Table of Contents

Introduction

Printed Circuit Boards (PCBs) are the foundation of modern electronics, enabling everything from IoT devices to advanced driver assistance systems (ADAS). As a leading PCB manufacturer in China, JHYPCB specializes in PCB fabrication (rigid, flexible, rigid-flex) and assembly services (SMT, THT, turnkey). A critical question for engineers and designers is: What are PCB boards made of? The materials used in PCBs directly influence their performance, durability, and cost. This comprehensive guide examines the key components of PCBs, with a particular focus on common substrates, and offers actionable insights for selecting the ideal materials. As the first in a series, this article sets the stage for in-depth exploration of PCB material topics, ensuring you have the knowledge to optimize your next project.

Core Components of a PCB: What Are PCB Boards Made Of?

To answer “What are PCB boards made of?”, let’s break down the essential materials that form a PCB. Each component plays a unique role in ensuring functionality, reliability, and manufacturability.

1. Substrate (Laminate)

The substrate, or laminate, is the backbone of a PCB, providing structural support and defining its electrical and thermal properties. Whether rigid, flexible, or rigid-flex, the substrate is critical to the board’s performance. Below, we explore the most common PCB substrates, their properties, and their applications to help you make informed decisions.

Common PCB Substrates

Choosing the right substrate is pivotal for meeting design requirements, from cost constraints to high-frequency performance. Here are the most widely used PCB substrates in 2025:

- FR-4 (Flame Retardant 4): The industry standard, FR-4 is a woven fiberglass epoxy resin laminate known for its affordability, mechanical strength, and flame-retardant properties. It’s versatile, supporting single-sided, double-sided, and multilayer PCBs. FR-4 is ideal for consumer electronics, automotive systems, and industrial controls due to its balance of cost and performance.

Key Benefits: Good dielectric properties, dimensional stability, and UL94 V-0 flame resistance. - High Tg FR-4: An advanced version of FR-4, High Tg (high glass transition temperature) FR-4 is designed for applications requiring superior thermal stability (Tg ≥ 170°C). It withstands lead-free soldering and high-temperature environments, making it perfect for power electronics, telecommunications, and multilayer PCBs.

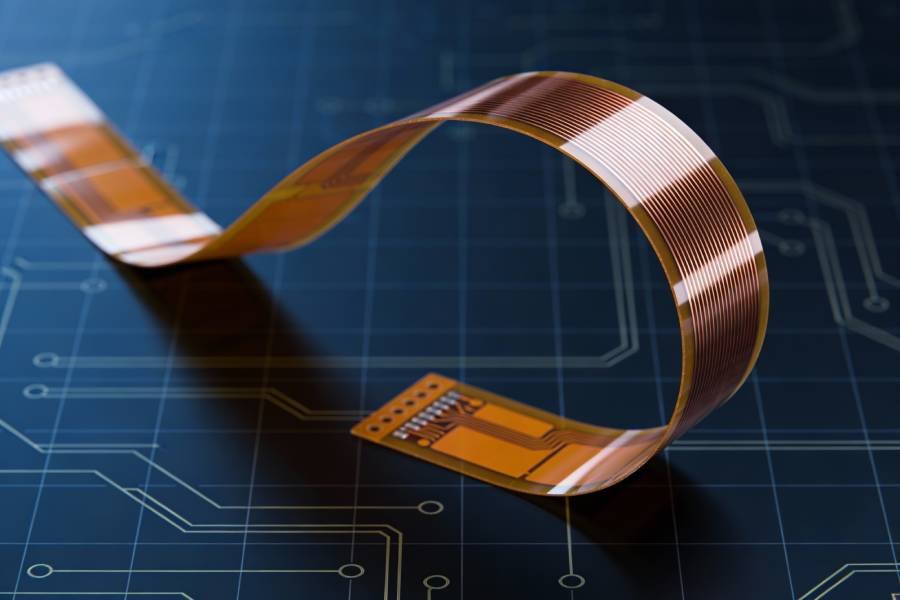

Key Benefits: Enhanced thermal endurance and reliability for demanding applications. - Polyimide: A high-performance, flexible substrate, polyimide excels in applications requiring bendability, such as wearable devices, medical implants, and aerospace electronics. It offers excellent thermal resistance (up to 260°C) and chemical stability.

Key Benefits: Flexibility, lightweight design, and suitability for dynamic applications. - Teflon (PTFE): Polytetrafluoroethylene (Teflon) substrates are the go-to choice for high-frequency applications like RF, microwave, and 5G systems. With a low dielectric constant (Dk ≈ 2.1–2.5) and minimal signal loss, Teflon ensures excellent signal integrity.

Key Benefits: Low loss tangent, high-frequency performance, and stability in harsh environments. - Ceramic: Used in high-power and high-temperature applications, ceramic substrates (e.g., alumina or aluminum nitride) offer superior thermal conductivity and electrical insulation. They’re common in LED modules, power electronics, and aerospace systems.

Key Benefits: Exceptional heat dissipation and reliability in extreme conditions. - Metal-Core (e.g., Aluminum or Copper): Metal-core substrates, often aluminum-based, are used in high-power applications like LED lighting and automotive electronics. They provide excellent thermal management by dissipating heat efficiently.

