circuit Board into One Unit. Rigid-Flex designs are more challenging than a typical rigid printed circuit board environment, as these circuit boards are designed in a 3D space and offer greater spatial efficiency.

Rigid-Flex PCB Manufacturer - JHYPCB

Benefits of Rigid-Flex PCB

Rigid-flex PCB combines the reliability of rigid PCB with the flexibility of flex circuits, making it ideal for compact, high‑reliability electronic products. By replacing multiple boards, connectors and cables with a single integrated rigid-flex solution, you can reduce size, weight and assembly complexity while improving overall system performance.

Why Choose JHYPCB for Rigid-Flex PCB Manufacturing

JHYPCB is a China-based rigid-flex PCB manufacturer with more than 10 years of experience in high‑density multilayer rigid-flex PCB fabrication and assembly. From quick‑turn prototypes to small and medium production runs, our team supports you through every stage of your rigid-flex project.

Complete Rigid-Flex Capability

DFM Support and Free Design Check

Quick-Turn Prototype and Low MOQ

One-Stop Fabrication and Assembly

Partnering with a specialized rigid-flex PCB manufacturer like JHYPCB helps you bring complex designs to market faster, with fewer risks and better reliability. Contact our engineering team today to discuss your rigid-flex PCB requirements or upload your Gerber files for a free DFM review.

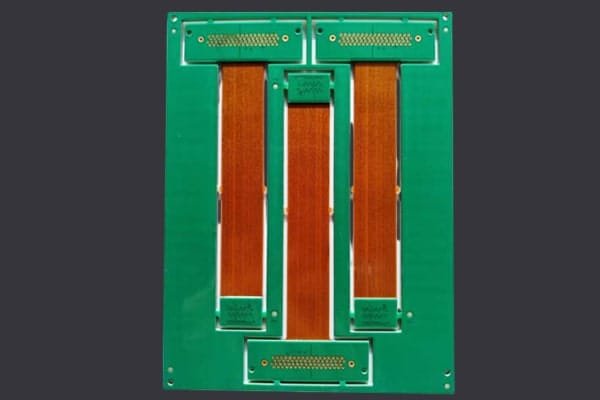

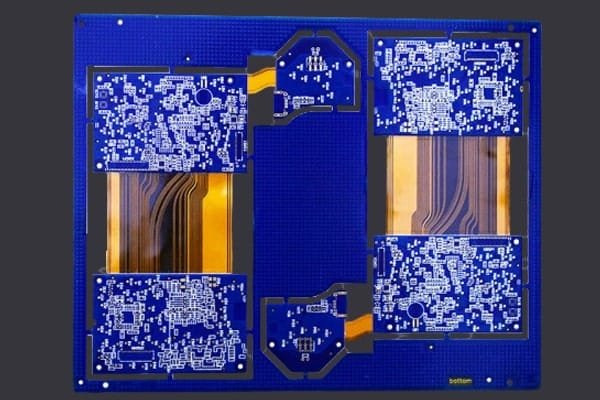

Rigid-Flex PCB Manufacturing Capabilities

JHYPCB provides complete rigid-flex PCB fabrication capabilities from single-layer to 12-layer constructions for prototypes and production runs. With advanced equipment and strict process control, we can meet demanding requirements for fine lines, controlled impedance and complex stackups.

| Capability | Specification |

|---|---|

| PCB Layers | 1–12 layer rigid-flex PCB |

| Materials | Polyimide (flex), FR4 (rigid), optional metal cores |

| Max Board Size | 610 × 640 mm |

| Board Thickness | 0.20–5.50 mm overall |

| Copper Thickness | 1/3–30 oz |

| Min Trace/Space | 2.5 mil / 2.5 mil |

| Solder Mask Colors | Green, White, Blue, Black, Red, Yellow |

| Surface Finishes | OSP, HASL, Lead-free HASL, ENIG, Immersion Tin/Silver, Flash Gold |

| Stiffener Options | PI, FR4, stainless steel, aluminum |

| Special Features | Blind/buried vias, controlled impedance, air-gap structure, panelization, shielding options |

These rigid-flex PCB capabilities enable compact, high‑reliability designs for medical, automotive, industrial and consumer applications.

