Table of Contents

Introduction: Why Substrate Material Matters in PCB Design

When it comes to creating high-performance electronics, the choice of printed circuit board core material is anything but trivial. The substrate—the internal layer that supports every trace, component, and connection on your board—dramatically impacts thermal management, durability, cost, and overall functionality.

As engineers and designers push devices to be smaller, faster, and more powerful, heat dissipation and reliability have never been more critical. That’s why many decision-makers find themselves comparing two leading options: copper core PCBs and aluminum core PCBs.

But which is better for your specific application? Should you go with copper’s legendary conductivity and strength, or the cost-effective, lightweight benefits of aluminum? This article delivers a clear, in-depth comparison of copper and aluminum PCB cores, exploring the science, real-world performance, and industry best practices—so you can confidently select the right core for your next electronics project.

Whether you’re building power-hungry LED lighting, automotive modules, or consumer gadgets, understanding the strengths and trade-offs between copper and aluminum substrates will help you create products that last longer, run cooler, and deliver top-tier results. Let’s dive in.

Overview of Copper Core PCBs

Copper core PCBs are renowned for their superior thermal management and exceptional reliability—making them the preferred choice for high-power and precision electronics. But what sets copper apart as a core material?

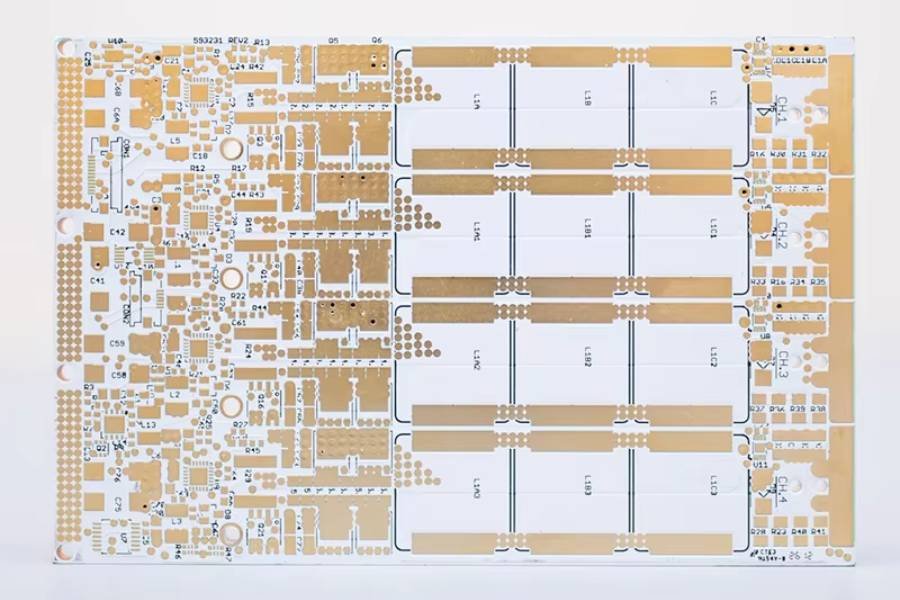

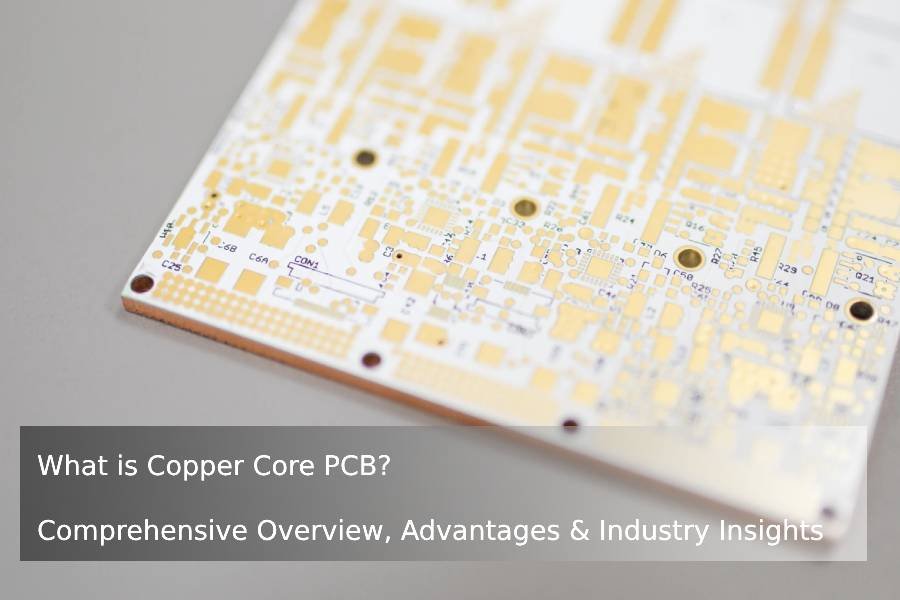

What is a Copper Core PCB?

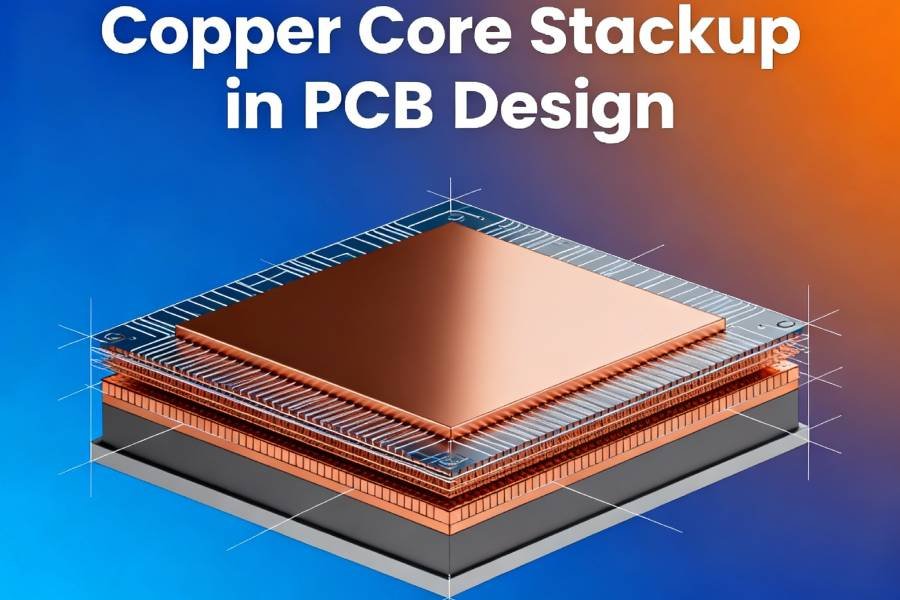

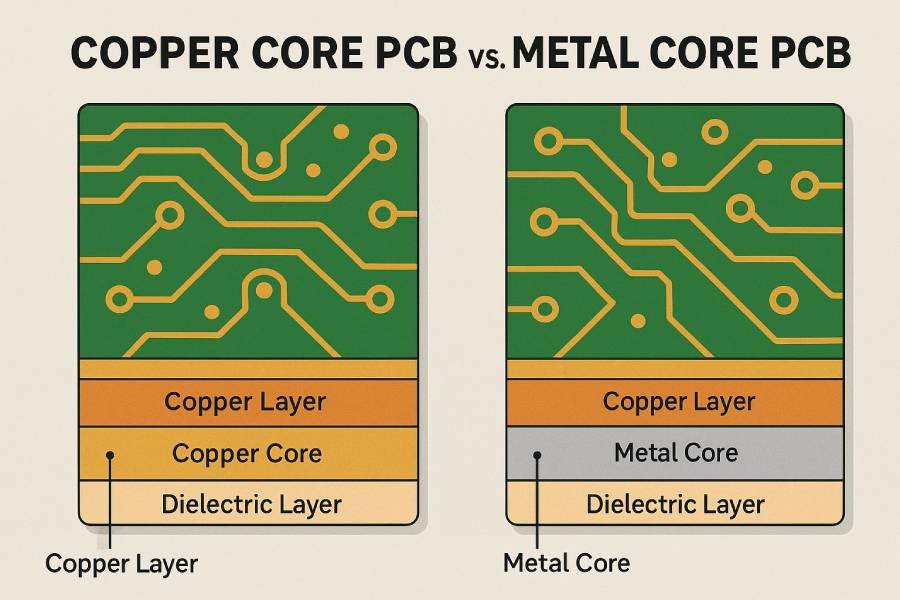

A copper core PCB features a solid copper plate as its substrate, typically sandwiched between one or more circuit layers and insulation. This structure isn’t just about strength; it’s designed to quickly draw heat away from delicate components, maintaining system stability and extending product life.

