Table of Contents

hy Choosing the Right Flexible PCB Manufacturer Matters

Flexible PCBs are transforming industries, from wearables and medical devices to automotive electronics. Their ability to bend and conform to unique shapes enables compact, innovative designs that rigid PCBs cannot achieve. However, the success of your product hinges on partnering with the right flexible PCB manufacturer. A trusted partner ensures high-quality boards, on-time delivery, and cost efficiency, helping you bring your vision to life.

In this guide, we outline six actionable steps to help you select a flexible PCB manufacturer that aligns with your project’s needs. Whether you’re developing a prototype or scaling production, these insights will guide you to the perfect partner.

Key Factors to Consider When Selecting a Flexible PCB Manufacturer

When evaluating flexible PCB manufacturers, focus on these critical factors to ensure a successful partnership:

- Technical Capabilities: The manufacturer should have advanced equipment and expertise in fine-line patterning, multi-layer boards, rigid-flex integration, and advanced materials like polyimide.

- Quality Control: Look for certifications like ISO 9001 and robust processes for first-article inspection, in-process checks, and final testing to guarantee consistent quality.

- Materials and Components: Ensure the manufacturer uses reliable, flex-grade materials (e.g., polyimide substrates, flexible adhesives) that withstand bending without compromising performance.

- Pricing and Lead Times: Competitive pricing and fast lead times are essential to meet budget and market demands. Negotiate to balance cost and quality.

- Production Capacity: Verify the manufacturer can handle your order volume and deliver on time without overbooking.

- Customer Service: Responsive communication and post-production support are vital for addressing issues and ensuring a smooth experience.

By prioritizing these factors, you’ll find a manufacturer capable of delivering high-quality flexible PCBs tailored to your needs.

6 Steps to Choose the Right Flexible PCB Manufacturer

Follow this structured approach to identify the ideal flexible PCB manufacturer for your project:

Step 1: Define Your Requirements

Clearly document your project specifications, including circuit design, material preferences, layer count, dimensional accuracy, and production volume. This creates a baseline for evaluating manufacturers. For example, specify if you need rigid-flex boards or high-density interconnects (HDI).

Step 2: Research Potential Manufacturers

Search for manufacturers with expertise in flexible PCBs. Explore company websites, industry directories, and trade publications. Create a shortlist of candidates with proven capabilities in flexible PCB manufacturing.

Step 3: Verify Qualifications

Review each candidate’s certifications (e.g., ISO 9001, UL) and technical capabilities. Ensure they have experience with complex flex PCB projects and adhere to industry standards. Narrow your list based on alignment with your requirements.

Step 4: Evaluate Past Work and Samples

Request samples of previous flexible PCB projects and review customer testimonials. If possible, contact past clients to gauge reliability and quality. This step provides insight into the manufacturer’s consistency and expertise.

Step 5: Compare Pricing and Lead Times

Request detailed quotes from shortlisted manufacturers. Compare pricing, lead times, and value-added services. Negotiate to optimize costs while ensuring quality. Confirm that lead times align with your project timeline.

Step 6: Validate Production Capacity

Ensure the manufacturer has sufficient capacity to handle your order volume without delays. Avoid partners with overbooked schedules, as this can lead to missed deadlines.

By following these steps, you’ll confidently select a manufacturer that meets your technical, budgetary, and timeline requirements.

How to Start Working with Your Chosen Manufacturer

Once you’ve shortlisted promising manufacturers, initiate collaboration with these steps:

- Send an RFQ: Share a detailed Request for Quote (RFQ) outlining your specifications, quantities, and quality expectations. Ask for a comprehensive response.

- Evaluate Responses: Review quotes for pricing, capabilities, and lead times. Seek clarification on any ambiguities.

- Engage in Discussions: Schedule calls or meetings to discuss your project with the manufacturer’s technical team. Build rapport and align goals.

- Conduct Facility Audits: Visit the manufacturer’s facility to observe their processes, quality systems, and ongoing projects. This ensures transparency and reliability.

