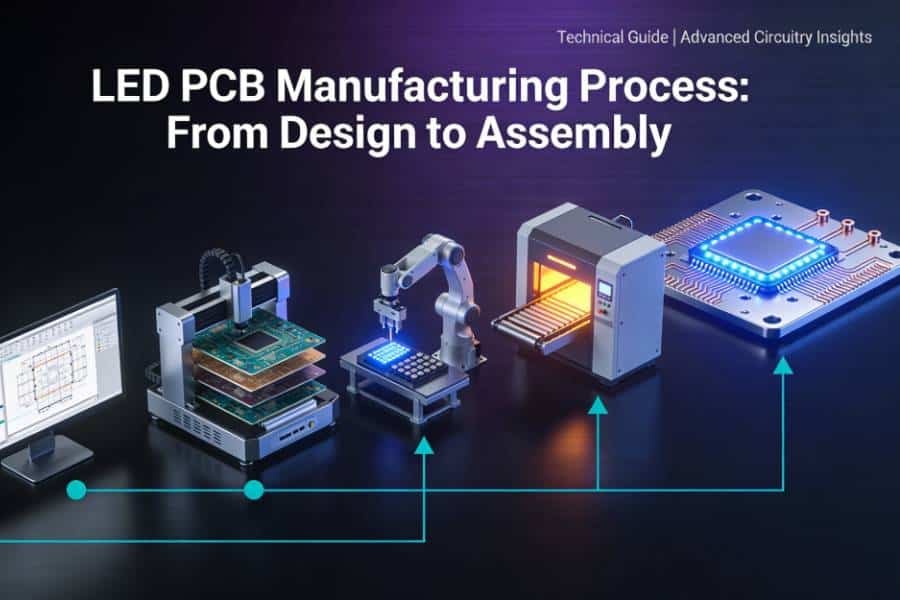

LED PCB Manufacturing Process: From Design to Assembly

LED PCB manufacturing transforms engineering files into reliable lighting modules through 10+ critical process steps. This guide details aluminum LED PCB lamination, drilling, plating, white solder mask application, SMT assembly with precise LED placement, reflow profiling, burn-in testing and ESD-safe packaging. Perfect for engineers seeking to optimize DFM, procurement teams evaluating China LED PCB manufacturers, and OEMs ensuring high first-pass yields for production LED PCB assemblies.

LED PCB Manufacturing Process: From Design to Assembly Read More »