Table of Contents

Introduction

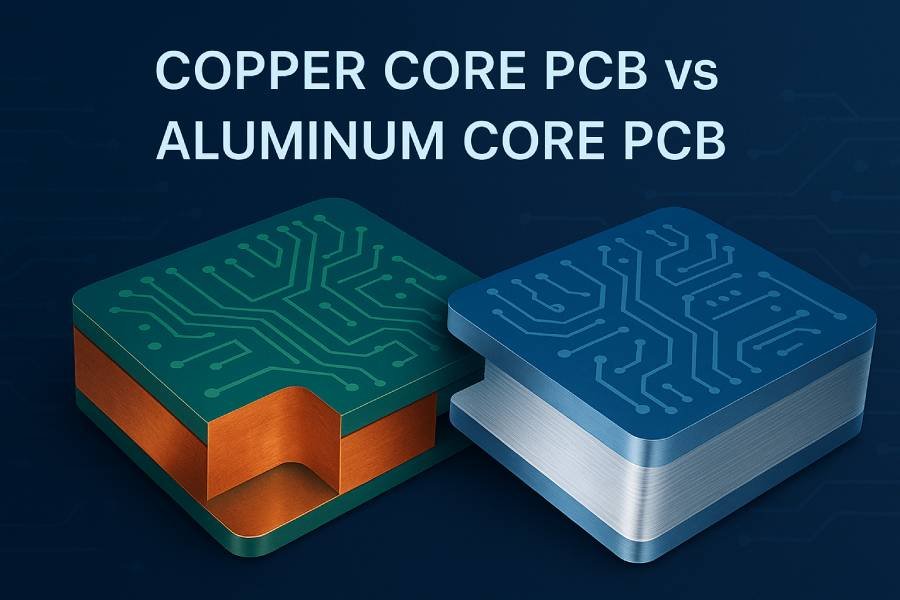

When designing high-performance PCBs, choosing the right copper substrate is essential for reliability, durability, and thermal management. With the rapid growth of power electronics and LED applications, engineers often face a critical decision: should they use a conventional copper PCB or invest in a thermoelectric separation copper substrate?

In this blog post, we’ll explore the fundamental differences between conventional copper substrates and thermoelectric separation copper PCBs—also known as SinkPad boards. By understanding the unique strengths and limitations of each type, you can make an informed choice that enhances product performance and meets the demands of modern electronics manufacturing.

Throughout this guide, you’ll learn:

- The core structure and properties of conventional copper PCBs

- What makes thermoelectric separation copper substrates distinct

- How each type handles heat management, mechanical stress, and cost

- Which scenarios suit one technology over the other

Whether you are designing LED lighting, automotive electronics, or high-power devices, this article will give you practical advice for selecting copper PCBs and optimizing your next project for thermal performance, cost, and reliability. Let’s dive into the world of copper substrates and uncover which option is best for your application.