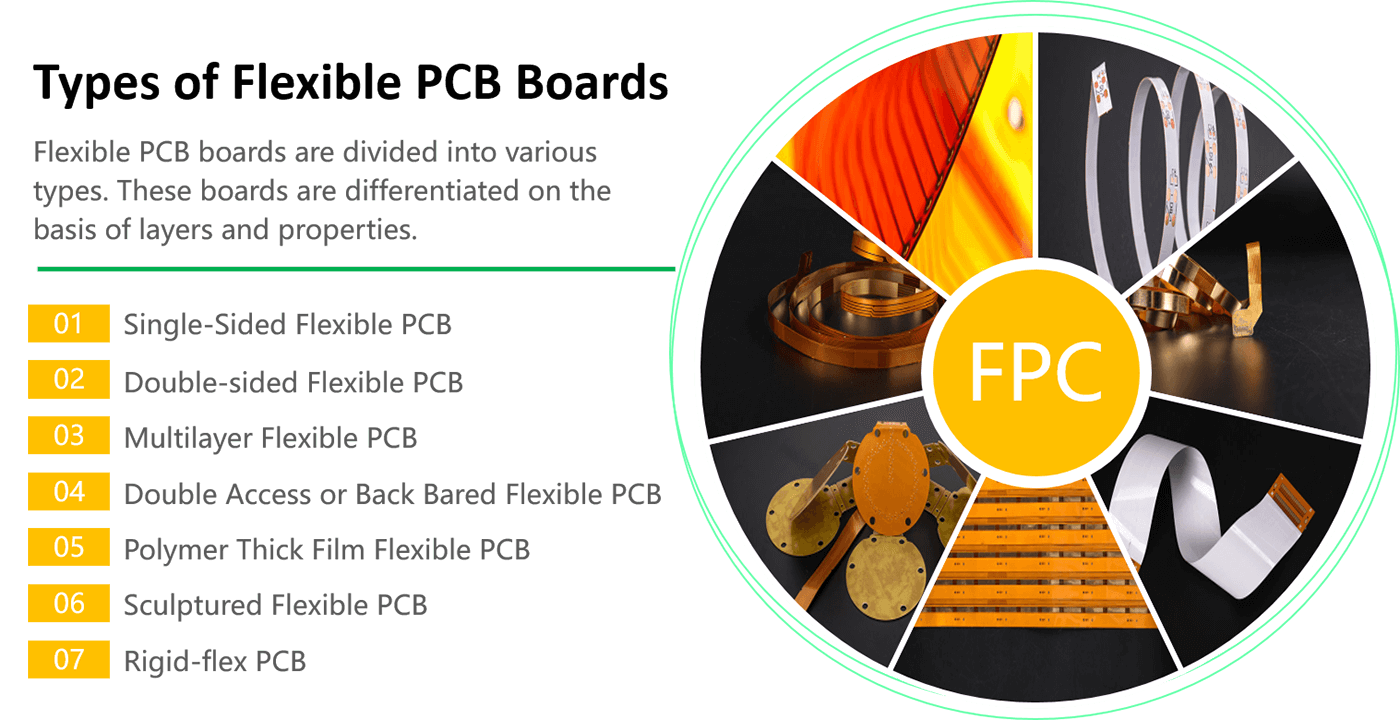

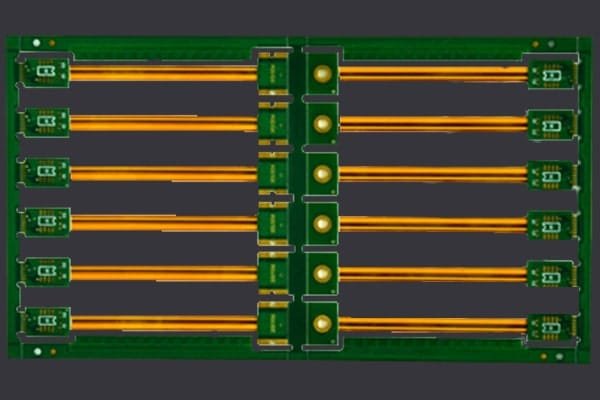

What Kinds of Rigid-Flex PCBs Can We Fabrication?

