Table of Contents

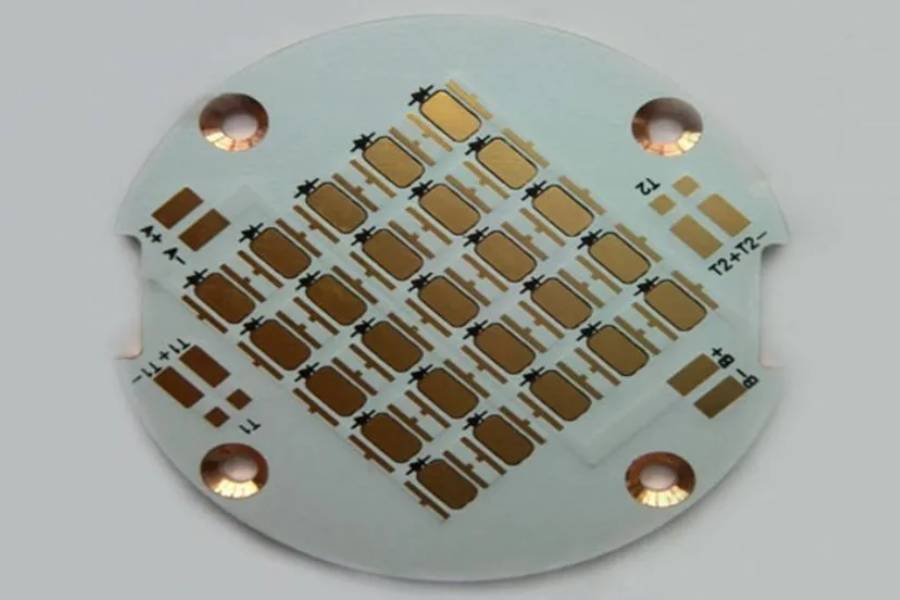

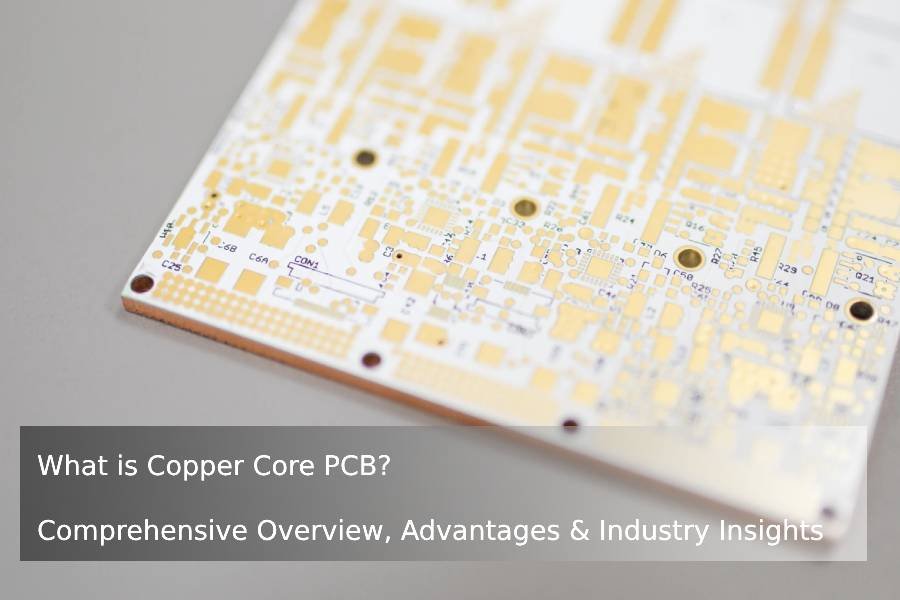

In the fast-paced world of electronics, where high-power LEDs are lighting up everything from massive industrial igniters to sleek automotive headlights, managing heat isn’t just a nice-to-have—it’s the make-or-break factor for longevity and efficiency. I’ve spent years at JHYPCB, our China-based PCB powerhouse, watching engineers wrestle with overheating components in 1000W+ setups. That’s where copper core PCBs come in as the unsung heroes of thermal management.

