Table of Contents

Imagine heading to the grocery store with a detailed shopping list to ensure you get everything you need, organized and error-free. In PCB manufacturing, a Bill of Materials (BOM) serves the same purpose for PCBA manufacturing. A well-crafted PCB BOM lists all components required for PCB assembly, guiding manufacturers like JHYPCB to deliver high-quality, cost-effective solutions for projects like rapid prototyping or full-scale production. At JHYPCB, we understand the critical role a BOM plays in streamlining procurement and ensuring your project meets specifications. In this guide, we’ll explore what a BOM is, why it’s essential, and how to create one to optimize your PCBA process. Let’s dive in!

What is the Bill of Materials (BOM)?

A Bill of Materials (BOM) is a comprehensive list detailing all components and materials needed for PCB assembly and PCBA manufacturing. It acts as a blueprint, ensuring manufacturers like JHYPCB procure the exact parts for your project. The PCB BOM includes critical details such as Manufacturer Part Numbers (MPNs), quantities, and reference designators, enabling accurate component sourcing and placement on the printed circuit board. For complex projects, a multi-level BOM organizes sub-assemblies, enhancing clarity. A well-prepared BOM minimizes errors, streamlines the PCBA process, and ensures your project meets design specifications, whether for prototyping or production.

Why is the BOM so Important?

A Bill of Materials (BOM) is the backbone of successful PCB assembly, acting as a critical guide for manufacturers like JHYPCB. A precise PCB BOM ensures efficiency and accuracy throughout the PCBA manufacturing process. Here’s why it’s essential:

- Streamlines Component Procurement: Organizes sourcing for efficient PCB manufacturing.

- Enables Accurate Cost Estimation: Lists quantities and part numbers to provide precise quotes for cost-effective projects.

- Optimizes Inventory Management: Prevents shortages or overstocking during production.

- Facilitates Material Planning: Tracks requirements for smooth workflows.

- Ensures Supply Chain Accuracy: Minimizes errors in part selection.

- Reduces Waste and Costs: Eliminates unnecessary purchases, supporting JHYPCB’s commitment to low-cost PCB assembly.

An accurate BOM ensures your project meets deadlines and quality standards, whether for startups needing prototypes or large-scale production.

What Should Be Included in a PCB BOM?

A well-structured PCB BOM is vital for seamless PCBA manufacturing, ensuring manufacturers like JHYPCB source and place components accurately. Including the right details minimizes errors and speeds up production. Below are the essential and recommended elements for your Bill of Materials:

- Manufacturer Part Number (MPN) – Essential

The MPN uniquely identifies each component, ensuring precise sourcing. For example, a capacitor’s MPN like “GRM188R71H104KA93D” helps JHYPCB procure the correct part. Include alternate MPNs to avoid delays. - Quantity – Essential

Specify the exact number of components needed. For instance, list “5” for five capacitors to enable efficient procurement. - Reference Designator – Essential

Designators (e.g., C1, R2, U5) indicate component placement on the PCB, aligning with the silkscreen. For example, list “C1, C5, C7” for capacitors to ensure accurate assembly. - Manufacturer Name – Recommended

Include the manufacturer’s name (e.g., Murata, Vishay) to guide sourcing. Verify availability to prevent delays, and list alternates for flexibility. - Description – Recommended

Provide details like capacitance (e.g., 0.1µF), voltage (e.g., 50V), or package type (e.g., 0603, 1206). This ensures clarity and reduces errors. - Component Value – Optional

Specify values like resistance (e.g., 10kΩ) or capacitance to assist manufacturers, though MPN often includes this information.

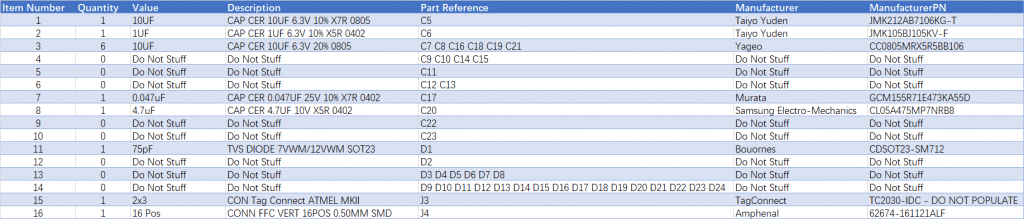

Here’s a sample PCB BOM for reference:

| Item No. | MPN | Manufacturer | Quantity | Designator | Description |

|---|---|---|---|---|---|

1 | GRM188R71H104KA93D | Murata | 5 | C1, C5, C7, C14, C20 | 0.1µF, 50V, 0603 |

2 | CRCW060310K0FKEA | Vishay | 2 | R1, R2 | 10kΩ, 1%, 0603 |

By including these elements, your BOM ensures JHYPCB delivers high-quality, error-free PCB assembly tailored to your needs.

