Table of Contents

Why Choosing the Right LED PCB Manufacturer Matters

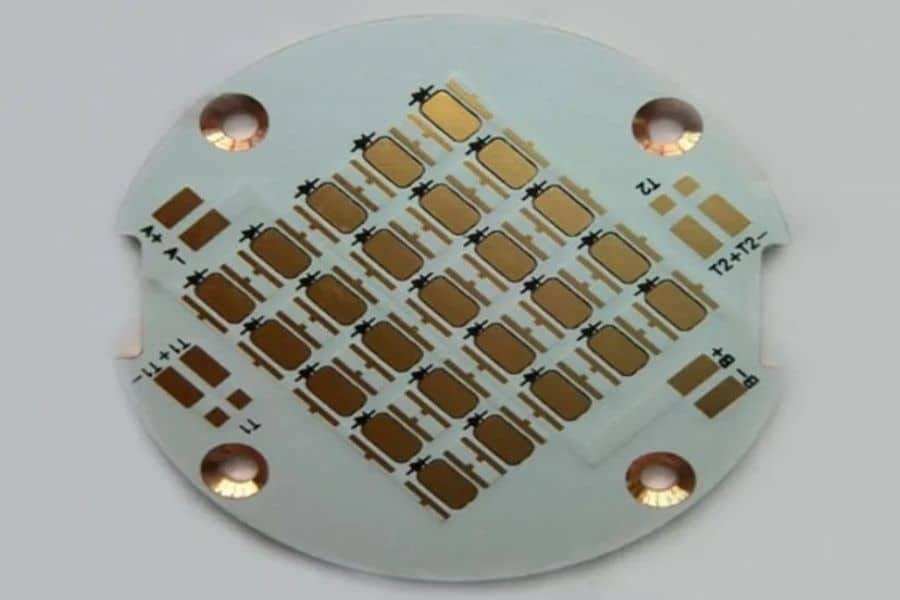

In modern lighting and electronics, the performance and reliability of your product depend heavily on the quality of its LED PCB. A well‑designed and well‑manufactured LED PCB directly affects heat dissipation, luminous efficiency, service life, and overall safety of LED lighting systems. For this reason, choosing a reliable LED PCB manufacturer is one of the most critical decisions for OEMs, lighting brands, and hardware startups.

Today, many buyers turn to China LED PCB manufacturers to take advantage of mature supply chains and competitive pricing. However, not every LED PCB factory can consistently deliver stable quality, fast lead times, and professional engineering support. The wrong choice can lead to frequent failures, color inconsistency, high RMA rates, and serious reputational damage in your target market.

This guide will walk you through how to evaluate and select a trustworthy LED PCB manufacturer for your next project. It will cover key factors such as aluminum LED PCB and metal‑core PCB capabilities, LED PCB assembly processes, quality certifications, engineering support, and after‑sales service. By following these practical steps and questions, you can identify a long‑term manufacturing partner that helps you launch high‑reliability LED products faster and at a lower total cost.

Understand Your LED PCB Requirements First

Before you start contacting any LED PCB manufacturer, it is essential to clearly define your technical and business requirements. A well‑defined specification helps you filter out unsuitable suppliers early and ensures that your aluminum LED PCB or FR‑4 LED board is designed for optimal performance, reliability, and cost.

1 Define Your LED PCB Type and Application

Different applications require different LED PCB structures and materials, so you should first clarify how and where your board will be used.

- Decide whether you need an aluminum LED PCB, standard FR‑4 LED PCB, metal core PCB (MCPCB), or flexible/rigid‑flex LED PCB, based on your thermal and mechanical requirements.

- Match the LED PCB type to the final product scenario, such as indoor LED lighting, outdoor street lights, automotive lighting, LED display modules, signage, backlight units, or high‑power industrial lamps.

- Consider environmental conditions including operating temperature, humidity, vibration, dust, and potential exposure to UV or chemicals, which may affect material selection and protective coatings.

2 Clarify Key Electrical and Thermal Parameters

Once the basic type and application are clear, you should refine the electrical and thermal specifications that your LED PCB manufacturer must meet.

- Specify working voltage and current, total power, power density, and the number of LEDs per board to ensure safe and stable operation of high‑power LED PCB designs.

- Define copper thickness, trace width and spacing, minimum hole size, and layer count so the LED PCB factory can confirm whether your design fits its manufacturing capabilities.

- Set clear thermal requirements, such as target junction temperature, required thermal conductivity of the metal core PCB, and heatsink or thermal via strategy, to guarantee efficient heat dissipation and longer LED lifetime.

3 Mechanical, Optical and Quality Requirements

Beyond basic electrical and thermal parameters, you should also think about mechanical constraints, optical performance, and quality standards.

