Table of Contents

Introduction to PCB Technology

Printed Circuit Boards (PCBs) form the foundation of nearly all modern electronic devices. Whether in smartphones, LED systems, or industrial machinery, PCBs ensure that electrical signals flow accurately and reliably. Over the past few decades, advancements in materials science have transformed PCB design—particularly with the introduction of metal-based cores to enhance heat dissipation.

What is a PCB?

A Printed Circuit Board (PCB) is a platform that mechanically supports and electrically connects components using conductive copper traces etched on a laminated substrate. It provides both structure and circuitry, allowing complex electronic systems to operate seamlessly.

Evolution of PCB Materials

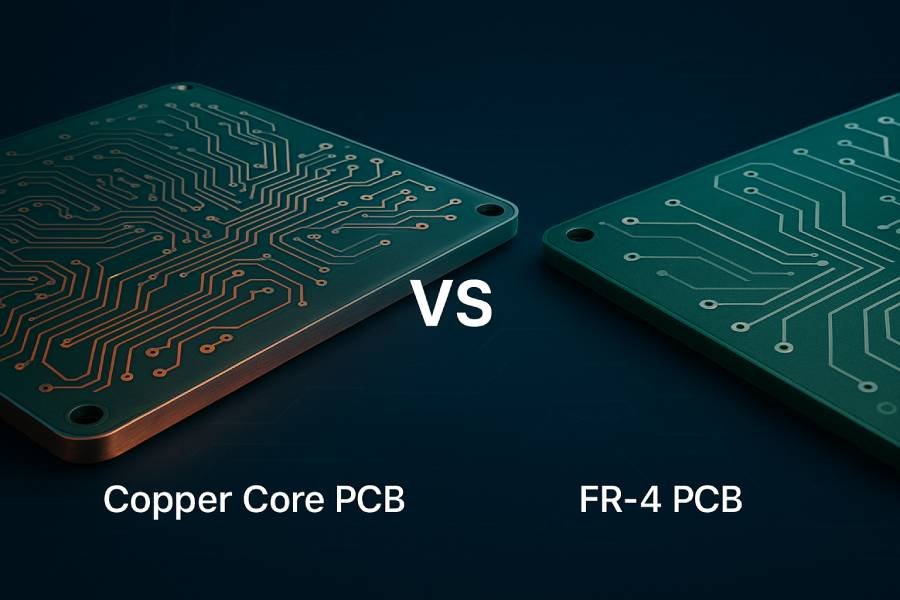

Initially, PCBs were made from FR4 epoxy glass laminate, suitable for low-power applications. As electronics became more compact and powerful, traditional FR4 materials struggled to manage heat effectively. This challenge led to the emergence of Metal Core PCBs (MCPCBs) and, later, Copper Core PCBs (CCPCBs)—both designed to enhance thermal management and overall performance.

Overview of Metal Core PCBs (MCPCBs)

What is a Metal Core PCB?

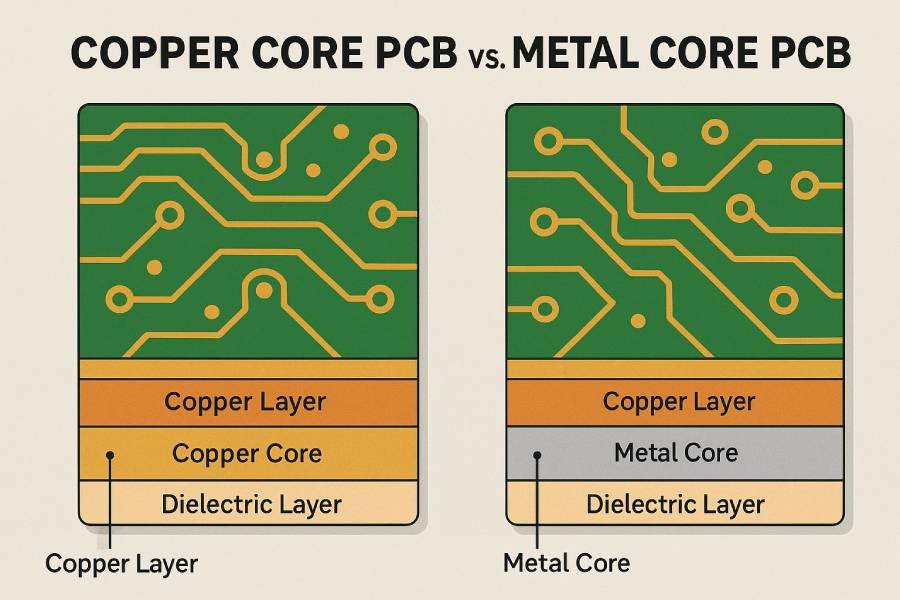

A Metal Core PCB incorporates a metal base—usually aluminum, copper, or stainless steel—beneath the dielectric and copper layers. This design enables efficient heat transfer from components to the core, keeping devices cooler during operation.

