High Volume PCB Assembly Services

With over 14 years of expertise, JHYPCB delivers cost-effective, scalable high volume PCB assembly services for automotive and medical industries. Our advanced automation and rigorous quality control ensure reliable PCBAs with fast global delivery.

What is High Volume PCB Assembly?

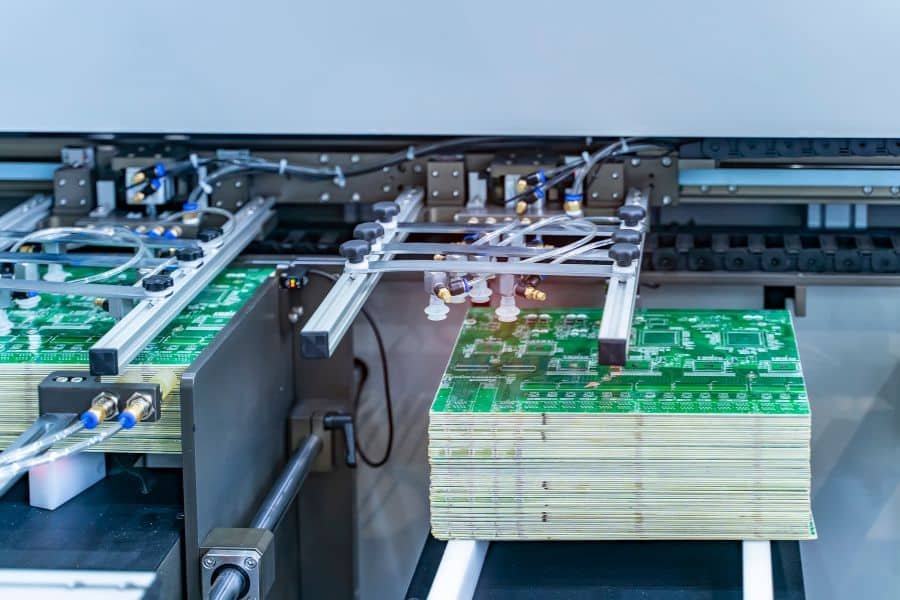

High volume PCB assembly refers to the large-scale production of PCBs designed to meet the demands of industries requiring thousands of units, such as automotive, medical devices, telecommunications, IoT, and consumer electronics. Unlike low volume or prototype PCB assembly, high volume production leverages advanced automation, streamlined processes, and rigorous quality control to ensure cost efficiency and consistency across large batches. At JHYPCB, we specialize in producing over 10,000 PCBAs per run, delivering reliable, high-quality boards tailored to your specifications.

Our high volume PCB assembly services are optimized for scalability and precision. Every board undergoes 100% testing, including automated optical inspection (AOI), X-ray, and functional tests, to meet stringent standards like ISO 9001 and IPC-A-610. Whether you need PCBs for automotive electronics or medical devices, our high volume PCBA services provide cost-effective solutions with fast global delivery, helping you meet market demands efficiently.

High Volume vs Low Volume PCB Assembly

| Metric | High Volume PCB Assembly | Low Volume PCB Assembly |

|---|---|---|

| Cost per Unit | Lower due to economies of scale | Higher due to smaller batches |

| Production Speed | Faster with automated lines | Slower, often manual processes |

| Scalability | Ideal for 10,000+ units | Suited for prototypes or <1,000 units |

| Quality Control | 100% testing (AOI, X-ray) | Selective testing |

Benefits of High Volume PCB Assembly with JHYPCB

Choosing JHYPCB for high volume PCB assembly ensures your project benefits from our advanced manufacturing capabilities. Here are six key advantages of partnering with us:

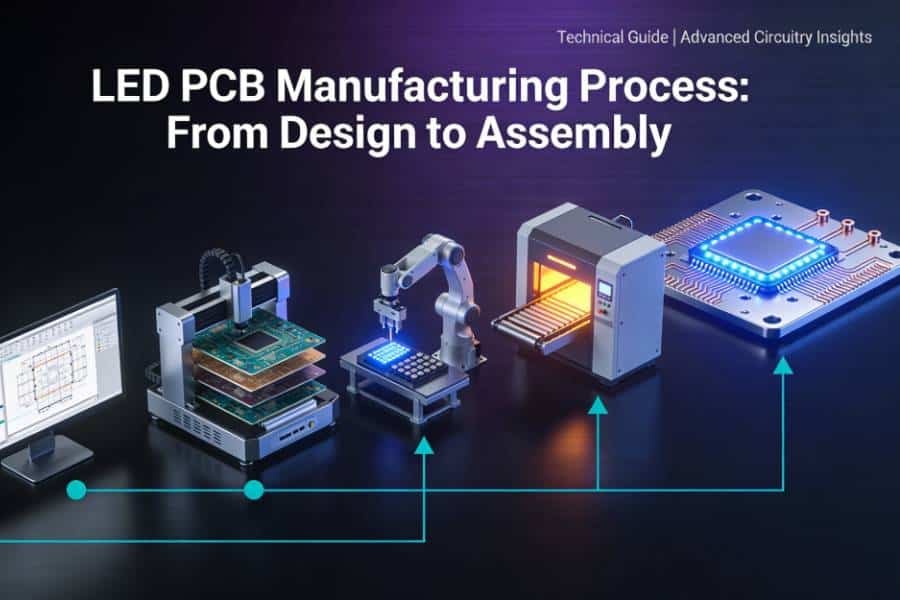

Our High Volume PCB Assembly Process

At JHYPCB, our high volume PCB assembly process is optimized for efficiency and quality, ensuring every board meets your specifications. Here’s how we do it:

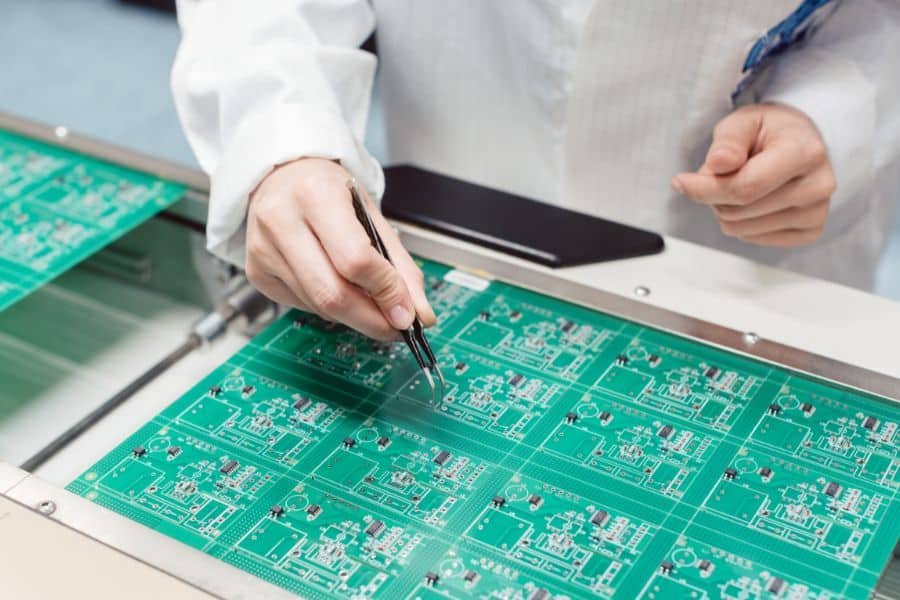

Incoming Material Inspection

We verify all components against the BOM and conduct electrical testing to ensure high quality for large-scale production.