Rigid-Flex PCB Types We Offer

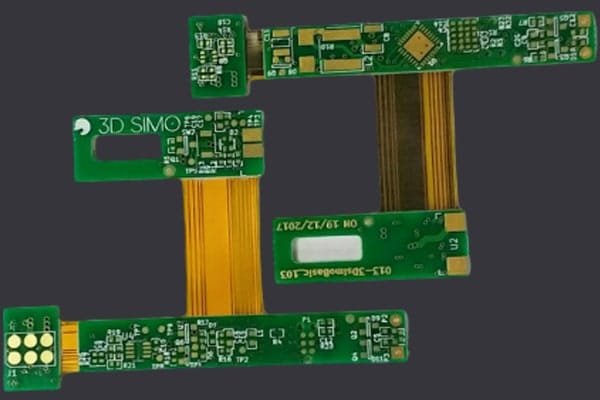

As a dedicated rigid-flex PCB manufacturer, JHYPCB supports a wide range of rigid-flex PCB types to match different design complexity, density and budget levels. From simple single-layer constructions to HDI rigid-flex PCBs, our engineering team can help you choose the right structure for your project.

Single-Layer Rigid-Flex PCB

Single-layer rigid-flex PCB uses one copper layer in the flex section, ideal for simple interconnections and cost‑sensitive applications that still require bending and space saving.

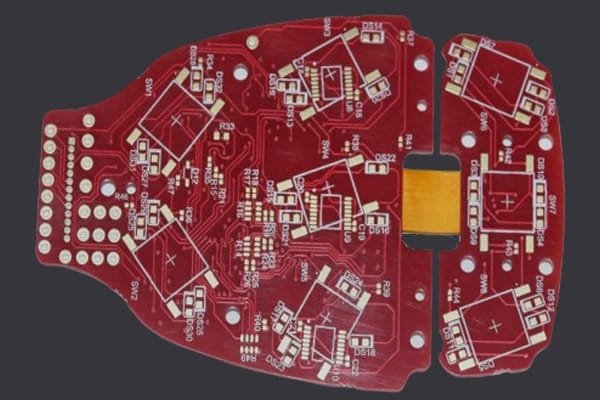

Double-Sided Rigid-Flex PCB

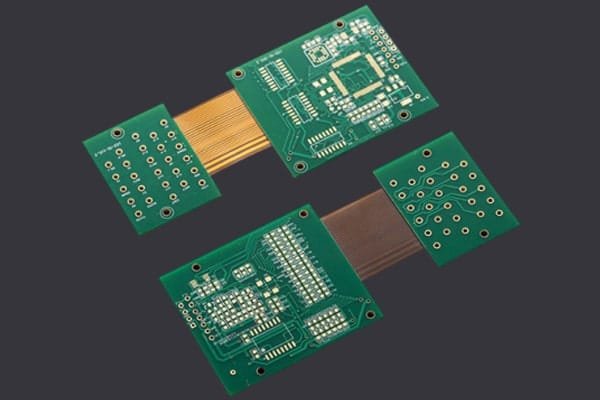

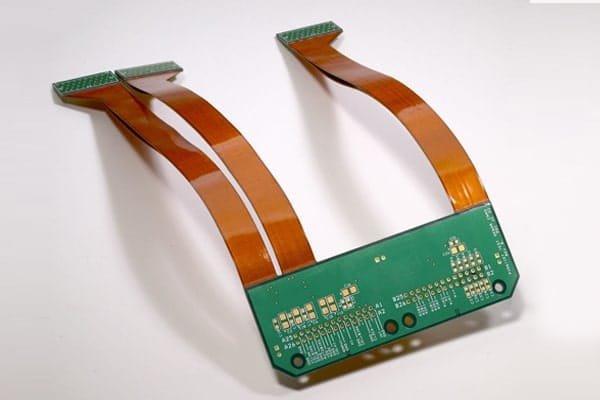

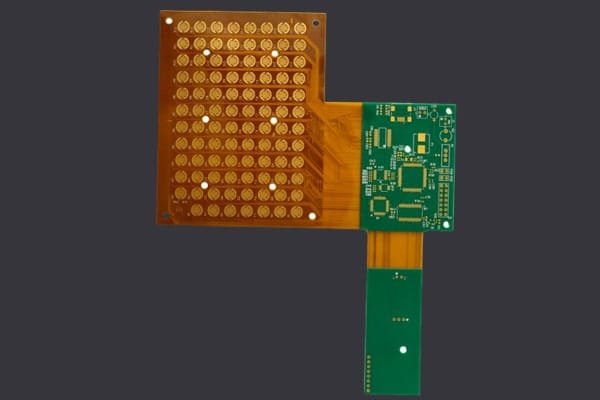

Double-sided rigid-flex PCB has two copper layers connected by plated through holes, providing higher routing density and more design freedom in compact devices.

