Table of Contents

What is a Copper Core PCB?

Copper Core PCB, sometimes called copper-based PCB or copper substrate PCB, is a type of printed circuit board where copper serves as the main core or base material. Unlike traditional FR4 boards or even aluminum PCBs, the copper core provides outstanding thermal conductivity, mechanical strength, and electrical performance.

So, why is copper chosen over other materials? The answer lies in copper’s fundamental properties:

- Superior Thermal Management: Copper’s high thermal conductivity enables rapid heat dissipation, making the board the ideal solution for high-power electronics and LED applications.

- Mechanical Stability: The solid copper core adds significant rigidity and durability, minimizing warping or damage during manufacturing, assembly, and real-world operation.

- Electrical Excellence: Copper’s low impedance allows circuits to handle more current with less signal loss, ensuring reliable performance in demanding environments.

Copper Core PCBs are most commonly found in devices that generate substantial heat or require robust reliability, such as automotive systems, power modules, industrial controllers, and next-generation LED products. By combining efficient heat dispersal with strong mechanical properties, these boards help engineers and manufacturers extend product life and reduce failure rates.

But what really sets Copper Core PCBs apart from standard alternatives is their ability to tackle technical challenges that other materials simply cannot address. For high-performance applications, especially those struggling with heat dissipation and electrical integrity, copper stands out as the optimal choice—bringing efficiency, stability, and innovation to the heart of modern electronics.

Key Features and Advantages of Copper Core PCBs

When it comes to high-performance electronics, choosing the right type of printed circuit board can make all the difference. Copper Core PCBs stand out for a range of powerful features that address modern engineering challenges and boost product reliability.

1. Outstanding Heat Dissipation

One of the most critical benefits of copper core PCBs is their exceptional thermal conductivity. Copper’s natural ability to transfer heat away from delicate circuit components prevents overheating, making these boards especially valuable in applications like LEDs, automotive power systems, and industrial machinery.

2. Superior Mechanical Strength

Copper cores give printed circuit boards extra rigidity compared to standard FR4 or aluminum substrates. This added strength means less risk of warping, damage during assembly, or long-term deterioration under heavy loads.

3. Enhanced Electrical Performance

Copper’s low electrical resistance translates to lower signal loss, higher current capacity, and improved power delivery. For applications where consistent performance is non-negotiable, copper is a no-brainer.

4. Durability and Reliability

Copper core PCBs are remarkably resistant to corrosion and extreme temperatures. This makes them the go-to choice for demanding environments—whether you’re building electronics for harsh industrial conditions or mission-critical automotive systems.

5. Versatility Across Applications

From high-powered LED lighting, automotive electronics, and laser modules to advanced industrial controls, copper core PCBs are trusted wherever utmost performance and reliability are required.

In summary, Copper Core PCBs bring together excellent heat management, reliability, and strength. Their use isn’t just a technical upgrade—it’s a strategic choice that ensures your products run cooler, last longer, and deliver consistent results in the real world.

Real-World Applications of Copper Core PCBs

Copper Core PCBs aren’t just a theoretical upgrade—they’re widely used across industries that demand superior heat management and uncompromising reliability.