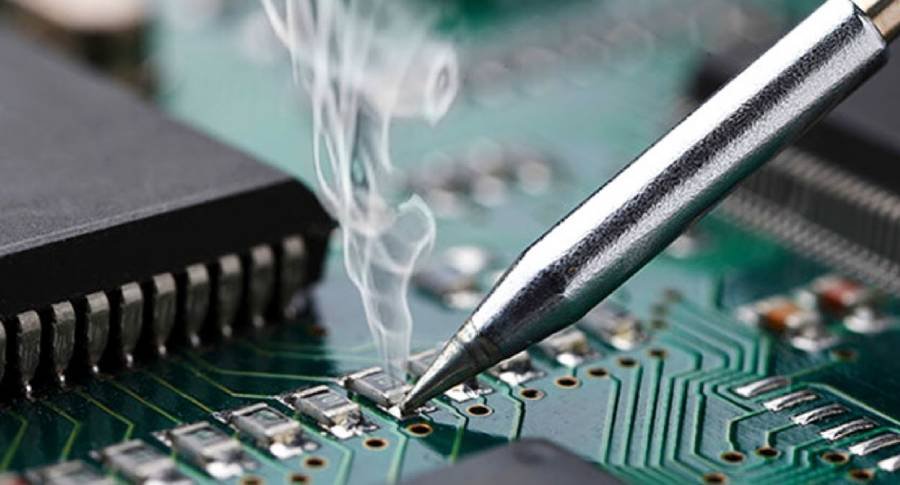

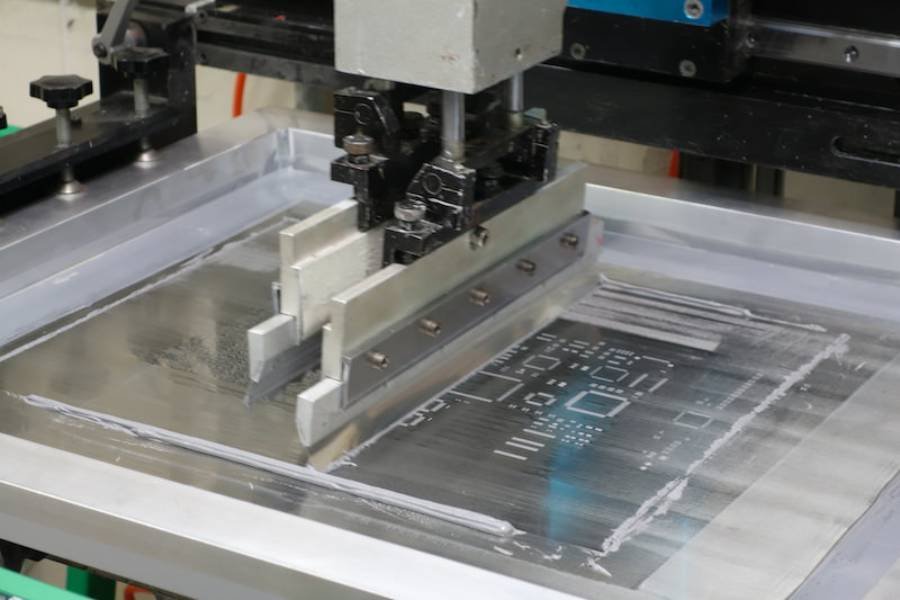

SMT & Reflow Soldering

Automated SMT places components precisely, followed by reflow soldering for speed and accuracy in large-scale production.

PTH & Wave Soldering

Through-hole components are inserted into PTH holes, with wave soldering ensuring robust connections.