Multilayer Rigid-Flex PCB

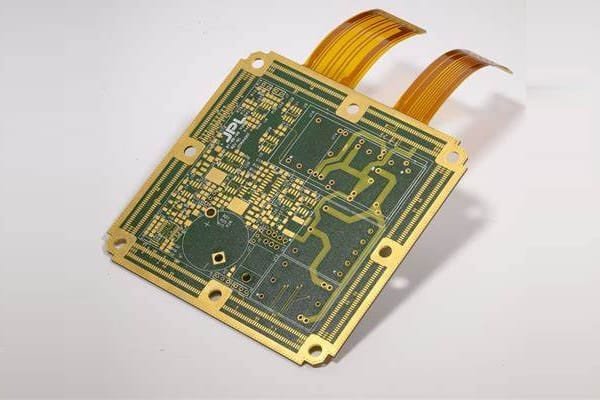

Multilayer rigid-flex PCB integrates multiple rigid and flex layers with plated-through holes, blind vias or buried vias to support complex, high‑density interconnections.

4 Layer Rigid-Flex PCB

A typical 4 layer rigid-flex PCB stackup combines a 4‑layer rigid PCB with a 2‑layer flex circuit, which is one of the most common choices for consumer and industrial products.

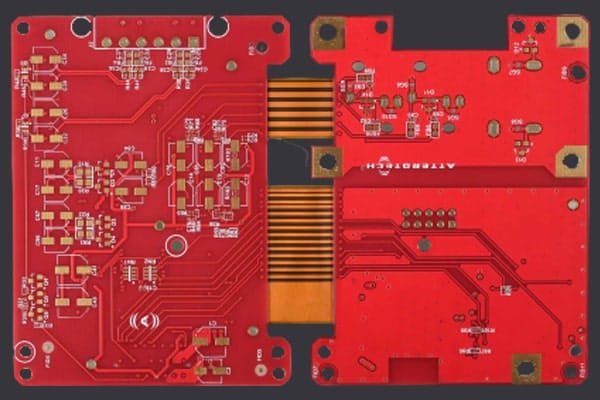

HDI Rigid-Flex PCB

HDI rigid-flex PCB uses microvias, fine lines and high‑density interconnects to achieve compact layouts, shorter signal paths and better high‑speed performance.

Quick-Turn Rigid-Flex PCB

JHYPCB offers quick‑turn rigid-flex PCB prototyping services to help you verify new designs in days, reducing development cycles and time‑to‑market.

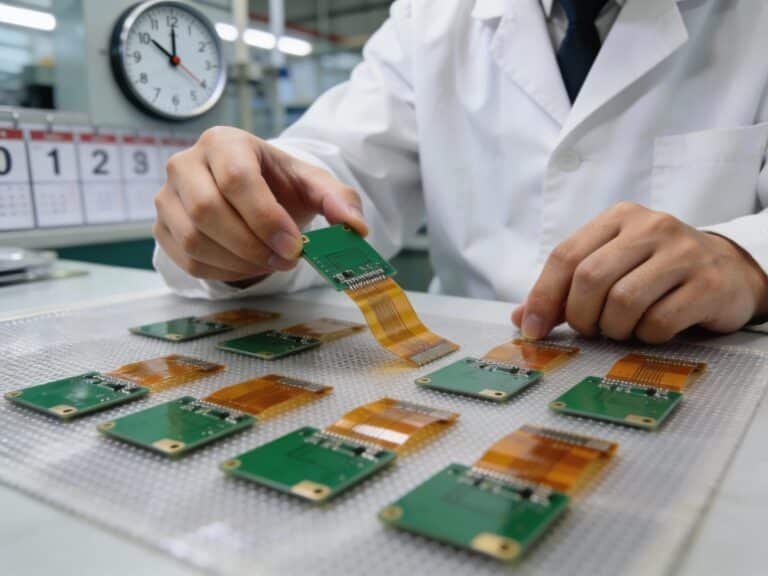

Rigid-Flex PCB Assembly Service

With in‑house SMT, through‑hole assembly and testing, JHYPCB provides one‑stop rigid-flex PCB assembly from bare board fabrication to fully assembled and tested boards.

