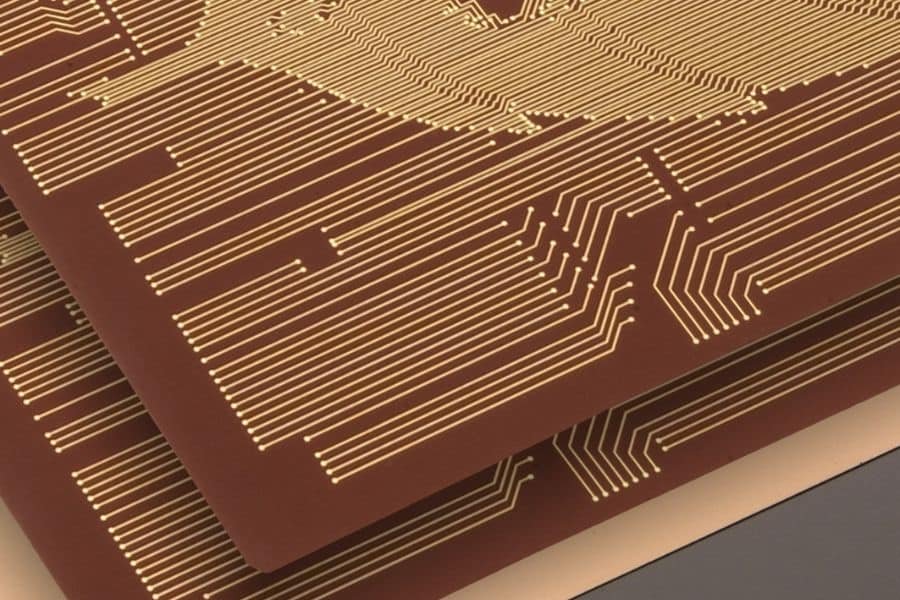

In the world of PCB manufacturing, Tg (Glass Transition Temperature) plays a crucial role in determining board performance under heat and stress. High Tg PCBs, with Tg values typically above 150°C, offer superior thermal stability, mechanical strength, and high-frequency capabilities compared to ordinary Tg PCBs (usually below 130°C). This makes them ideal for high-heat environments like automotive, aerospace, and telecommunications, where ordinary boards may fail due to warping or signal loss. If you’re designing for reliability in extreme conditions, high Tg PCBs provide better heat resistance, lower thermal expansion, and enhanced durability, ensuring long-term performance without compromising on environmental standards.