Table of Contents

Introduction

Imagine this: You’re in the middle of a PCB assembly run, and suddenly, you notice uneven solder paste causing shorts and voids, derailing your production timeline. It’s a nightmare scenario for any electronics manufacturer. The culprit? Often, it’s an ill-suited SMT stencil. At JHYPCB, a leading PCB manufacturer in China, we’ve seen firsthand how choosing the right SMT stencil can make or break your assembly process. Whether you’re prototyping a single-layer board or scaling up for high-volume production, SMT stencils ensure precise solder paste deposition, minimizing errors and boosting efficiency.

In this guide, we’ll dive deep into the world of SMT stencils, covering their types, practical applications, benefits, and expert tips for selecting the perfect one for your project. With our decades of experience in PCB manufacturing and assembly, including services like SMT, THT, and turnkey solutions, we’ll share actionable insights to help you achieve flawless results. Ready to optimize your PCB assembly? Let’s explore how SMT stencils can elevate your process. Contact us for custom solutions tailored to your needs.

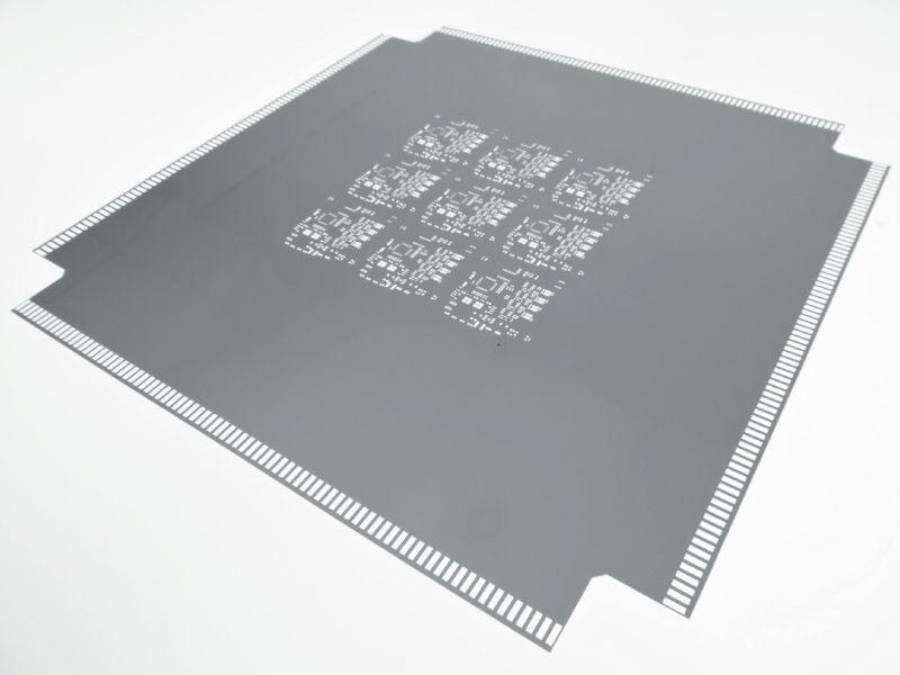

What is an SMT Stencil?