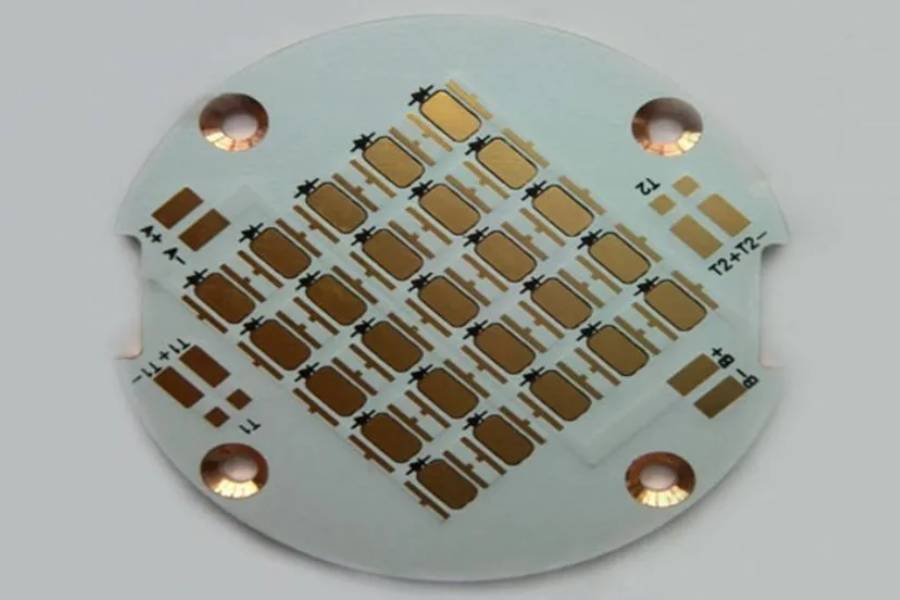

LED Lighting Solutions

Perhaps the most common use of copper core PCBs is in high-power LED lighting. LEDs produce significant heat, and poor thermal management can shorten their lifespan or affect brightness. Copper’s excellent thermal conductivity keeps LEDs cool, drastically improving performance and longevity in everything from commercial lighting panels to automotive headlights.

Automotive Electronics

Modern vehicles rely on sophisticated electronics—systems that control engines, safety features, and infotainment all generate heat. Copper core PCBs help maintain stable operation, resisting thermal fatigue and preventing malfunction in harsh conditions. Electric vehicles, in particular, benefit from copper’s ability to carry higher current and handle heat.

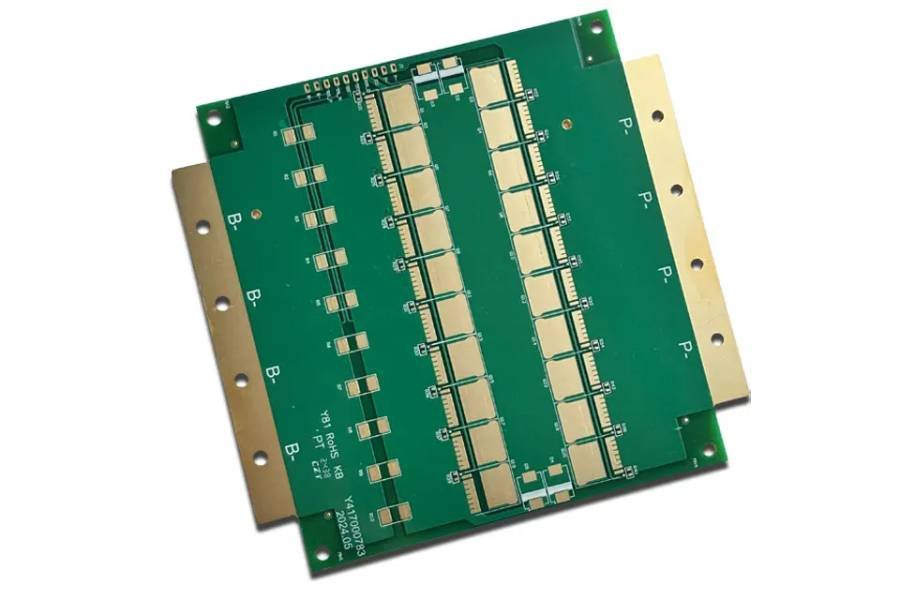

Industrial Equipment & Power Modules

Factories and heavy machinery use complex control systems and power modules operating under demanding loads. With copper core PCBs, these devices boast improved durability and consistent electrical performance, even during prolonged high-power operation or extreme environments.

Laser Devices and Advanced Controls

Precision laser modules, industrial controllers, and other specialized electronics require unwavering performance. Copper core PCBs deliver this by minimizing signal loss, managing heat, and safeguarding sensitive components against failure.

Medical & Aerospace Systems

Reliability is critical in medical devices and aerospace applications. Copper core PCBs are often selected for high-end equipment where performance, safety, and longevity are non-negotiable.

Structure and Types of Copper Core PCBs

Copper Core PCBs come in a variety of designs, each tailored for specific technical requirements and project needs. Understanding their structure and available types can help you choose or design the right board for your next innovation.