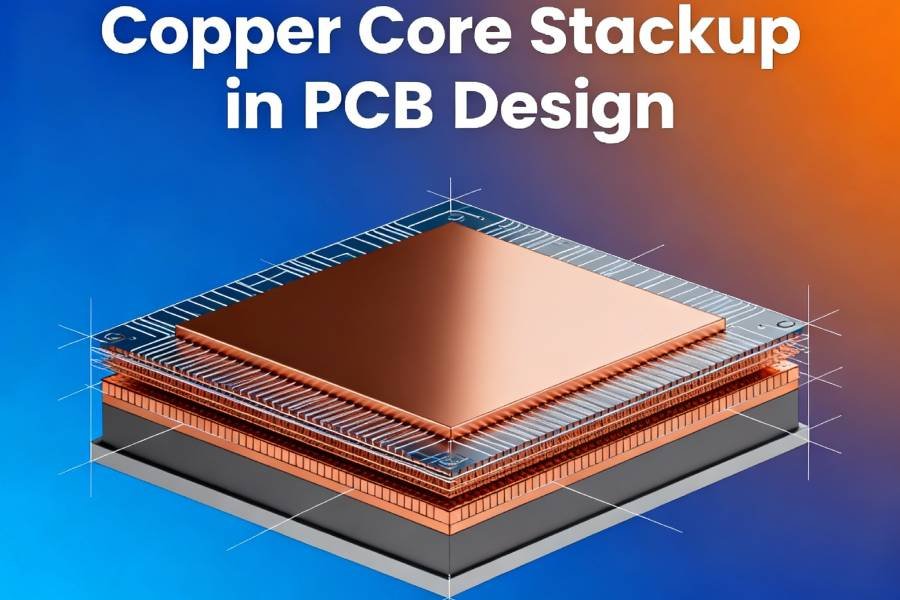

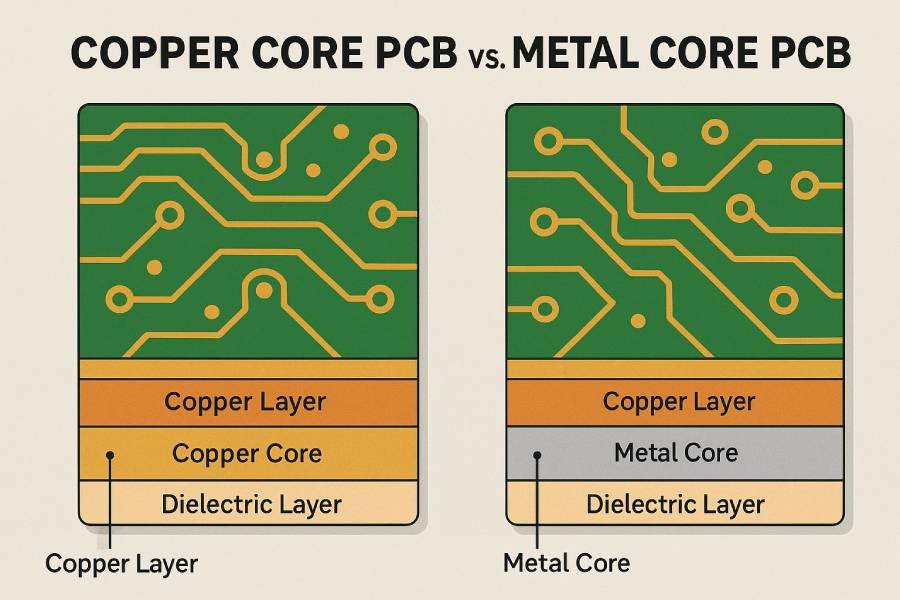

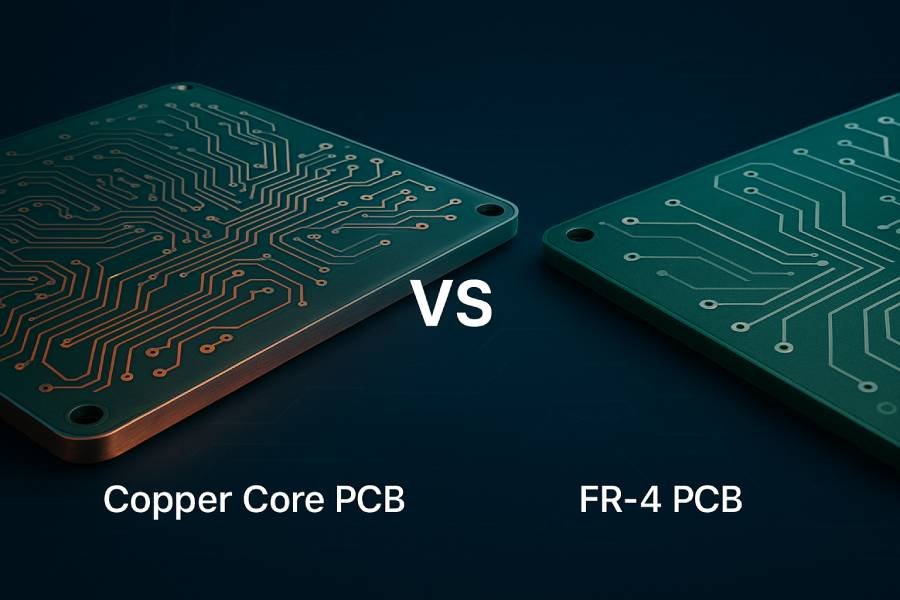

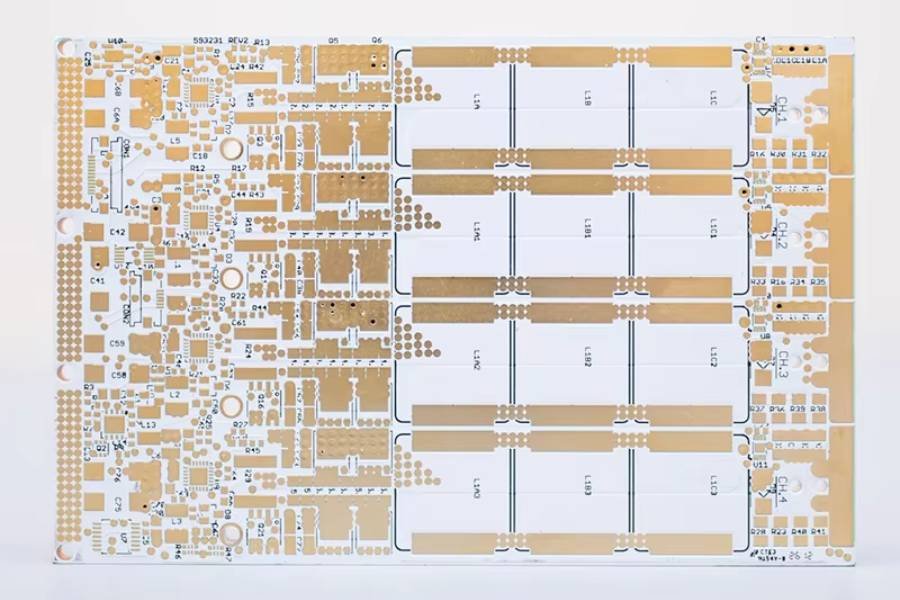

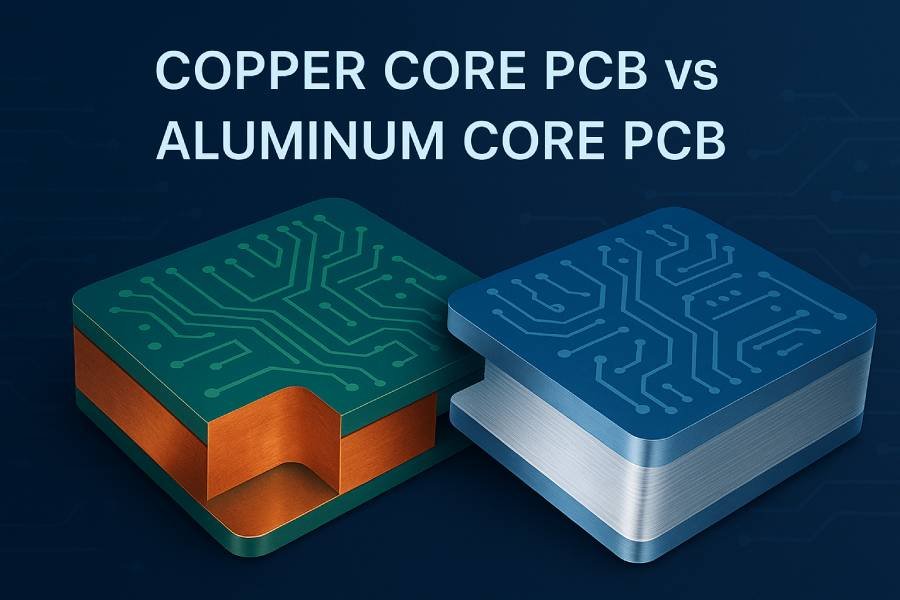

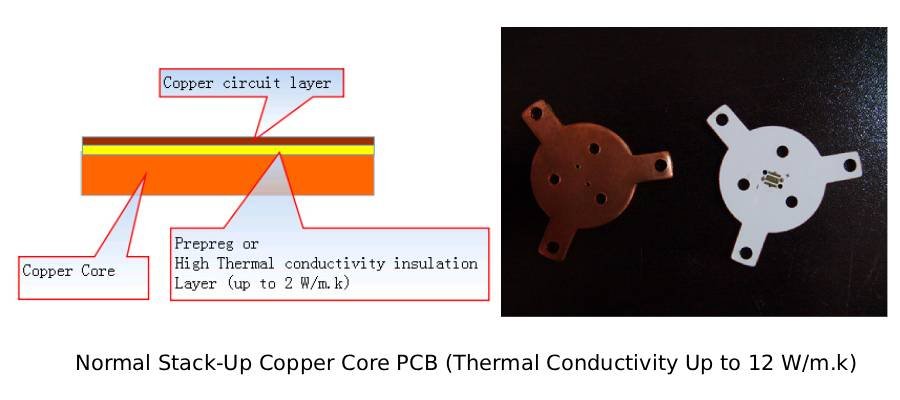

Unlike standard FR4 boards that can turn into hotspots under heavy loads, copper core PCBs—also called copper base PCBs, copper substrate PCBs, or even heavy copper MCPCBs—leverage a solid copper foundation topped with an insulating dielectric layer and a copper circuit layer. This stack-up delivers exceptional thermal conductivity, often hitting up to 12 W/m.k, spreading heat evenly and keeping your LEDs cooler for longer. As a dedicated MCPCB manufacturer specializing in rigid, flex, and rigid-flex boards, we’ve crafted countless copper core PCB prototypes and production runs for clients tackling power-hungry applications.

