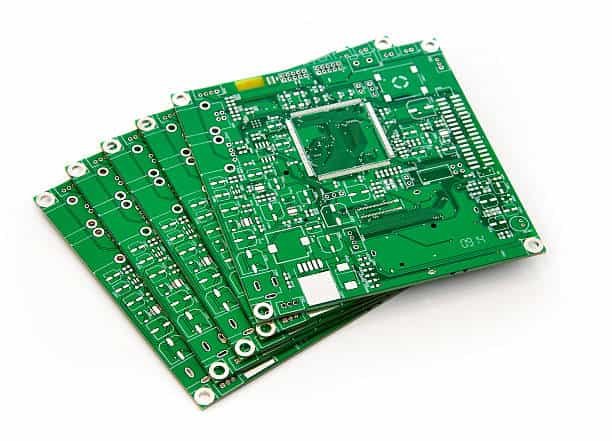

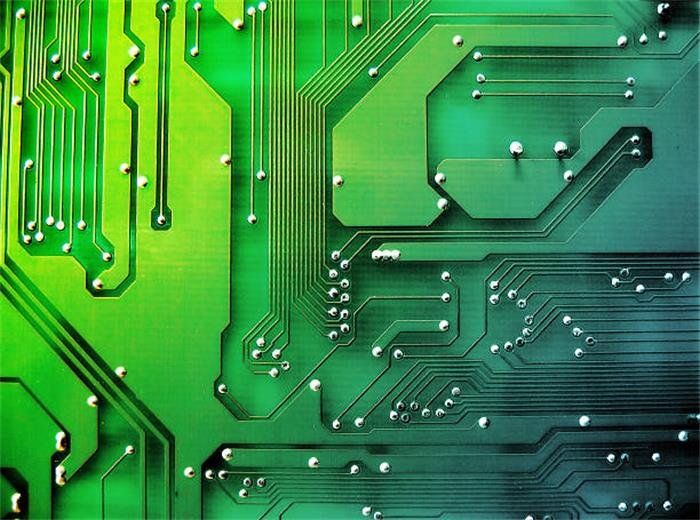

Custom PCB Manufacturing in China

China Custom PCB Manufacturer

As a leading custom PCB manufacturer in China, JHYPCB specializes in providing high-quality and cost-effective custom PCB manufacturing solutions tailored to your specific needs. With state-of-the-art facilities, advanced manufacturing capabilities, and a strong focus on quality and innovation, we are dedicated to delivering exceptional custom PCB products and services. Our team of experts works closely with clients to understand their unique requirements, ensuring that every custom PCB we produce meets the highest standards of precision, reliability, and performance. From rapid PCB prototyping to high-volume PCB production runs, JHYPCB is committed to being your trusted PCB partner for all your custom PCB manufacturing needs in China.

The Importance of Custom PCB Manufacturing for Electronics Innovation

Consumer electronics manufacturers are increasingly seeking customized products tailored to individual preferences. This can involve fully customized devices like computers or semi-customized products with interchangeable features for mass production.

Digital cameras exemplify semi-custom products that allow software and hardware upgrades, requiring custom printed circuit boards with versatile designs to accommodate new functionalities.

In today’s fast-paced electronics landscape, simply keeping up is no longer enough for companies to stay competitive and profitable. Innovation through custom PCB manufacturing is crucial – if you cannot rapidly and consistently bring new products to market, you risk falling behind.

That’s why partnering with the right custom PCB manufacturing and assembly service in China is critical for your success. In addition to choosing an expert custom PCB manufacturer, you need a fast PCB production solution to accelerate your time-to-market. For custom printed circuit board manufacturing, you want a provider with cutting-edge technology and expertise to deliver reliable, high-quality custom PCBs.

How do you know which of the many manufacturers that provide custom printed circuit board services is up to the task?

Choosing the Right Custom PCB Manufacturer in China

When selecting a reliable custom PCB manufacturing partner in China, there are several key criteria to consider to ensure you receive high-quality custom printed circuit boards tailored to your needs:

Comprehensive Custom PCB Services

Look for a manufacturer offering a full range of custom PCB services from rapid PCB prototyping to high-volume PCB production runs. At JHYPCB, our custom PCB manufacturing capabilities cover prototype PCB fabrication, turnkey PCB assembly, box build, SMT, through-hole, mixed technology, and quick-turn PCB assembly service.