Key Features:

Outstanding Heat Dissipation:

With copper’s high thermal conductivity (about 400 W/mK), these PCBs excel at dispersing heat, protecting sensitive chips and LEDs from overheating.Superior Mechanical Strength:

Copper substrates provide rigidity, minimizing warping, flex, and physical damage—even in demanding environments or during soldering/assembly.High Current Handling:

Thanks to copper’s low electrical resistance, copper core PCBs manage higher currents safely and efficiently, supporting powerful loads and complex circuits.

Typical Applications:

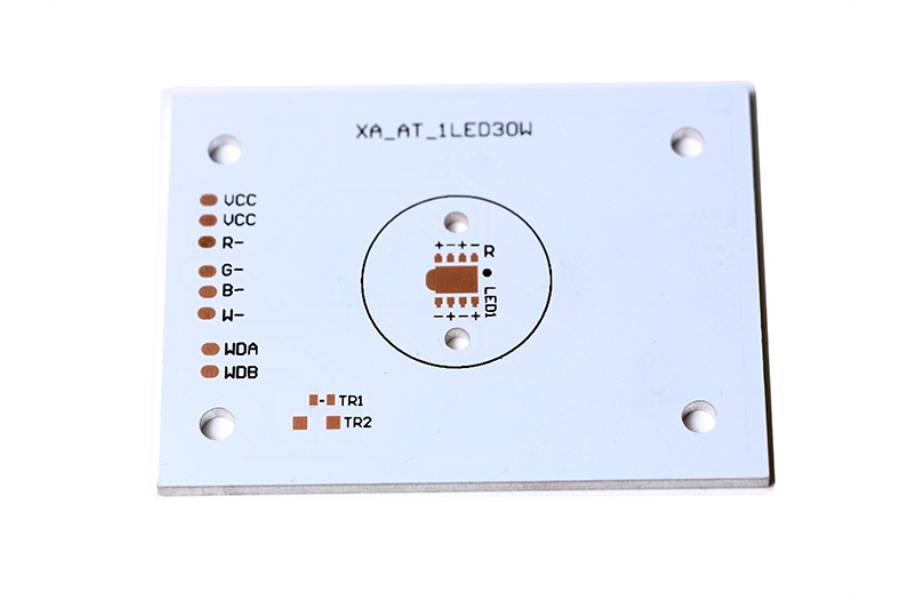

You’ll find copper core PCBs in LED lighting modules, automotive control systems, industrial power units, and high-current electronics—areas where consistent thermal performance and structural durability are mission-critical.

Manufacturing Considerations:

These boards require specialized fabrication techniques, from precision substrate cutting to controlled dielectric lamination and high-temperature soldering. This complexity does increase cost, but the results are undeniable: boards that resist heat fatigue, extend component longevity, and deliver top-tier electrical performance.

Copper core PCBs are more than just a premium material upgrade—they’re often a necessity in industries where failure is not an option and heat control is essential to optimal product function.

Overview of Aluminum Core PCBs

Aluminum core PCBs (also called metal core PCBs or MCPCBs) are a popular alternative to copper for many modern electronics, especially when heat must be managed and budgets are a concern.