- Define board outline, dimensions, thickness, panelization method, connector positions, and any special mechanical features, especially for custom aluminum LED PCB shapes used in architectural or automotive lighting.

- Consider optical requirements like LED spacing, color consistency, color temperature, brightness uniformity, and compatibility with lenses or light guides for your LED PCB assembly.

- Identify the quality and compliance standards you must meet (such as RoHS, REACH, UL, or automotive/industrial standards) and prepare any required reliability tests, including thermal cycling, aging tests, or IP‑rating related verifications.

4 Budget, Volume and Lead Time Expectations

Clear commercial expectations are also part of your requirements and will influence which LED PCB manufacturer is most suitable.

- Estimate your prototype, small batch, and mass production volumes, and decide whether you need a China LED PCB factory that can support both quick prototypes and long‑term stable mass production.

- Define your target cost range per board or per set, considering not only PCB fabrication but also LED PCB assembly, component sourcing, testing, and logistics.

- Set realistic lead time expectations for samples and mass production, especially if you have strict product launch schedules or seasonal demand peaks.

Evaluate Core Manufacturing Capabilities

Choosing a reliable LED PCB manufacturer starts with a clear understanding of its real manufacturing capabilities. A factory may claim to offer aluminum LED PCB, high‑power LED PCB, and one‑stop LED PCB assembly services, but only detailed capability verification can tell you whether it truly fits your project. By checking process limits, equipment, and production flow, you reduce the risk of hidden quality problems and production delays.

1 PCB Fabrication Capabilities

First, you should confirm whether the manufacturer can steadily produce the type of LED PCB you need, especially for metal core PCB and aluminum LED PCB used in high‑power lighting.

- Check the supported PCB types: single‑sided and double‑sided aluminum LED PCB, FR‑4 LED PCB, metal core PCB (MCPCB), multi‑layer boards, and rigid‑flex or flexible LED boards.

- Ask for clear process capability data, such as minimum trace width and spacing, minimum hole size, maximum panel size, copper thickness range, and board thickness range for your LED PCB designs.

- Confirm whether the factory can handle special requirements like thick copper for high‑current LED circuits, heavy plating, controlled impedance, or special surface finishes (ENIG, HASL, OSP, etc.).

2 LED PCB Assembly and SMT Capabilities

For many projects, it is more efficient to work with a manufacturer that can provide both LED PCB fabrication and LED PCB assembly under one roof. This reduces communication gaps and speeds up time‑to‑market.

- Verify the SMT equipment level, including high‑speed pick‑and‑place machines, reflow ovens with well‑controlled temperature profiles, and the ability to handle a wide range of LED packages (SMD, COB, high‑power LEDs, CSP, etc.).

- Confirm whether the LED PCB assembly line supports mixed technology (SMT + THT), double‑sided assembly, and special processes such as conformal coating or potting for outdoor and automotive LED applications.

- Ask about sample and mass production capabilities: Can the factory provide quick‑turn prototypes, small‑batch runs, and stable large‑volume production for the same LED PCB project?

3 Process Control, Automation and Yield

Beyond basic equipment, you should pay attention to how well the LED PCB manufacturer controls its processes and yield. Stable process control is a key indicator of a truly reliable LED PCB factory.

- Ask about standard operating procedures (SOPs), work instructions, and how process parameters are monitored and recorded during PCB fabrication and LED PCB assembly.

- Understand the factory’s automation level, such as automated solder paste printing, SPI, AOI, and inline testing, which help reduce defects and maintain consistent quality for high‑volume LED PCB orders.

- Request typical yield data or defect rates for similar LED PCB products, and ask how the manufacturer analyzes and solves issues like solder joint defects, LED failures, or warpage on aluminum LED PCB panels.

4 Support for Special LED Applications

If your project targets demanding applications, you should further verify whether the manufacturer has specific experience and capabilities in that field.

- For high‑power LED lighting, check their experience with thermal management, thick copper designs, and advanced metal core PCB structures.

- For outdoor or automotive LED applications, confirm their ability to meet requirements related to waterproofing, vibration resistance, wide operating temperature ranges, and long‑term reliability.

- For LED display modules, signage, or backlight units, ask about their experience in ensuring color consistency, brightness uniformity, and tight mechanical tolerances across large panel arrays.

Check Quality System, Certifications and Testing

A truly reliable LED PCB manufacturer is not only defined by its equipment and process capabilities, but also by its quality system and traceable testing practices. Robust quality management helps ensure that every aluminum LED PCB or metal core PCB leaving the factory meets your performance, safety, and reliability requirements over the entire product life cycle.

1 Quality Management System and Certifications

The first step is to verify whether the manufacturer operates under a formal quality management framework and holds relevant certifications for your target markets.