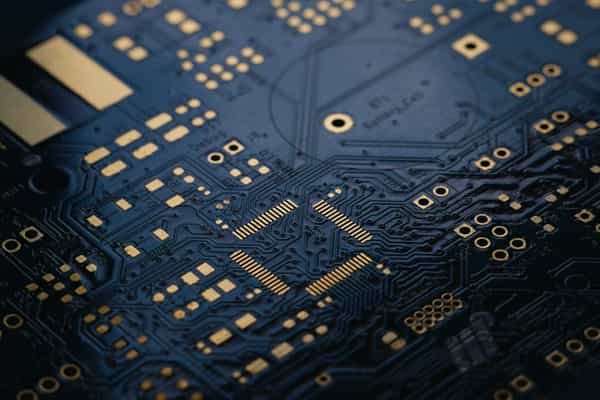

Advanced Manufacturing Capabilities

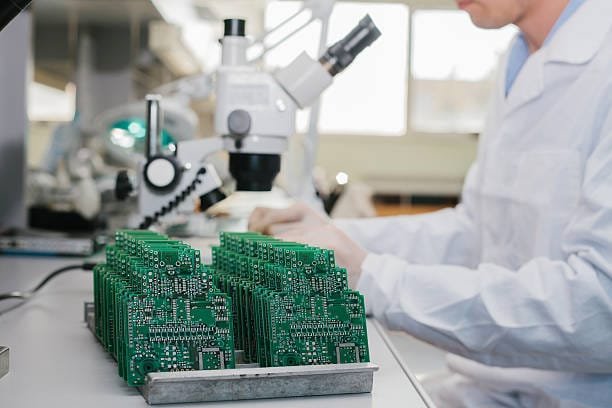

State-of-the-art facilities and equipment are essential for producing precise, reliable custom PCBs. Our surface mount and through-hole assembly lines integrate pick-and-place machines, reflow ovens, AOI systems, wave soldering, and in-circuit testing for efficient custom PCB production.

Stringent Quality Standards

Adherence to strict quality control and industry certifications like IPC-610 is paramount. JHYPCB's commitment to consistent quality ensures your custom PCB order meets the highest standards every time.

Robust Global Supply Chain

A trusted, transparent supply chain mitigates risks like counterfeit components when manufacturing custom PCBs in China. Our worldwide sourcing capabilities secure authentic, cost-competitive components.

We are JHYPCB, a leading China PCB manufacturer specializing in PCB manufacturing in China and PCB assembly in China. As one of the best PCB manufacturers in China, we provide full-service PCB manufacturers in China, including prototype and production of single-sided, double-sided, multilayer, rigid-flex, HDI, and metal base PCBs.

With state-of-the-art facilities and equipment, we enable fast and high-quality China PCB assembly. Our automated production lines ensure efficiency and precision at every step – from CAM to China PCB fabrication, China PCB board service, China PCB production, testing, to delivery. We also have an in-house engineering team providing China PCB design support.

As a leading China PCB supplier and China PCB factory, we are able to offer very competitive pricing with our global sourcing capabilities and supply chain advantages in China. Our high on-time delivery rate provides assurance for timely China PCB manufacturing. We welcome prototyping and production orders from hobbyists, startups, and enterprises globally.

High Quality Custom PCB Printing Service

Advantages of Custom PCBs

- Space-saving compact design – Complex custom PCB circuitry fits into limited spaces, ideal for custom electronic products and devices.

- Cost-effective custom PCB manufacturing – Automated processes lower labor costs while ensuring consistency and precision.

- Streamlined installation and maintenance – Custom PCB designs simplify component integration, replacement, and servicing.

- Integrated functionality – Direct printing of legends and integral LED lights enable instant operation verification on custom PCBs.

Custom printed circuit boards are well-suited for high-volume production where consistent, tailored designs are required and design changes are infrequent. With JHYPCB’s custom PCB manufacturing capabilities in China, we can produce high-quality, cost-effective custom PCBs tailored to your product specifications.

High Quality Custom PCB Manufacturing in China

JHYPCB is a manufacturer based in China specializing in custom PCB printing, from prototypes to low and high volume manufacturing. Our fabrication services are highly customizable to meet any budget or requirement.

Custom PCB printing services with a quick turnaround time

Assemblers and designers from different parts of the world have relied on us for fast turn Custom PCB Printing for the past ten years. Large and small businesses alike know they can rely on us for mission-critical Custom PCB Printing.

Customers have come to appreciate our industry-leading on-time percentage. We recognize the value of keeping our promises, which is why we give a 100% customer satisfaction guarantee. If you are dissatisfied with our delivery, we will promptly rectify the situation.

PCB Prototype Printing on Demand

We can produce low-volume single and double-sided PCBs to complex multilayer PCBs with blind and buried vias at reasonable prices using custom PCB prototyping. We can handle all of your Custom PCB prototyping needs in-house, whether you’re an electronics hobbyist or a serious electronic industry business.

JHYPCB doesn’t outsource your work to other companies as PCB brokers do; you deal directly with us, the PCB manufacturer. We have our PCB manufacturing plant in China.

Multilayer PCB Printing on Demand

JHYPCB can produce low-cost PCBs with 1 to 16 layers. Our normal PCB manufacturing turnaround time is determined by the complexity and quantity of the boards required.

Custom Single Layer PCB

In a single-layer PCB, there is only one substrate layer and one circuitry layer. Single-sided circuit boards are simple in design, easy to manufacture, and widely used.