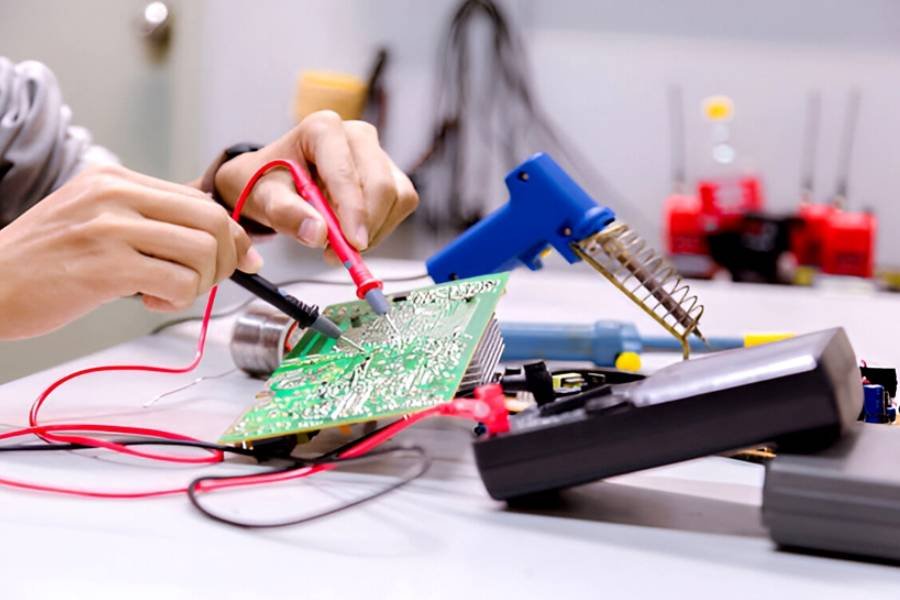

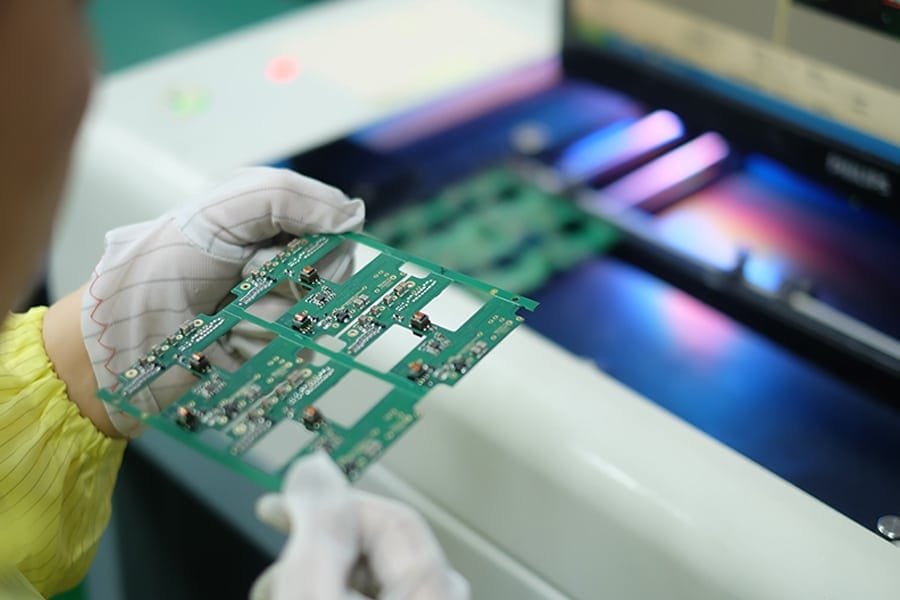

Quality Control

100% testing with AOI, X-ray, and functional tests, using laser-cut stainless steel stencils for 99.8% SMT accuracy.

Why Choose JHYPCB for High Volume PCB Assembly?

With 14 years in the EMS industry, JHYPCB is your ideal partner for high volume PCB assembly. Here are six reasons to choose us:

Customized Solutions

Tailored services for industries like automotive and medical.

Sustainable Practices

Lead-free soldering reduces 90% of harmful emissions.

How to Choose a High Volume PCB Assembly Partner

Selecting the right partner for high volume PCB assembly can significantly impact your project’s success. Here’s how JHYPCB stands out:

Industries We Serve

JHYPCB provides high volume PCB assembly services tailored to meet the needs of diverse industries, ensuring reliability, precision, and scalability:

Frequently Asked Questions

What is high volume PCB assembly?

How does JHYPCB ensure quality in high volume production?

What types of PCBs are supported in high volume assembly?

How fast are JHYPCB’s turnaround times for high volume orders?

How can I request a quote for high volume PCB assembly?

Get Started with JHYPCB

Ready to elevate your high volume PCB assembly project for automotive and medical industries? JHYPCB offers consigned and turnkey solutions with fast delivery. Request your quote now!