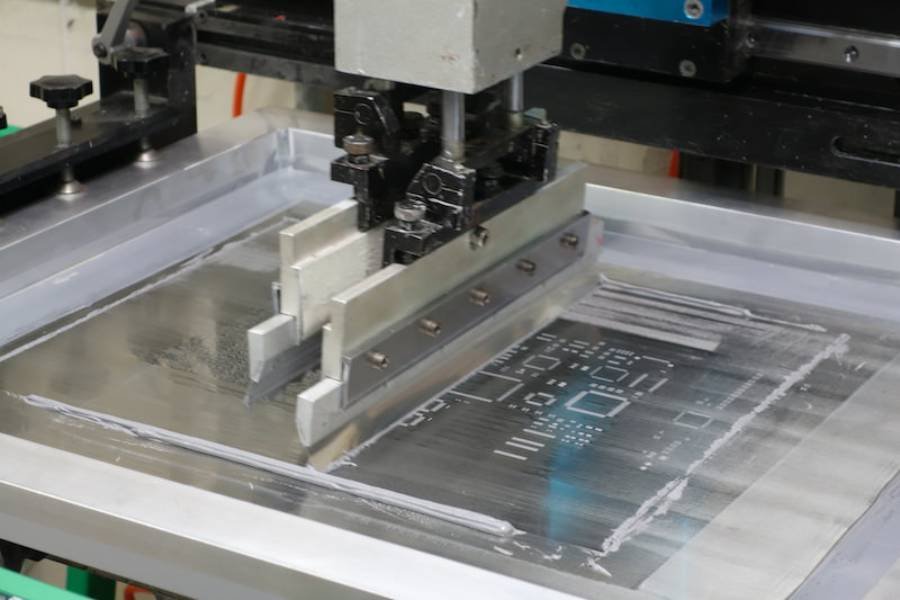

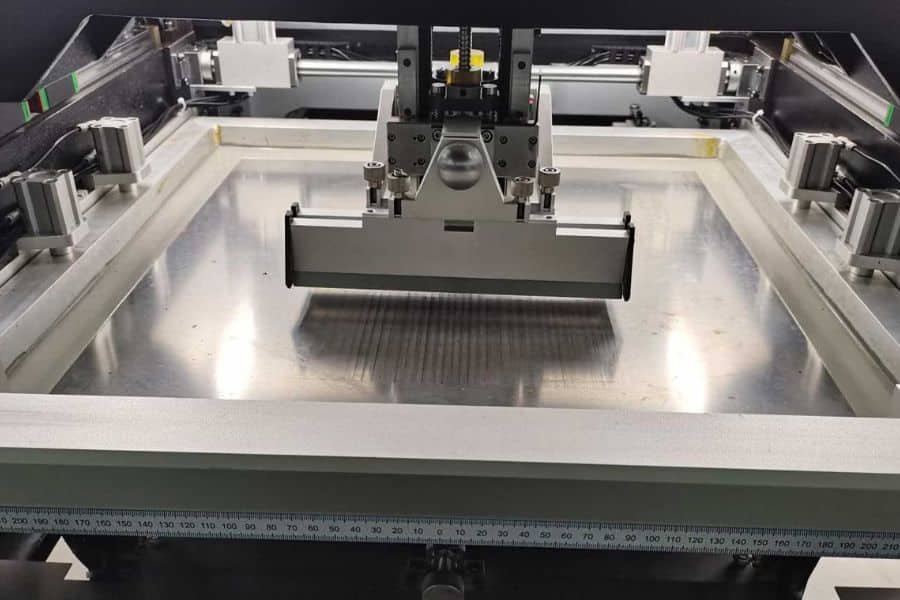

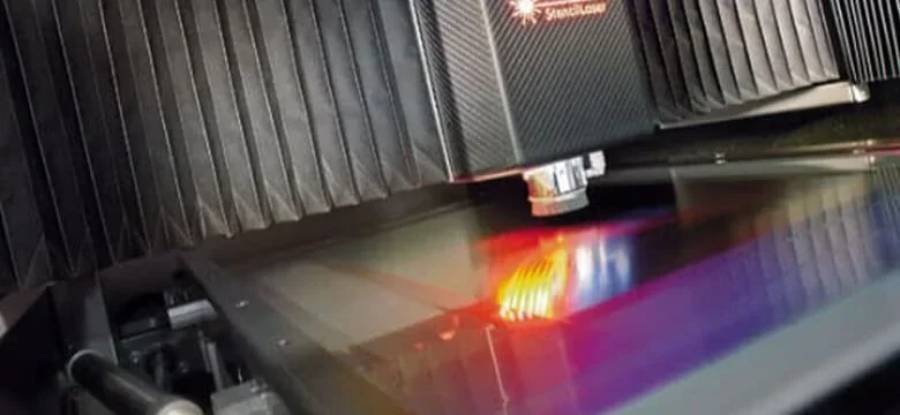

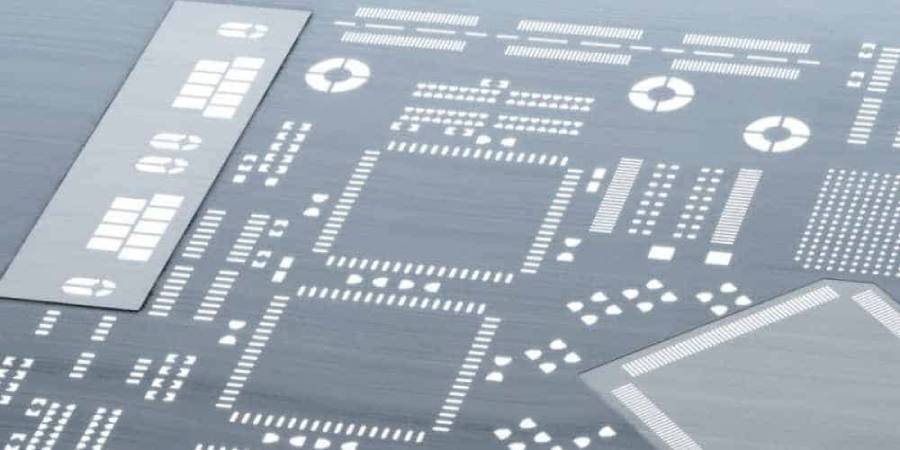

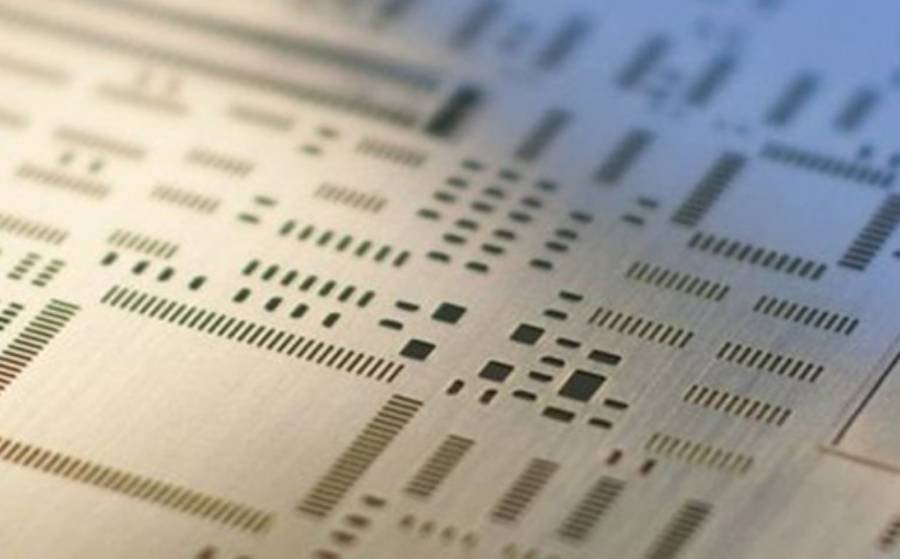

An SMT (Surface-Mount Technology) stencil is a thin, precision-engineered sheet—typically made of stainless steel or occasionally aluminum—with laser-cut apertures that align perfectly with the pads on a printed circuit board (PCB). These apertures act as a template, guiding solder paste application to ensure components are securely bonded during assembly. The process is simple yet critical: the stencil is placed over the PCB, solder paste is spread across it with a squeegee, and the paste flows through the apertures onto the board’s pads in a controlled, uniform manner.

Why does this matter? Accurate solder paste deposition is the foundation of reliable SMT assembly. Too much paste can cause bridging; too little can lead to weak joints. At JHYPCB, we’ve found that material choice plays a big role in stencil performance. Stainless steel, our go-to material, offers durability and precision for high-volume runs, while aluminum can be a cost-effective option for less demanding applications. However, aluminum may wear faster, impacting long-term reliability. By choosing the right stencil, you set the stage for error-free soldering, whether you’re building rigid, flexible, or rigid-flex PCBs.

Types of SMT Stencils by Frame Design

SMT stencils come in two primary frame designs, each suited to specific production needs. Let’s break them down:

Framed SMT Stencils

Framed SMT stencils are the workhorses of high-volume PCB assembly. These stencils feature a stainless steel foil securely mounted in a rigid aluminum frame, ensuring stability during repeated printing cycles. The frame maintains consistent tension, which is crucial for smooth aperture walls and precise solder paste application. At JHYPCB, we recently used framed stencils for a client’s high-volume consumer electronics project, reducing solder defects by 20% compared to their previous setup.

- Best for: Mass production, automated SMT lines.

- Pros: High durability, consistent paste volume, ideal for complex multi-layer PCBs.

- Cons: Higher cost, less flexible for quick design changes.

Frameless SMT Stencils

Frameless stencils, also known as foil-only stencils, are designed for flexibility and cost-efficiency. They use a reusable tensioning system, allowing you to swap stencils in and out of a single master frame. This makes them perfect for low-volume runs, such as PCB prototyping or small-batch production. Despite their lower cost, frameless stencils deliver high-quality prints when properly tensioned.