But here’s the thing: not all copper core PCBs are created equal. In the LED realm especially, there are six distinct types, each fine-tuned for specific thermal paths, densities, and budgets. Whether you’re prototyping a COB LED array or scaling up power supplies, understanding these copper base PCB types can save you headaches (and redesigns) down the line. Let’s dive in—I’ll break them down with real-world insights from our fabrication floor, so you can pick the winner for your next project.

Why Choose Copper Core PCBs for LEDs and Power Electronics?

Before we get to the types, a quick reality check: High-power LEDs generate intense heat—think 1000W+ in a single module for things like plasma cutters or stage lighting. Without proper dissipation, you’re looking at dimming output, shortened lifespans, or outright failures. Copper core PCBs shine here because copper’s innate thermal prowess (far superior to aluminum in pure conductivity) allows direct heat sinking, reducing junction temperatures by up to 30-50% compared to traditional boards.

At JHYPCB, we see this daily in our turnkey assembly lines, where we pair copper core PCB manufacturing with SMT, THT, mixed-tech assembly, and even component sourcing. The result? Compact, reliable boards that meet UL standards and push the boundaries of what’s possible in thermal management for PCBs. If you’re searching for a copper core PCB manufacturer who gets the nuances of high thermal conductivity PCB design, you’re in the right place.

