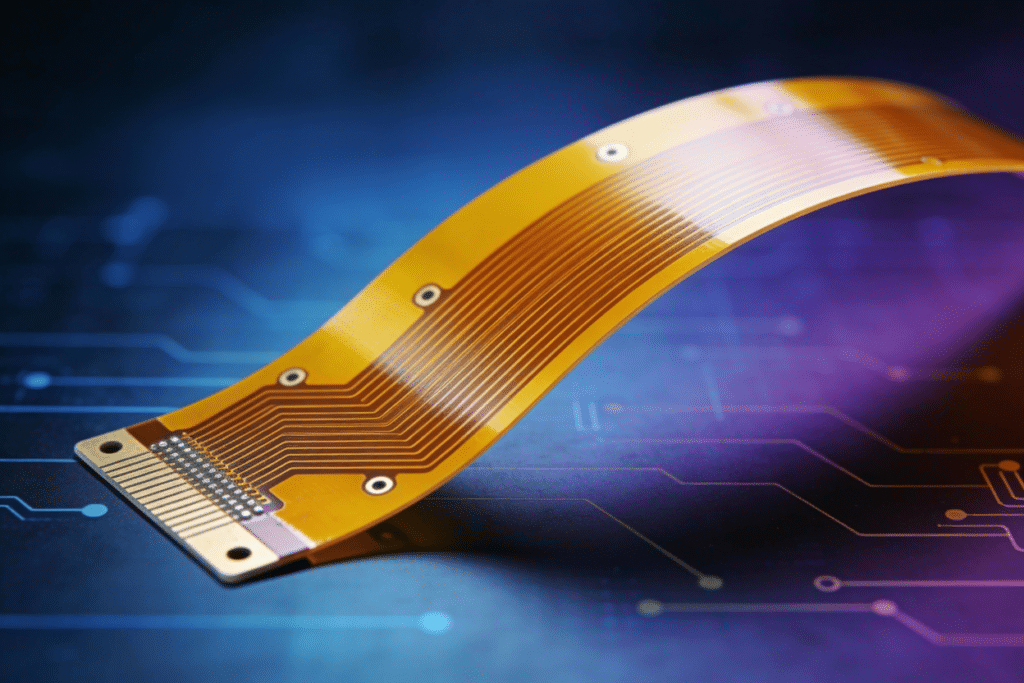

Flexible PCB Manufacturer & Flex PCB Fabrication

Custom single-layer, double-sided, and multilayer flexible PCBs for prototypes and production with fast turnaround and stable quality.

As a dedicated flexible PCB manufacturer in China, JHYPCB supports complex flex and rigid-flex designs for demanding applications.

24/48H quick-turn flex PCB prototype | ISO/UL certified factory | Serving global customers

Flexible PCB Manufacturing Capabilities

JHYPCB provides flexible PCB manufacturing capabilities from single-layer flex PCB prototypes to complex multilayer flexible PCBs and rigid-flex PCB solutions. As a flexible PCB manufacturer in China, we support quick-turn prototypes and stable production with reliable quality and engineering support.

Why Our Flex PCB Capabilities Matter

- Single-layer, double-sided, and multilayer flexible PCB manufacturing for prototypes and production.

- Flexible PCB fabrication using high-quality polyimide materials and reliable surface finishes.

- Minimum trace/space and hole size suitable for complex flex PCB and rigid-flex PCB designs.

- Quick-turn flexible PCB prototype service with low MOQ and stable process control.

Key Flexible PCB Capabilities

Layers

1–8 layer flexible PCBs (single-layer, double-sided, and multilayer flex)