- Best for: Prototyping, small-scale production, or frequent design iterations.

- Pros: Cost-effective, easy to store, reusable with a master frame.

- Cons: Less stable for high-volume runs, requires careful handling.

Comparison Table:

Feature | Framed SMT Stencil | Frameless SMT Stencil |

|---|---|---|

Best Use | High-volume production | Prototyping, small runs |

Cost | Higher | Lower |

Durability | Excellent | Good, with care |

Setup Time | Faster for automation | Slightly longer |

Types of SMT Stencils by Manufacturing Process

The manufacturing process of an SMT stencil determines its precision, durability, and suitability for specific applications. Here are the main types we use at JHYPCB:

Laser-Cut Stencils

Laser-cut stencils are the gold standard for precision. Using advanced laser technology, apertures are cut with micron-level accuracy, ensuring perfect alignment with PCB pads. These stencils integrate seamlessly with tensioning systems, maintaining stability during printing. They’re ideal for high-reliability applications, such as medical or aerospace PCBs, where precision is non-negotiable.

- Best for: Fine-pitch components, high-precision assemblies.

- JHYPCB Tip: Regular cleaning extends laser-cut stencil life, especially for dense boards.

Step (Ladder) Stencils

Step stencils, also called ladder stencils, are designed for PCBs with components of varying heights or thicknesses. They feature step-up or step-down areas on the stencil surface, allowing tailored solder paste volumes for different pads. This ensures even deposition across complex boards, like those with mixed SMT and THT components.

- Best for: Hybrid or multi-level PCBs, such as rigid-flex designs.

- Unique Insight: At JHYPCB, we’ve used step stencils to streamline assembly for IoT devices with diverse component profiles.

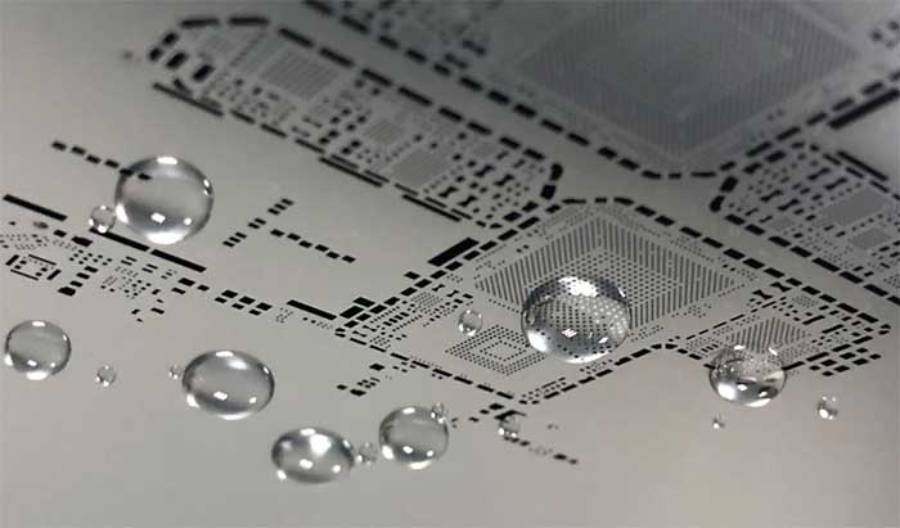

Nano-Coated Stencils

Nano-coated stencils are treated with oleophobic and hydrophobic coatings, repelling oil and water to improve solder paste release. This reduces bridging and cleaning frequency, making them ideal for fine-pitch or high-density boards. The coating also enhances stencil longevity, a cost-saving feature for frequent use.

- Best for: High-density boards, fine-pitch ICs, or projects requiring minimal maintenance.

- Long-tail keyword: “Nano-coated SMT stencils for fine-pitch PCB assembly.”

Electroformed Stencils

Electroformed stencils are created through electrolysis, depositing metal onto a mold to form precise, trapezoidal apertures. These trapezoidal shapes facilitate easier paste release compared to traditional etched stencils, reducing defects. Their robust mechanical properties make them suitable for high-pressure printing environments.

- Best for: High-volume, high-pressure SMT lines.

- JHYPCB Insight: We recommend electroformed stencils for clients needing ultra-reliable paste application over thousands of cycles.

Electropolished Stencils

Electropolishing creates a mirror-like finish on stencil surfaces, smoothing aperture walls for seamless solder paste flow. This minimizes blockages and ensures clean, consistent prints, even after repeated use. The process is particularly effective for high-precision boards.

