Table of Contents

Introduction

In today’s fast-evolving electronics industry, understanding cutting-edge materials is key to staying competitive. But what is a single-sided double-layer aluminum PCB? This innovative circuit board, crafted to meet specific project needs, is transforming the design and production of high-performance devices. Let’s dive into the essentials of this technology and why it matters for your next endeavor.

What Are Single-Sided Double-Layer Aluminum PCBs?

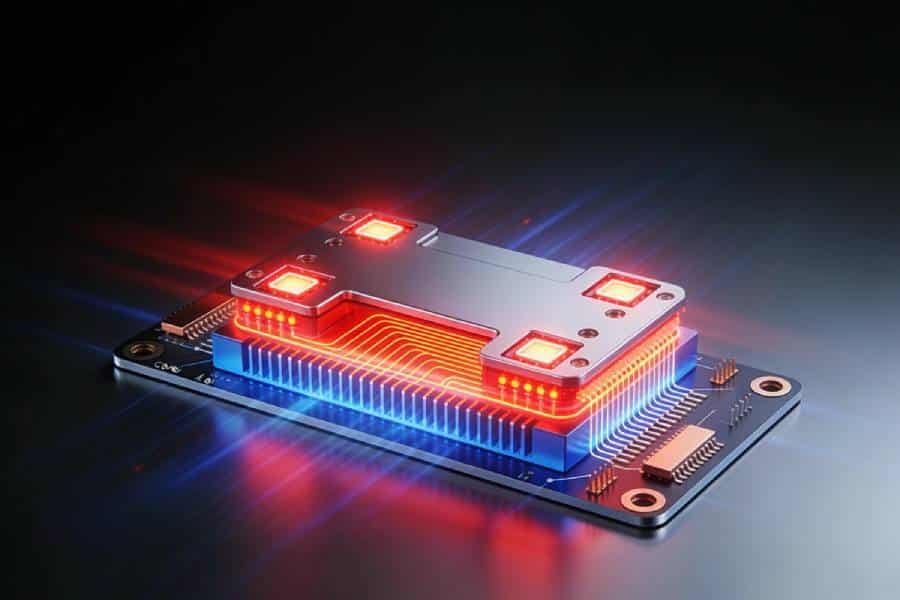

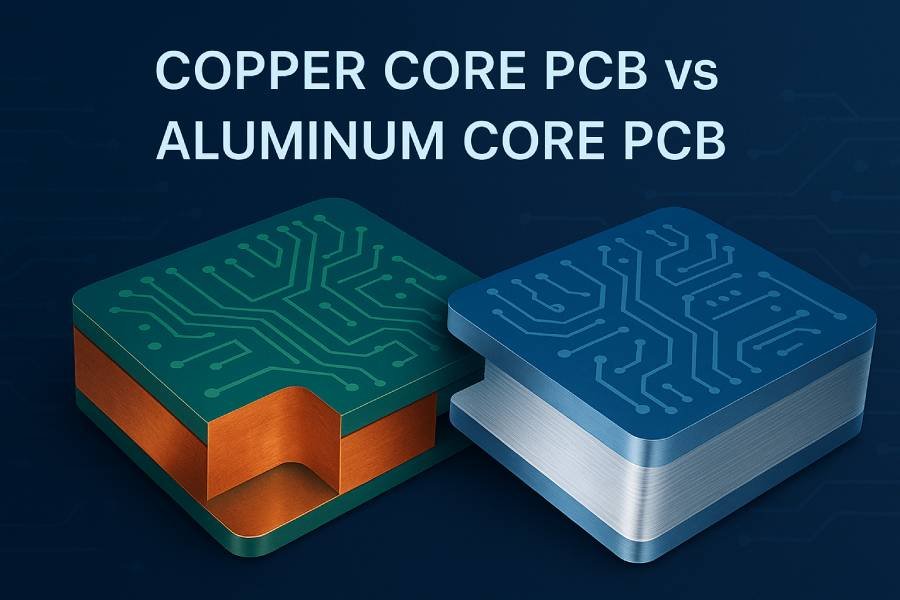

So, what is a single-sided double-layer aluminum PCB? It’s a specialized circuit board featuring a robust aluminum base, layered with copper circuits and dielectric materials. This design offers exceptional voltage resistance, heat tolerance, and corrosion resistance, making it ideal for demanding applications. Compared to standard FR4 PCBs, it provides superior thermal conductivity, keeping components cool and efficient, and is perfect for a range of innovative designs.

