Table of Contents

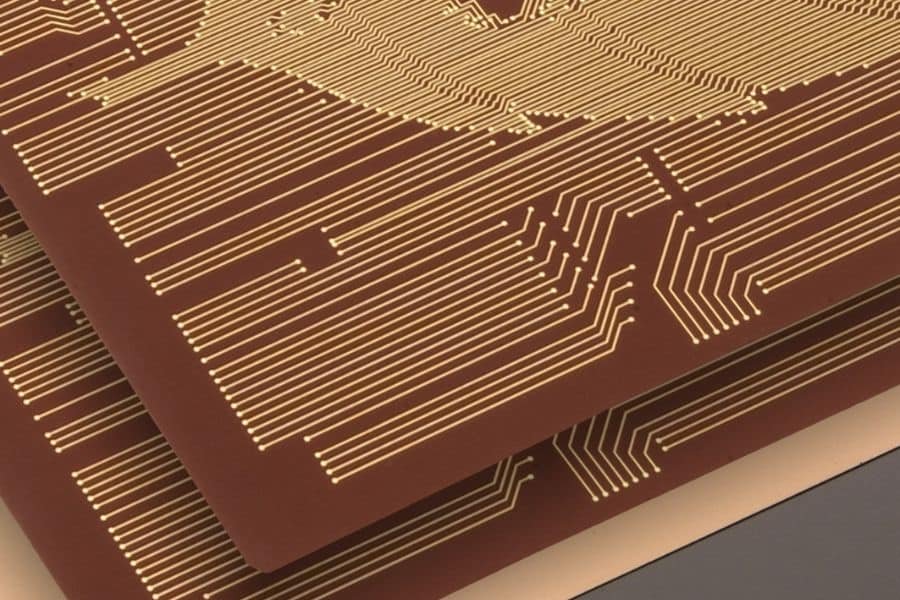

What Are High Tg PCB Materials?

In the realm of PCB manufacturing, High Tg PCB materials are engineered to withstand elevated temperatures without compromising structural integrity or electrical performance. The term “Tg” refers to the Glass Transition Temperature, the point at which a PCB substrate transitions from a rigid to a softened state, typically measured in degrees Celsius (°C). Standard FR4 materials have a Tg of approximately 130-140°C, while High Tg PCBs, with a Tg of 170°C or higher, offer superior thermal stability for demanding applications. For instance, in high-temperature environments like automotive engine control units or industrial power modules, standard PCBs risk delamination or warpage, leading to circuit failure. High Tg materials mitigate these risks by maintaining mechanical strength and dimensional stability under thermal stress. At JHYPCB, a leading PCB manufacturer in China, we specialize in High Tg PCB fabrication and assembly, ensuring reliability for industries such as aerospace, automotive, and consumer electronics. This guide explores the benefits, types, applications, and selection criteria of High Tg materials, providing actionable insights for engineers and designers. Contact us at sales@pcbjhy.com to discuss your project needs, and read on to understand why High Tg PCBs are critical for high-performance electronics.

Advantages and Benefits of High Tg PCB Materials

High Tg PCB materials, with a glass transition temperature (Tg) of 170°C or higher, deliver superior performance in high-temperature environments compared to standard FR4 PCBs (Tg ≈ 130-140°C). At JHYPCB, we leverage these materials to ensure reliability for demanding applications. Below, we outline the key advantages of High Tg PCBs, supported by technical insights and practical benefits for engineers and manufacturers.

Enhanced Thermal Stability

High Tg materials maintain structural integrity at elevated temperatures, resisting softening or deformation. This is critical for applications like automotive engine control units, where temperatures often exceed 150°C. Unlike standard FR4, which risks delamination under thermal stress, High Tg PCBs ensure consistent performance, extending circuit lifespan.

Reduced Coefficient of Thermal Expansion (CTE)

High Tg substrates exhibit lower CTE, minimizing dimensional changes during thermal cycling. For multilayer PCBs, this reduces stress on vias and solder joints, preventing cracks. For instance, in LED lighting, High Tg materials maintain alignment, ensuring reliable electrical connections.

Improved Mechanical Strength

High Tg PCBs offer superior mechanical durability, resisting warpage and bending under heat. This is vital for dense assemblies in industrial power modules, where robust substrates enhance longevity and reduce maintenance costs.