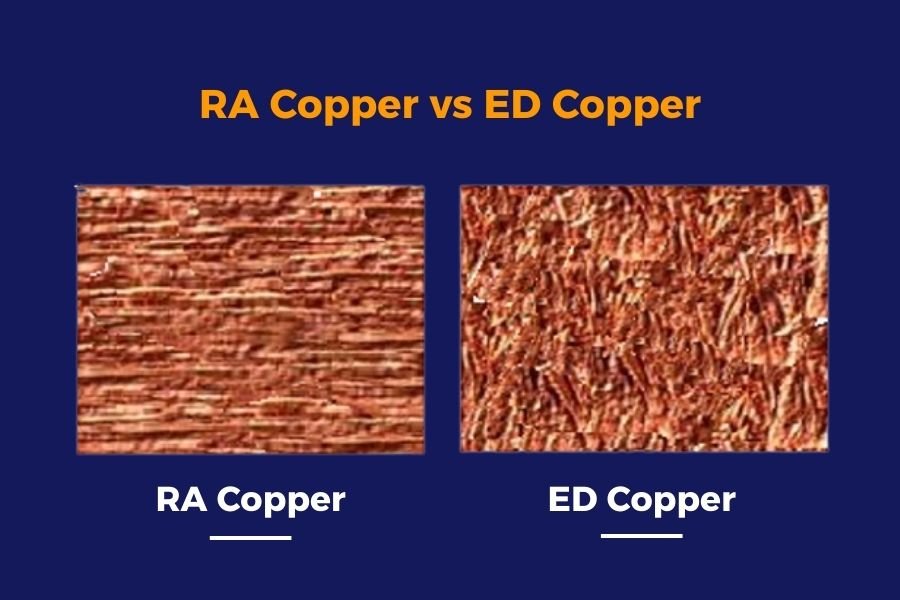

Material

Polyimide (PI) and other flexible laminates for flex PCB manufacturing

Thickness

Typical flex PCB thickness from 0.05 mm to 0.4 mm

Minimum Hole Size

Down to 0.1 mm for flex and rigid-flex PCB designs

Surface Finish

ENIG, OSP, Immersion Tin, and other options for flexible PCBs

Lead Time

Quick-turn flexible PCB prototype lead time from 24 hours for urgent projects

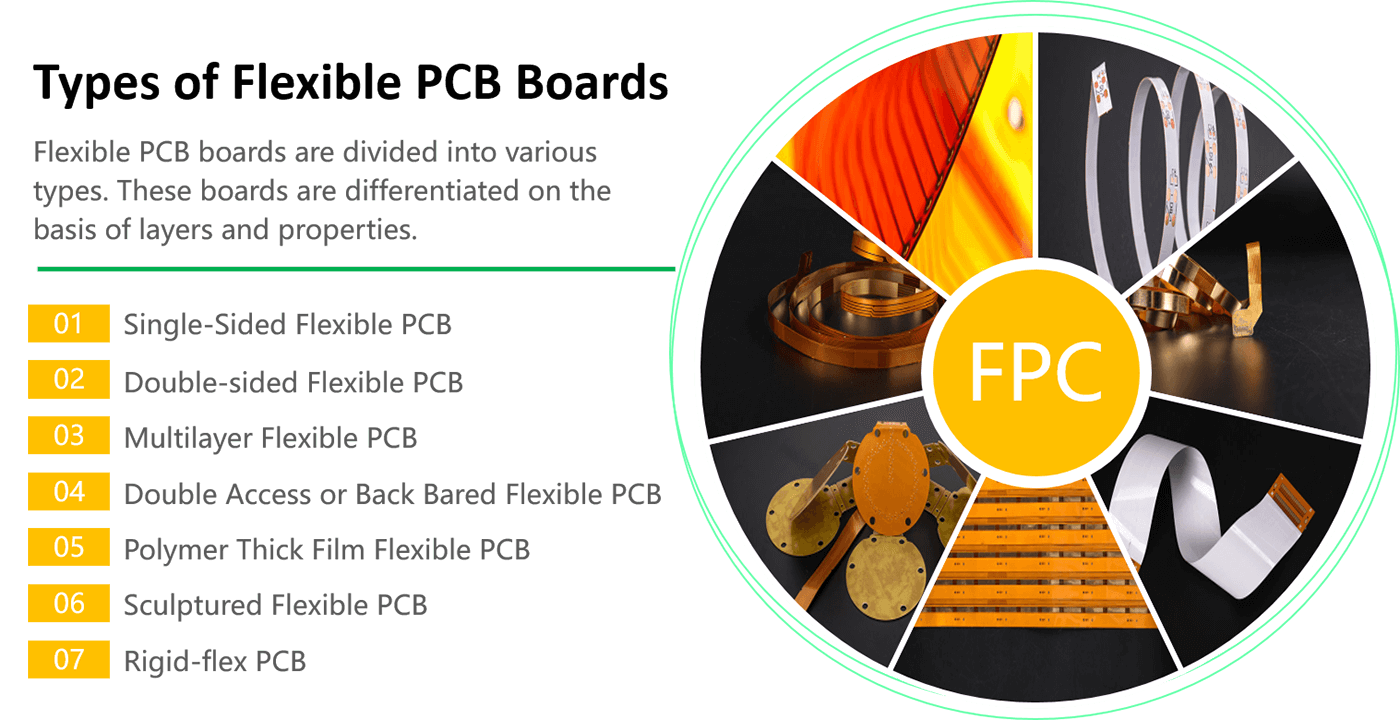

Types of Flexible PCBs We Manufacture

JHYPCB manufactures different types of flexible PCBs to match your prototype and production needs. From simple single-layer flex PCB to complex multilayer flexible PCB and rigid-flex PCB solutions, our flexible PCB manufacturing services cover a wide range of applications.