- Check if the LED PCB manufacturer is certified to standards such as ISO 9001 for quality management and ISO 14001 for environmental management, which indicates that key processes are documented, monitored, and continuously improved.

- Confirm whether the factory has product safety and compliance certifications such as UL recognition for PCB materials and structures, as well as RoHS and REACH compliance for hazardous substances control.

- If your application is in automotive, medical, or other highly regulated industries, ask whether they have experience complying with standards like IATF 16949 or specific customer/industry‑level quality requirements.

2 Incoming Material Control and Traceability

Material quality is critical for LED performance and reliability, especially for aluminum substrates, copper foil, solder mask, and LED components used in LED PCB assembly.

- Ask how the manufacturer manages incoming inspection of base materials, including aluminum cores, FR‑4 laminates, solder mask inks, and chemical solutions, and whether these are sourced from reputable, traceable suppliers.

- Confirm whether each batch of aluminum LED PCB or metal core PCB can be traced back to specific material lots and production records, so that any quality issue can be quickly contained and analyzed.

- Check if the factory keeps material certificates, test reports, and compliance documents that you can use in your own product documentation and regulatory filings.

3 In‑Process Control and Final Testing

Even with good materials, poor process control can still lead to failures in the field, so you should understand how the factory monitors quality during PCB fabrication and LED PCB assembly.

- Verify whether the manufacturer performs 100% electrical testing (flying‑probe or fixture‑based) on PCBs to detect open/short circuits before assembly, especially for complex LED layouts or high‑power designs.

- Ask about optical inspection and X‑ray inspection capabilities used during LED PCB assembly, such as AOI for solder paste and component placement, and X‑ray for hidden joints or voids under high‑power LED packages.

- Confirm the existence of detailed first‑article inspection (FAI) and process audits, which help ensure that the first batch of your LED PCB meets all critical dimensions, layout, and functional requirements before mass production.

4 Reliability, Aging and Special Tests

For high‑power and long‑life LED lighting products, reliability tests and aging processes are particularly important.

- Ask whether the LED PCB manufacturer can perform thermal cycling, high‑temperature/high‑humidity storage, and power‑on aging tests to simulate real usage conditions for aluminum LED PCB and metal core PCB products.

- For outdoor, automotive, or industrial applications, confirm whether they can support tests related to vibration, corrosion resistance, IP rating (dust and water protection), and UV exposure.

- Request example test reports or reliability data for similar LED PCB assemblies, including failure modes and corrective actions, to better understand how the factory handles potential quality issues.

5 Documentation, Reporting and Continuous Improvement

Beyond performing tests, a professional LED PCB factory should be able to document and communicate the results in a transparent and structured way.

- Confirm whether you will receive complete documentation packages, such as inspection reports, test data, certificates of compliance, and PPAP‑like documents where necessary.

- Ask how non‑conformities are recorded and handled, including root‑cause analysis, corrective and preventive actions (CAPA), and how lessons learned are fed back into daily production.

- Evaluate whether the manufacturer is open to periodic quality reviews, audits, and continuous improvement discussions, which are essential for building a long‑term, high‑reliability supply relationship.

Assess Engineering Support and DFM/DFT Capability

Strong engineering support is one of the key differences between an average LED PCB manufacturer and a truly reliable long‑term partner. A capable engineering team can help you optimize the PCB structure and manufacturing process at an early stage, significantly reducing rework, delays, and field failures, especially for complex aluminum LED PCB and high‑power LED PCB projects.

1 Professional Engineering Team and Communication

- Evaluate whether the LED PCB manufacturer has a dedicated engineering team with hands‑on experience in aluminum LED PCB, metal core PCB (MCPCB), and high‑power LED layouts, not only standard FR‑4 boards.

- Confirm that their engineers can communicate clearly in English, interpret Gerber files, BOM, assembly drawings, and provide practical process suggestions instead of simply “building to print”.

- Ask if you will have a fixed engineering contact or project manager who follows your job from prototype, through engineering review, to mass production ramp‑up.

2 DFM (Design for Manufacturability) Review

A robust DFM review helps identify potential issues before production, so problems do not emerge only during LED PCB assembly or in the field.

- Check whether the LED PCB manufacturer provides a structured DFM report that covers board thickness, copper thickness, minimum trace width and spacing, via design, solder mask openings, panelization, and process rails.

- Ask if they can propose optimization suggestions for high‑power LED traces, copper pour areas, thermal via arrays, and panel design to improve yield and reduce hotspots or soldering defects.

- Confirm that they will proactively communicate with you when they find major risks, such as silkscreen covering pads, unclear LED polarity markings, or insufficient clearance that might lead to short circuits.

3 DFT (Design for Testability) and Test Strategy

For high‑reliability LED applications, design for testability is equally important, because it ensures that defects can be detected efficiently during production.