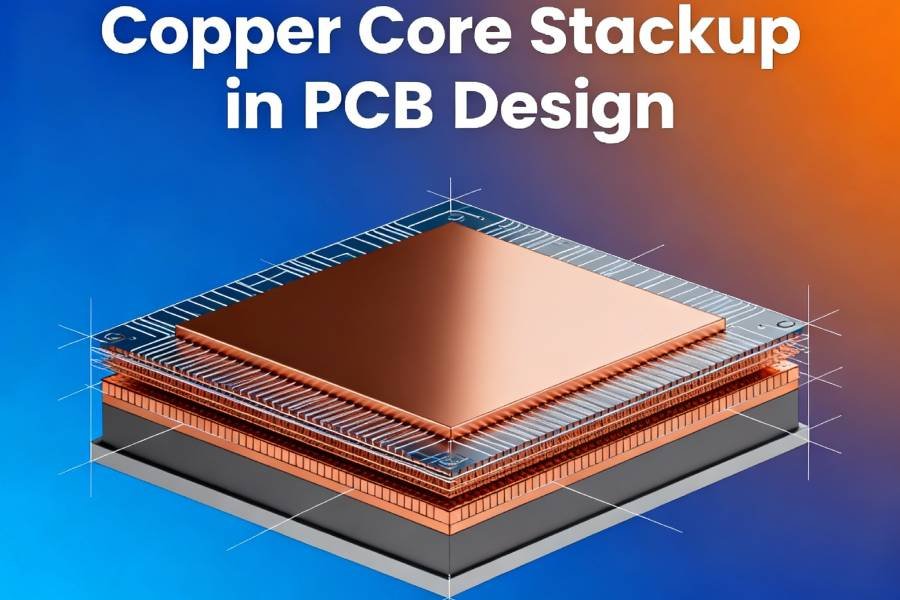

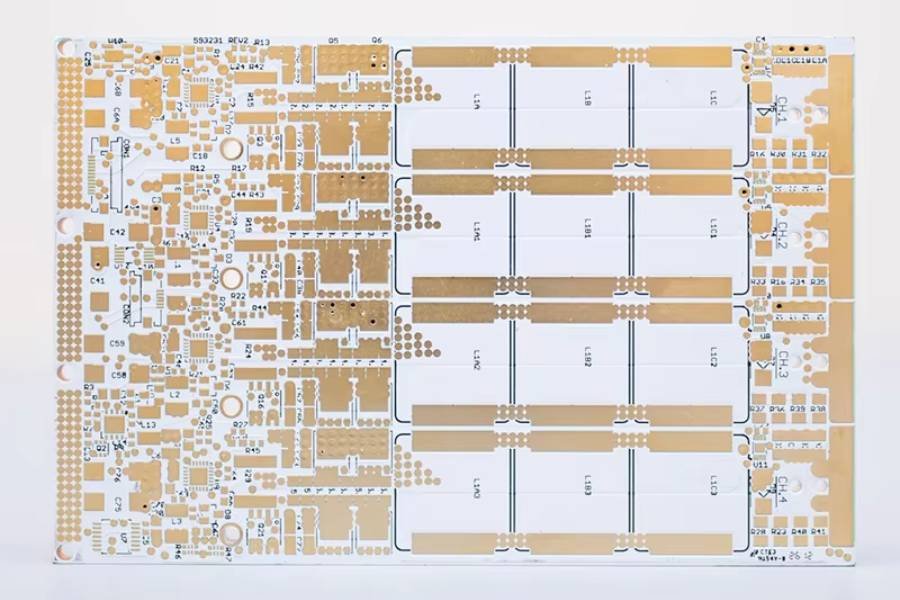

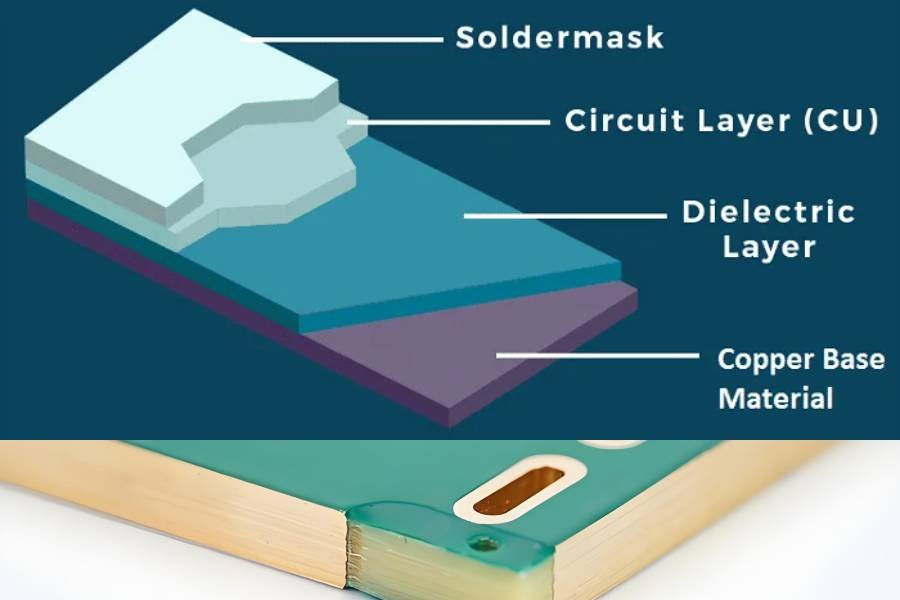

Single-Layer Copper Core PCB

The simplest version features a copper core as the base, topped with a thin layer of dielectric (insulating) material and a circuit layer made of copper foil. These are ideal for basic thermal management needs in compact designs, like small LED boards.

Double-Layer and Multi-Layer Copper Core PCBs

For more complex circuits, double-layer or multi-layer copper core PCBs stack several circuit layers, sometimes separated by additional dielectric layers. This architecture supports higher component density, advanced routing, and greater power handling—perfect for demanding industrial and automotive systems.

Copper Core Thickness Options

Copper cores are available in various thicknesses, commonly ranging from 0.5mm to several millimeters. The thickness affects both heat dissipation and mechanical strength, so engineers can select the perfect fit for their specific project and performance requirements.

Copper Foil Thickness

The thickness of the copper foil itself is another critical parameter, typically measured in ounces per square foot (oz/ft²). Thicker foil supports higher current and provides extra reliability, especially in power-intensive applications.

Stack-Up and Layout Customization

Modern copper core PCBs offer flexible stack-up possibilities. From basic 1-layer boards to intricate multi-layer arrangements, stack-up design allows for tailored thermal management, signal integrity, and compact size—all essential for cutting-edge electronics.