Common Materials Used in MCPCBs

Among all metals, aluminum is the most commonly used because it’s lightweight, cost-effective, and offers decent thermal conductivity. Copper, while superior in conductivity, is heavier and more expensive, making it suitable for specialized use. Steel, on the other hand, provides rigidity but sacrifices some heat performance.

Applications of Metal Core PCBs

MCPCBs are widely used in LED lighting, automotive electronics, power converters, and telecommunication systems. They are ideal for situations where moderate heat management is necessary, but cost efficiency remains important.

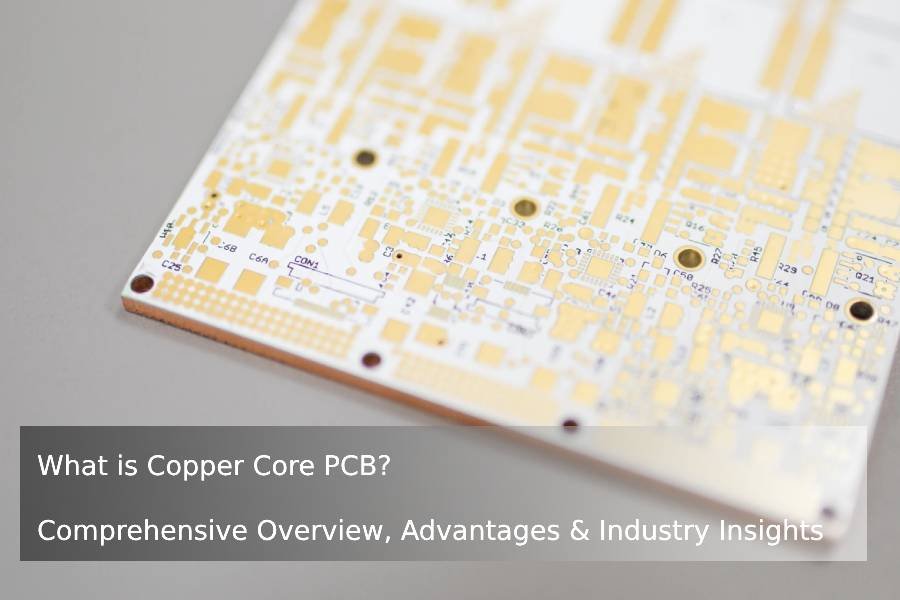

Understanding Copper Core PCBs (CCPCBs)

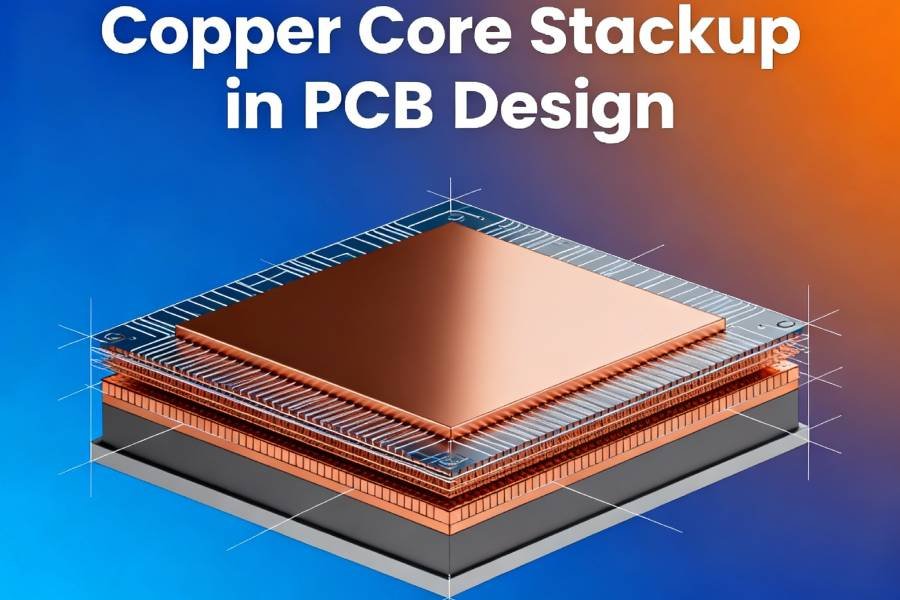

What Makes Copper Core PCBs Unique?