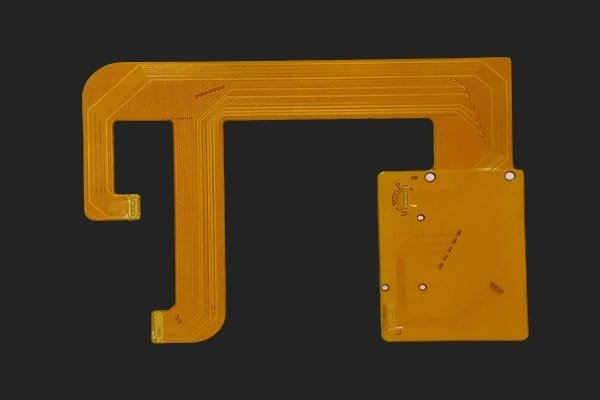

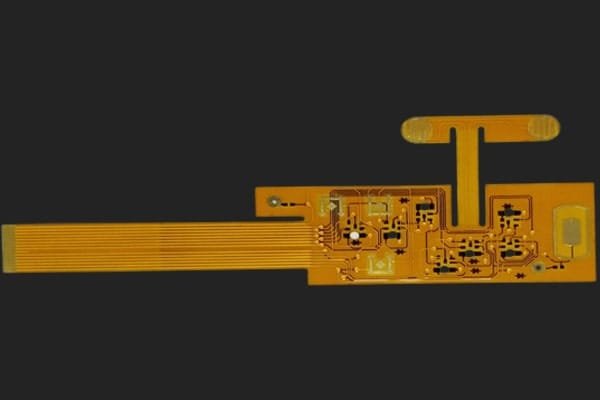

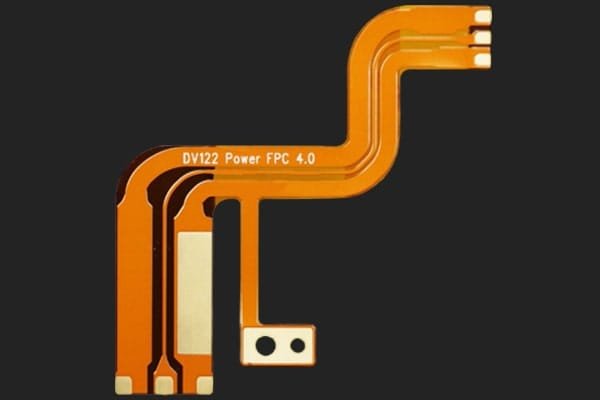

Single-Layer Flex PCB

Single-layer flexible PCBs use one copper layer on a flexible polyimide base and are ideal for simple interconnections, LED strips, and cost-sensitive applications. JHYPCB offers single-layer flex PCB prototypes and production with stable flexible PCB fabrication quality.

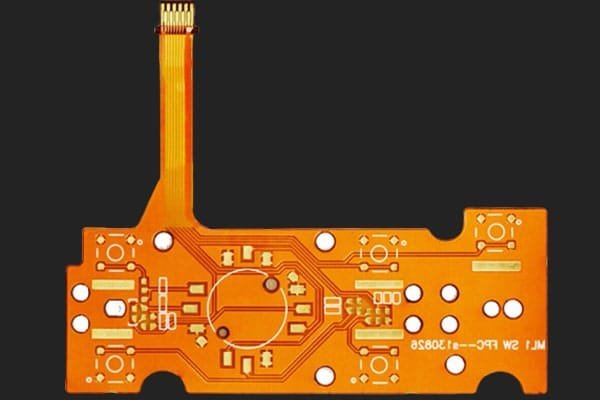

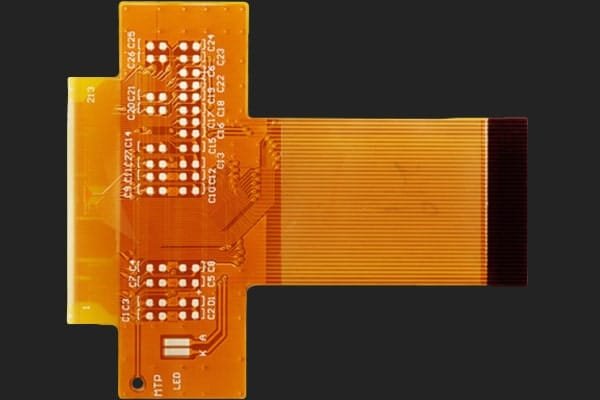

Double-Sided Flex PCB

Double-sided flex PCBs have copper on both sides of the flexible substrate and plated-through holes to connect the circuits, enabling more complex layouts and higher component density. Our double-sided flexible PCB manufacturing supports quick-turn prototypes and small to medium production runs.