Enhanced Electrical Performance

With better dielectric stability at high temperatures, High Tg materials support consistent signal integrity, crucial for high-frequency applications like aerospace radar systems. They also resist moisture absorption, reducing the risk of electrical failures in humid environments.

| Property | Standard FR4 (Tg: 130-140°C) | High Tg FR4 (Tg: 170-180°C) |

|---|---|---|

| Thermal Stability | Limited above 130°C | Stable up to 170°C+ |

| CTE (ppm/°C) | ~14-18 | ~10-14 |

| Moisture Absorption | Moderate | Low |

| Typical Applications | Consumer electronics | Automotive, aerospace |

Common Types of High Tg PCB Materials

High Tg PCB materials, characterized by a glass transition temperature (Tg) of 170°C or higher, are tailored for applications requiring robust thermal and mechanical performance. As a leading PCB manufacturer in China, JHYPCB leverages a range of High Tg materials to meet diverse industry needs, from automotive to aerospace. This section explores the most common types—High Tg FR4, Polyimide, and PTFE-based substrates—detailing their properties, applications, and trade-offs to guide material selection.

High Tg FR4

High Tg FR4, an enhanced version of standard FR4, offers a Tg of 170-180°C, making it a cost-effective choice for applications like automotive electronics and industrial controls. Its epoxy-based composition, often reinforced with ceramic fillers, improves thermal stability and reduces the coefficient of thermal expansion (CTE). At JHYPCB, we frequently use High Tg FR4 for multilayer PCBs, balancing performance and affordability.

Polyimide

Polyimide substrates, with a Tg exceeding 200°C, excel in extreme environments, such as aerospace avionics and military electronics. They provide superior chemical resistance and flexibility, ideal for flex or rigid-flex PCBs. However, their higher cost limits widespread use. JHYPCB’s advanced lamination processes ensure Polyimide PCBs meet stringent reliability standards.

PTFE-Based Materials (e.g., Rogers)

PTFE-based substrates, like Rogers materials, combine High Tg (often >200°C) with excellent dielectric properties, making them suitable for high-frequency applications, such as 5G antennas and radar systems. Their low dielectric loss enhances signal integrity, but complex processing increases costs.

Material Type | Tg Range (°C) | Key Features | Applications | Cost Level |

|---|---|---|---|---|

High Tg FR4 | 170-180 | Cost-effective, low CTE, reliable | Automotive, industrial controls | Moderate |

Polyimide | 200-250 | High thermal/chemical resistance | Aerospace, military, flex PCBs | High |

PTFE (e.g., Rogers) | 200+ | Low dielectric loss, high-frequency | 5G, radar, RF applications | Very High |

Selecting the right High Tg material depends on your project’s thermal, electrical, and budget requirements. JHYPCB offers expert consultation and prototyping to ensure optimal material performance. Contact us at sales@pcbjhy.com to discuss your High Tg PCB needs and explore our comprehensive manufacturing solutions.

Applications of High Tg PCBs Across Industries

High Tg PCB materials, with a glass transition temperature (Tg) of 170°C or higher, are critical for electronics operating in extreme thermal environments. As a trusted PCB manufacturer in China, JHYPCB leverages High Tg materials to deliver reliable solutions for diverse industries. This section explores key applications in automotive, aerospace, industrial equipment, and consumer electronics, highlighting how High Tg PCBs enhance performance and durability.

Automotive Electronics

In automotive applications, High Tg PCBs ensure reliability under high temperatures and vibrations. Engine control units (ECUs) and battery management systems (BMS) often operate near 150°C. High Tg FR4, with its low CTE and thermal stability, prevents delamination and maintains signal integrity. For example, JHYPCB supplied multilayer High Tg PCBs for an automotive supplier’s ECU, ensuring consistent performance in harsh conditions.

Aerospace and Defense

Aerospace electronics, such as satellite communication systems and avionics, demand materials that withstand extreme temperatures and radiation. Polyimide-based High Tg PCBs, with Tg exceeding 200°C, provide superior chemical resistance and durability.

Industrial Equipment

High Tg PCBs are vital for industrial applications like variable frequency drives and welding machines, where thermal cycling is common. Their enhanced mechanical strength resists warpage, ensuring long-term reliability.