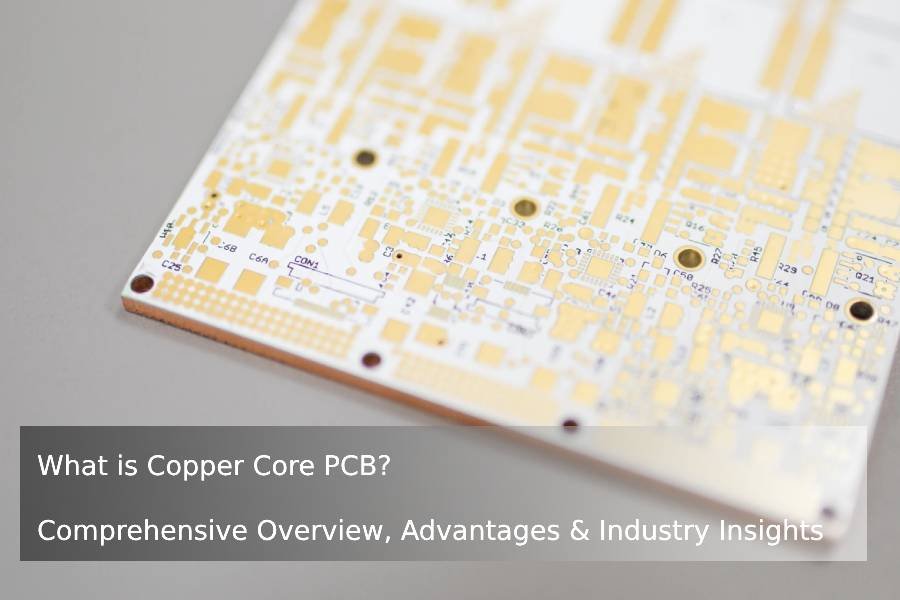

What Is a Conventional Copper Substrate?

A conventional copper substrate, often called a standard copper-core PCB, is widely used across the electronics industry for its excellent balance of cost, manufacturability, and thermal performance. But what exactly sets it apart?

