Table of Contents

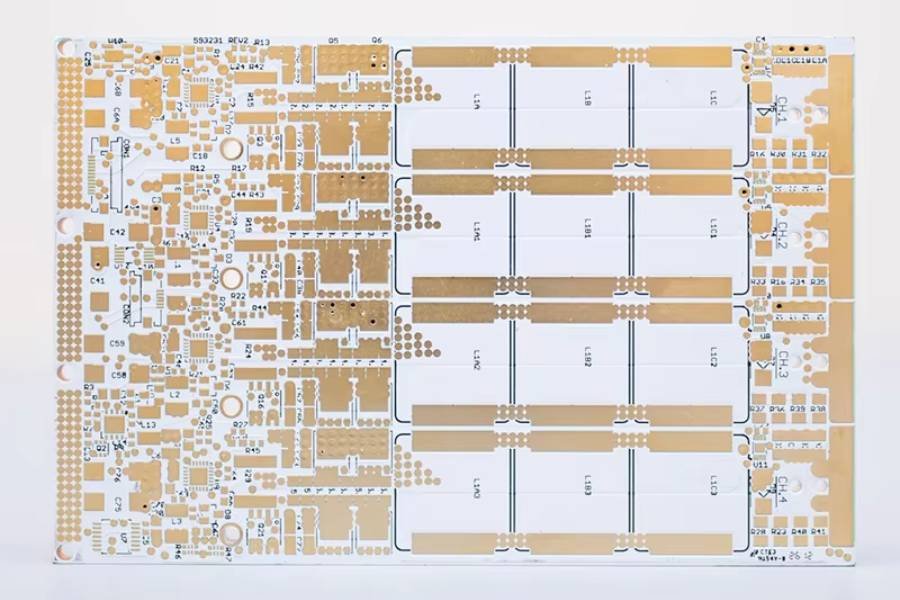

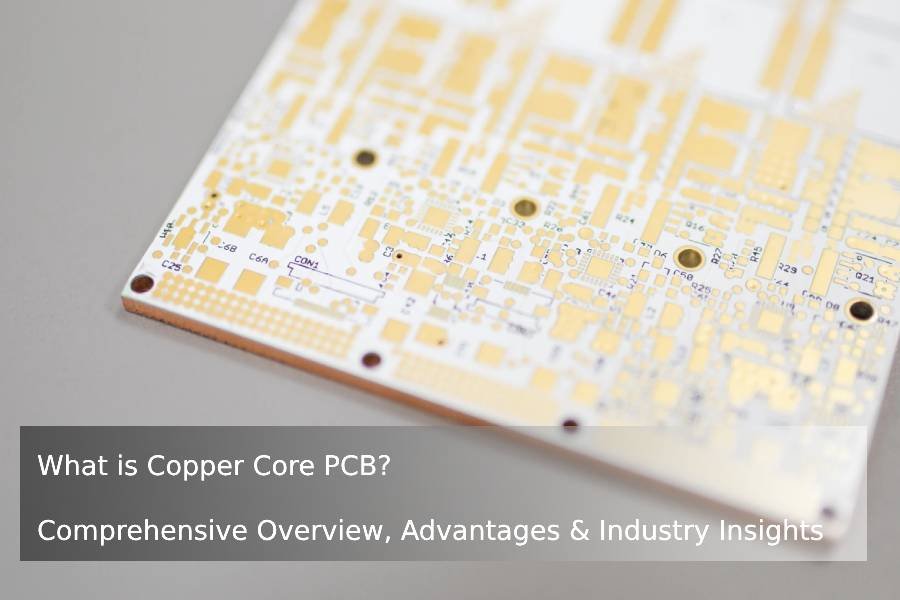

With the rapid evolution of electronics, reliable thermal management and power performance are becoming more critical than ever. As a result, copper core PCBs (also called copper metal core PCBs or copper base PCBs) are getting lots of attention from designers, engineers, and purchasing agents worldwide.

But with all the options out there—aluminum core, FR4, hybrid technologies—how do you know if a copper core PCB is right for your next high-performance project? This FAQ blog breaks down everything you need to know.