Consumer Electronics

In high-power consumer devices, such as fast-charging adapters and LED lighting, High Tg materials prevent thermal degradation. Their low moisture absorption ensures stable performance in humid environments, enhancing product lifespan.

| Industry | Typical Application | High Tg Material Used | Key Benefit |

|---|---|---|---|

| Automotive | ECUs, BMS | High Tg FR4 | Thermal stability, low CTE |

| Aerospace | Avionics, satellites | Polyimide | High Tg, chemical resistance |

| Industrial Equipment | Welding machines, drives | High Tg FR4 | Mechanical durability |

| Consumer Electronics | LED lighting, chargers | High Tg FR4, PTFE | Moisture resistance, longevity |

How to Choose the Right High Tg PCB Material

Selecting the appropriate High Tg PCB material, with a glass transition temperature (Tg) of 170°C or higher, is critical to ensuring reliability in high-temperature applications. As a leading PCB manufacturer in China, JHYPCB provides expert guidance to help engineers and designers make informed decisions. This section outlines a step-by-step approach to choosing High Tg materials, balancing performance, cost, and project requirements.

Step 1: Assess Operating Environment

Evaluate the maximum operating temperature and thermal cycling conditions of your application. For example, automotive engine control units may require a Tg of 170-180°C, while aerospace avionics may need Polyimide with a Tg above 200°C. Consider environmental factors like humidity, as High Tg materials like PTFE offer low moisture absorption.

Step 2: Verify Tg and Td Values

Check the material’s Tg and thermal decomposition temperature (Td) against your project’s thermal profile. Tg indicates the point of softening, while Td (typically 300°C+) marks material degradation. JHYPCB recommends materials compliant with IPC-4101 standards, ensuring reliable performance data.

Step 3: Consider Layer Count and Thickness

High Tg materials are often used in multilayer PCBs, where low CTE prevents via cracking. Thicker boards may require robust materials like High Tg FR4 for cost-efficiency.

Step 4: Balance Cost and Performance

High Tg FR4 is economical for most applications, while Polyimide or PTFE suits specialized needs but increases costs. Assess trade-offs using material datasheets. JHYPCB offers free consultation to optimize material selection within budget constraints.

Step 5: Avoid Common Pitfalls

Mismatching CTE between layers can cause delamination, and overlooking Td may lead to material failure. Use testing methods like Differential Scanning Calorimetry (DSC) to validate material properties. JHYPCB’s prototyping services help verify selections early.

Consideration | Key Question | Recommended Action |

|---|---|---|

Operating Temperature | Does it exceed 150°C? | Choose Tg ≥ 170°C (e.g., High Tg FR4) |

Layer Count | Is it a multilayer PCB? | Prioritize low CTE materials |

Budget | Can you afford premium materials? | Balance with High Tg FR4 if viable |

JHYPCB’s expertise in High Tg PCB manufacturing ensures optimal material choices for your project. Contact us at sales@pcbjhy.com for free consultation and prototyping services to achieve reliable, high-performance PCBs.

