Turnkey PCB Assembly Services (Full & Partial)

JHYPCB provides one-stop turnkey PCB assembly services, covering PCB fabrication, component sourcing, SMT/THT assembly and testing under one roof.

Whether you choose full turnkey or partial turnkey, our team helps startups, design houses and OEMs move from Gerber files to reliable assembled boards faster and with less hassle.

- Full & partial turnkey options for prototypes and low-volume production.

- In-house PCB fabrication, stable component sourcing and strict quality control in China.

JHYPCB offers turnkey PCB assembly services that combine PCB fabrication, component sourcing, SMT/THT assembly and testing into a single, streamlined process. With both full turnkey and partial turnkey options, we help you reduce vendor management effort, control total project cost and shorten the time from design files to finished, tested boards. Scroll down to see our turnkey PCB assembly capabilities and how full and partial turnkey services work for prototypes and low-volume production.

JHYPCB Turnkey PCB Assembly Services

JHYPCB provides complete turnkey PCB assembly services that cover every stage from bare PCB fabrication to fully assembled and tested boards. With flexible full turnkey and partial turnkey options, you can decide how much of the material sourcing and logistics we handle, while relying on our in-house production and quality control in China. This one-stop approach helps you simplify supplier management, reduce hidden costs and keep your projects on schedule.

- PCB Fabrication

- Component Sourcing

- SMT & Through-Hole Assembly

- Inspection & Electrical Testing

- Logistics

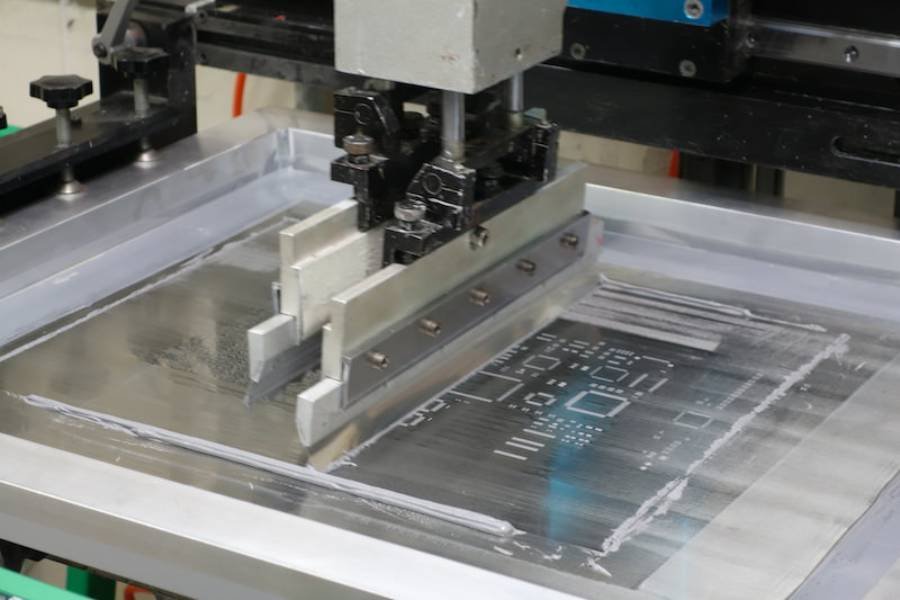

In-house and partner PCB manufacturing for prototypes and low-volume production, supporting a wide range of materials, stackups and finishes suitable for turnkey builds.

Professional sourcing team to purchase components from trusted distributors and local suppliers, manage alternatives for hard-to-find parts and optimize your BOM for cost and lead time.