1. What is a copper core PCB and how is it different from standard PCBs?

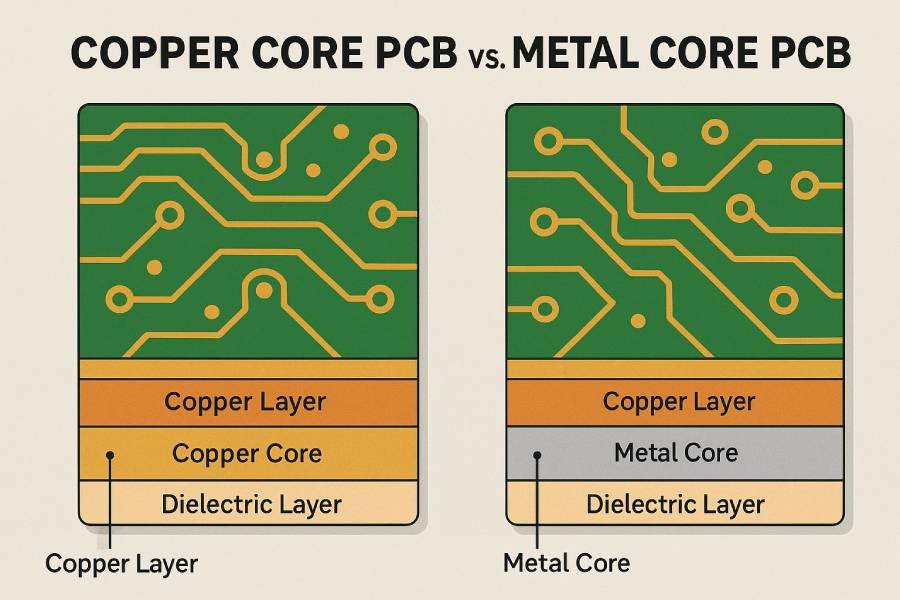

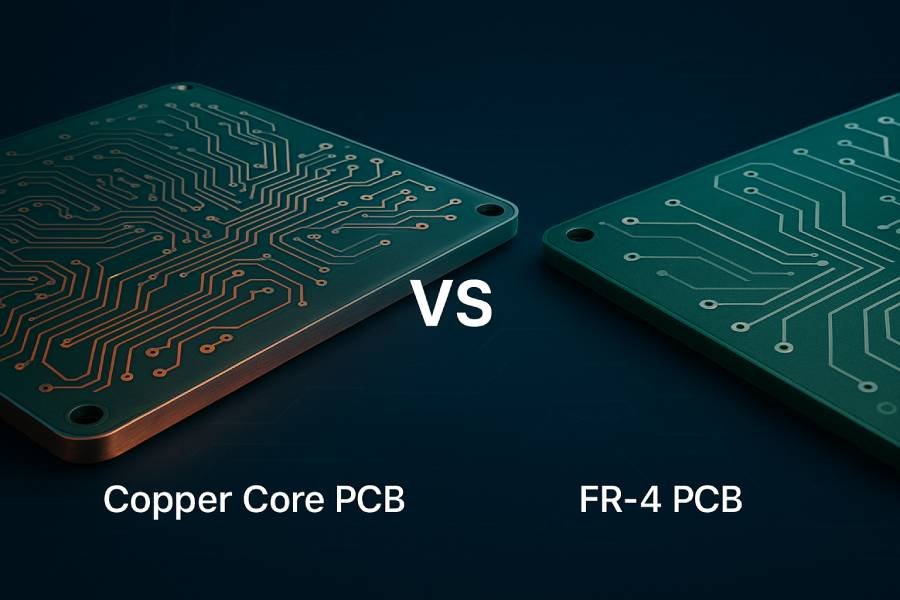

A copper core PCB is a type of metal core printed circuit board (MCPCB) where the substrate is made primarily of copper. This construction provides superior thermal conductivity, mechanical strength, and electrical performance compared to standard FR4 or even aluminum-core PCBs, making them highly preferred for high-power LED circuits, power electronics, and advanced automotive applications.

2. What are the main advantages of copper core PCBs?

- Exceptional heat dissipation: Up to 400 W/m·K or higher, ideal for applications requiring maximum thermal conductivity (e.g., high-power LED drivers, automotive lighting, industrial power modules).

- Better electrical performance: Lower resistance and higher current-carrying capacity, perfect for circuits with demanding power loads.

- Superior reliability: Copper’s high mechanical strength minimizes warping, wear, and micro-cracks in harsh environments.

- Extended lifespan: Electronic devices last longer with optimal cooling.