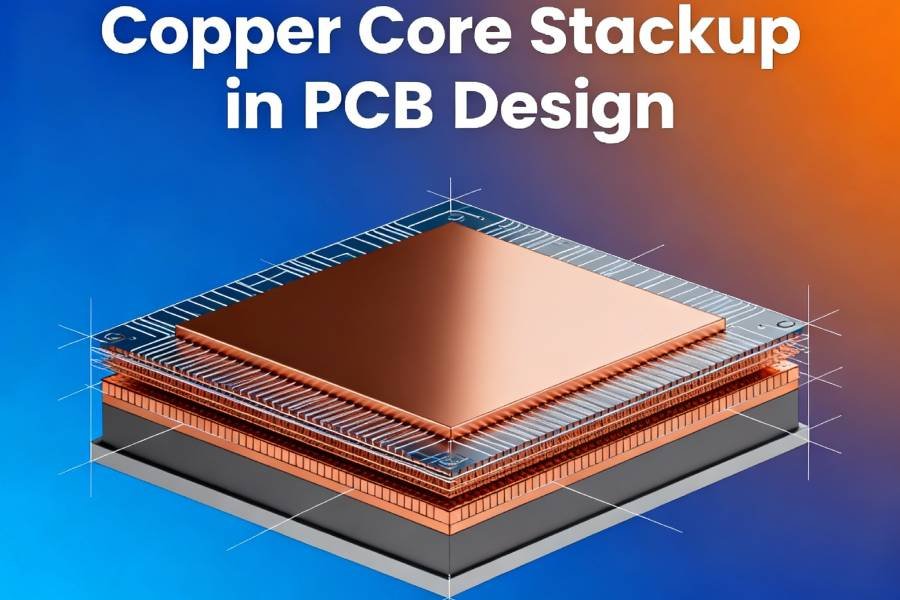

Structure and Composition

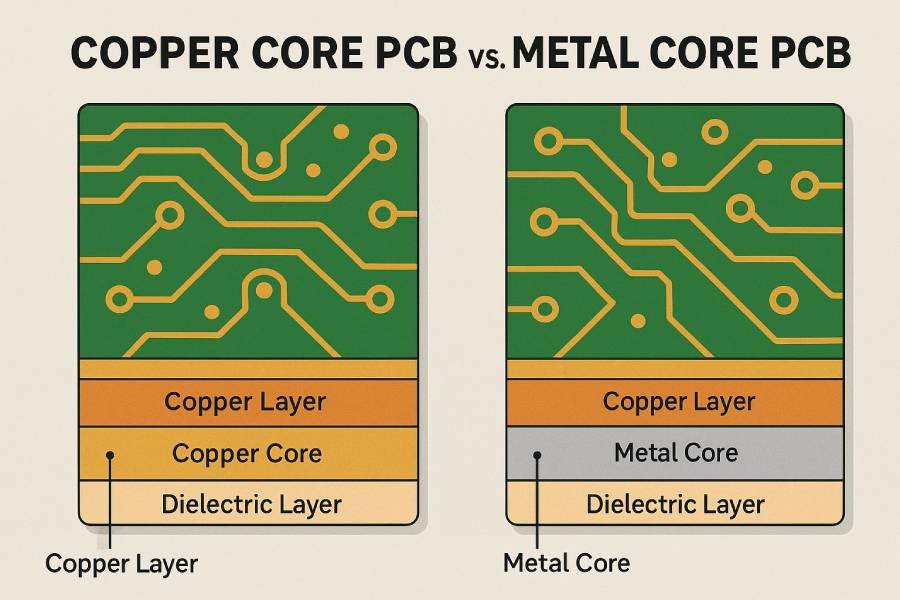

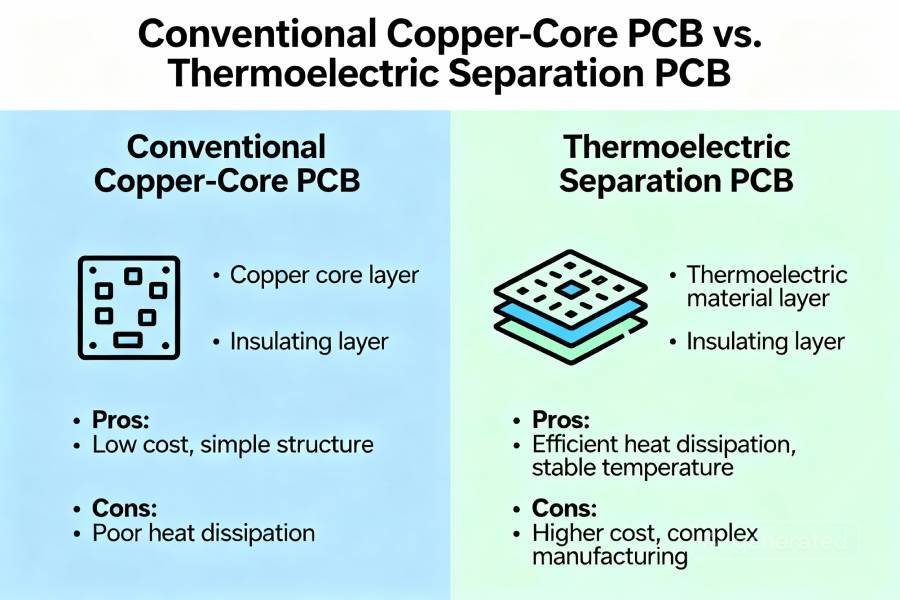

Conventional copper substrates typically consist of three main layers:

Copper Foil: Forms the circuitry, offering excellent electrical conductivity.

Dielectric Layer: An insulating material—usually an epoxy resin or ceramic-filled polymer—designed to isolate the copper circuitry from the metal base while allowing for some heat transfer.

Metal Base (Copper Plate): A solid copper plate delivers mechanical strength and acts as a heat spreader, improving overall device reliability.

This basic stackup allows manufacturers to achieve effective heat dissipation and high-density wiring, which are essential for today’s compact and demanding electronic devices.