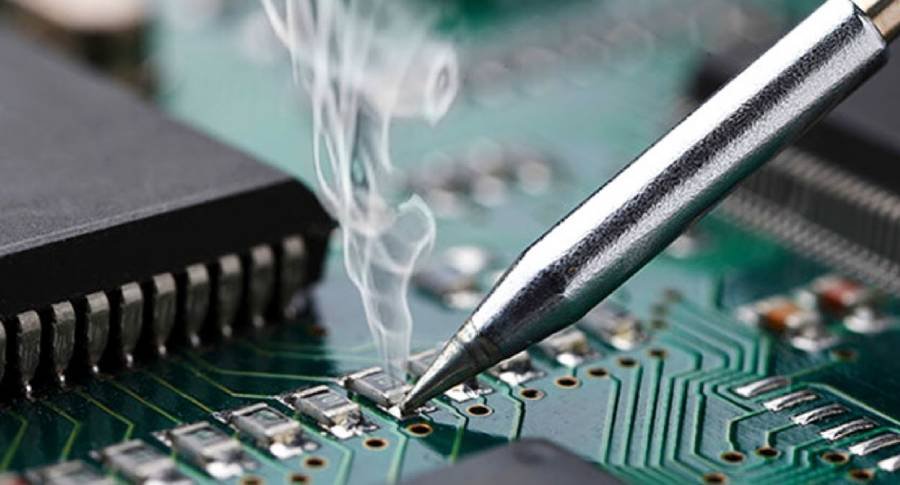

Automated SMT lines and skilled through-hole assembly for simple to high-density boards, including mixed-technology builds, fine-pitch devices and BGA packages.

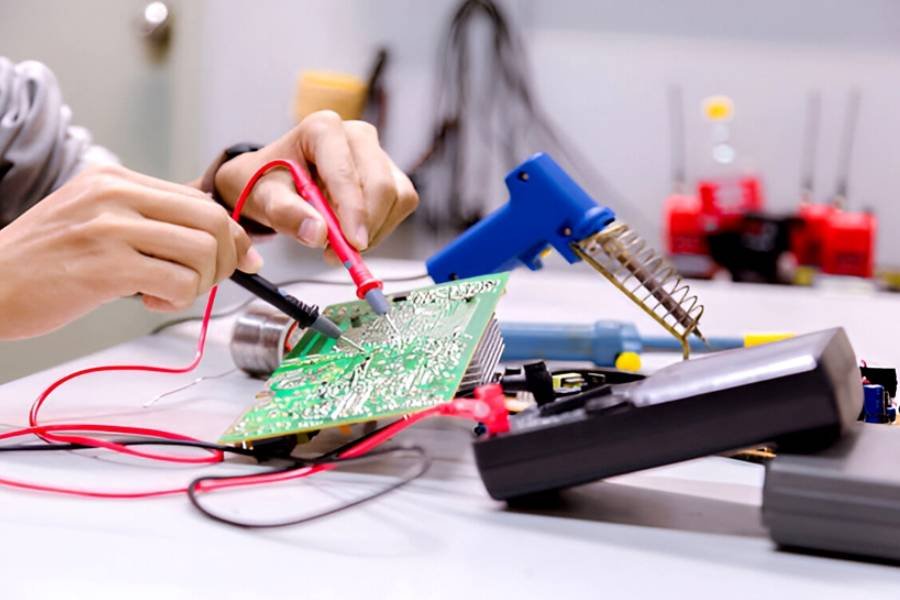

AOI, X-ray (where applicable), ICT and functional testing options to verify solder quality, placement accuracy and board performance before shipment.

Coordinated packing, shipping and after-sales support so you receive ready-to-use assembled boards, with engineering assistance available for any technical questions during your project.

Turnkey PCB Assembly Capabilities

Our turnkey PCB assembly capabilities are designed to support fast prototypes, engineering builds and low-volume production with both full turnkey and partial turnkey service modes. From SMT and through-hole assembly to inspection and testing, JHYPCB combines in-house manufacturing with reliable local partners to deliver consistent quality and predictable lead times. The summary below shows the key aspects of our turnkey PCB assembly capability.

| Capability item | JHYPCB turnkey capability |

|---|---|

| Assembly types | SMT, THT and mixed-technology PCB assembly, including single- and double-sided placement for prototypes and low-volume runs. |

| Turnkey service modes | Full turnkey PCB assembly (we source all materials) and partial turnkey PCB assembly (you provide part of the BOM and we handle the rest), plus consigned assembly on request. |

| Board types | FR-4 rigid, flex and rigid-flex PCBs, single-layer to multilayer designs suitable for quick-turn and small-batch turnkey assembly. |

| Component range | Support for fine-pitch ICs, BGAs/uBGAs, CSPs and small passive components, alongside larger connectors, power devices and mechanical parts. |

| Soldering processes | Leaded and lead-free soldering, including reflow, wave soldering and selective soldering, with manual touch-up for special components. |

| Inspection & testing | AOI, X-ray inspection where required, ICT and functional testing options to verify solder joints, placement accuracy and electrical performance. |

| Typical project scope | Turnkey prototype PCB assembly from a few pieces, through engineering lots, up to selected higher-volume production, depending on design complexity and requirements. |

What Is Turnkey PCB Assembly?