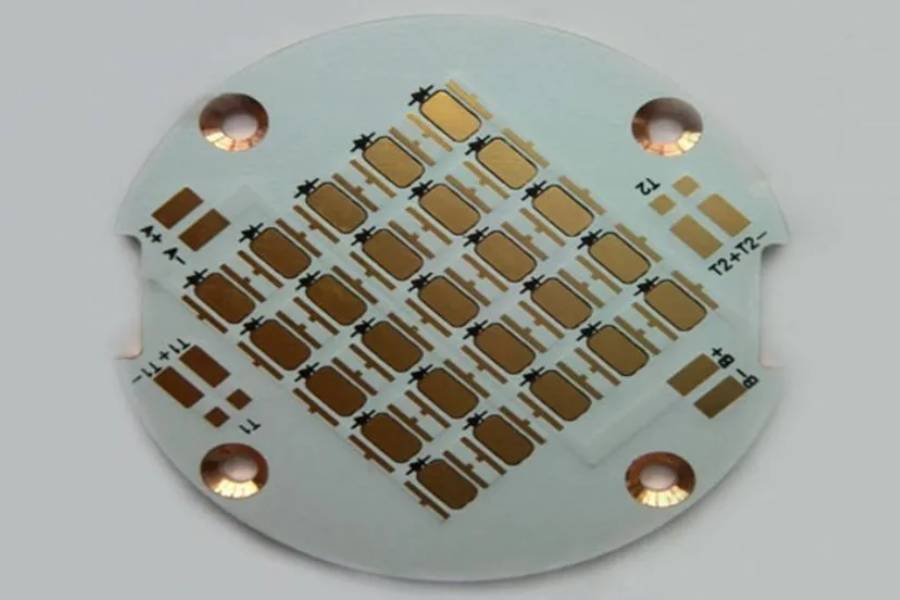

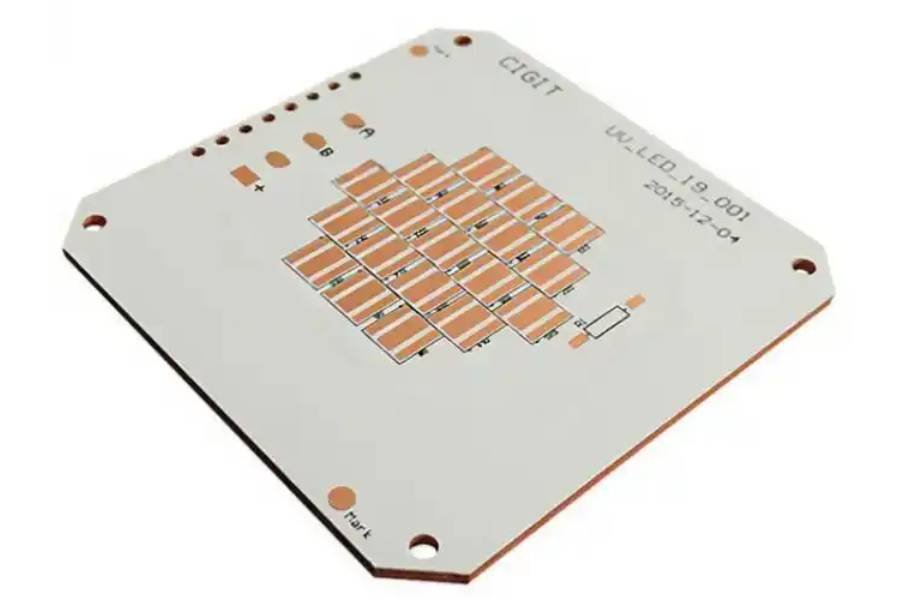

What is an Aluminum Core PCB?

An aluminum core PCB consists of a solid aluminum substrate covered by a dielectric insulating layer and one or more copper circuit layers. This structure provides a combination of lightweight thermal management and reliable electrical performance at a fraction of the cost of copper core counterparts.

Key Features:

Good Thermal Conductivity:

Aluminum core PCBs conduct heat efficiently (typically 1–2.2 W/mK for standard boards and up to 200 W/mK for the substrate), which is significantly higher than traditional FR4 PCBs, making them well suited for applications like LED lighting and power electronics.Cost Efficiency:

Aluminum is less expensive than copper. This allows manufacturers to offer high-performance, thermally stable boards that meet tight budget constraints, making them an attractive choice for mass-market products.Mechanical Lightweight and Flexibility:

Aluminum core boards are lighter than copper core PCBs of similar size and strength, which is a plus for designs where total weight must be minimized.

Best Applications:

Aluminum core PCBs are widely used in LED lamps and modules, consumer power supplies, automotive lighting, and any situation where moderate thermal control is needed at a competitive price.

Manufacturing and Design Benefits:

Aluminum core PCBs are simpler and less costly to manufacture. They are easily machined, drilled, and routed, and the lighter substrate reduces handling issues during assembly.