- Best for: Applications requiring ultra-clean prints, like automotive electronics.

- Pro Tip: Pair electropolished stencils with automated inspection to catch defects early.

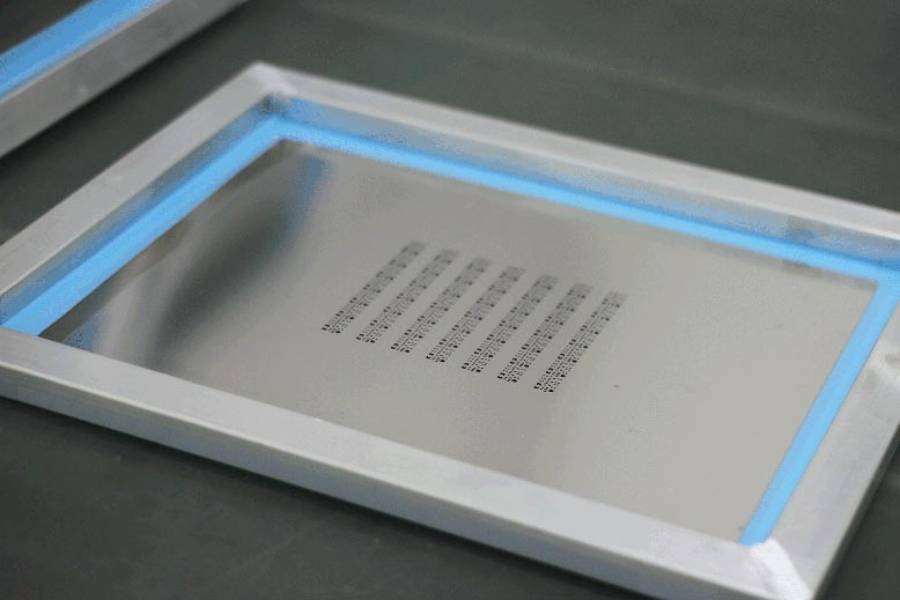

Types of SMT Stencils by Text and Marking

Text and markings on SMT stencils aid in alignment and component identification, especially in automated assembly. Here are the two main types:

Half-Lasered Text

Half-lasered text involves partially cutting fiducials or labels into the stencil surface. These markings are visible without affecting solder paste flow, making them ideal for solder mask stencils. Fiducials, etched reference points, guide automated systems for precise alignment.

- Best for: Automated assembly with solder mask requirements.

- JHYPCB Advantage: We use half-lasered fiducials for hybrid PCBs, ensuring alignment accuracy in mixed-technology assemblies.

Lasered-Through Text

Lasered-through text involves fully cutting markings through the stencil material, creating clear, durable labels for component identification. This method maintains stencil strength while providing visible guides for manual or automated processes.

- Best for: Manual assembly or boards with complex component layouts.

- Unique Value: Our engineers recommend lasered-through text for prototypes, as it simplifies visual checks during setup.

Types of SMT Stencils by Solder Paste Application

SMT stencils are also categorized by their role in solder paste application, aligning with specific assembly needs:

Prototype Stencils

Prototype stencils are designed for manual solder paste application, often using CAD or Gerber files for accuracy. They minimize printing errors during early-stage testing, making them ideal for R&D or low-volume runs.

Best for: PCB prototyping, small-batch testing.

JHYPCB Service: We offer rapid-turnaround prototype stencils to accelerate your design validation.

Framed and Frameless Stencils

As discussed earlier, framed stencils excel in high-volume automated lines, while frameless stencils suit prototyping. For turnkey PCB assembly, JHYPCB often combines both, using framed stencils for production and frameless for initial runs to optimize costs.

Hybrid Option: For mixed-technology boards, we pair prototype stencils with framed setups for seamless transitions from testing to production.

Benefits of Using SMT Stencils in PCB Assembly

SMT stencils are indispensable for efficient, high-quality PCB assembly. Here are their key advantages, backed by our experience at JHYPCB:

- Cost-Efficiency: Stencils are reusable, reducing per-unit costs, especially in high-volume production.

- Repeatability: Precise apertures ensure consistent solder paste application across thousands of boards.

- Error Reduction: Accurate paste deposition prevents shorts, voids, or weak joints, improving yield rates.

- Scalability: Stencils support both manual and automated processes, from prototypes to mass production.

- Versatility: Suitable for rigid, flexible, and rigid-flex PCBs, accommodating diverse project needs.