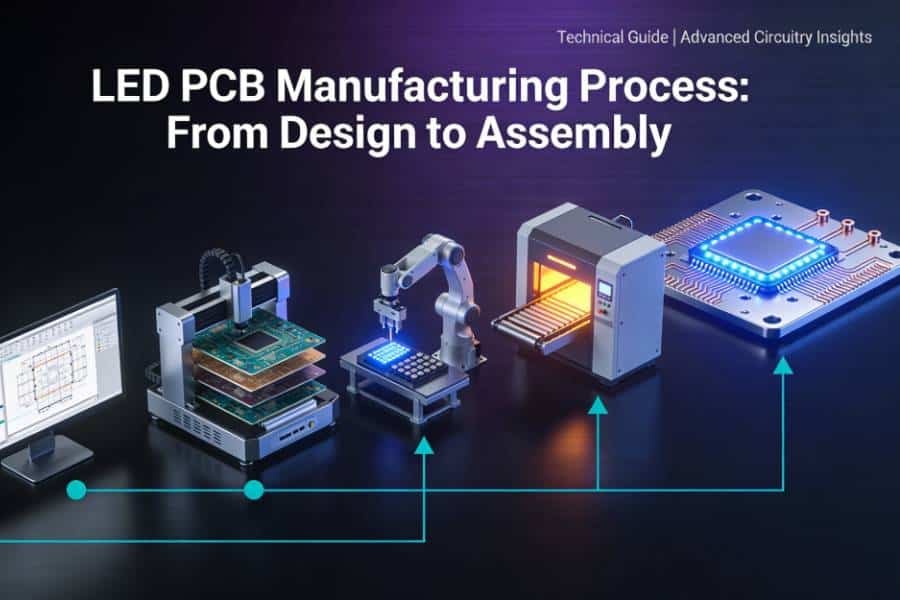

PCB assembly is the process of placing and soldering electronic components onto bare printed circuit boards to create functional electronic assemblies. It typically involves SMT and/or through-hole assembly, soldering, inspection and testing to ensure that each board meets electrical and reliability requirements.

Turnkey PCB Assembly

Turnkey PCB assembly is a service model where a single supplier takes responsibility for almost every step of your PCB project, from PCB fabrication and component procurement to assembly, inspection, testing and final shipment. Instead of coordinating multiple vendors for boards, parts and assembly, you work with one turnkey PCB assembly partner who manages the entire process on your behalf, helping you save time, reduce risk and focus on design and product development.

At JHYPCB, turnkey PCB assembly is available in both full turnkey and partial turnkey modes. In a full turnkey PCB assembly service, we handle all PCB manufacturing and component sourcing for you, while in a partial turnkey PCB assembly service you can supply part of the BOM and let us take care of the remaining materials and complete assembly. The following sections explain how each mode works and how to choose the best option for your project.

Full Turnkey PCB Assembly Services

Full turnkey PCB assembly is a service model where JHYPCB takes responsibility for almost every step of your PCB project, from PCB fabrication and component sourcing to assembly, inspection, testing and final shipment. This option is ideal if you do not want to manage multiple suppliers or component purchasing yourself and prefer a single turnkey PCB assembly partner to deliver ready-to-use boards.

In a full turnkey PCB assembly service, JHYPCB typically handles:

- PCB fabrication according to your stackup, materials and surface finish requirements.

- Component sourcing from authorized distributors and trusted local suppliers, including management of alternatives for hard-to-find or obsolete parts.

- SMT and through-hole assembly using automated production lines and experienced operators.

- Inspection and electrical testing such as AOI, X-ray where required, ICT and functional tests to verify quality before shipment.

- Packing and logistics so that you receive assembled boards ready for integration or end-use.

To start a full turnkey PCB assembly project with JHYPCB, you only need to provide the key design and production documents:

- Gerber files and stackup information for PCB fabrication.