Learn more about 6 types of copper core PCBs

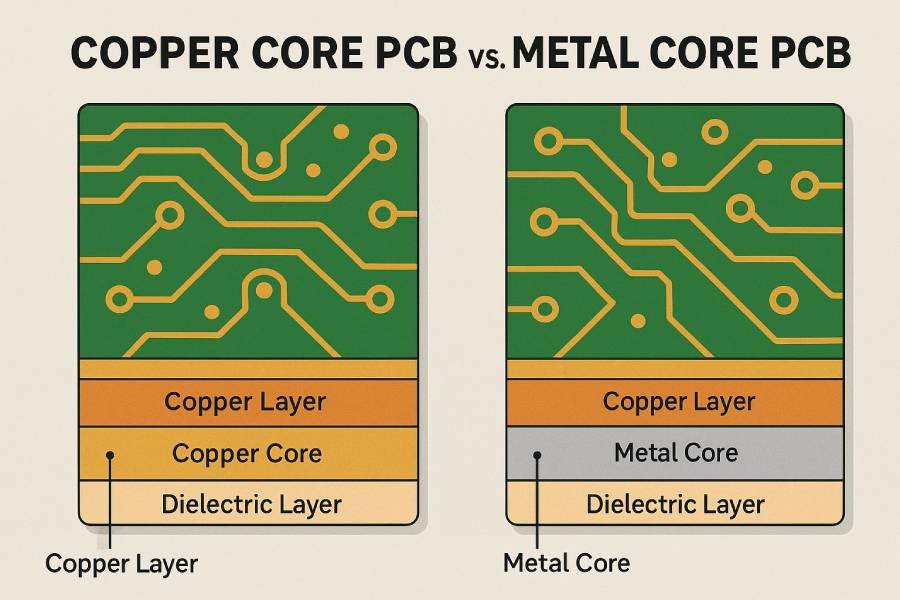

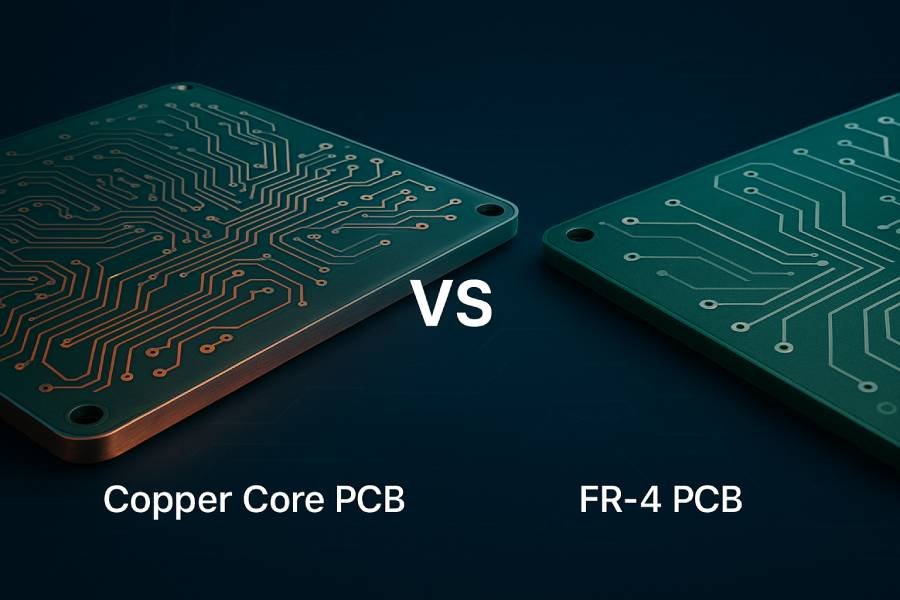

How Copper Core PCBs Compare with Standard FR4 Boards

While FR4-based PCBs use fiberglass as the substrate, copper core PCBs swap this out for a high-conductivity copper plate. This delivers far superior heat performance while also increasing board strength, durability, and, often, price.

By understanding the range of structures and customization possibilities, you can harness the full potential of copper core PCBs for projects that demand efficient cooling, robust design, and reliable high-power performance.

Design and Manufacturing Process of Copper Core PCBs

Creating a reliable Copper Core PCB requires thoughtful design and specialized manufacturing techniques. Whether you’re an engineer or a project manager, understanding these steps can help ensure optimal performance and durability.

Design Considerations

The first stage is careful PCB layout design using professional software like Altium Designer or KiCad. For copper core boards, pay extra attention to heat flow, component placement, and current pathways. Maximizing thermal conductivity often means positioning heat-generating components directly above the copper core and optimizing trace widths for current capacity.

Material Selection

Selecting the right copper core thickness, copper foil ounce rating, and dielectric layer all influence the board’s capabilities. Thicker copper enhances heat dissipation and strength, but also affects weight and cost—engineers must balance these factors based on application needs.

Manufacturing Steps

Copper core PCB manufacturing starts with precision cutting and mechanical processing of the copper substrate. The dielectric layer is then laminated onto the core, followed by the application and etching of copper foil circuits. Multi-layer boards include sequential stack-ups and bonding steps to create complex, robust structures.

Welding and Machining

Copper’s high thermal mass affects wave soldering and reflow processes. Manufacturers may implement specialized protocols, like adjusting soldering temperatures or using reinforced drill bits for mounting holes, to maintain board integrity.

Surface Treatment

To prevent oxidation and ensure long-term reliability, copper core PCBs are often finished with protective coatings, such as anti-oxidation layers or tin plating. These surface treatments boost corrosion resistance, solderability, and overall lifespan.

Thoughtful design and advanced manufacturing are the backbone of every high-quality copper core PCB—guaranteeing the board will perform under pressure and endure in demanding environments.