Real-World Example: For a recent client project involving a complex rigid-flex PCB for a wearable device, our framed SMT stencils reduced soldering defects by 15%, saving the client significant rework costs. This kind of reliability is why stencils are a cornerstone of our turnkey assembly services.

How to Use an SMT Stencil Effectively

Using an SMT stencil correctly is critical for flawless PCB assembly. Here’s a step-by-step guide, with tips from JHYPCB’s production line:

For Manual Assembly (Frameless Stencils)

- Align the Stencil: Secure the frameless stencil over the PCB, ensuring apertures match the board’s pads.

- Apply Solder Paste: Spread paste across the stencil using a squeegee at a 45-degree angle.

- Inspect the Print: Check for uniform paste deposits and clean any excess to avoid bridging.

- Clean the Stencil: Wipe with isopropyl alcohol to maintain aperture clarity for reuse.

For Automated Assembly (Framed Stencils)

- Set Up the Machine: Configure the SMT printer with CAM data, adjusting blade speed and pressure.

- Load the Stencil: Place the framed stencil in the machine, ensuring proper tension.

- Run the Conveyor: Feed PCBs through the printer for automated paste application.

- Perform SPI: Use Solder Paste Inspection (SPI) to verify deposit accuracy before component placement.

Common Mistakes to Avoid: Over-applying paste, misaligning the stencil, or neglecting cleaning can lead to defects. At JHYPCB, we use automated SPI to catch issues early, ensuring zero-defect boards for our clients.

Polishing Processes for SMT Stencils

Polishing enhances stencil performance by smoothing surfaces and removing burrs. Here are the main methods:

Mechanical Polishing

- Process: Uses abrasive pads to remove burrs manually or with basic tools.

- Pros: Low cost, easy to perform in-house.

- Cons: Time-consuming, less precise for fine-pitch stencils.

- Best for: Low-budget or low-volume operations.

Chemical Polishing

- Process: Applies acid or alkaline solutions to dissolve surface imperfections.

- Pros: High accuracy, smooth finish for fine apertures.

- Cons: Requires specialized handling, higher cost.

- Best for: High-precision stencils for complex boards.

Electropolishing

- Process: Uses electric current to smooth surfaces, creating a mirror-like finish.

- Pros: Superior smoothness, consistent results, ideal for high-volume use.

- Cons: Requires expensive equipment.

- Best for: Mission-critical applications like aerospace or medical PCBs.

JHYPCB Recommendation: For high-volume clients, we suggest outsourcing electropolishing to maintain stencil quality without investing in costly tools. For prototypes, mechanical polishing often suffices.

How to Choose the Right SMT Stencil for Your Project

Selecting the right SMT stencil depends on your project’s needs. Here’s a checklist to guide your decision:

- Production Volume: Choose framed stencils for high-volume runs, frameless for prototypes.

- Board Complexity: Use step or nano-coated stencils for fine-pitch or multi-level PCBs.

- Budget: Frameless or mechanically polished stencils are cost-effective for small runs.

- Component Type: Laser-cut or electroformed stencils suit fine-pitch or high-density components.

- Assembly Method: Automated lines benefit from framed, electropolished stencils; manual processes work well with frameless options.

Selection Table:

| Project Type | Recommended Stencil | Key Features |

|---|---|---|

| Prototyping | Frameless, Laser-Cut | Cost-effective, high precision |

| High-Volume | Framed, Electropolished | Durable, consistent prints |

| Fine-Pitch Boards | Nano-Coated, Laser-Cut | Superior paste release |

| Mixed-Tech PCBs | Step Stencil | Handles varying component heights |

Ready to choose the perfect stencil? Contact JHYPCB at sales@pcbjhy.com for a custom quote tailored to your PCB assembly needs.

Conclusion

SMT stencils are the unsung heroes of PCB assembly, ensuring precision, efficiency, and reliability from prototype to production. Whether you need a framed stencil for high-volume runs, a nano-coated option for fine-pitch components, or a cost-effective frameless stencil for prototyping, choosing the right type is critical to success. At JHYPCB, we leverage our expertise in PCB manufacturing and assembly to deliver high-quality SMT stencils that meet your unique requirements. From rigid to flexible PCBs, our turnkey solutions and component sourcing services streamline your process, saving you time and cost.

Ready to optimize your PCB assembly with top-tier SMT stencils? Email us at sales@pcbjhy.com or visit our website for more insights and custom solutions.