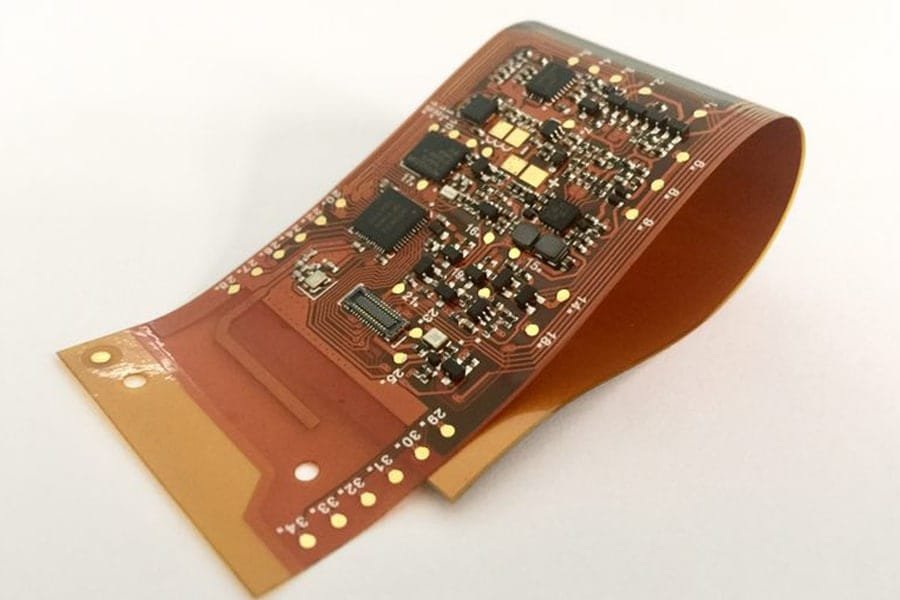

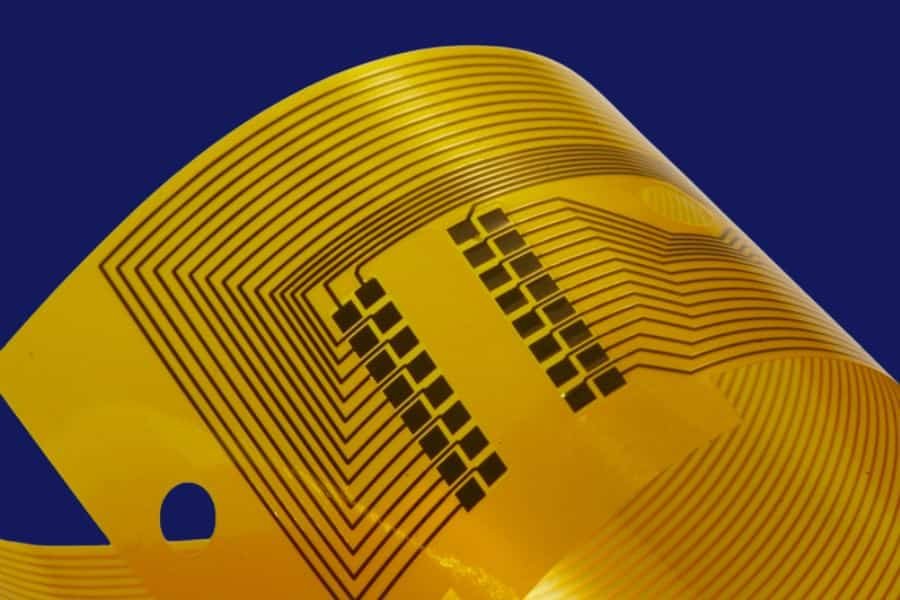

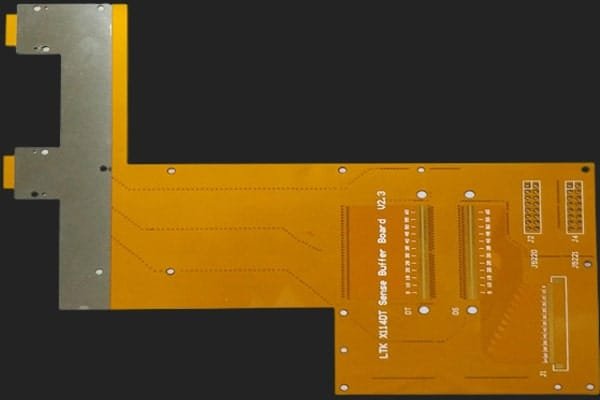

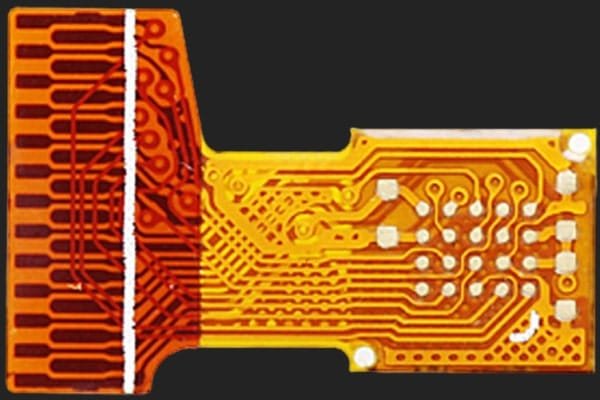

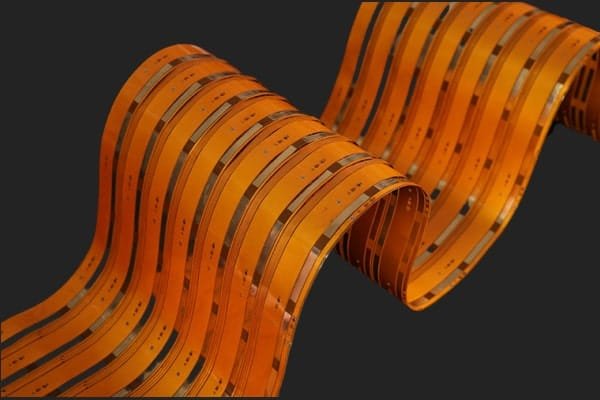

Multilayer Flexible PCB

Multilayer flexible PCBs stack three or more conductive layers separated by insulating films, providing high routing density for compact and complex electronics. JHYPCB’s multilayer flexible PCB fabrication is suitable for advanced devices that require controlled impedance and reliable dynamic bending performance.