Rgid-Flex PCB Assembly Service

JHY has extensive experience assembling flexible and rigid-flex PCBs. We offer a one-stop solution — including fabrication, components sourcing, assembly, and testing — we can work out any issues and possible problems before assembly. This not only minimizes any possible project delays, but it also saves our customers time and money.

If you are not sure which rigid-flex PCB type or stackup is best for your design, our engineers can review your requirements and recommend an optimized solution. Send us your Gerber files and specifications to get a tailored rigid-flex PCB quotation and free DFM feedback.

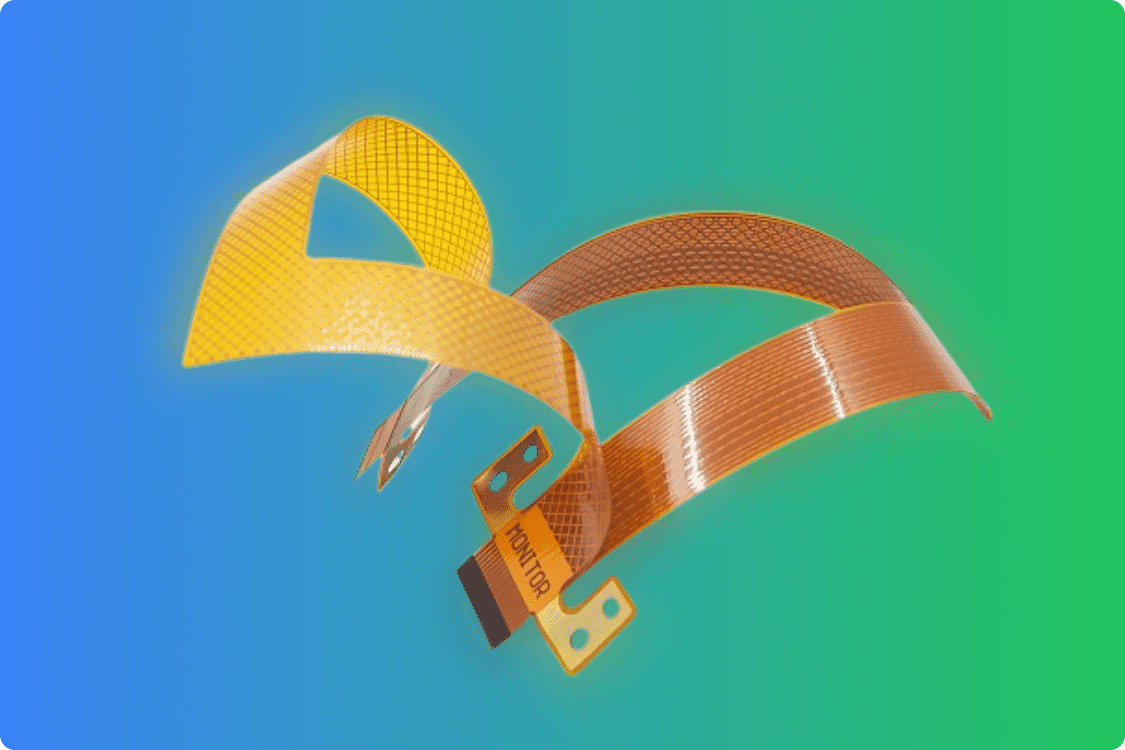

Rigid-Flex PCB Applications

Rigid-flex PCB is widely used in applications that require compact size, high reliability and the ability to withstand repeated bending or harsh environments. From communication equipment to medical devices and automotive electronics, rigid-flex PCB helps engineers integrate more functions into smaller and lighter products.

Medical Devices

Many medical devices, such as ultrasound systems, patient monitors, diagnostic equipment, pacemakers and cochlear implants, rely on rigid-flex PCB to achieve compact size and high reliability.

Consumer Electronics

Consumer products such as cameras, wearable devices, smart home products and foldable displays often use rigid-flex PCB to integrate multiple functions into slim and stylish designs.

Industry-Focused

Rigid-Flex PCB Solutions

JHYPCB works closely with customers in different industries to provide rigid-flex PCB solutions that meet specific standards, environmental conditions and lifecycle requirements. Our engineering team understands the design and manufacturing challenges behind each application and can help you optimize cost, reliability and performance.

If you are working on a new project and need a reliable rigid-flex PCB supplier for your industry, JHYPCB can provide tailored design-for-manufacturing advice and fast prototypes. Share your application requirements with our team to get a customized rigid-flex PCB solution and quotation.