How to Create a PCB BOM?

Creating an accurate PCB BOM is essential for seamless PCBA manufacturing. A well-prepared BOM ensures manufacturers like JHYPCB source components efficiently and assemble your PCB without errors. Follow these steps to create a reliable Bill of Materials:

Choose a Format

Use a spreadsheet like Microsoft Excel or a CSV file, compatible with PCB design software (e.g., Altium Designer, KiCAD). These formats are widely accepted by manufacturers like JHYPCB.Define Column Headers

Create clear headers to organize component details, such as:- Item Number

- Manufacturer Part Number (MPN)

- Quantity

- Reference Designator

- Manufacturer Name

- Description (e.g., capacitance, package type)

Component Value (e.g., 10kΩ)

Fill in Component Details

List each component’s information. For example:- MPN: GRM188R71H104KA93D

- Quantity: 5

- Designator: C1, C5, C7, C14, C20

Description: 0.1µF, 50V, 0603 Cross-reference with your PCB schematic for accuracy.

Verify and Validate

Double-check for errors using a checklist:- Are all MPNs valid and available?

- Do designators match the schematic?

- Are quantities sufficient?

Are alternate parts listed if needed? JHYPCB can review your BOM to ensure compatibility.

Submit to Manufacturer

Export your BOM as Excel or CSV and submit it. JHYPCB’s 24/7 support clarifies requirements for a smooth PCB manufacturing process.

Pro Tip: Use PCB design software like Altium Designer or OpenBOM to automate BOM creation. For complex projects, a multi-level BOM can organize sub-assemblies.

These steps help create a precise PCB BOM, minimizing delays and ensuring quality results with JHYPCB’s expertise.

Common PCB BOM Mistakes and How to Avoid Them

Creating an accurate PCB BOM is critical, but errors can lead to delays or faulty assemblies. Below are common PCB BOM mistakes and tips to avoid them, with JHYPCB’s expertise to guide your PCBA manufacturing process.

Incorrect Manufacturer Part Numbers (MPNs)

Mistake: Wrong or outdated MPNs result in sourcing incorrect components.

Solution: Verify MPNs using datasheets or distributors like DigiKey or Mouser. Include alternates. JHYPCB can confirm part accuracy.Missing or Incorrect Reference Designators

Mistake: Omitting or mismatching designators (e.g., C1, R2) causes assembly errors.

Solution: Cross-check with Gerber files and schematics. Use tools like Altium Designer for automation.Inaccurate Quantities

Mistake: Wrong quantities lead to shortages or excess inventory.

Solution: Calculate based on schematics, adding spares. JHYPCB optimizes quantities for cost efficiency.Ignoring Component Availability

Mistake: Obsolete parts delay production.

Solution: Check availability on distributor websites. List alternates or consult JHYPCB for substitutes.Incomplete Component Descriptions

Mistake: Vague descriptions (e.g., missing capacitance or package type) cause confusion.

Solution: Include details like 0.1µF, 50V, 0603. Use standardized formats.

BOM Accuracy Checklist

Before submitting to JHYPCB:

- Are all MPNs valid and sourced from reliable distributors?

- Do designators match the schematic and Gerber files?

- Are quantities accurate, with spares included?

- Have you verified component availability and listed alternates?

- Are descriptions complete, including values and package types?

- Is the BOM exported in Excel or CSV?

Avoiding these mistakes streamlines your PCB assembly process. JHYPCB’s 24/7 support offers BOM reviews for error-free results.

Tools and Software for PCB BOM Creation and Management

Efficient PCB BOM creation and management are key to successful PCBA manufacturing. The right tools simplify the process and reduce errors. Below are popular tools tailored for PCB manufacturing:

PCB Design Software

Altium Designer, KiCAD, and Eagle generate BOMs from schematics, including MPNs, quantities, and designators, ensuring accuracy.- Why Use: Automates BOM creation, minimizing errors.

Tip: Export BOMs in Excel or CSV, compatible with JHYPCB’s workflow.