Copper Core PCBs stand out due to their exceptional thermal conductivity, which ranges from 385 to 400 W/m·K—significantly higher than aluminum-based alternatives. This superior performance allows CCPCBs to handle intense heat loads and maintain electrical stability even under extreme conditions.

Key Features of Copper Core PCBs

Copper Core PCBs are known for their mechanical robustness, durability, and low thermal expansion coefficient. These qualities make them particularly suited for demanding environments where both heat resistance and dimensional stability are critical. Moreover, copper’s electrical conductivity ensures minimal signal loss, which is vital for high-frequency circuits.

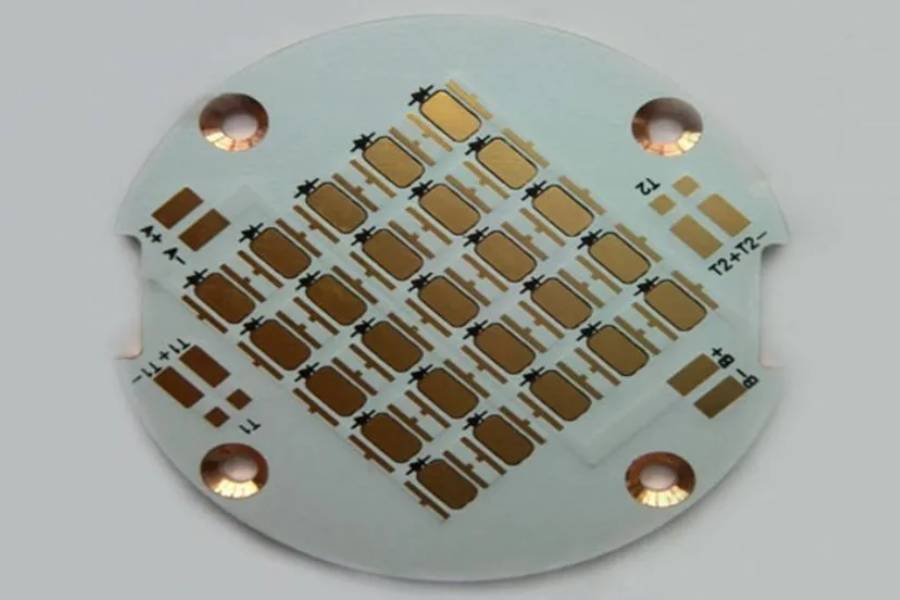

Applications of Copper Core PCBs

Industries such as aerospace, defense, industrial automation, and high-power LED manufacturing rely heavily on copper-based PCBs. Their ability to withstand mechanical stress and temperature fluctuations ensures reliability in mission-critical applications.