Rigid-Flex PCB Design Guide

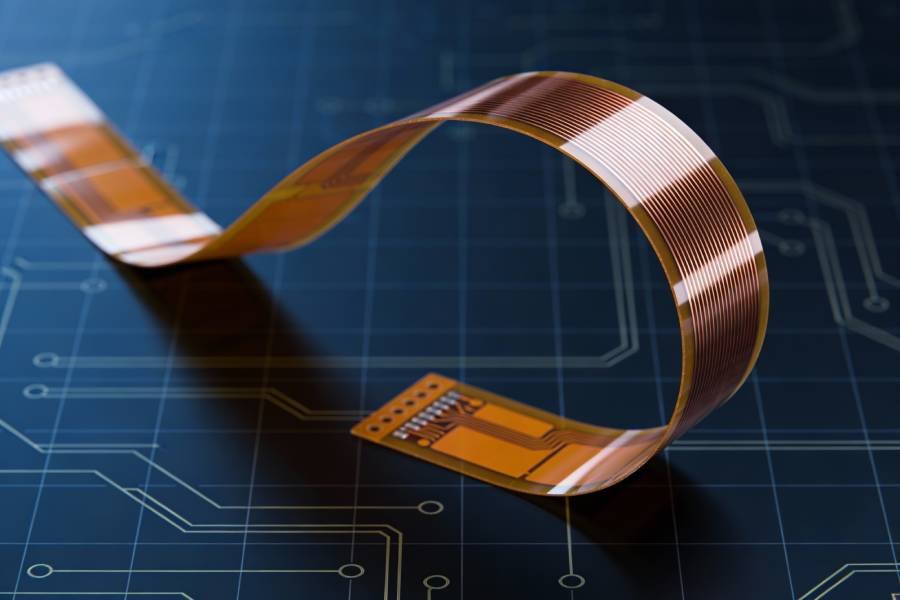

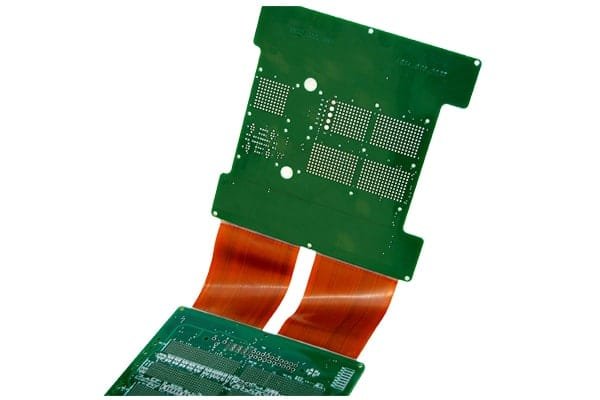

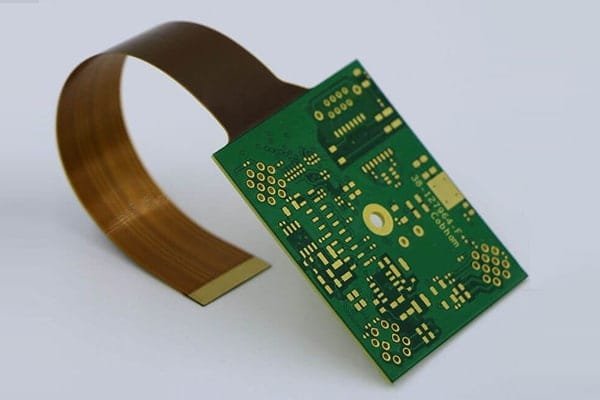

Designing a rigid-flex PCB is a true 3D design process that requires careful planning of how the rigid and flex sections will bend and fit inside the final product. Proper stackup, material selection and layout of the rigid‑to‑flex transition areas are essential to ensure long‑term reliability.