Key Physical and Thermal Properties

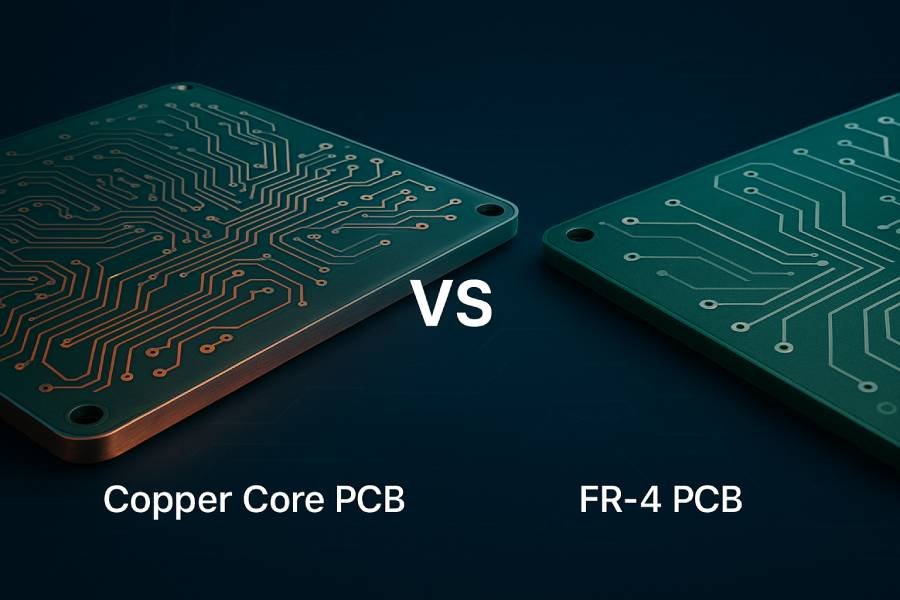

Thermal Conductivity: Conventional copper-core PCBs generally offer thermal conductivities in the range of 1–3 W/mK, which is significantly higher than FR-4 substrates but lower than specialized solutions like thermoelectric separation boards.

Mechanical Strength: With metal as the core, these PCBs provide robust support and reduced warping compared to traditional fiberglass-based boards.

Electrical Performance: The copper layer ensures minimal resistance and reliable signal transmission, crucial for high-power and high-frequency designs.

Advantages of Conventional Copper-Core PCBs

Balanced cost and efficiency, making them a go-to option for mass-market products

Improved thermal management compared to standard FR-4 PCBs

Suitable for a wide range of applications, from power supplies to consumer electronics

Limitations to Consider

While superior to FR-4 in heat dissipation, standard copper substrates may not be enough for applications with extreme heat loads.

Design flexibility is somewhat limited compared to advanced multilayer or separation-type boards.

Best-Fit Applications

Conventional copper-core PCBs excel in LEDs, power modules, motor controllers, and situations where moderate to high heat needs to be managed efficiently—without the premium cost of specialized thermal substrates.

By understanding what a conventional copper substrate offers, you can better evaluate whether its characteristics align with your project’s performance and budget requirements. In the next section, we’ll explore thermoelectric separation copper substrates and highlight why they are chosen for even greater thermal challenges.

What Is a Thermoelectric Separation Copper Substrate?

Thermoelectric separation copper substrates—often referred to as SinkPad copper PCBs or thermal separation copper-core boards—are engineered for demanding applications where heat removal is critical for component performance and reliability.

Unique Structure and Technology

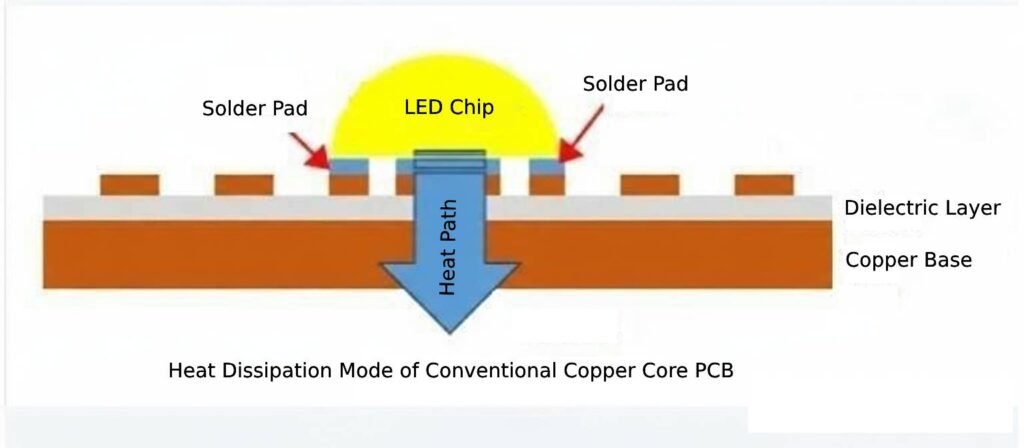

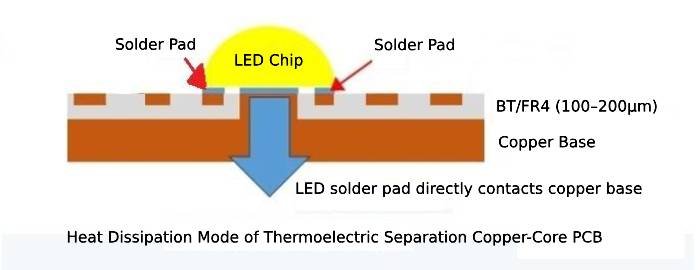

Unlike conventional copper substrates, thermoelectric separation PCBs feature a design that separates the heat-generating component (typically the LED or power device) from the rest of the circuitry. This is usually achieved through specialized manufacturing processes, such as:

Removing the dielectric layer directly beneath high-heat devices

Allowing the heat source to make direct contact with the copper base

Creating “SinkPad” or exposed copper regions for ultra-efficient thermal transfer

This direct heat path minimizes thermal resistance, ensuring maximum heat dissipation and protecting sensitive components from thermal stress.

Key Physical and Thermal Properties

Exceptional Thermal Conductivity: Thermoelectric separation copper PCBs can achieve thermal conductivities up to 400 W/mK, dramatically outperforming standard copper-core and FR-4 boards.

Improved Thermal Management: Heat is conducted away from critical components much faster, leading to higher reliability and longer lifespan.

Mechanical Strength: Retains the robust mechanical properties of metal-core PCBs, with added benefits in specific high-power layouts.

Advantages of Thermoelectric Separation Copper Substrates

Designed for extreme-heat environments, such as high-power LED modules, automotive lighting, and industrial power electronics

Direct thermal path results in lower junction temperatures and better efficiency

Ideal for miniaturized, high-density layouts where thermal constraints are the biggest challenge

Potential Drawbacks

Typically higher production cost due to complex manufacturing processes

May require specialized assembly methods and design expertise

Flexibility in circuit layout can be somewhat more restrictive compared to regular metal-core PCBs

Best-Fit Applications

Thermoelectric separation copper PCBs are the gold standard where exceptional heat dissipation is non-negotiable. They’re widely adopted in automotive headlights, Ultra-High-Power LED systems, communication base stations, RF modules, and advanced power management solutions.

By understanding the structure and advantages of thermoelectric separation copper substrates, PCB designers and engineers can select the most suitable solution for products that demand maximum thermal reliability. Next, we’ll compare these two copper-core technologies side by side to help you choose the right type for your specific requirements.

Primary Differences at a Glance

Choosing between conventional copper substrates and thermoelectric separation copper PCBs requires understanding how they stack up in critical performance areas. Below is a concise side-by-side comparison to help you see the major distinctions at a glance.

| Feature | Conventional Copper Substrate | Thermoelectric Separation Copper Substrate (SinkPad) |

|---|---|---|

| Thermal Conductivity | 1–3 W/mK | Up to 400 W/mK |

| Mechanical Strength | High, solid copper core | High, similar strength |

| Heat Dissipation Path | Through dielectric layer to copper | Direct from device to copper base |

| Cost | Moderate, mass-market friendly | Higher, premium manufacturing required |

| Design Complexity | More flexible for circuit layout | Requires specialized design for heat separation |

| Typical Applications | Power modules, LEDs, consumer electronics | Automotive LED, ultra-high power LEDs, RF, industrial |

| Production Challenges | Standard PCB processes | Advanced processes, skilled assembly |

Key Takeaways:

Thermoelectric separation copper substrates stand out in extreme heat conditions, making them essential for high-power and high-density applications where heat can affect reliability and performance.

Conventional copper-core PCBs strike a great balance between cost and thermal efficiency, fitting the majority of mid-range to moderately demanding electronics.

Understanding these practical differences lays the foundation for making an informed selection. In the following sections, we’ll detail typical use cases and selection strategies for each PCB type.

Application Scenarios

Understanding the best-fit scenarios for conventional copper substrates and thermoelectric separation copper PCBs is key to maximizing performance and reliability in your end products.

When to Choose Conventional Copper PCBs:

General Power Electronics:

Conventional copper-core PCBs are the go-to solution for power modules, motor controllers, and mid-range LED lighting where thermal demands are moderate and cost efficiency is a priority.Consumer and Industrial Electronics:

These boards offer a reliable thermal management upgrade over traditional FR-4, ideal for compact consumer devices and industrial controls.Widespread LED Applications:

For LED lighting systems up to 1W or 3W, standard copper substrates offer a dependable mix of thermal conductivity and mechanical strength without driving up manufacturing cost.High-Density, Standard Layouts:

Their flexibility in circuit design makes them suitable in applications not requiring extreme heat dissipation.