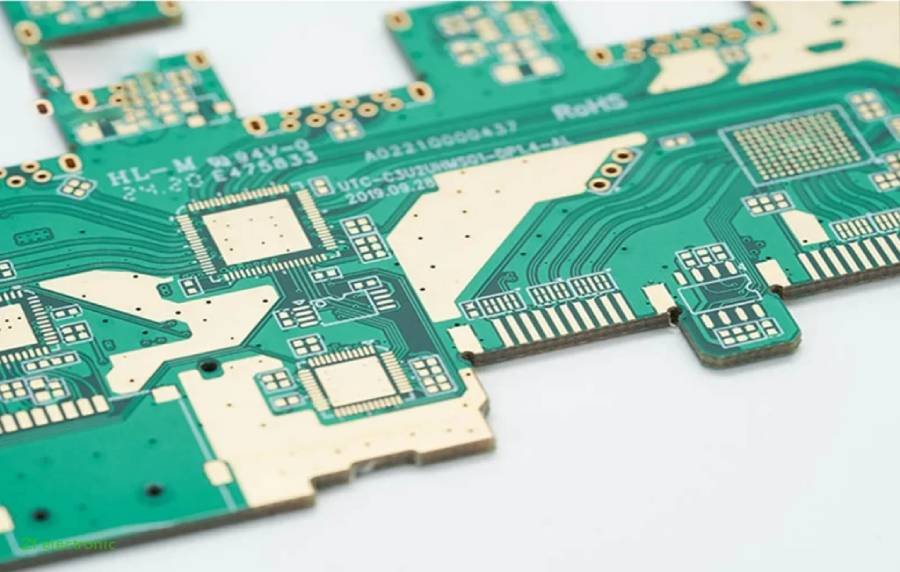

Manufacturing Process and Considerations for High Tg PCBs

The manufacturing of High Tg PCBs, with a glass transition temperature (Tg) of 170°C or higher, requires specialized processes to ensure thermal stability and reliability. As a leading PCB manufacturer in China, JHYPCB employs advanced equipment and stringent quality controls to produce High Tg PCBs for demanding applications. This section outlines the key manufacturing steps and critical considerations to achieve optimal performance.

Lamination Process

High Tg materials, such as High Tg FR4 or Polyimide, demand precise temperature and pressure control during lamination to prevent voids or delamination. Unlike standard FR4, High Tg substrates require higher curing temperatures (e.g., 180-200°C) to bond layers effectively. JHYPCB’s automated lamination systems ensure uniform pressure distribution, minimizing internal stresses.

Drilling and Plating

Drilling High Tg materials is challenging due to their enhanced mechanical strength. High-speed, laser-assisted drilling is often used to achieve precise via formation without microcracks. Electroless copper plating must account for the material’s low CTE to ensure reliable interconnects. JHYPCB adheres to IPC-6012 standards for consistent via integrity.

Surface Mount Technology (SMT) Compatibility

High Tg PCBs are well-suited for SMT assembly, as they withstand reflow soldering temperatures (up to 260°C). However, careful thermal profiling is essential to avoid board warpage. JHYPCB’s advanced reflow ovens and real-time monitoring ensure compatibility with complex assemblies.

Key Considerations

Thermal Management: Overheating during lamination or soldering can degrade Tg properties. Use controlled cooling to prevent thermal shock.

Material Consistency: Variations in resin content or filler distribution can affect performance. JHYPCB sources materials compliant with IPC-4101.

Quality Testing: Employ tests like Differential Scanning Calorimetry (DSC) to verify Tg and Thermal Mechanical Analysis (TMA) for CTE. JHYPCB conducts 100% quality inspections.

Manufacturing Step | Challenge | JHYPCB Solution |

|---|---|---|

Lamination | Voids, delamination | Automated pressure control |

Drilling | Microcracks | Laser-assisted precision drilling |

SMT Assembly | Warpage | Optimized thermal profiling |

JHYPCB’s expertise in High Tg PCB manufacturing ensures defect-free boards for high-temperature applications. Contact us to leverage our advanced processes and quality assurance for your next project.

High Tg PCBs vs. Other High-Temperature Solutions

High Tg PCBs, with a glass transition temperature (Tg) of 170°C or higher, are a cornerstone for high-temperature electronics, but other solutions like ceramic PCBs and metal-core PCBs (MCPCBs) also address thermal challenges. As a leading PCB manufacturer in China, JHYPCB helps clients choose the optimal substrate for their needs. This section compares High Tg PCBs with ceramic and metal-core alternatives, evaluating cost, performance, and applications to guide informed decisions.

High Tg PCBs

High Tg PCBs, such as High Tg FR4 or Polyimide, offer a Tg of 170-250°C, balancing cost and thermal stability. They excel in multilayer designs for automotive and aerospace applications, providing low CTE and reliable electrical performance. However, they may not match the thermal conductivity of other solutions.

Ceramic PCBs

Ceramic PCBs, made from materials like alumina or aluminum nitride, operate at temperatures exceeding 300°C and offer superior thermal conductivity (20-200 W/m·K). Ideal for high-power RF modules, their high cost and brittleness limit use in complex, multilayer designs. JHYPCB recommends ceramics for niche, high-heat applications.

Metal-Core PCBs (MCPCBs)

MCPCBs, with aluminum or copper cores, excel in heat dissipation (1-10 W/m·K), making them suitable for LED lighting and power electronics. Their lower Tg (typically <130°C) restricts use in extreme thermal cycling. JHYPCB’s expertise ensures precise MCPCB fabrication for thermal management.