- Establish a Partnership: Maintain open communication, sign NDAs if needed, and clarify roles to foster a long-term relationship.

These steps ensure a smooth start to your collaboration, setting the stage for a successful project.

Why Choose JHYPCB for Your Flexible PCB Needs

At JHYPCB, we bring over a decade of expertise in flexible PCB manufacturing, empowering innovative products worldwide. Our key advantages include:

- Cutting-Edge Technology: Advanced capabilities for fine-line patterning, multi-layer boards, and rigid-flex integration.

- Rigorous Quality Control: ISO 9001-certified processes with comprehensive testing at every stage.

- Fast Turnaround: Rapid prototyping and high-volume production to meet tight deadlines.

- Dedicated Support: Responsive customer service to guide you from concept to completion.

- Competitive Pricing: High-value solutions tailored to your budget.

Ready to bring your flexible PCB project to life? Contact JHYPCB today for a quote or to discuss your needs with our expert team.

FAQs About Flexible PCB Manufacturing

What is a flexible PCB?

A flexible PCB is a circuit board made from flexible materials like polyimide, allowing it to bend and conform to unique shapes. It’s ideal for compact devices in industries like medical, automotive, and wearables.

Why is ISO 9001 certification important for a PCB manufacturer?

ISO 9001 ensures the manufacturer follows strict quality management standards, resulting in consistent, high-quality products and reliable processes.

How long does it take to manufacture a flexible PCB?

Lead times vary based on complexity and volume but typically range from 1-4 weeks for prototypes and 4-8 weeks for production runs. Contact JHYPCB for precise timelines.

Can flexible PCBs be used in high-volume production?

Yes, with the right manufacturer, flexible PCBs can be produced at scale while maintaining quality. JHYPCB offers high-mix production capacity for large orders.

How do I request a quote for flexible PCB manufacturing?

Submit an RFQ with your specifications to JHYPCB’s contact page. Our team will respond promptly with a detailed quote.

Conclusion

Choosing the right flexible PCB manufacturer is critical to your product’s success. By focusing on technical capabilities, quality control, and production capacity, and following our 6-step guide, you can find a partner that delivers high-quality boards on time and within budget.

At JHYPCB, we’re committed to helping you realize your product vision with cutting-edge flexible PCB solutions. Get in touch today to start your project and experience our industry-leading expertise!

Related Posts

- Custom Flex PCB:Tailored Solutions for Your Applications

- Custom PCB Fabrication in China – Prototyping & Mass Production

- Expedited PCB Services – Quick Turnaround for Your Urgent Needs

- JHYPCB: The Best Prototype PCB Manufacturer for Your Needs

- Rapid PCB Prototyping Services: A Comprehensive Introduction

- Introduction to Semi-Flex PCBs: Bridging Rigid and Flex PCBs

- Layer Stackup in Rigid-Flex PCB

- What Are The Types of Flexible Circuit Boards?

- Why is Flexible PCB so Expensive?

- The Manufacturing Process Of Double-sided Flexible PCB Coverlay

- What Are The Advantages And Applications Of Rigid-Flex PCBs?

- Rigid PCB vs Flex PCB: What Is The Difference?

- How to Solder On Flex PCB?

- Flexible Printed Circuit For Today’s Packaging

- 16 Factors Affecting The Cost And Price of Flexible PCB

- Complete Introduction of Flexible Circuit Board Materials

- The terms you have to know related to the manufacture of Flexible PCB

- Knowledge of Flexible PCB Manufacturing Process Steps

- Knowledge of Plating on Flexible Circuit Board Surface

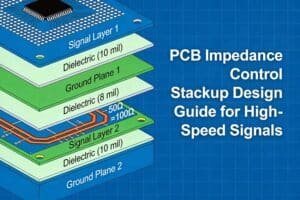

- Five factors that FPC PCB designers should know about impedance control

- Key Process Flow of Rigid-Fled PCB Production