Table of Contents

Selecting the right low-volume PCB assembly manufacturer is critical for startups, engineers, and businesses launching innovative products. Whether you need small batch PCB assembly, prototype PCB services, or turnkey PCB assembly, a reliable partner ensures quality, cost efficiency, and timely delivery. Low-volume PCB assembly, typically involving orders under 1,000 units, is ideal for testing prototypes or serving niche markets. However, finding a trusted contract manufacturer requires careful evaluation.

In this 2025 guide, we outline 12 essential factors to consider when choosing a low-volume PCB assembly manufacturer, backed by industry insights, practical tips, and actionable tools. Let’s dive in.

1. Understanding Your Low-Volume PCB Quantity Needs

Low-volume PCB assembly is designed for small runs, often under 1,000 units, making it perfect for prototypes or specialized products. Choosing a manufacturer specializing in small batch PCB assembly ensures cost efficiency and faster turnaround times. For instance, a 2024 industry report by Electronics Manufacturing Trends found that specialized low-volume providers reduce lead times by up to 20% compared to high-volume-focused factories.

How to Evaluate: Confirm the manufacturer’s expertise in handling orders matching your quantity. Ask: “Do you specialize in low-volume runs under 1,000 units?”

2. Evaluating Minimum Order Quantities (MOQ)

Some low-volume PCB assembly manufacturers impose minimum order quantities (MOQs), which can increase costs if your needs are smaller. Flexible MOQs are crucial to avoid overstocking or inflated budgets.

How to Evaluate: Inquire about MOQ policies upfront. For example, ask: “What is your MOQ for orders under 500 units?” A manufacturer with no or low MOQs is ideal for small batch PCB assembly.

Pro Tip: Download our free Low-Volume PCB Manufacturer Evaluation Checklist to assess MOQ and other key factors.

3. Prioritizing Flexibility in Production

Low-volume PCB assembly often faces unexpected challenges, such as component shortages or last-minute design changes. A flexible manufacturer can adapt quickly, ensuring on-time delivery. For example, during the 2023 global chip shortage, flexible manufacturers with backup suppliers maintained production schedules while others faced delays.

How to Evaluate: Ask about contingency plans. Questions like “How do you handle component shortages?” or “Can you accommodate design revisions mid-production?” reveal a manufacturer’s adaptability.

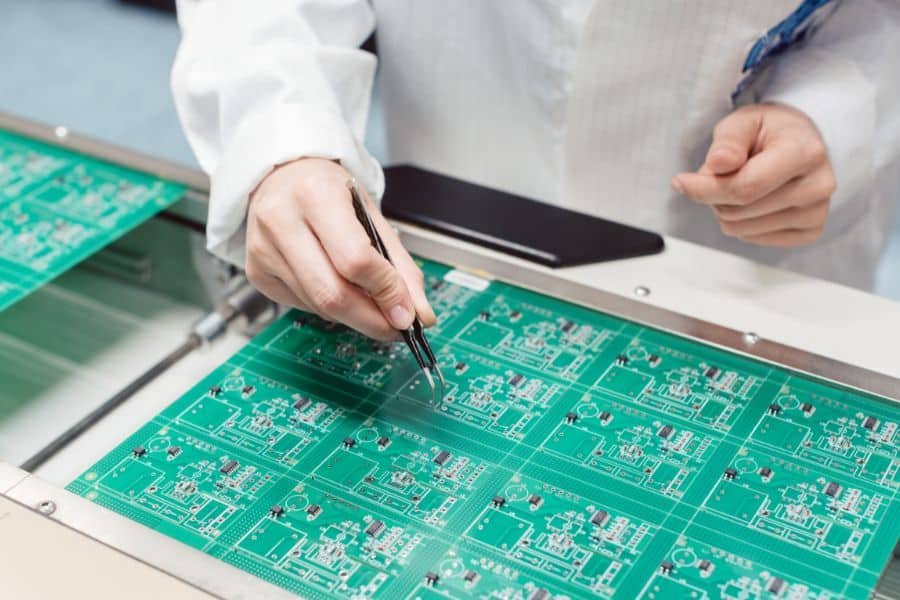

4. Ensuring One-Stop PCB Assembly Services

A turnkey PCB assembly provider handles everything—PCB fabrication, component sourcing, assembly, testing, and shipping—under one roof. This minimizes communication errors and ensures consistent quality. Outsourcing critical steps, like component procurement, can lead to delays or quality issues.

How to Evaluate: Confirm the manufacturer offers in-house services. Ask: “Do you outsource any part of the PCB assembly process?” A one-stop provider is your best choice for low-volume PCB assembly.