Custom Double-Sided PCB

Different from the single-sided PCB, the double-sided PCB has two substrate surfaces coated with conductive metal layers with the components fixed to the two sides.

The double-sided circuit board realizes the electrical connection on both sides of the circuit through plated through holes (blind holes or buried holes).

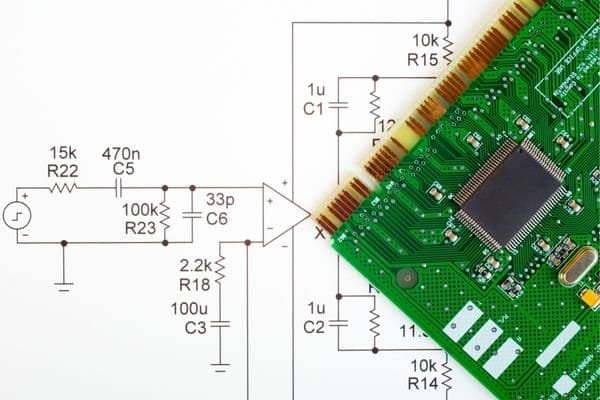

When designing a rigid PCB, specific design rules must be followed, including minimum hole size, minimum space and trace width, minimum distance to the board edge, copper, and overall design thickness. The rigid PCB manufacturing process includes lamination, drilling, electroplating, optical imaging, development, etching, etc.

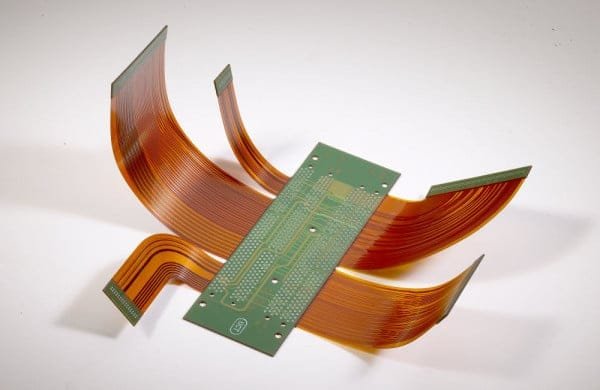

A flexible PCB, also known as a flexible circuit, is a printed circuit board different from a rigid PCB. It can twist and fold. A flexible PCB comprises a polymer insulating film with a conductive circuit pattern. Its advantages are that it is lightweight, small, flexible, highly reliable, and durable.

Custom Rigid-flex PCB

The rigid-flex PCB board has both the characteristics of FPC and the characteristics of rigid PCB, so it can be used in some products with special requirements. The combination of rigid-flex PCB boards is of great help in saving the internal space of the product, reducing the volume of the finished product, and improving the product’s performance.

FAQs on Custom PCB Manufacturing

Our custom PCB manufacturing lead times can range from 3-5 days for fast prototypes to 10-15 days for standard production orders. For larger high-volume or complex custom PCB orders, please consult our team for an accurate timeline. We offer expedited services for urgent custom PCB requirements.

Custom PCB pricing depends on multiple factors like board layers, dimensions, material, solder mask colors, silkscreen, order quantity, and turnaround time required. We provide free PCB fabrication and assembly quotes – simply upload your Gerber files and BOM file and our team will promptly provide a detailed quote covering your custom PCB specifications.

For custom PCB design and manufacturing, we support all major PCB CAD software like Altium, OrCAD, Allegro, etc. Acceptable PCB data formats include Gerber (RS-274X), ODB++, IPC-D-356, and GenCAD. Our experts can also assist with PCB design and layout services if needed.

We adhere to stringent IPC-A-600 and IPC-6012 Class 3 standards in our custom PCB manufacturing processes. From bare board fabrication to assembly, our ISO-certified facilities maintain rigorous quality control with AOI, AXI and other inspections for high-reliability custom PCBs.

Yes, in addition to single and double-layer PCBs, our custom PCB capabilities include multi-layer (up to 32 layers), rigid-flex, HDI (high-density interconnect), aluminum/metal-core PCBs and other advanced custom PCB designs and technologies as per your requirements.

Related Posts

- PCB and PCBA Manufacturing Files

- The Best PCB Manufacturer In China

- How To Search for a Reliable PCB Manufacturer?

- Why Choose a Chinese PCB Manufacturer?

- JHYPCB: The Best Prototype PCB Manufacturer for Your Needs

- Shenzhen – The Global Hub for High-Quality PCB Assembly Manufacturing

- Evaluating and Selecting Quick-Turn PCB Assembly Manufacturers in China

- Choosing the Right PCB Assembly Manufacturer for Your Needs

- Finding the Right China PCB Manufacturers:5 Vetting Tips

- The Importance of Choosing a Reliable PCB Prototype Manufacturer

- How to Select the Right Low-volume PCB Assembly Manufacturer