The 6 Types of Copper Core PCBs: A Deep Dive

Drawing from our extensive MCPCB portfolio, here’s the lineup of copper core PCB types optimized for LED applications. Each one builds on that core copper substrate + insulation + copper circuit formula but tweaks it for peak performance.

1. Normal Stack-Up Copper Core PCB (Thermal Conductivity Up to 12 W/m.k)

This is your reliable workhorse—the classic copper base PCB where everything stacks neatly: copper substrate at the bottom for heat collection, a thin dielectric layer for insulation, and the copper circuit layer on top for traces and pads. It’s straightforward, cost-effective, and punches above its weight with thermal conductivity reaching 12 W/m.k.

We’ve used this type extensively for general LED modules and DC-DC power converters, where even heat spread across the board prevents hotspots. Pros? Easy to prototype and scale. Cons? It’s not the absolute fastest path for ultra-high-power spots. If you’re starting with copper core PCB prototypes, this is your entry point—think affordable thermal relief without overcomplicating things.

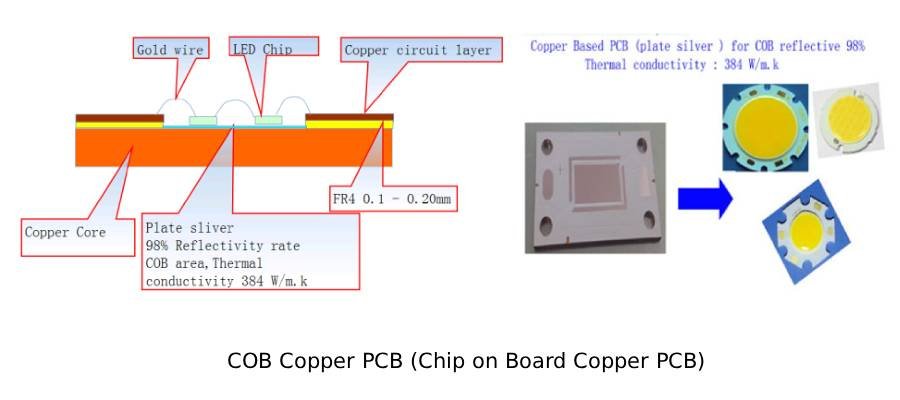

2. COB Copper PCB (Chip on Board Copper PCB)

Step up to density: In a COB copper PCB, LED chips bond directly onto the copper substrate, bypassing extra layers for near-instant heat transfer. No more thermal bottlenecks—the chip sinks heat straight to the massive copper base below.

Picture this in action: Our clients love it for packed LED arrays in medical devices or high-lumen spotlights, where space is tight but brightness isn’t negotiable. The payoff is dramatic—lifespans extend by years thanks to that direct thermal sink. On the flip side, it demands laser-precise chip placement during assembly, which is why our SMT expertise at JHYPCB makes all the difference. If “compact high-power LED PCB” is your mantra, COB is calling.

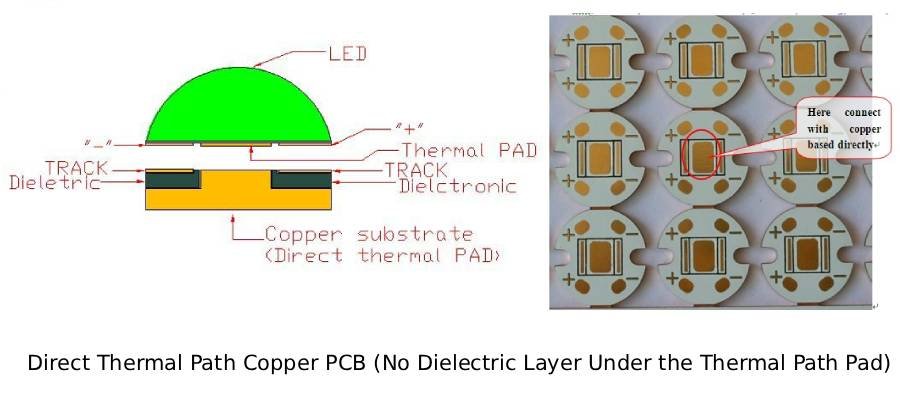

3. Direct Thermal Path Copper PCB (No Dielectric Layer Under the Thermal Path Pad)

Want to crank the efficiency? This type strips away the dielectric right under the thermal pad, creating a zero-resistance highway for heat to flow from the LED pad to the copper core. It’s like giving your board a VIP lane for thermal escape.