Limitations:

While aluminum offers good thermal and mechanical properties, it cannot dissipate heat as efficiently as copper. For extremely high-power or demanding applications, copper core PCBs remain superior.

Aluminum core PCBs provide a great balance of cost, thermal management, and manufacturability. They are an excellent fit for designers seeking efficient performance in price-sensitive and mid-range electronics.

Copper Core vs Aluminum Core PCBs: Side-by-Side Comparison

To help you quickly grasp the practical differences between copper and aluminum core PCBs, here’s a direct feature-by-feature comparison:

| Feature | Copper Core PCB | Aluminum Core PCB |

|---|---|---|

| Thermal Conductivity | Up to 400 W/mK (very high) | Up to 200 W/mK (high, but lower) |

| Mechanical Strength | Excellent rigidity & durability | Good, but less rigid than copper |

| Electrical Performance | Lower resistance, supports high current | Good performance, suitable for moderate loads |

| Weight | Heavier and denser | Lightweight, easier to handle |

| Machinability | Harder to process and drill | Easy to process, drill, and route |

| Cost | More expensive | More budget-friendly |

| Best Applications | High-power LEDs, industrial, automotive, aerospace, medical | LED panels, consumer electronics, power supplies |

| Corrosion Resistance | Very high, especially when coated | Good, but susceptible to oxidation if unprotected |

Key Points:

Thermal Management: Copper core PCBs are the top choice for the most heat-intensive and demanding applications thanks to their superior conductivity.

Cost Efficiency: Aluminum core PCBs win for cost-sensitive projects while offering more than enough thermal management for everyday uses.

Weight and Assembly: If product weight is a concern (e.g., portable devices), aluminum makes assembly and handling easier.

Bottom Line:

Copper core PCBs deliver the ultimate in heat dissipation, durability, and electrical performance for high-end electronics, but their price and weight make aluminum core PCBs attractive for cost-conscious and mid-range applications.

Use this table and analysis to guide your substrate selection, optimize your electronics for performance, cost, and reliability, and address real-world design challenges effectively.

Application-Specific Analysis: Choosing Copper or Aluminum Core PCBs for Different Industries

When deciding between copper and aluminum core PCBs, context matters. Each substrate shines in specific applications, and understanding these differences can help you optimize your electronics for reliability, cost, and performance.

LED Lighting

Copper core: Perfect for high-power LEDs and lighting modules where maximum heat dissipation is essential, such as stage lighting, stadium lights, and automotive LED systems.

Aluminum core: Widely used in everyday LED bulbs, commercial panels, and signage that require good thermal management at a lower cost.

Automotive & Industrial Power

Copper core: Ideal for engine control units, power converters, battery management systems, and industrial drives that experience heavy current loads and intense thermal cycling.

Aluminum core: Common in automotive lighting assemblies, dashboard components, and industrial power supplies operating under moderate temperature and mechanical demands.

Consumer Electronics

Copper core: Used in high-end laptops, gaming devices, and advanced home appliances where thermal stresses may challenge performance.

Aluminum core: Suitable for standard power adapters, routers, small home electronics, and budget devices where price sensitivity is critical.

Harsh Environment Uses

Copper core: The go-to choice for aerospace, medical imaging, and military technologies exposed to extreme conditions, long duty cycles, or must-have reliability.

Aluminum core: Fits applications where moderate heat, cost limits, and light weight are important, but the environment isn’t as demanding.

Tip:

Always match the substrate to your project’s unique requirements. Copper core PCBs bring unmatched thermal and electrical advantages for critical applications, while aluminum core PCBs offer a proven, cost-effective solution for most general electronics. The right choice ensures longevity, stability, and optimal system performance.

When to Choose Copper, When to Choose Aluminum: Practical Decision Guide

Selecting the right PCB core material isn’t just a technical decision—it’s a strategic one. Here’s how you can decide between copper and aluminum core PCBs to best serve your specific application, budget, and performance needs.

Choose Copper Core PCBs If:

- You need maximum heat dissipation for high-power electronics, such as advanced LED modules, battery systems, or industrial power converters.

- Your application demands top-tier mechanical strength and minimal risk of warping or failure, especially in harsh operating environments.