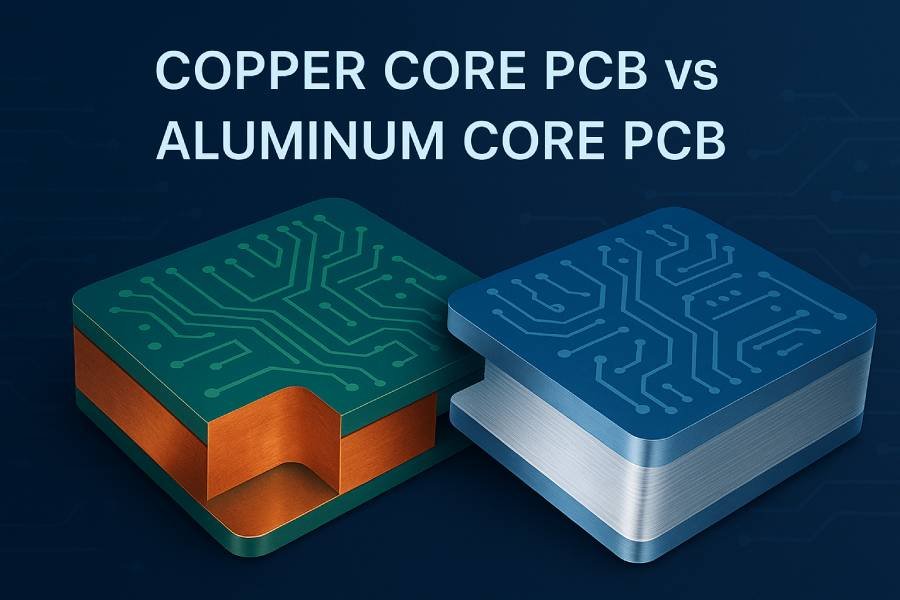

Copper Core PCBs vs. Aluminum PCBs: Which Is Best for Your Project?

If you’re searching for the ideal PCB for thermal management and robust performance, you’ll run into two main contenders: copper core PCBs and aluminum PCBs. Both have their strengths—but which one is the best fit for your needs?

Thermal Conductivity

Copper has a much higher thermal conductivity (up to 400 W/mK) than aluminum (about 200 W/mK). This means copper core PCBs excel at dissipating intense heat, making them the go-to choice for very high-power applications.

Mechanical Strength

Copper is stiffer and stronger, offering better rigidity and resistance to flexing and warping. This supports heavy components and high-stress environments, while aluminum is lighter and easier to machine.

Cost and Availability

Aluminum PCBs are generally less expensive and easier to source for mass production. Copper core PCBs offer premium performance but come at a higher price point—great for mission-critical electronics where reliability is paramount.

Manufacturing Complexity

Manufacturing copper core PCBs can be more demanding, requiring special equipment and expertise. Aluminum PCBs are simpler and more common, making them ideal for basic lighting or mid-range consumer electronics.

Typical Applications

- Copper core PCBs: High-power LEDs, automotive and industrial power electronics, aerospace, advanced medical equipment.

- Aluminum PCBs: Standard LED panels, consumer electronics, general-purpose power supplies.

| Feature | Copper Core PCB | Aluminum PCB |

|---|---|---|

| Thermal Conductivity | Up to 400 W/mK | Up to 200 W/mK |

| Mechanical Strength | Superior | Moderate |

| Price | Higher | Lower |

| Weight | Heavier | Lighter |

| Manufacturing | Complex | Easier |

| Best For | High power, critical | Economy, mid-power |

Key takeaway:

If your project demands maximum heat dissipation, top-tier reliability, and robust mechanical strength—copper core PCBs are the ultimate solution. For cost-sensitive products with average thermal needs, aluminum PCBs are often the better choice. Decide based on your application, budget, and the level of performance you require.

Market Overview and Buying Guide for Copper Core PCBs

Selecting the right copper core PCB supplier is just as important as choosing the board design itself. The market offers a wide range of manufacturers, each with competitive pricing, quality standards, and unique capabilities.

Major Suppliers and Manufacturers

Global leaders like JHYPCB, JLCPCB, PCBWay, and Candor Industries specialize in copper core PCBs, providing options for rapid prototyping, low-volume orders, and full-scale mass production. When browsing for suppliers, look for those with ISO certifications, advanced testing procedures, and a proven track record in automotive, LED, and industrial sectors.

Key Purchase Factors

- Copper Core Thickness: Thicker cores improve heat dissipation but increase weight and cost; align your choice with your application’s thermal and mechanical needs.

- Copper Foil Specifications: Double-check foil thickness (measured in ounce/ft²) and ensure it meets your current capacity requirements.