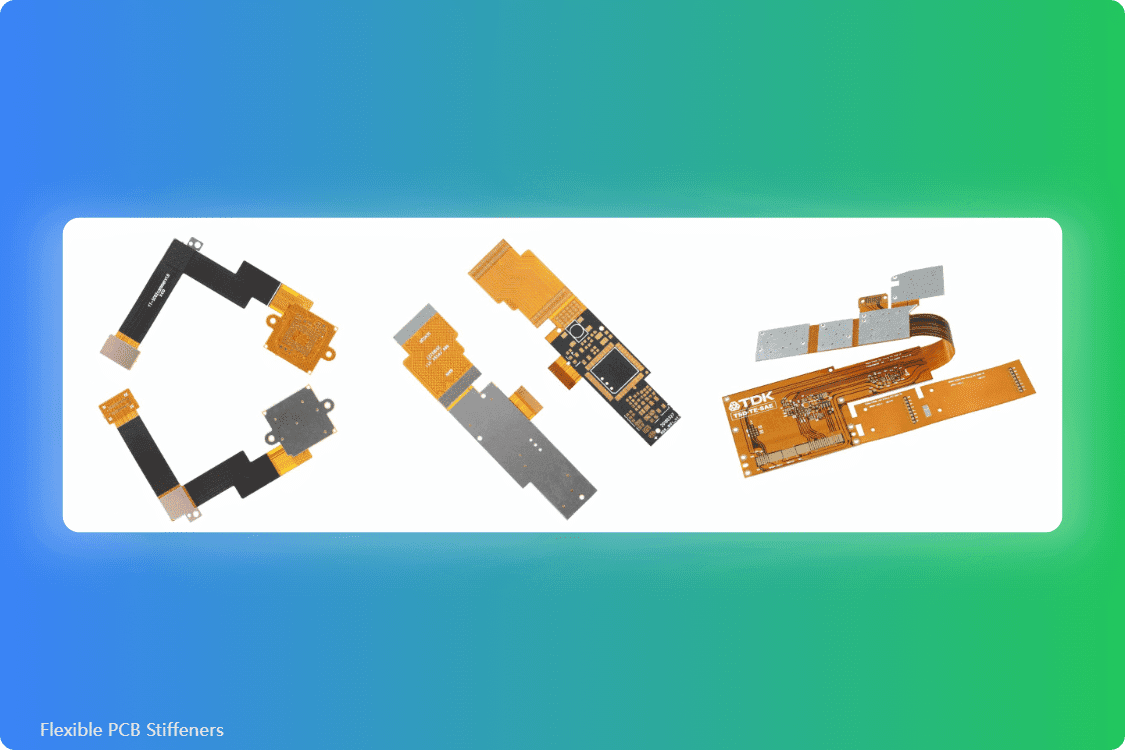

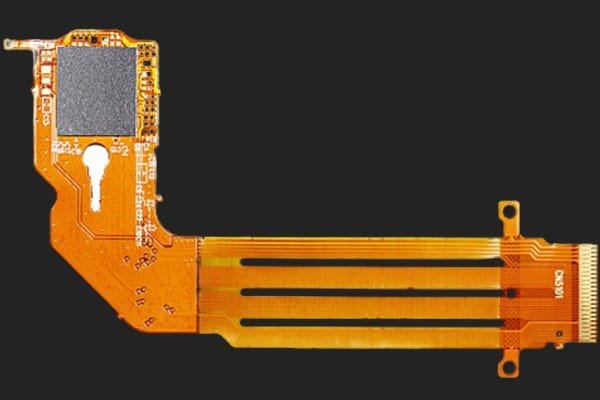

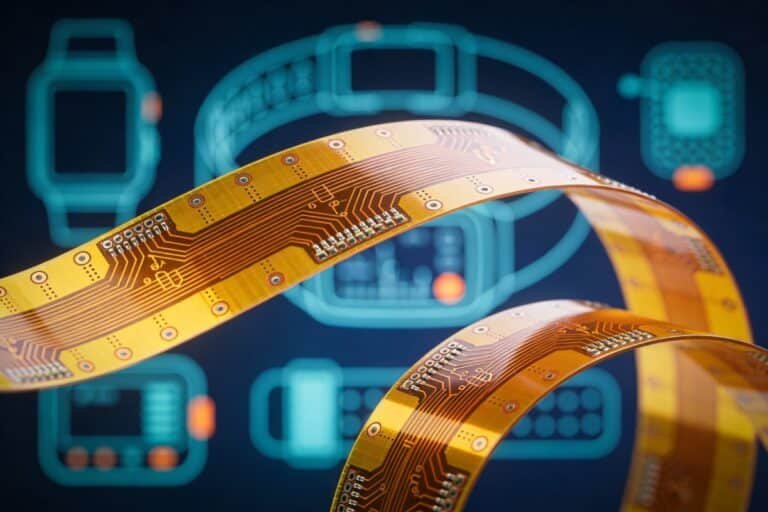

Rigid-Flex PCB Solutions

Rigid-flex PCBs combine rigid FR4 sections with flexible PCB layers to create a single, robust interconnect structure, reducing connectors and improving reliability. As a flexible PCB manufacturer with rigid-flex PCB capabilities, JHYPCB supports 1–12 layer rigid-flex PCB designs for space-constrained and mission-critical applications.

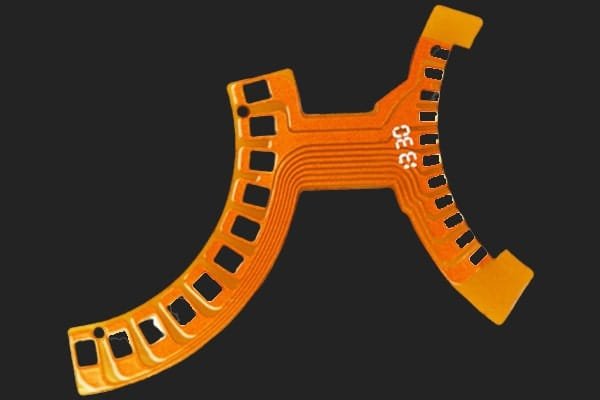

Flexible PCB Applications

Flexible PCBs are widely used in compact and lightweight electronic products where space saving and dynamic bending are critical. As a flexible PCB manufacturer, JHYPCB supplies flex PCB and rigid-flex PCB solutions for various industries and demanding applications.

Consumer Electronics

Wearable & Medical Devices

Automotive & Industrial Electronics

Telecom & Data Communication

Why Choose JHYPCB as Your Flexible PCB Manufacturer

Choosing a reliable flexible PCB manufacturer is critical for product performance, cost, and time-to-market. JHYPCB offers quick-turn flexible PCB prototype and stable production services with strict quality control, helping you bring flexible and rigid-flex designs to market faster and more reliably.

Quick-Turn Flex PCB Prototype

JHYPCB provides quick-turn flexible PCB prototype services to support fast design validation and engineering changes. Short lead times for flex PCB and rigid-flex PCB prototypes help you reduce development cycles and respond quickly to customer demands.