3. In which industries or scenarios should I choose a copper core PCB?

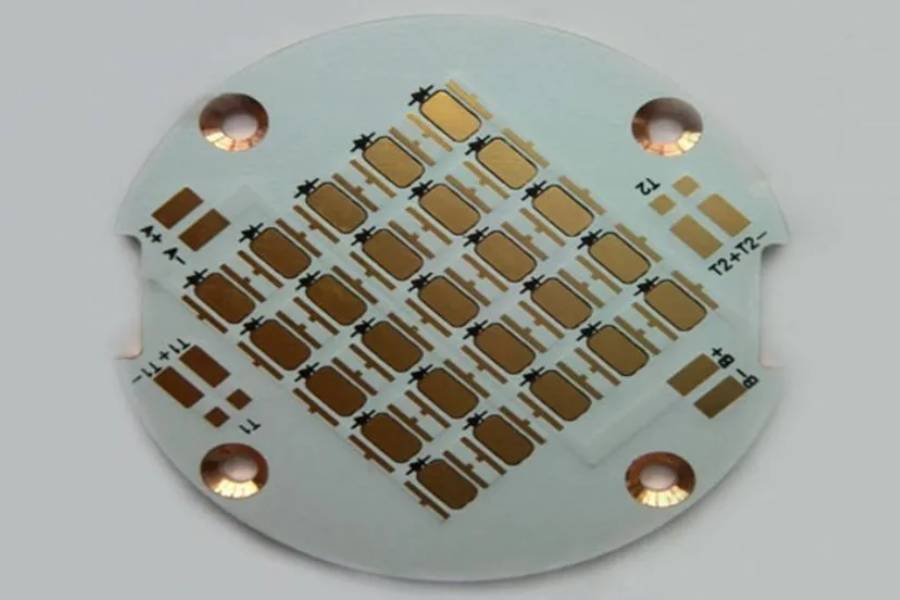

Copper core PCBs excel wherever efficient heat management and robust mechanical structure are crucial. Popular use cases include:

- LED lighting panels (streetlights, stadium lighting, high-bay LEDs)

- Electric vehicle power modules and inverter systems

- Industrial automation (motor drives, high-power relays)

- RF and microwave circuits where both thermal and electrical performance matter

- Military, aerospace, and harsh-environment electronics

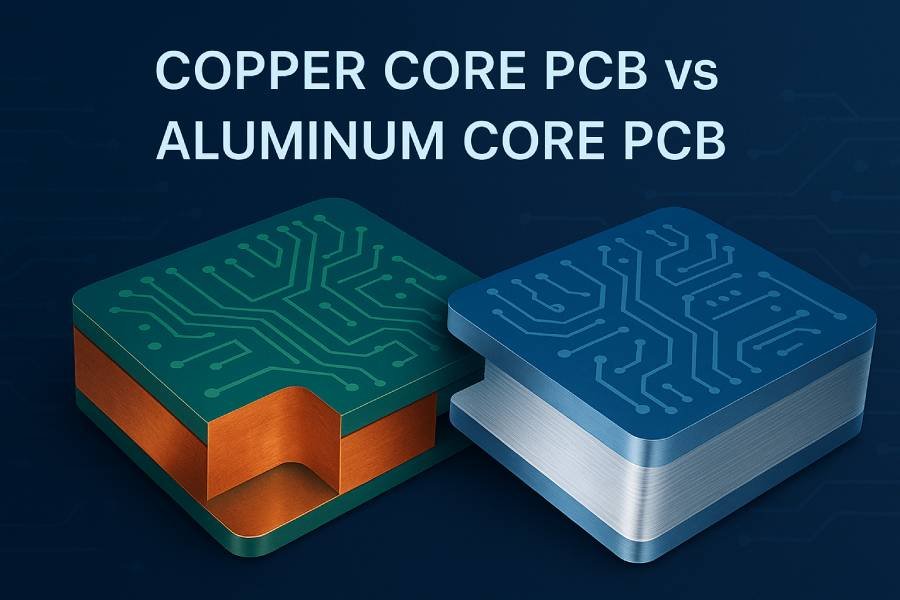

4. How does copper core compare to aluminum core PCBs?

Copper core PCBs deliver higher thermal conductivity and better mechanical stability than aluminum core PCBs, albeit at a higher cost and weight. Aluminum core PCBs are still widely used when budget or weight savings are a priority and the ultimate performance of copper isn’t required.

(For a detailed comparison, see our in-depth “Copper Core PCB vs Aluminum Core PCB” article.)

5. What are the available thicknesses and copper base options?

Copper core PCBs are highly customizable. Standard copper core thicknesses range from 0.5mm to 5mm or even thicker for custom designs. Common copper weights include 1oz, 2oz, and heavy-copper options for ultra-high current. You can also tailor the copper alloy, surface coating, and dielectric pre-preg material to your needs.

6. What’s the price difference between copper core and regular FR4 or aluminum core PCBs?

Copper core PCBs are typically 2–5 times more expensive than standard FR4 boards and 30–100% more than aluminum core PCBs—mainly due to higher raw material costs, specialized processing, and custom engineering.

Factors influencing price include:

- Copper base thickness and purity

- Board size and layer count

- Special manufacturing requirements (via filling, surface finish, laser drilling, etc.)

- Order volume and turnaround time

7. What design recommendations and pitfalls should I be aware of?

Design tips for copper core PCB success:

- Always confirm heat dissipation requirements upfront and select the right copper thickness accordingly.