- Board Dimensions and Tolerances: Confirm that the supplier can meet your size specifications, tight tolerances, and offer custom routing or drilling.

- Quality Control and Certifications: Prioritize manufacturers with strict quality inspection, offering guarantees or third-party certifications.

- Production Lead Time: Evaluate sample lead time and mass production cycle—speedy turnaround can be crucial for time-sensitive projects.

Product Categories and Price Ranges

Copper core PCBs are available as single-layer, double-layer, or multi-layer boards. Pricing depends on copper thickness, board complexity, size, and order quantity. Expect to pay a premium over standard PCBs, especially for low-quantity orders or thick-copper models.

Ordering Tips

- Request engineering samples or prototype runs for testing before full production.

- Communicate your thermal, electrical, and mechanical requirements clearly.

- Work closely with the supplier’s engineering team to address manufacturability or design-for-assembly (DFA) issues early.

With careful supplier selection and clear technical communication, you’ll get a copper core PCB engineered for both performance and reliability—giving your project a clear competitive edge.

Common Questions About Copper Core PCBs (FAQ)

How much does a copper core PCB improve heat dissipation?

Copper core PCBs can dissipate heat up to twice as fast as standard aluminum or FR4 boards, thanks to copper’s thermal conductivity of around 400 W/mK. This makes them ideal for high-power applications, prolonging component life and boosting stability.

How thick should the copper core be?

The optimal copper core thickness depends on your thermal and mechanical requirements. Common options range from 0.5mm to 3mm. Thicker cores lead to better cooling but also increase cost and board weight. For most LED or power electronics, 1–2mm strikes a good balance.

Are copper core PCBs much more expensive than regular PCBs?

Yes, copper core PCBs typically cost more than FR4 or aluminum boards—sometimes significantly so, especially for small orders or boards with thick copper. The price premium is justified for critical projects demanding maximum reliability and heat performance.

Can copper core PCBs be manufactured in multi-layer structures?

Absolutely! Multi-layer copper core PCBs are widely available, supporting advanced circuit complexity and higher component density. Be sure to coordinate stack-up and via planning with your supplier for optimum results.

Is there any downside to using copper core PCBs?

The main considerations are increased material cost, added weight, and the need for specialized manufacturing processes. For applications with moderate power or where weight/cost are primary concerns, aluminum or FR4 PCBs may still be better options.

How do I order a custom copper core PCB?

Start by preparing precise technical specifications, including copper and foil thickness, thermal requirements, and any special design restrictions. Most major suppliers offer online customization tools and expert engineering support to help you get it right.

If you have specific requirements or wonder which PCB type fits your project, contact your preferred supplier for tailored advice—they’ll help you find the best thermal, mechanical, and cost-effective solution.

Conclusion & Future Trends for Copper Core PCBs

Copper core PCBs are reshaping the landscape of modern electronic design. With unmatched thermal performance, mechanical strength, and electrical reliability, they’ve become the preferred solution for high-power, mission-critical, and innovation-driven projects across industries.

Why Choose Copper Core PCBs?

Choosing copper core PCBs means embracing cutting-edge thermal engineering and durability. From advanced automotive electronics to next-generation LED lighting, these boards set the standard for managing heat and ensuring long-term stability.

Emerging Technologies and Market Growth

The demand for copper core PCBs continues to rise, driven by surging applications in electric vehicles, smart manufacturing, renewable energy, medical imaging, and high-performance industrial controls. As circuits become increasingly compact—and heat management ever more critical—expect copper substrates to gain a larger foothold.

Technical Innovations Ahead

Manufacturers are actively developing smarter copper core PCB materials, new stack-up designs, and advanced fabrication methods. This includes hybrid boards combining copper with other metals or ceramics, improved dielectric layers, and ultra-precise routing for demanding signal integrity needs.

A Competitive Advantage for Tomorrow

Investing in copper core PCBs is more than just a technical upgrade—it’s a strategic decision that helps your products outperform competition. Whether you’re tackling design complexity, heat issues, or reliability challenges, copper core technology will be at the heart of future electronics innovation.

In a fast-evolving world, copper core PCBs ensure your products are built to last, operate efficiently, and unlock the next wave of electronic breakthroughs. Now is the time to explore and apply this powerful solution as you shape the future of your industry.