Thermal Management in LED PCB: How to Prevent Overheating (2026 Engineering Guide)

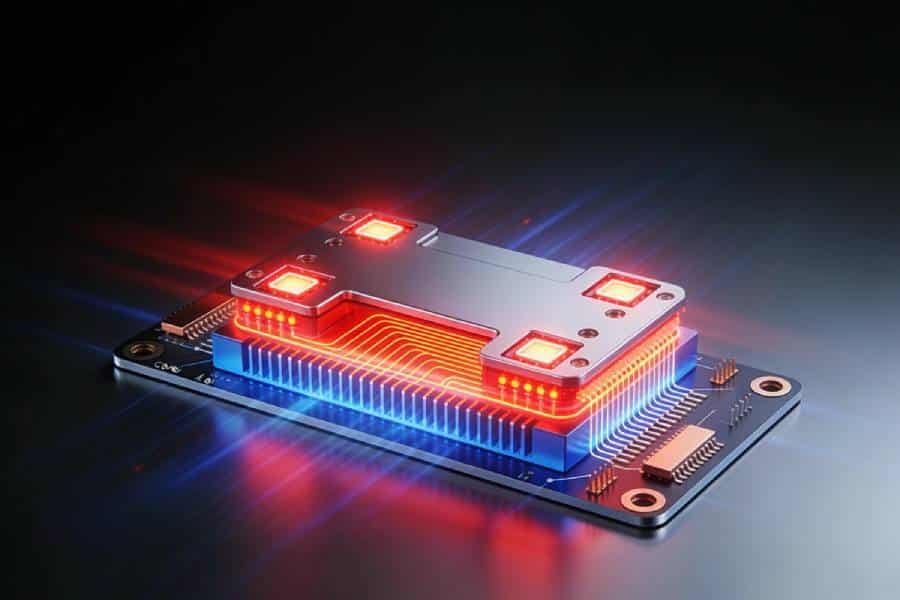

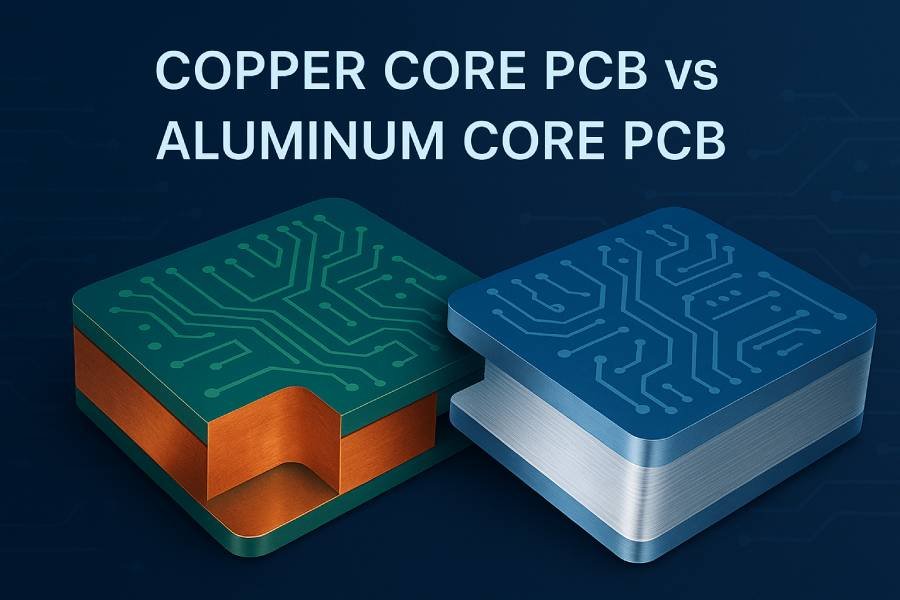

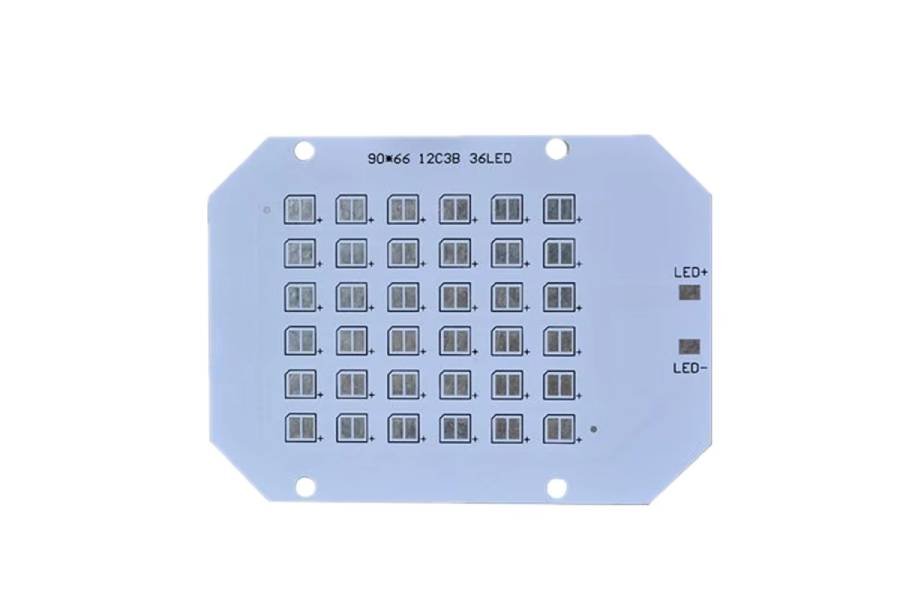

LED junction temperatures above 85°C cut lifespan by 50%+. This deep dive covers aluminum LED PCB thermal engineering: MCPCB dielectric k-values (1-8 W/m·K), thermal via arrays (8-12/cm²), copper thickness optimization (2-3oz), heatsink TIM interfaces, FEA simulation workflows, and JEDEC51 validation testing. Essential strategies for street lights, automotive and industrial LED designs ensuring L70>50,000 hours reliability.

Thermal Management in LED PCB: How to Prevent Overheating (2026 Engineering Guide) Read More »