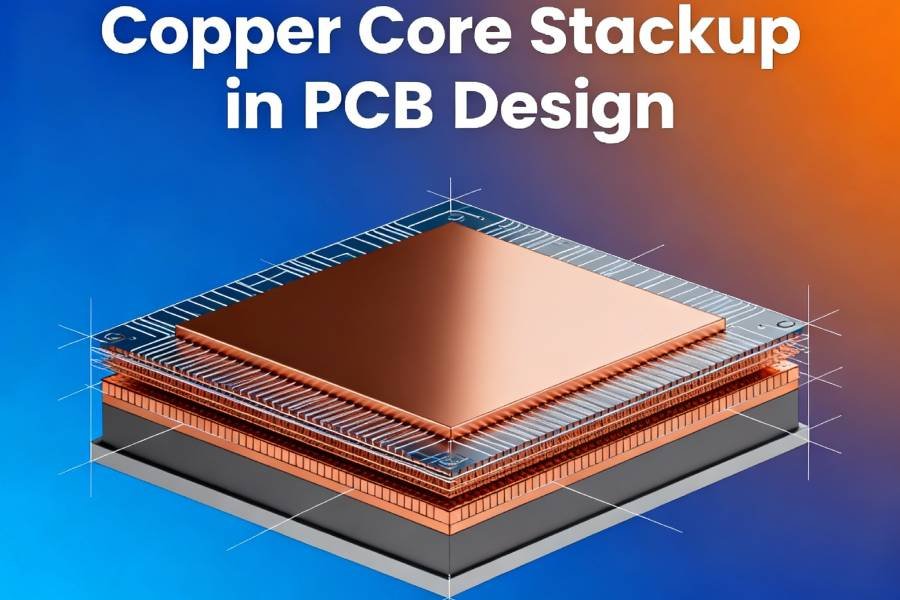

- Consult your manufacturer early regarding stack-up and mechanical mounting.

- Use thermal vias, copper pours, and optimized trace width to maximize performance.

- Consider possible warping and differential expansion, especially for multi-layer and extra-large PCBs.

- Choose appropriate solder mask and surface finish (ENIG, OSP, HASL) based on component type and final application.

Common mistakes to avoid:

- Neglecting thermal expansion differences, which can cause delamination or cracking over time.

- Underestimating assembly challenges—copper’s weight can strain mounting points.

- Over-specifying copper thickness when not strictly required (adds cost and weight).

8. Can copper core PCBs be manufactured as double-sided or multi-layer boards?

Yes! While most copper core PCBs are single or double-layer, advances in engineering now enable the fabrication of multi-layer copper core PCBs (even 4-layer or higher). However, costs and complexity rise substantially with each added layer, so it’s best to consult with your supplier to optimize the stack-up for your application.

9. What industry certifications and quality tests should I expect from a copper core PCB supplier?

Top copper core PCB manufacturers should provide certifications and tests such as:

- ISO/TS certification for quality management

- Conductivity and resistance measurements

- Thermal cycling & reliability testing

- RoHS and lead-free guarantees

Feel free to request specific samples or test data tailored to your industry standards.

10. What are the most popular surface finishes for copper core PCBs?

The most used finishes are:

- ENIG (Electroless Nickel Immersion Gold): Offers strong solderability and anti-oxidation, great for SMT and fine-pitch assembly.

- OSP (Organic Solderability Preservative): Environmentally friendly, good for through-hole and simple SMT.

- HASL (Hot Air Solder Leveling): Cost-effective, commonly used in high-volume production.

Some customers also opt for immersion silver or tin, depending on the end use.

11. Can I get a completely customized copper core PCB for a special project?

Absolutely. Leading suppliers offer full customization:

- Special copper core thickness or alloy composition

- Complex shaped cutouts, countersunk holes, or embedded components

- Custom surface finish, solder mask color, and silkscreen

Provide your Gerber files and requirements—most suppliers will offer a free quote and DFM (Design For Manufacturability) support.

12. Real project stories: Lessons from engineers and sourcing managers

Many successful LED lighting projects saw a 40% increase in longevity after switching from aluminum to copper core PCBs due to improved heat transfer.

Common issues encountered by first-time engineers included over-specifying copper thickness, which inflated costs, or underestimating mounting requirements for heavier boards. Directly communicating with the supplier’s technical team solved most of these problems upfront.

Conclusion & Further Resources

Copper core PCBs are unlocking new design freedom for demanding electronics, from automotive control units to ultra-bright LEDs and high-frequency communication modules. By understanding their unique benefits, manufacturing options, and potential challenges, you’ll be positioned to make the best choice for your next project.

Have more questions or need a rapid quotation?

Contact us today for expert advice or custom copper core PCB manufacturing solutions.