- Define rigid-to-flex transition areas clearly

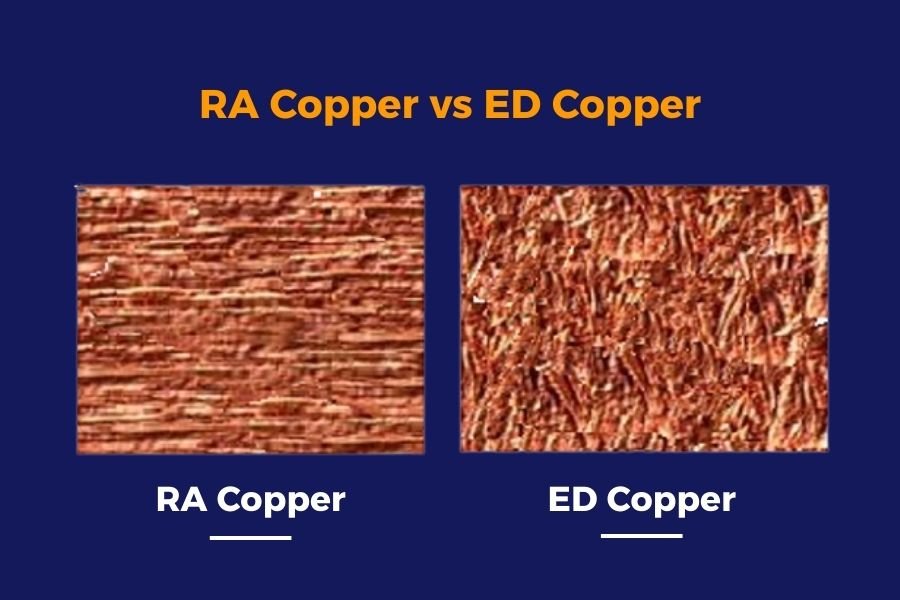

Mark rigid and flex regions, bend lines and keepout zones in your design so that the flex section can bend without stressing copper or vias. - Choose suitable materials and copper types

Select polyimide, FR4 and rolled annealed copper or electro‑deposited copper based on the required flexibility, thickness and operating environment. - Plan a robust stackup

Define rigid and flex stackups, coverlay, adhesive layers and stiffeners early to control thickness, impedance and bending performance. - Avoid stress in bend areas

Keep vias, pads, sharp corners and heavy copper away from bend lines and use staggered traces with smooth curves in flex regions to prevent cracking. - Include dedicated Gerber layers for flex features

Add extra Gerber layers to define coverlay openings, bond ply areas and stiffener outlines so that fabrication matches your design intent. - Consider assembly and test from the beginning

Reserve enough space for components, test pads and connectors on rigid areas, and design panelization features compatible with pick‑and‑place and testing.

Want to learn more about how to design rigid-flex PCB in Altium Designer and how to build a proper stackup? Download our rigid-flex PCB design guidebook and check the detailed rigid-flex PCB stackup examples and layout tips.

Free DFM Check for Your Rigid-Flex PCB

Before starting fabrication, JHYPCB offers a free DFM check for your rigid-flex PCB design to identify potential manufacturing risks and cost drivers. Our engineers review your Gerber files, stackup and specifications to make sure your design can be produced reliably and efficiently.

- Verify rigid and flex regions, stackup and layer count.

- Check minimum trace/space, drill sizes and annular rings against our rigid-flex PCB capabilities.

- Confirm coverlay openings, bond ply layers and stiffener drawings.

- Review rigid‑to‑flex transition areas and bend radius for long‑term reliability.

- Suggest cost‑effective material and surface finish options based on your application.

Send us your Gerber files, stackup information and basic requirements, and our team will provide DFM feedback and a quotation for your rigid-flex PCB within 24 hours.

Rigid-Flex PCB Manufacturing Process

JHYPCB follows a well‑controlled rigid-flex PCB manufacturing process to ensure consistent quality from prototype to production. Each step is monitored by experienced engineers and supported by advanced equipment to meet your rigid-flex PCB reliability requirements.

Material Selection & Preparation

We select the right materials for rigid and flex sections, typically polyimide for flex and FR4 for rigid, based on your specifications and application needs. The base materials are cleaned and cut to the required panel size to lay a solid foundation for the entire process.

Drilling & Via Formation

Precise mechanical or laser drilling is used to create through holes, blind vias or buried vias according to your Gerber files. After drilling, the panels are carefully cleaned and prepared for copper plating to ensure good hole wall quality, especially in delicate polyimide layers.

Copper Plating & Imaging

A controlled copper plating process builds the required copper thickness in the holes and on the surface to form reliable conductive paths. Then, photo‑resist and UV exposure are used to transfer the circuit pattern onto the rigid and flex sections.

Etching of Circuit Patterns

The panels go through an etching process to remove unwanted copper, leaving precise circuit traces and pads on both rigid and flex areas. For polyimide flex layers, etching chemistry is carefully selected and controlled to avoid material swelling and maintain dimensional stability.