Ideal for those beastly 1000W+ LED igniters we’ve built—applications where every degree counts, like industrial welding tools. The result? Substantially lower thermal impedance, meaning brighter, cooler operation. Drawback: Circuit routing gets trickier around that exposed path, but with our controlled impedance capabilities, it’s a non-issue. For engineers chasing “direct thermal path copper core PCB” specs, this one’s a game-changer.

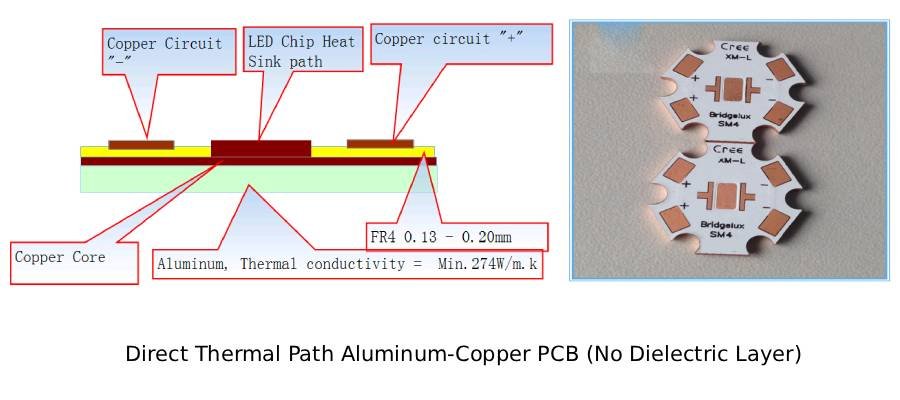

4. Direct Thermal Path Aluminum-Copper PCB (No Dielectric Layer)

A smart hybrid twist: This blends aluminum for structural beef with copper for thermal supremacy, again ditching the dielectric under the path for seamless heat conduction. It’s tougher than pure copper against mechanical stress while keeping costs in check.

We’ve deployed these in rugged power supplies for outdoor LED installations, where vibration and weather are foes. Thermal performance rivals full copper but at a friendlier price point—perfect for scaling prototypes to volume. The trade-off? Slightly tempered conductivity versus all-copper siblings, but for most “aluminum-copper PCB thermal path” needs, it’s spot-on value.

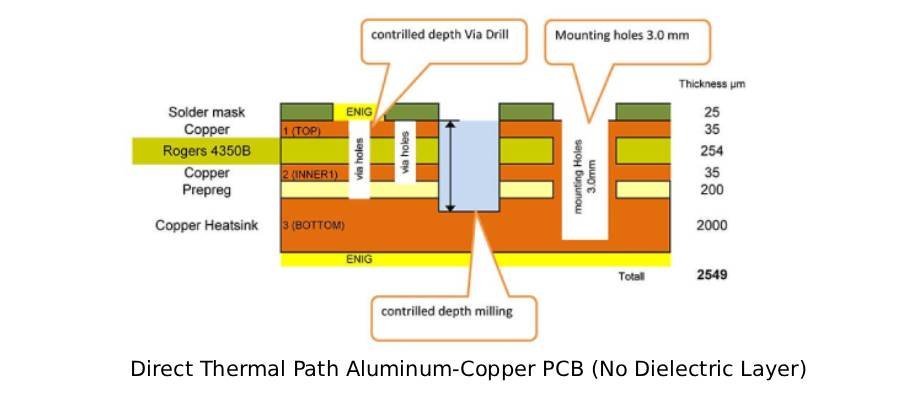

5. Copper Core PCB + 2 Layers Rogers 4350B PCB + Controlled Depth Milling/Drilling

For when your design mixes heat with high-frequency signals: Layer a copper core with two sheets of Rogers 4350B (that low-loss laminate pros swear by), then use controlled depth milling and drilling to craft precise vias without piercing the core.