Substrate Type | Tg Range (°C) | Thermal Conductivity (W/m·K) | Cost | Applications |

|---|---|---|---|---|

High Tg PCB | 170-250 | 0.3-0.5 | Moderate | Automotive, aerospace, multilayer |

Ceramic PCB | 300+ | 20-200 | High | RF modules, high-power circuits |

MCPCB | <130 | 1-10 | Low | LED lighting, power electronics |

Choosing between these solutions depends on thermal, electrical, and budget requirements. High Tg PCBs offer versatility for most high-temperature needs, while ceramics and MCPCBs suit specialized cases. JHYPCB’s consultation and prototyping services help optimize your choice.

Frequently Asked Questions (FAQ) About High Tg PCBs

High Tg PCBs, with a glass transition temperature (Tg) of 170°C or higher, are critical for high-temperature applications, but they raise common questions among engineers and designers. As a leading PCB manufacturer in China, JHYPCB addresses these queries with expertise to guide your project decisions. Below are answers to frequently asked questions about High Tg PCBs.

What Is the Minimum Tg for a High Tg PCB?

A High Tg PCB typically has a Tg of 170°C or above, compared to standard FR4’s 130-140°C. This ensures stability in environments exceeding 150°C, such as automotive ECUs.

Are High Tg PCBs More Expensive Than Standard PCBs?

Yes, High Tg materials like FR4 High Tg or Polyimide are costlier due to advanced resin systems and processing. However, their reliability reduces long-term failure costs. JHYPCB offers cost-effective solutions to balance performance and budget.

How Do I Verify the Quality of High Tg Materials?

Quality is verified through tests like Differential Scanning Calorimetry (DSC) for Tg and Thermal Mechanical Analysis (TMA) for CTE. JHYPCB adheres to IPC-4101 standards, ensuring material consistency with 100% quality inspections.

Can High Tg PCBs Be Used in Flexible Circuits?

Yes, materials like Polyimide enable High Tg flexible or rigid-flex PCBs, ideal for aerospace or wearables.

When Should I Choose High Tg Over Ceramic or MCPCB?

High Tg PCBs are versatile for multilayer designs with moderate thermal needs (170-250°C). For extreme heat (>300°C), ceramics excel; for heat dissipation, MCPCBs are preferred.

Do High Tg PCBs Support High-Frequency Applications?

High Tg materials like PTFE (e.g., Rogers) support high-frequency signals due to low dielectric loss. JHYPCB optimizes these substrates for 5G and RF applications.

Question | Key Consideration | JHYPCB Solution |

|---|---|---|

Minimum Tg for High Tg PCB | Tg ≥ 170°C | High Tg FR4, Polyimide options |

Cost vs. Standard PCB | Higher due to materials, processing | Cost-effective manufacturing |

Quality Verification | DSC, TMA tests | IPC-4101 compliance, full testing |

Why Choose JHYPCB as Your High Tg PCB Partner

High Tg PCBs, with a glass transition temperature (Tg) of 170°C or higher, are indispensable for electronics operating in high-temperature environments, offering superior thermal stability, low CTE, and reliable performance. As explored in this guide, these materials—ranging from High Tg FR4 to Polyimide—cater to diverse industries like automotive, aerospace, and consumer electronics. Their manufacturing demands precision, from lamination to SMT assembly, to ensure durability and signal integrity. Choosing the right material involves balancing thermal, electrical, and cost requirements, a process JHYPCB streamlines with expert guidance.

At JHYPCB, a leading PCB manufacturer in China, we specialize in High Tg PCB fabrication and assembly, delivering tailored solutions from prototyping to full-scale production. Our adherence to IPC-4101 and IPC-6012 standards ensures quality, while our advanced equipment and rigorous testing (e.g., DSC, TMA) guarantee reliability. Whether you need multilayer High Tg FR4 for automotive ECUs or Polyimide for aerospace avionics, our comprehensive services—including component sourcing and SMT assembly—meet your needs efficiently. We’ve empowered clients worldwide with high-performance PCBs that withstand extreme conditions, ensuring long-term success.

Ready to elevate your project with High Tg PCBs? JHYPCB offers free consultations and rapid prototyping to bring your designs to life. Contact us at sales@pcbjhy.com to discuss your requirements and partner with a trusted manufacturer committed to quality and innovation.