- You require the lowest possible electrical resistance and highest current handling ability (critical for mission-critical systems like aerospace, automotive control units, and high-speed computing).

- Longevity, safety, and premium reliability outweigh cost considerations.

- Your project faces strict regulatory or quality certifications that only copper can meet.

Choose Aluminum Core PCBs If:

- Your primary goal is to keep costs low while still achieving good thermal management—in LED lamps, power adapters, and consumer gadgets.

- Weight and easy handling are important, such as in portable devices or budget electronics.

- You’re working with modest current and heat loads, where copper’s advantages are less impactful.

- Fast, cost-efficient mass production is desirable, and the manufacturing process needs to be simple and scalable.

- Price sensitivity is higher than absolute performance, and short product lifecycles are expected.

Real-World Examples:

Copper core: High-power automotive LED headlights, industrial motor drivers, professional medical devices, and robust outdoor control systems.

Aluminum core: Everyday light bulbs, standard desktop power supplies, mass-market routers, and handheld consumer electronics.

Quick Tip:

If in doubt, consult with your PCB manufacturer about your heat, mechanical, and electrical performance targets. Often, a brief application and budget review makes the optimal choice very clear—saving you headache and delivering results.

Using these guidelines, you’ll be able to confidently pick the right PCB substrate—giving your project the ideal mix of reliability, cost, and performance.

Frequently Asked Questions: Copper Core vs Aluminum Core PCBs

Which is better for LED lighting—copper or aluminum core PCB?

Copper core PCBs offer superior heat dissipation, making them ideal for high-power or professional LED modules. Aluminum core PCBs, while slightly less effective thermally, are an affordable and reliable choice for most standard or consumer-grade LED lights.

Are copper core PCBs always more expensive than aluminum?

Yes, due to material costs and manufacturing complexity, copper core PCBs typically come at a premium compared to aluminum core PCBs. If cost is a major priority for your project, aluminum is usually the more economical choice.

Can both PCB types be made as multi-layer boards?

Absolutely! Both copper and aluminum core PCBs can be designed in single-layer, double-layer, and multi-layer configurations. However, copper multi-layer boards may require more specialized manufacturing equipment.

Are there weight differences between copper and aluminum core PCBs?

Yes. Copper is denser and heavier than aluminum, which can affect overall product weight, especially in portable or lightweight designs.

Do aluminum core PCBs offer enough heat dissipation for power electronics?

For most moderate-power applications, aluminum’s thermal performance is more than sufficient. But for extreme conditions, high current, or mission-critical devices, copper’s thermal superiority is essential.

Which substrate is better for harsh environments?

Copper provides improved mechanical strength and corrosion resistance (especially with protective coatings), making copper core PCBs preferable in aerospace, industrial, and medical applications exposed to stress, vibration, or humidity.

Can I use aluminum and copper in the same PCB?

Some advanced designs use hybrid structures or mixed-metal stack-ups to optimize cost and thermal management. Consult with your PCB manufacturer for feasibility and best practices.

If you have more questions about choosing between copper core and aluminum core PCBs, reach out to your supplier—they can help you navigate design, price, and technical performance for your project.

Conclusion: Choosing the Right PCB Core for Your Next Project

Copper core PCBs excel when heat dissipation, premium durability, and maximum electrical performance are paramount—even if it means a higher cost and heavier board.

Aluminum core PCBs are ideal for budget-conscious, lightweight, and mass-produced electronics that still require efficient thermal control, but not at a premium level.

As electronic devices become more powerful and compact, the importance of optimal substrate selection grows. Industry trends point toward:

Increased use of hybrid PCB designs (combining both cores),

Innovations in thermal dielectric materials,

Rising demand for reliable, high-performance boards in EVs, smart manufacturing, and advanced LEDs.

Takeaway:

Always evaluate your operating environment, power requirements, desired lifetime, and budget before making a choice. Consulting with PCB manufacturers or suppliers early in the design process ensures you select the right substrate—delivering reliability, safety, and competitive advantage in the final product. If you’re still unsure, request samples or prototypes of both types for real-world performance tests.

The future belongs to designers and engineers who understand their options and select substrates that match their application’s technical and commercial goals. With the right PCB core, your products will run cooler, last longer, and perform better—no matter the challenge.