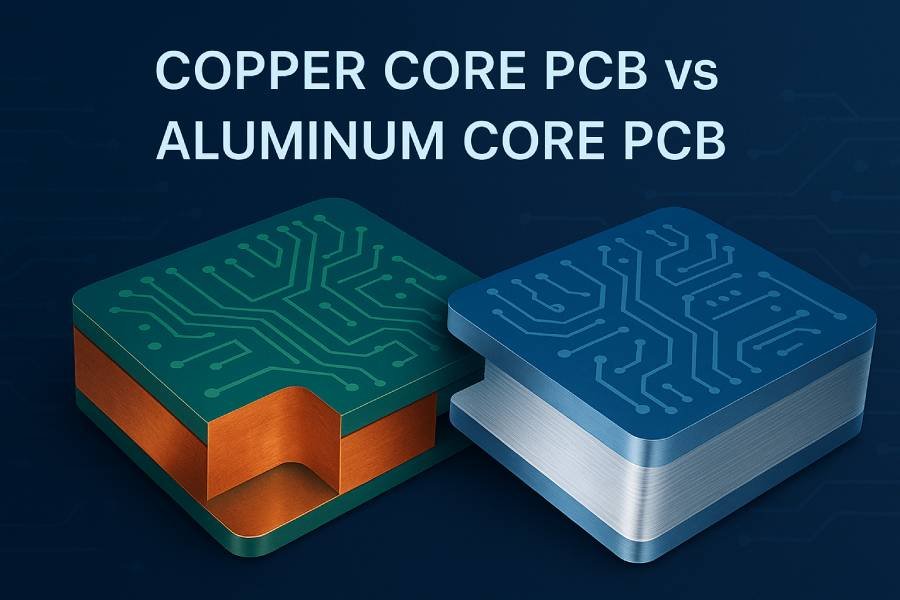

Copper Core PCB vs. Metal Core PCB: A Detailed Comparison

When comparing Copper Core PCB vs. Metal Core PCB, several factors determine which one best suits a particular design.

| Parameter | Copper Core PCB | Metal Core PCB (Aluminum/Steel) |

|---|---|---|

| Thermal Conductivity | 385–400 W/m·K | 150–235 W/m·K |

| Cost | Higher | Lower to Moderate |

| Weight | Heavier | Lighter |

| Electrical Stability | Excellent | Good |

| Mechanical Strength | Very High | Moderate |

| Applications | Aerospace, power modules | LED, automotive, telecom |

Thermal Conductivity

Copper has almost double the thermal conductivity of aluminum, meaning it transfers heat faster and more evenly. This makes copper core PCBs particularly effective in high-power designs where even minor thermal buildup could affect performance.

Cost and Manufacturing Complexity

Manufacturing copper-based boards is more challenging due to the density and hardness of the metal. This increases production costs but results in longer-lasting, more stable PCBs—especially beneficial for precision engineering.

Electrical and Mechanical Performance

From an electrical standpoint, copper’s superior conductivity ensures consistent signal transmission, reducing losses and electromagnetic interference. Mechanically, copper offers better rigidity and stability under thermal cycling, which helps prevent delamination or warping.

Weight and Design Flexibility

Aluminum-based MCPCBs are lighter and easier to handle, making them more suitable for portable electronics or devices where weight constraints matter. Copper, though heavier, provides superior reliability where performance outweighs portability.

Pros and Cons of Copper Core PCBs

Copper core boards deliver unmatched performance but at a premium cost. They provide extraordinary heat dissipation, robust structural integrity, and high durability. However, their weight and price make them less ideal for mass-market consumer products. For specialized, high-reliability systems, they are often the first choice.

Pros and Cons of Metal Core PCBs

Metal core boards—especially aluminum-based ones—strike a balance between performance and affordability. They handle moderate heat well and can be produced at scale. Yet, they don’t achieve the same level of conductivity or stability as copper-based designs. Their biggest strength lies in cost efficiency and widespread usability.

Choosing Between Copper Core and Metal Core PCBs

Selecting between these two PCB types depends on your project’s technical and economic priorities. If your application involves high-power LEDs, defense systems, or aerospace-grade electronics, copper is the way to go. For general lighting or mid-range power circuits, aluminum-based MCPCBs deliver adequate performance at a lower cost.

Future Trends in PCB Materials

The future of PCB manufacturing is shifting toward hybrid cores that combine metals with composite materials for optimized weight and performance. Innovations such as graphene-enhanced substrates and nano-ceramic dielectrics promise to push thermal management and miniaturization to new levels.

FAQs About Copper Core and Metal Core PCBs

What is the key difference between Copper Core and Metal Core PCBs?

Copper Core PCBs use a solid copper base, while Metal Core PCBs typically use aluminum or steel for cost and weight advantages.

Which PCB is better for high-power applications?

Copper Core PCBs, due to their high thermal conductivity and electrical stability.

Are Metal Core PCBs more affordable?

Yes. Aluminum-based MCPCBs are more economical to produce and still offer good thermal performance.

Can Copper Core PCBs be used in LED lighting?

Yes, particularly in high-brightness LED modules requiring stable thermal control.

What industries rely on Copper Core PCBs?

Aerospace, defense, industrial power systems, and high-performance computing sectors.

What innovations are shaping the future of PCBs?

Material advancements like graphene and ceramic composites are expected to redefine performance and efficiency.

Conclusion

In summary, the choice between Copper Core PCB vs. Metal Core PCB depends on your project’s performance expectations and budget constraints. Copper core boards offer unparalleled thermal and electrical properties for demanding applications, while metal core boards—especially aluminum variants—provide cost-effective solutions for mainstream electronics. Understanding these distinctions ensures you select the right PCB for optimal performance and longevity.