Solder Mask, Coverlay & Surface Finish

Solder mask is applied to rigid areas to protect copper and prevent solder bridges, while coverlay is used on flex sections to provide mechanical protection and flexibility. Then, an appropriate surface finish such as OSP, HASL, ENIG, Immersion Tin or Immersion Silver is applied to ensure good solderability and long‑term reliability.

Legend Printing, Stiffeners & Assembly Preparation

Default description

Electrical Testing & Final Inspection

Each rigid-flex PCB is tested using flying probe, in‑circuit test or other methods to verify there are no shorts or opens. Automated optical inspection (AOI) and visual checks are performed to ensure that traces, pads and surface finishes meet design and quality standards.

Cleaning, Packaging & Shipment

After passing all tests, the boards are cleaned, dried and packaged with anti‑static and moisture‑barrier protection to prevent damage during transportation. JHYPCB ships your rigid-flex PCB prototypes or production orders on time, ready for assembly or direct integration into your products.

QA

Quality Assurance for

Rigid-Flex PCB

Quality is built into every stage of JHYPCB’s rigid-flex PCB manufacturing process, from incoming material inspection to final testing and packaging. Our strict quality management system and dedicated QA team help ensure consistent performance across different batches and order sizes.

ISO, UL and RoHS Compliance

JHYPCB operates under ISO-certified quality management and complies with UL and RoHS requirements to support global customers in different industries.

Comprehensive Electrical and Functional Testing

Depending on your needs, we can provide flying probe test, in‑circuit test, AOI, X‑ray inspection and burn‑in testing for rigid-flex PCB assemblies.

Strict Process Control and Traceability

Key processes such as drilling, plating, etching and lamination are closely monitored and recorded to maintain stable quality and full traceability for your projects.

Prototype to Mass Production Consistency

The same engineering and process standards are used for prototypes and volume orders, helping you scale from evaluation to mass production with minimal risk.

If your project requires specific industry standards or additional reliability testing for rigid-flex PCB, JHYPCB can customize the process and test plan to meet your requirements. Contact our team to discuss your quality and certification needs for current or upcoming rigid-flex PCB projects.

Rigid-Flex PCB FAQs

Most frequent questions and answers about rigid-flex PCB

A rigid-flex PCB combines rigid PCB sections with flexible circuits into a single board, allowing it to bend and fold while keeping components mounted on rigid areas. It is the best choice when your product requires compact size, weight reduction, high reliability and the ability to withstand repeated bending or vibration.

To provide an accurate quotation, JHYPCB needs basic information such as board size, layer count, materials, copper thickness, minimum trace/space, surface finish, quantity and any special requirements like impedance control or HDI structure. Sending Gerber files, stackup details and assembly needs will help our team respond faster with pricing and lead time.

Rigid-flex PCB prototype lead time usually ranges from a few days to around two weeks depending on layer count, complexity and material availability. Mass production orders may require additional time for tooling, material preparation and full process verification.

JHYPCB supports both prototypes and small‑volume production, so there is effectively no strict minimum order quantity for rigid-flex PCB. You can start with a single prototype to verify your design before committing to larger production runs.

Yes, JHYPCB offers one‑stop rigid-flex PCB solutions including bare board fabrication, components sourcing, SMT and through‑hole assembly as well as testing and inspection. This integrated service helps you shorten your supply chain and reduce the risk of communication gaps between different vendors.

Our engineering team provides free DFM checks for rigid-flex PCB designs, reviewing stackup, layer definitions, rigid‑to‑flex transitions, bend radius and manufacturing rules. We will highlight potential risks, suggest design improvements and offer cost‑effective material and process options before fabrication.

JHYPCB can manufacture controlled-impedance rigid-flex PCB and HDI rigid-flex PCB with microvias, fine lines and high‑density interconnect structures. Our engineers can help define stackup and trace geometry to meet your impedance targets for high‑speed or RF designs.

Talk to Our

Rigid-Flex PCB Experts

Choosing the right rigid-flex PCB structure and manufacturing partner is critical to the success of your project. With more than 10 years of experience in high-density rigid-flex PCB fabrication and assembly, JHYPCB can help you turn complex concepts into reliable products faster and at a competitive cost.

Send your files and requirements to sales@pcbjhy.com and our team will reply with DFM feedback and quotation within 24 hours.