5. Verifying Industry Experience

Not all low-volume PCB assembly manufacturers have expertise in your industry. A manufacturer experienced in your sector (e.g., medical, automotive, or IoT) understands specific requirements, such as regulatory standards or material tolerances.

Case Study: A medical device startup partnered with a manufacturer experienced in ISO 13485-compliant PCB assembly, reducing their certification timeline by 30%.

How to Evaluate: Request case studies or references in your industry. Ask: “Have you completed low-volume projects for [your industry]?”

6. Assessing Delivery and Scheduling Capabilities

For prototype PCB assembly, rapid delivery and functional testing are often more critical than perfection. However, many manufacturers prioritize high-volume orders, delaying smaller runs. A low-volume PCB assembly manufacturer should offer quick turnaround times, typically 5-15 days for small batches.

How to Evaluate: Discuss production scheduling. Ask: “How do you prioritize low-volume orders?” or “What is your average lead time for 100-unit runs?”

7. Evaluating Supply Chain Management

Strong supply chain management is vital for low-volume PCB assembly. Reliable component sourcing ensures quality parts at competitive prices, preventing delays. A 2024 Supply Chain Electronics Report noted that manufacturers with robust supplier networks reduced component costs by 15% on average.

How to Evaluate: Inquire about supplier relationships. Ask: “How many component suppliers do you work with?” or “Can you source hard-to-find parts?”

8. Why Design for Manufacturability (DFM) Matters

Design for Manufacturability (DFM) analysis identifies design flaws, process risks, or cost inefficiencies before production. A low-volume PCB assembly manufacturer with DFM expertise can save up to 25% in production costs by reducing prototype iterations.

How to Evaluate: Request a sample DFM report. Ask: “Do you provide DFM analysis before production?” or “How do you address design-process mismatches?”

9. Checking Industry Reputation

A manufacturer’s reputation reflects its reliability. Platforms like Google Reviews, Trustpilot, or industry forums provide insights into customer satisfaction. Manufacturers with over 80% positive feedback are generally trustworthy, per a 2024 PCB Industry Survey.

How to Evaluate: Research online reviews and ask for references. Questions like “Can you share customer testimonials?” help gauge reputation.

10. Balancing Cost and Quality

Cost is a key factor, but the cheapest low-volume PCB assembly manufacturer may compromise quality. Conversely, high prices don’t always guarantee excellence. Compare quotes based on services, not just price.

How to Evaluate: Request detailed quotes, including DFM, testing, and shipping costs. Ask: “What services are included in your pricing?” Aim for a balance of affordability and reliability.

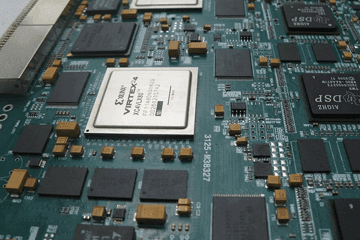

11. Inspecting Scale and Equipment

Modern equipment, like SPI solder paste inspectors, X-ray machines, and automated SMT lines, ensures precision in low-volume PCB assembly. A manufacturer with multiple SMT lines and 50+ staff can handle complex orders efficiently.

How to Evaluate: Ask about equipment and capacity. Questions like “How many SMT lines do you operate?” or “Do you use X-ray inspection?” reveal technical capabilities.

12. Confirming Certifications and Management Systems

Certifications like ISO 9001 (quality management), ISO 13485 (medical devices), or IATF 16949 (automotive) indicate a manufacturer’s commitment to standards. A robust factory management system, such as 5S or ESD (electrostatic discharge) protocols, ensures consistent quality.

How to Evaluate: Verify certifications and management practices. Ask: “Which certifications do you hold?” or “Do employees follow ESD protocols?”

Questions to Ask Your Low-Volume PCB Assembly Manufacturer

Before signing a contract, ask these critical questions to ensure alignment:

- What is your MOQ for low-volume orders?

- Can you provide a DFM report before production?

- How do you handle component shortages or design changes?

- What is your average lead time for 100-500 unit orders?

- Do you offer in-house testing and inspection services?

Conclusion: Partnering for Success

Choosing the right low-volume PCB assembly manufacturer requires thorough evaluation of quantity needs, flexibility, services, and more. A trusted partner like JHYPCB, with over 15 years of experience in prototype PCB assembly, SMT PCB assembly, and turnkey PCB services, can streamline your production process. Our advanced equipment, ISO 9001 certification, and robust supply chain ensure high-quality, on-time deliveries.

Ready to find the perfect low-volume PCB assembly partner? Contact JHYPCB today for a free quote and DFM analysis. Download our Low-Volume PCB Manufacturer Checklist to start your evaluation process.