Structural and Technical Characteristics

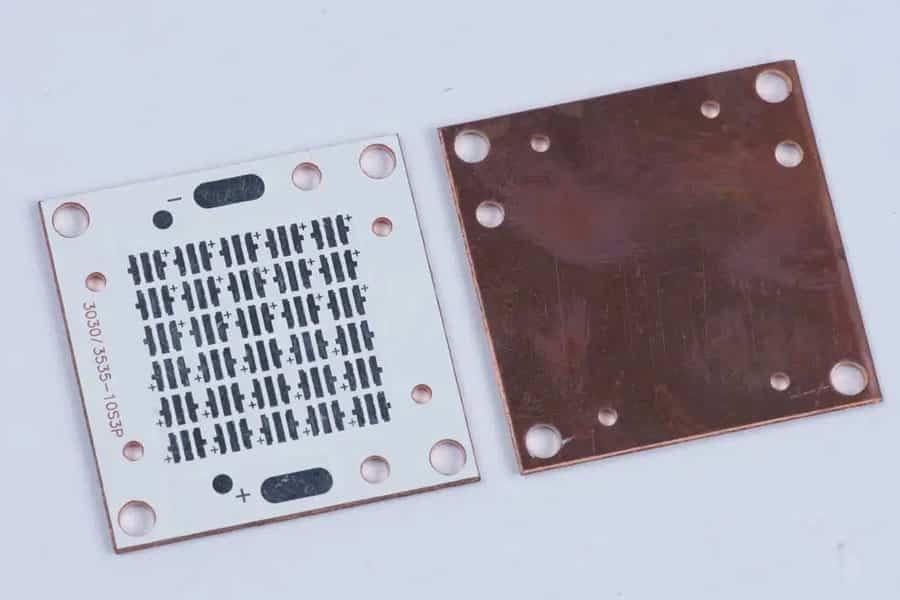

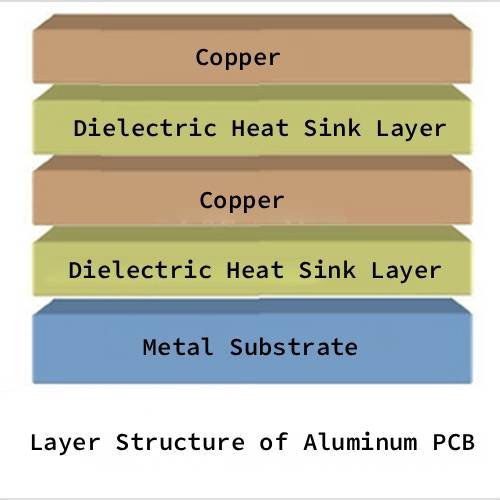

The strength of these PCBs lies in their well-engineered structure, which typically includes:

- Copper Layers: Deliver precise electrical conductivity.

- Dielectric Heat Sink Layer: Provides insulation while enhancing heat dissipation.

- Metal Substrate: A durable aluminum base, typically 0.8-3.0mm thick, offering mechanical stability.

With thermal conductivity options of 1/1.5/2W/mK and tensile strength surpassing 200MPa, these boards can handle temperatures up to 200°C. Their resistance to bending and corrosion makes them a dependable choice for challenging environments, showcasing the value of advanced manufacturing techniques.

Manufacturing Process Unveiled

Producing a single-sided double-layer aluminum PCB involves a detailed process tailored to project requirements. Here’s an overview:

- Material Selection: High-quality 5052 aluminum, fiberglass, and thermal adhesives are chosen to match project needs.

- Lamination: High-temperature, high-pressure processing bonds the layers securely.

- Laser Etching: Precision carving ensures accurate circuit patterns.