Stable Quality & Certifications

All flexible PCB manufacturing is carried out under strict process control with advanced production equipment and testing. With robust quality management and industry certifications, JHYPCB delivers stable, repeatable flex PCB performance even for demanding automotive and industrial applications.

Engineering Support for Flex & Rigid-Flex

Our engineering team supports customers early in the design phase with DFM reviews, stack-up suggestions, and material selection for flexible and rigid-flex PCBs. Involving the manufacturer early helps avoid redesigns, optimize reliability, and control total project cost.

Cost-Effective Manufacturing in China

As a flexible PCB manufacturer in China, JHYPCB combines efficient production, optimized material sourcing, and scalable capacity to offer competitive pricing. You can get high-quality flexible PCB fabrication without sacrificing cost control or delivery reliability.

Flexible PCB Manufacturing Process & Quality Control

Flexible PCB manufacturing follows a precise process from material preparation and circuit imaging to surface finish and final testing. JHYPCB applies strict process control and comprehensive inspection at each key step to ensure reliable flexible PCB and rigid-flex PCB performance.

Flexible PCB Manufacturing Process

Material Preparation & Cutting

Flexible copper-clad laminates and coverlay materials are inspected and cut to size according to the flex PCB design requirements.

Drilling & Hole Metallization

Precision drilling creates vias and holes, followed by copper plating to form reliable interlayer connections for single, double-sided, and multilayer flexible PCBs.

Circuit Imaging & Etching

Photoresist imaging transfers the circuit pattern to the copper, and controlled etching removes unwanted copper to form accurate flex PCB traces and pads.

Coverlay Lamination & Surface Finish

Coverlay is laminated to protect the flexible circuits, and surface finishes such as ENIG or OSP are applied for good solderability and long-term reliability.

Profiling, Forming & Final Inspection

Flexible PCBs are routed or punched to final shape, formed if required, and then undergo electrical test and visual inspection before packaging and shipment.

Flexible PCB Quality Control

Incoming Material Inspection

All flexible PCB base materials, coverlays, and chemicals are checked for thickness, adhesion, and appearance before entering production to prevent defects from the source.

In-Process AOI & Electrical Test

Automated optical inspection verifies trace width, spacing, and registration after circuit etching, followed by 100% electrical testing to detect opens and shorts.

Reliability & Bending Performance Checks

Item content. Click the edit button to change this text.

Final Inspection & Packaging

Before shipment, flexible PCBs undergo final visual inspection and sampling tests, and are packed with moisture and ESD protection for safe global delivery.

Get a Quote for

Your Flexible PCB

Share your flexible PCB design files and key specifications to receive a fast and accurate quotation. JHYPCB supports single-layer, double-sided, multilayer flexible PCBs and rigid-flex PCBs for both prototype and production orders.

You can upload Gerber, ODB++, or PDF files and include basic information such as board size, layer count, quantity, material, and surface finish. Our flexible PCB engineering team will review your design and get back to you with pricing and lead time as soon as possible.

Flexible PCB FAQs

Find quick answers to common questions about flexible PCB manufacturing, design options, lead times, and quotation requirements. These FAQs help you understand how JHYPCB supports your flex PCB and rigid-flex PCB projects from prototype to production.