- A complete bill of materials (BOM) with part numbers, package types and approved substitutes where applicable.

- Pick-and-place (centroid) or XY data for SMT assembly.

- Assembly drawings, test requirements and any special process notes, such as critical components, keep-out areas or coating needs.

Full turnkey PCB assembly is the best choice when you have limited in-house sourcing resources, need to move quickly from design to prototypes, or want to consolidate responsibility for quality and lead time with one supplier. In the next sections, you can see how our partial turnkey PCB assembly service works and how to decide between full and partial turnkey for your specific project.

PCB Manufacturing

PCB Assembly

Components Sourcing

PCB Assembly Testing

Partial Turnkey PCB Assembly Services

Partial turnkey PCB assembly is a service mode where the customer supplies part of the components or materials, and JHYPCB provides the remaining components, PCB fabrication and complete assembly. It sits between full turnkey PCB assembly, where we handle everything, and fully consigned assembly, where you provide almost all parts.

In a partial turnkey PCB assembly service, responsibilities are shared between you and JHYPCB:

- You select and supply some of the components, typically key or proprietary parts, from your preferred vendors or existing inventory.

- JHYPCB fabricates the PCBs according to your design files and stackup requirements.

- Our sourcing team purchases the remaining components on the BOM, coordinating with you on any suggested alternatives.

- We perform SMT and through-hole assembly, inspection and testing, and deliver fully assembled boards using both your components and ours.

Partial turnkey PCB assembly is a good fit when you already have some components in stock, want to use specific brands or distributors, or need tight control over certain critical or long-lead parts. It allows you to leverage your own supply chain advantages while still relying on JHYPCB for PCB manufacturing, remaining component sourcing, assembly and quality control.

To keep lead times predictable on partial turnkey projects, it is important that customer-supplied components are clearly labeled, packaged and shipped to us in time for production. Our team will confirm quantities, perform incoming inspection and coordinate any discrepancies before assembly, helping you avoid delays and ensure that your partial turnkey PCB assembly orders run as smoothly as full turnkey builds.

Full Turnkey vs Partial Turnkey PCB Assembly

Both full turnkey and partial turnkey PCB assembly services are designed to simplify your supply chain, but they distribute responsibility and material control in different ways. The table below summarizes the main differences so you can quickly decide which turnkey PCB assembly mode fits your next project.

Key Differences Between Full and Partial Turnkey

| Item | Full Turnkey PCB Assembly | Partial Turnkey PCB Assembly |

|---|---|---|

| Material procurement | JHYPCB sources all components and arranges PCB fabrication based on your BOM and design files. | You supply some components, while JHYPCB purchases the remaining parts and fabricates the PCBs. |

| Vendor management | Single point of contact – JHYPCB manages all board, component and assembly vendors on your behalf. | Shared responsibility – you manage your own component vendors for supplied parts, JHYPCB manages the rest. |

| Control over key parts | JHYPCB follows your BOM and approved manufacturer list, but we handle the actual purchasing and logistics. | You retain direct control over selected or proprietary components, including sourcing channels and inventory. |

| Impact on lead time | Lead time is mainly driven by PCB fabrication and component availability managed by JHYPCB. | Lead time also depends on how quickly customer-supplied components are prepared, shipped and received. |

| Cost structure | Higher service coverage with fewer internal purchasing and logistics costs for you; easier to see total project cost in one quote. | Potential savings if you already have inventory or better pricing on some parts, but you bear more internal purchasing and inventory costs. |

| Typical use cases | Startups, design houses and OEMs that prefer a one-stop solution for prototypes and low-volume production. | Customers with existing component stock, strict sourcing policies or proprietary parts they must purchase themselves. |

How to Choose Between Full and Partial Turnkey

- Choose full turnkey PCB assembly if you want a single supplier to handle PCB fabrication, all component purchasing and assembly, especially for new designs, prototypes and small production runs with tight schedules.

- Choose partial turnkey PCB assembly if you already own some components, need to use specific vendors or brands, or want more control over critical or long-lead parts while still relying on JHYPCB for the rest of the turnkey PCB assembly process.