Key Benefits: High thermal conductivity and mechanical robustness. - Rogers Materials: Specialized laminates like Rogers 4000 series are designed for high-frequency and high-speed applications. They offer low dielectric loss and stable performance in RF and microwave circuits.

Key Benefits: Precision signal control for advanced telecommunications and radar systems.

Why Substrates Matter: The substrate determines the PCB’s mechanical strength, thermal performance, and electrical properties. For example, FR-4 is cost-effective for general-purpose PCBs, while Teflon or Rogers materials are essential for high-frequency designs. At JHYPCB, we help you select the optimal substrate based on your application, ensuring performance and cost efficiency.

2. Copper Foil

Copper foil forms the conductive traces, pads, and planes that carry electrical signals. Its thickness (e.g., 1 oz = 35 µm) impacts current capacity and signal integrity.

- Properties: High conductivity, precise thickness, and strong adhesion to the substrate.

- Applications: Thicker copper for power electronics; thinner copper for high-density interconnect (HDI) designs.

Why It Matters: Copper quality affects signal integrity, heat dissipation, and manufacturability.

3. Dielectric Layers (Core and Prepreg)

In multilayer PCBs, dielectric layers insulate copper layers:

- Core: A rigid substrate (e.g., FR-4) with copper on both sides, forming the PCB’s core structure.

- Prepreg: Fiberglass impregnated with semi-cured resin, bonding cores and copper layers during lamination.

Why It Matters: These layers ensure electrical isolation and structural integrity in complex designs.

4. Solder Mask

The solder mask is a protective polymeric layer that prevents short circuits and oxidation while enhancing durability.

- Colors: Green (standard), red, blue, black, or white.

- Properties: Insulates traces, protects against environmental damage, and improves reliability.

Why It Matters: A robust solder mask ensures reliable soldering and long-term performance.

5. Silkscreen

The silkscreen layer includes labels, fiducials, and markings for component placement and traceability.

- Uses: Guides assembly, aids inspection, and provides branding.

- Materials: Durable epoxy-based ink.

Why It Matters: Clear silkscreen improves assembly accuracy and traceability.

6. Surface Finish

Surface finishes protect copper pads and ensure solderability. Common options include:

- HASL: Cost-effective, suitable for general PCBs.

- ENIG: Corrosion-resistant, ideal for fine-pitch components.

- OSP: Eco-friendly, lead-free option.

- Immersion Tin/Silver: Good solderability for specific applications.

Why It Matters: The right finish enhances solderability and protects against oxidation.

Factors to Consider When Selecting PCB Materials

Material selection is critical for meeting performance, cost, and regulatory requirements. Key factors include:

1. Electrical Performance

- Dielectric Constant (Dk): Low Dk substrates (e.g., Teflon) are ideal for high-frequency signals.

- Loss Tangent: Minimizes signal loss in RF and microwave applications.

- Voltage/Current Capacity: Ensures materials handle electrical loads.

2. Thermal Performance

- Coefficient of Thermal Expansion (CTE): Prevents cracking during thermal cycling.

- Glass Transition Temperature (Tg): High Tg materials withstand elevated temperatures.

- Thermal Conductivity: Critical for heat dissipation in power electronics.

3. Mechanical Strength

- Tensile/Flexural Strength: Ensures durability under stress.

- Dimensional Stability: Prevents warping during manufacturing.

4. Manufacturability

- Drilling/Lamination: Substrates must support precise fabrication processes.

- Assembly Compatibility: Materials should withstand soldering and mechanical processes.

5. Regulatory Compliance

- ROHS/REACH: Ensures environmental safety.

- UL Certification: Confirms flame-retardant properties.

6. Cost

Balancing performance and budget is key. FR-4 is cost-effective, while Teflon or ceramic substrates are pricier for specialized applications.

Why Material Selection Matters

Material choices impact PCB performance, reliability, and cost. Poor selections can lead to signal loss, thermal issues, or manufacturing defects. At JHYPCB, we leverage our expertise to guide clients in choosing materials that optimize performance while meeting budget and regulatory needs.

Why Choose JHYPCB?

JHYPCB offers comprehensive PCB solutions, from prototyping to mass production, including SMT, THT, and turnkey assembly. Our expertise in material selection, adherence to ROHS/REACH, and commitment to quality make us a trusted partner.

- End-to-End Services: Fabrication, assembly, component sourcing, and SMT stencils.

- Expert Support: Guidance on material selection for optimal performance.

- Global Standards: Compliance with international quality and environmental regulations.

Contact us at sales@pcbjhy.com to discuss your PCB needs.

Conclusion

Understanding what PCB boards are made of is essential for designing reliable, high-performance electronics. Substrates like FR-4, polyimide, Teflon, ceramic, and metal-core materials, along with copper, solder masks, and surface finishes, form the foundation of a PCB’s functionality. By selecting materials based on electrical, thermal, and mechanical requirements, you can ensure success in your projects. This article is the first in our series on PCB materials, with future posts exploring flexible substrates, high-frequency materials, and more. Stay tuned to JHYPCB’s blog for expert insights, and let us help you build cutting-edge PCBs.