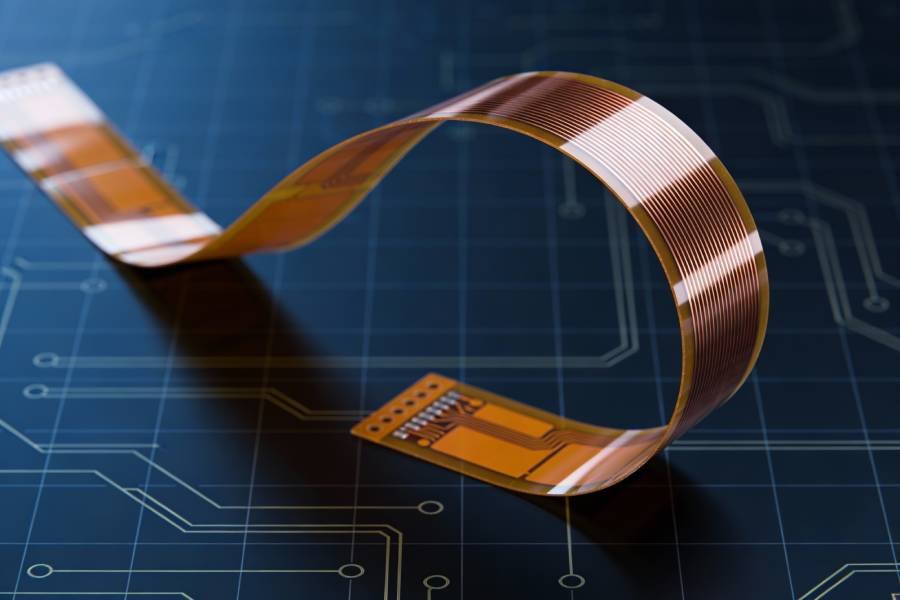

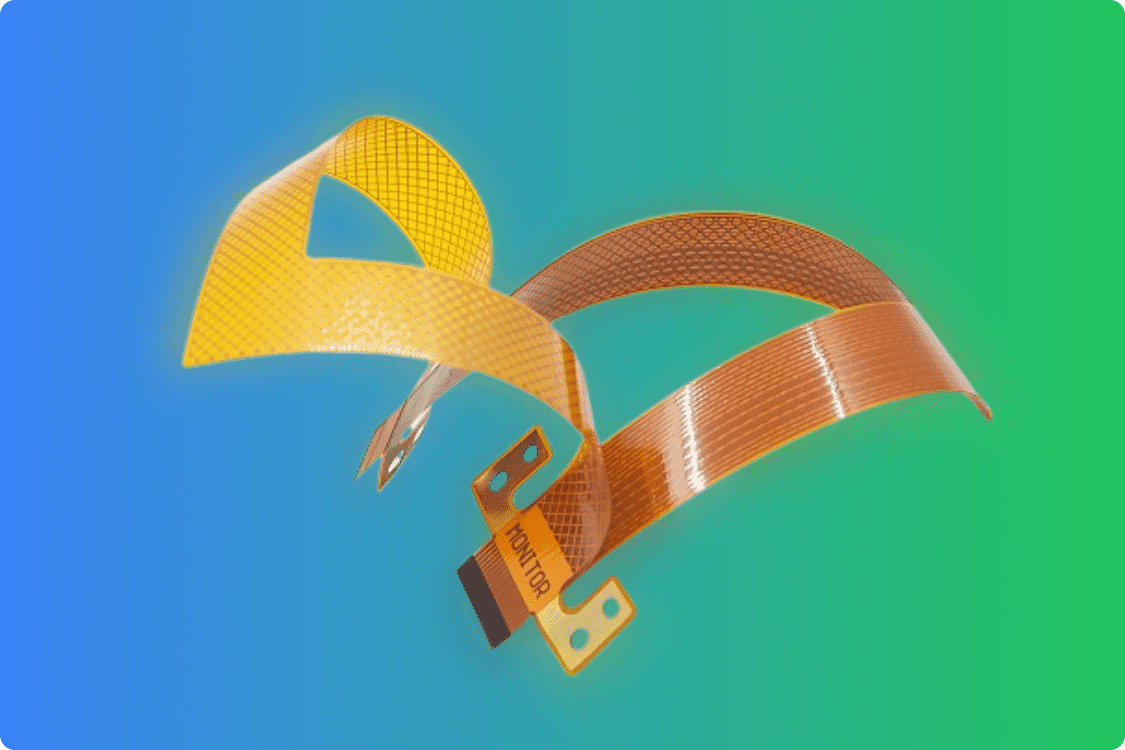

A flexible PCB, or flex PCB, is a printed circuit board built on a bendable polyimide or similar flexible substrate instead of rigid FR4 material. It allows the circuit to bend, fold, or twist to fit compact 3D spaces while maintaining reliable electrical connections.

A flex PCB is made entirely from flexible materials and is used mainly as a bendable interconnect between components or boards. A rigid-flex PCB combines rigid PCB sections with integrated flexible layers, forming a single structure that replaces separate rigid boards and cables or connectors.

For an accurate flexible PCB quotation, please provide Gerber or ODB++ files, layer count, board dimensions, material type, surface finish, copper thickness, quantity, and any special requirements such as impedance control or stiffeners. Clear application and reliability requirements also help our team recommend suitable flex PCB manufacturing options and pricing.

Typical lead times for flexible PCB prototypes range from about 2 to 7 working days depending on layer count, complexity, and special processes such as impedance control or rigid-flex structures. Urgent quick-turn flex PCB orders can often be produced faster after engineering review and confirmation.

Key design points for flexible PCBs include selecting suitable polyimide materials, controlling bend radius, choosing appropriate copper thickness, and avoiding sharp corners or abrupt trace direction changes in flex areas. Proper stiffener placement, coverlay openings, and component layout also improve reliability and manufacturability in flex and rigid-flex PCB designs.