Benefits of Turnkey PCB Assembly

Turnkey PCB assembly offers more than just convenience; it changes how you plan, source and build hardware by consolidating multiple steps under one accountable partner. When you combine full turnkey and partial turnkey options, you gain flexibility in how much of the supply chain you outsource while still benefiting from an integrated process.

- Shorter time-to-market

By having PCB fabrication, component sourcing, assembly and testing managed in a single workflow, you remove delays between separate vendors and avoid repeated handoffs, helping you bring products to market faster. - Simplified vendor and project management

Instead of coordinating multiple suppliers, logistics providers and test houses, you work with one turnkey PCB assembly partner, which reduces communication overhead, documentation work and the risk of misalignment between different companies. - Better visibility and control over total cost

Turnkey PCB assembly combines materials, labor, testing and logistics into a single quote, making it easier to understand and optimize your overall project cost, including hidden management and logistics expenses that are often overlooked with multi-vendor setups. - Early issue detection and lower technical risk

With one team overseeing fabrication, sourcing and assembly, design or BOM issues can be spotted earlier, and feedback loops are shorter, which reduces the risk of costly rework, schedule slips and field failures. - Scalability from prototype to production

Once your prototype is validated, the same turnkey process and documentation can be used to support repeat builds and scaling to higher volumes without re-qualifying new vendors or changing processes.

Why Choose JHYPCB for Turnkey PCB Assembly?

JHYPCB combines PCB fabrication, component sourcing and PCB assembly services under one roof, giving you a single accountable partner for full turnkey and partial turnkey PCB assembly projects. This one-stop model reduces vendor coordination, shortens lead times and makes it easier to control total project cost and quality.

One-stop full & partial turnkey services

Work with a single supplier for PCB manufacturing, component purchasing, assembly, inspection and shipping, whether you choose full turnkey or partial turnkey PCB assembly.Experience with prototypes and low-volume builds

Our processes and equipment are optimized for quick-turn prototypes, engineering builds and low-volume production, helping you move from design files to tested boards in a short time frame.Stable supply chain and smart component sourcing

Dedicated sourcing teams, established relationships with major distributors and local suppliers, and the ability to propose alternatives for hard-to-find or obsolete parts help control BOM cost and avoid delays.Consistent quality control throughout the process

Integrated fabrication and assembly, AOI and X-ray inspection where required, plus ICT and functional testing options ensure that quality is monitored from bare boards to finished assemblies.Responsive engineering and support

Engineering support is available for DFM/assembly reviews, BOM risk checks and production queries, so that issues can be identified early and your turnkey PCB assembly project runs smoothly.

Turnkey PCB Assembly Cost & Pricing Factors

Turnkey PCB assembly pricing includes all major elements of your project – PCB fabrication, components, assembly, testing and logistics – combined into one quotation. Instead of looking only at the per-board assembly fee, it is important to consider how board complexity, BOM structure, order volume and test requirements affect the total turnkey cost.

Cost structure of turnkey PCB assembly

A typical turnkey PCB assembly quotation from JHYPCB will consolidate:

- PCB fabrication costs (board size, layer count, material, finish, special processes such as impedance control or blind/buried vias).

- Component procurement costs (BOM structure, component types, sourcing channels, minimum order quantities and lifecycle/availability).

- Assembly process costs (SMT/THT operations, single- or double-sided assembly, fine-pitch and BGA handling, stencil and setup).

- Inspection and testing costs (AOI, X-ray where required, ICT and functional testing, if requested).

- Logistics and handling costs (packing, shipping method, customs-related handling if applicable).

Key factors that influence turnkey PCB assembly pricing

The final unit price of a turnkey PCB assembly project mainly depends on:

- PCB design complexity – board size, number of layers, routing density, substrate material and surface finish have a direct impact on fabrication cost and lead time.

- BOM structure and components – overall component count, use of high-value or specialized ICs, packaging types like BGA/QFN and availability of suitable alternates strongly affect the component budget.

- Assembly and testing requirements – double-sided SMT, mixed technology (SMT + THT), fine-pitch parts and deeper test coverage increase assembly and testing effort.

- Order volume and required lead time – prototypes and very small batches carry higher per-unit costs due to setup and NRE, while larger, less time-critical orders benefit from economies of scale.