BOM Management Platforms

OpenBOM, Arena PLM, and OrCAD offer real-time collaboration and inventory tracking, ideal for complex projects.- Why Use: Supports multi-level BOMs and team workflows.

Tip: Use OpenBOM to manage alternate parts.

Spreadsheet Tools

Microsoft Excel and Google Sheets are flexible for manual BOM creation, allowing easy editing of MPNs and descriptions.- Why Use: Cost-effective and widely accepted by JHYPCB.

Tip: Use JHYPCB’s templates for complete fields.

Online Component Databases

DigiKey, Mouser, and Octopart verify MPNs and availability, ensuring practical BOMs.- Why Use: Prevents errors from obsolete parts.

Tip: Cross-reference MPNs before finalizing.

Choosing the Right Tool

- For startups or small projects, KiCAD or Excel is sufficient.

- For complex designs, Altium Designer or OpenBOM offers advanced features.

For collaboration, Google Sheets or OpenBOM enables real-time updates.

JHYPCB supports Excel and CSV BOMs, with 24/7 guidance to choose the best tool. Download our free BOM template to start!

Tips for Collaborating with Your PCBA Manufacturer

Effective collaboration with your PCBA manufacturer ensures your PCB BOM translates into high-quality PCB assembly. Partnering with JHYPCB streamlines the process. Here are tips to optimize BOM submission and communication:

Confirm BOM Format Requirements

Verify the preferred format (e.g., Excel, CSV). JHYPCB provides free templates for compatibility.Tip: Request a sample BOM from JHYPCB.

Communicate Non-Standard or Obsolete Parts

Notify JHYPCB early about non-standard or obsolete components. Our team suggests alternate MPNs to avoid delays.Tip: List alternates in your BOM.

Request BOM Review and Feedback

Submit your BOM for review to catch errors. JHYPCB offers expert validation for accuracy.Tip: Include detailed descriptions (e.g., capacitance, package type).

Clarify Assembly Requirements

Specify assembly type (e.g., SMT, THT) and special instructions. JHYPCB aligns your BOM with project needs.Tip: Note critical components in the BOM.

Plan for Urgent Projects

Communicate timelines early and use available components. JHYPCB’s rapid response team meets tight deadlines.Tip: Use JHYPCB’s 24/7 support for urgent needs.

Maintain Open Communication

Regular updates prevent misunderstandings. JHYPCB’s 24/7 service resolves queries promptly.Tip: Use email or JHYPCB’s online portal.

Collaboration Checklist

To work efficiently with JHYPCB:

- Confirm BOM format (Excel, CSV).

- List alternate MPNs for non-standard parts.

- Request a BOM review.

- Specify assembly type (SMT, THT).

- Communicate timelines and requirements.

FAQ: PCB BOM and PCBA Manufacturing

1. What is the difference between a PCB BOM and Gerber files?

A PCB BOM lists components (MPNs, quantities, designators), while Gerber files detail PCB layout (traces, placement). Both are essential for JHYPCB’s PCB assembly services.

1. What is the difference between a PCB BOM and Gerber files?

Excel and CSV are widely accepted, compatible with PCB manufacturing software. JHYPCB supports both for seamless processing.

1. What is the difference between a PCB BOM and Gerber files?

Yes, alternate MPNs prevent delays from unavailable components. Specify substitutes meeting design requirements.

4. What should I do if a component is obsolete?

List alternate MPNs with similar specifications. JHYPCB can source replacements to keep your project on schedule.

5. Why use a multi-level BOM for complex projects?

Ready to create your BOM? Contact JHYPCB for a free template or consultation to ensure project success!

Final Words on PCB BOM and PCBA Manufacturing

A PCB BOM is the cornerstone of successful PCBA manufacturing, guiding component sourcing and assembly for projects from prototyping to full-scale production. By including details like MPNs, quantities, and designators, and using tools like Altium Designer or Excel, you can create an accurate BOM that minimizes errors and optimizes costs. JHYPCB, a leading PCB manufacturing provider since 2011, leverages its ISO 9001:2008 certified expertise to deliver high-quality, low-cost PCB assembly. Our 24/7 support assists with BOM reviews, templates, or quotes. Ready to start? Contact JHYPCB today to download a free BOM template or get a fast quote for your PCB assembly project!

Video introduction to what is BOM

BOM Basics – What is a Bill of Material? What does it contain and why is it important?

Creating a well organized BOM (Bill of Materials)

Bill of Materials Excel Template Step-by-Step Video Tutorial by Simple Sheets