- Quality Control: Thorough testing confirms each board meets industry standards.

Attention to surface smoothness and material tensile strength ensures reliable performance, making this process a cornerstone of custom PCB manufacturing.

Our Manufacturing Capabilities

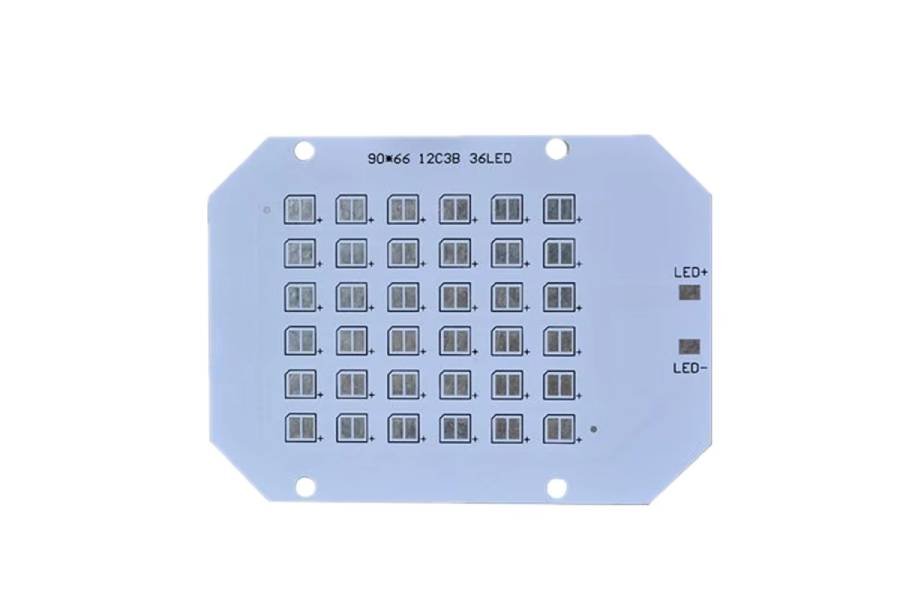

Expert PCB services offer versatile production capabilities to meet diverse client needs. Key specifications include:

- Base Material: High-quality 5052 aluminum.

- Layer Count: 2 layers.

- Thickness: Ranging from 0.8mm to 3.0mm.

- Thermal Conductivity: Options of 1/1.5/2/3W/mK in the dielectric layer.

- Copper Thickness: Available in 35/70/105/140μm.

- Solder Mask Colors: White, black, matte black, green, red, or yellow.

- Silkscreen Colors: Red, black, white, orange, yellow, or blue.

- Shaping Methods: CNC routing, CNC V-cut, mold forming, and laser shaping.

- Inspection Tests: AOI, high-speed flying probe, high-voltage testing, and custom tests.

- Surface Finishes: Lead-free HASL, ENIG, or OSP.

- Lead Time: Fast delivery within 6-8 days.

This flexibility ensures high performance and timely results for a variety of projects.

Wide-Ranging Applications

These PCBs are highly versatile across multiple industries:

- Aerospace: Improves thermal management in navigation systems.

- Automotive: Supports durable LED lighting and power controls.

- Electronics: Enhances reliability in high-density circuits.

By optimizing heat dissipation and insulation, these aluminum PCBs extend the lifespan of electronic components, making them a smart choice for future-proof designs.

Market Trends and Future Prospects

The growing demand for high-performance materials is driving the adoption of single-sided double-layer aluminum PCBs. Industries seek solutions that balance efficiency and sustainability, and custom manufacturing services are at the forefront of this shift. With expertise in rigid, flexible, and rigid-flex PCBs, these services are well-positioned to meet evolving market needs with innovative solutions.

Conclusion

Now that you know what a single-sided double-layer aluminum PCB is, it’s clear they form a vital foundation for reliable, high-performance electronics, crafted to meet specific project demands. Expert PCB manufacturing services deliver the precision and quality needed to bring your designs to life. Ready to start your project? Reach out at sales@pcbjhy.com for a solution tailored to your specifications.