Why turnkey PCB assembly in China can be cost-effective

Working with a China-based turnkey PCB assembly partner often reduces total project cost due to mature local supply chains, competitive PCB fabrication pricing and lower labor and overhead rates. Easy access to a wide range of components, combined with efficient logistics and large-scale production infrastructure, helps keep turnkey PCB assembly prices attractive while maintaining quality and reasonable lead times.

How to Order Turnkey PCB Assembly from JHYPCB

Ordering turnkey PCB assembly from JHYPCB is straightforward – you prepare a few standard design and production files, we review them, confirm pricing and lead time, and then start fabrication, sourcing and assembly. The steps below apply to both full turnkey and partial turnkey PCB assembly projects.

Step-by-step ordering process

- Prepare your design and production files

Get your Gerber files, BOM, pick-and-place (centroid) data and any assembly drawings or special instructions ready in standard formats so we can review your design and quote accurately. - Submit your turnkey PCB assembly request

Send your files through our online quote form or by email, along with quantity, desired lead time, preferred turnkey mode (full or partial) and any component sourcing notes or approved vendor lists. - Engineering and BOM review

Our engineering and sourcing teams check your files for manufacturability, component availability and any obvious risks, then communicate with you about clarifications, alternative parts and cost/lead-time options if needed. - Quotation and order confirmation

You receive a turnkey PCB assembly quotation that covers PCB fabrication, components, assembly, testing and logistics; once you confirm the quote and place the order, we schedule production. - Fabrication, assembly, testing and shipment

JHYPCB fabricates the PCBs, procures components (for full or partial turnkey), assembles and tests the boards, and then packs and ships the finished assemblies to your specified address.

File requirements for turnkey PCB assembly

To generate an accurate quote and start your turnkey PCB assembly order efficiently, please provide:

- Bill of materials (BOM)

In Excel or CSV format with reference designators, part descriptions, manufacturer part numbers, package, quantity and any approved alternative parts or preferred vendors for turnkey sourcing. - Gerber files for PCB fabrication

Standard RS-274X Gerber files, including at least copper, solder mask, silkscreen and, for SMT sides, solder paste layers, plus drill files and, if available, stackup or impedance notes. - Pick-and-place (centroid / XY) data

Component placement file for SMT assembly, indicating X/Y coordinates, rotation, side (top/bottom) and reference designator for each part. - Assembly drawings and special instructions

PDF or other clear drawings that show polarity, orientation for critical parts, mechanical details, test points, no-pop components and any coating or special process requirements.

Turnkey PCB Assembly FAQ

Turnkey PCB assembly consolidates PCB fabrication, component sourcing, assembly, testing and shipping under a single supplier, which reduces vendor management effort, shortens handoff times and helps prevent errors between different companies.

In full turnkey PCB assembly, JHYPCB fabricates the PCBs and purchases all components on your BOM, then assembles, tests and ships the finished boards. In partial turnkey PCB assembly, you supply some components while we handle PCB fabrication, the remaining components and full assembly and testing.

For both full and partial turnkey projects, please provide Gerber files, a complete BOM, pick-and-place (centroid/XY) data and any assembly drawings or special instructions so we can review manufacturability, check component availability and prepare an accurate quotation.

Yes. With partial turnkey PCB assembly, you can send us customer-supplied components while we source the rest of the BOM; we will confirm incoming quantities and quality before starting assembly.

Actual lead times depend on PCB complexity and component availability, but turnkey PCB assembly often allows prototypes and small batches to be completed in significantly shorter times than coordinating multiple vendors separately.

No. While turnkey PCB assembly is very popular for prototypes and low-volume runs, the same model can also be used for selected higher-volume builds when you want to keep procurement, fabrication and assembly with a single partner.

Ready to Start Your Turnkey PCB Assembly Project?

If you are working on a time‑critical prototype, engineering build or low‑volume production run, JHYPCB is ready to support you with reliable turnkey PCB assembly services. With both full turnkey and partial turnkey options, we can handle PCB fabrication, component sourcing, assembly and testing from our China-based facilities so you can focus on design and product launch.

Send us your Gerber files, BOM and assembly requirements today, and our engineering and sourcing teams will review your project, suggest suitable turnkey options and provide a clear quotation with feasible lead times.