When to Adopt Thermoelectric Separation Copper PCBs:

High-Power LED Modules:

Products like automotive headlights, stadium floodlights, and architectural spotlights demand maximum heat dissipation—making thermoelectric separation copper substrates indispensable.Automotive and RF Electronics:

Industrial environments with intense heat require robust performance, reliability, and maximum junction temperature control that only SinkPad or separation-type boards provide.Power Management in Industrial Systems:

Communication base stations, power conditioning circuits, and advanced RF modules thrive on the high thermal conductivity and direct heat path these boards offer.Miniaturized, High-Density Designs:

If your design is densely packed and heat cannot be managed through conventional means, separation-type copper boards solve the problem with lower thermal resistance and improved component lifespan.

Practical Advice:

Evaluate your product’s peak heat load and target junction temperature.

For cost-sensitive projects with moderate heat, conventional copper-core PCBs are often the best match.

For mission-critical, high-power, or miniature device applications, thermoelectric separation copper substrates provide unmatched thermal performance.

Choosing the right copper substrate based on your specific scenario will ensure peak performance and long-term reliability—whether building everyday electronics or pushing the boundaries of technology.

Selection Criteria & Practical Tips

Selecting the ideal copper substrate for your PCB project depends on a combination of technical requirements, budget, and long-term reliability goals. Here are essential criteria and actionable tips to guide your decision-making process:

1. Assess Power and Heat Dissipation Needs

Identify peak power loads, operating temperature ranges, and component thermal sensitivity.

Use conventional copper PCBs for moderate heat and mass-market devices.

Choose thermoelectric separation copper substrates for high-power, high-heat, or miniaturized designs requiring top-tier thermal management.

2. Balance Performance and Cost

Conventional copper boards offer a cost-effective upgrade over FR-4 while maintaining solid performance for most applications.

Separation-type copper PCBs generally come with a higher price tag due to special manufacturing and design, but pay off in advanced reliability and lifespan in critical uses.

3. Consider Design Flexibility

Standard copper-core PCBs support more diverse layouts, making them suitable for products needing complex circuitry.

Thermoelectric separation boards may require more precise layouts and design expertise, but deliver superior heat control in dense arrangements.

4. Factor in Manufacturing and Assembly Capabilities

Ensure your PCB manufacturer can support advanced processes if you require separation-type copper substrates.

Check for assembly compatibility, particularly in high-volume production environments.

5. Plan for Future Proofing and Product Upgrades

If your applications are expected to scale in power or require future miniaturization, opting for a higher-performance copper substrate early can reduce redesign costs.

Quick Decision Checklist

Moderate heat, general electronics → Conventional copper substrates

Extreme heat, compact high-power devices → Thermoelectric separation copper substrates (SinkPad, exposed copper)

By carefully evaluating these criteria, you will ensure your PCB design is both cost-effective and future-ready, providing maximum reliability and thermal performance as your technology evolves.

Conclusion

Choosing the right copper substrate for your printed circuit board project can dramatically influence your product’s performance, reliability, and overall cost. Conventional copper-core PCBs deliver a well-balanced solution for applications where good thermal management meets cost efficiency, making them ideal for most power supplies, consumer electronics, and moderate-power LED lighting.

On the other hand, thermoelectric separation copper substrates—such as SinkPad and advanced direct thermal path boards—are engineered for today’s most demanding environments. They ensure you can tackle extreme heat loads in automotive LEDs, industrial systems, and miniaturized high-power designs, securing long-term reliability and device longevity.

By thoroughly analyzing your project’s heat dissipation needs, budget, design constraints, and future scalability, you can confidently select the optimal copper PCB for your specific requirements.

For more technical resources, details on advanced PCB stackups, or a tailored selection guide, connect with reputable PCB manufacturers and stay up to date with the latest advancements in copper substrate technology. Your decision today will influence your product’s performance for years to come.