This beast excels in LED drivers that double as RF modules—think smart lighting systems with wireless controls. The Rogers adds signal integrity, while the copper handles the heat load. It’s pricier due to the materials and precision tooling, but for “Rogers 4350B copper core PCB” projects demanding both thermal and electrical finesse, it’s indispensable. Our milling tolerances at JHYPCB ensure it comes out flawless every time.

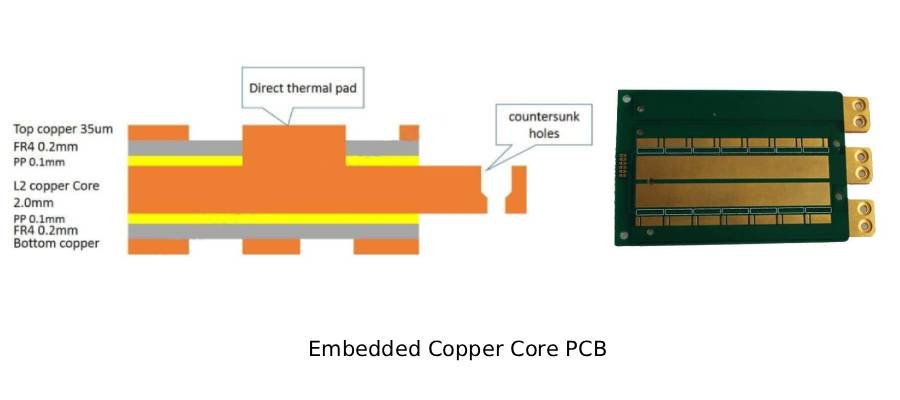

6. Embedded Copper Core PCB

The stealthy innovator: Here, the copper core embeds deep within the board, woven into the layers for uniform heat distribution and rock-solid mechanical integration. No surface-level bulk—just seamless thermal highways throughout.

We’ve embedded these in compact EV charging LEDs and aerospace power boards, where reliability under duress is non-negotiable. Benefits include better warp resistance and even cooling across dense layouts. Challenge: It requires advanced lamination tech, but that’s our wheelhouse. Searching for “embedded copper core PCB” solutions? This type future-proofs your designs beautifully.

Quick Comparison: Which Copper Core PCB Type Fits Your Project?

To make selection easier, here’s a snapshot from our design playbook:

| Type | Thermal Conductivity | Cost Level | Best For | Key Challenge |

|---|---|---|---|---|

| 1. Normal Stack-Up | Up to 12 W/m.k | Low | General LEDs, Prototypes | Basic heat paths |

| 2. COB Copper | Excellent (Direct Sink) | Medium | Dense Arrays | Chip Placement Precision |

| 3. Direct Thermal Path (Pure Copper) | Superior | Medium-High | 1000W+ Igniters | Circuit Routing |

| 4. Aluminum-Copper Hybrid | High | Low-Medium | Rugged Power Supplies | Slightly Lower Conductivity |

| 5. + Rogers 4350B | High + RF Friendly | High | Signal-Mixed Drivers | Material/Process Cost |

| 6. Embedded | Uniform & High | High | Compact, High-Reliability | Fabrication Complexity |

This table’s based on real builds—use it to match your power needs and budget.

Wrapping Up: Elevate Your Thermal Game with the Right Copper Core PCB

From the straightforward normal stack-up to the embedded wizardry of Type 6, these copper core PCB types offer a toolkit for taming heat in LEDs and beyond. At JHYPCB, we’re not just manufacturers; we’re partners in pushing thermal boundaries, whether it’s a quick copper base PCB prototype or full-scale production with stencils and sourcing.

Got a high-stakes project brewing? Drop us a line at sales@pcbjhy.com—we’ll chat types, tweak stack-ups, and get you samples faster than you can say “12 W/m.k.” Here’s to cooler, brighter innovations ahead. What’s your go-to copper substrate PCB challenge? Tell us!