- Ask whether the engineering team can provide DFT suggestions on test point placement, test interfaces, and functional test concepts, so your LED PCB can be tested effectively in mass production.

- Confirm that the manufacturer can support multiple test methods, such as flying‑probe testing, in‑circuit testing (ICT), functional test fixtures, and lighting tests for assembled LED PCB boards.

- Evaluate whether they can help define test coverage and sampling plans according to your application (for example, automotive lighting, outdoor lighting, or LED display modules), instead of only performing basic continuity checks.

4 File Formats, Data Handling and Design Support

A mature LED PCB manufacturer should be able to handle different engineering data formats and manage them securely and efficiently.

- Confirm which file formats are supported, including Gerber, ODB++, native CAD files, BOM, and pick‑and‑place files, and ask about their data backup and confidentiality policies.

- Ask if they can assist with minor design adjustments, such as optimizing copper areas, designing panelization, adding process rails, or fine‑tuning via and pad sizes to better match their process capabilities and improve yield.

- Check whether they offer early‑stage feasibility evaluations, helping you compare different materials, copper thicknesses, and stack‑ups and how these choices affect thermal performance, cost, and lead time.

5 Prototyping Support and Design Iteration

High‑quality engineering support is also reflected in how the manufacturer handles prototypes and design iterations.

- Evaluate whether the LED PCB manufacturer can provide fast prototyping services and also share feedback after each trial run, instead of only shipping boards without any engineering comments.

- Ask how they manage multiple design revisions: Do they keep clear version control and engineering change (ECO) records to ensure old versions are not produced by mistake?

- Confirm that they will re‑review critical DFM/DFT points when your project moves from prototype to mass production, ensuring that the success of small‑batch builds can be reliably replicated at higher volumes.

Review Materials, Supply Chain and Component Sourcing

For LED products, material selection and component sourcing are just as important as PCB manufacturing itself. A reliable LED PCB manufacturer should not only offer good aluminum LED PCB and metal core PCB processing, but also manage its supply chain carefully to ensure long‑term stability, consistency, and compliance.

1 Base Materials and Thermal Performance

- Confirm which base materials the manufacturer uses for aluminum LED PCB and metal core PCB (MCPCB), including the brands and grades of aluminum core, dielectric layer, and copper foil.

- Ask about the thermal conductivity of the dielectric layer, glass transition temperature (Tg), and recommended operating temperature range to ensure your high‑power LED PCB can maintain safe junction temperatures.

- Check whether the factory can provide UL‑listed or certified materials, and whether they can offer material certificates and data sheets for your technical documentation and compliance checks.

2 Solder Mask, Surface Finish and Solderability

- Verify the type and brand of solder mask inks used, and whether they are optimized for LED applications, for example high reflectivity white solder mask for better luminous efficiency.

- Ask which surface finishes are available (such as HASL, lead‑free HASL, ENIG, immersion silver, OSP) and which one they recommend for your LED PCB assembly process and component types.

- Confirm that the manufacturer has proven process control to avoid issues like poor solderability, surface oxidation, or discoloration that could impact LED performance and appearance.

3 LED Components and BOM Sourcing

If you plan to use one‑stop LED PCB assembly services, the manufacturer’s component sourcing capability becomes a critical factor.

- Ask whether the LED PCB manufacturer sources LEDs and other components directly from authorized distributors or original manufacturers, to minimize the risk of counterfeit or degraded parts.

- Check if they can work with your approved vendor list (AVL) and specific LED brands or series, especially when color consistency, LM‑80/LM‑79 data, or bin control are important for your project.

- Confirm how they handle alternatives or substitutions: you should approve any replacement for critical parts such as LEDs, drivers, connectors, or thermal interface materials.

4 Supply Chain Stability and Lead Time Risk

- Evaluate the manufacturer’s supply chain resilience by asking about their key material and component suppliers, as well as backup options in case of shortages or disruptions.

- Ask how they forecast and manage lead times for aluminum cores, laminates, solder mask, and key LED components, and whether they can support buffer stock or vendor‑managed inventory for long‑term projects.

- Check if they have experience handling global supply challenges (for example, sudden demand peaks or logistics delays) and what contingency plans they can offer for your LED PCB assemblies.

5 Compliance, Environmental and Documentation Requirements

- Confirm that all materials and components used in your LED PCB and LED PCB assembly are compliant with regulations such as RoHS and REACH, and request supporting documentation such as declarations and test reports.

- Ask whether the factory can support additional requirements like halogen‑free materials or specific regional regulations if your LED products will be sold in markets with stricter rules.

- Ensure that the manufacturer can provide a complete documentation package covering material lists, certificates, and traceability information, so that your quality and regulatory teams can easily audit and maintain compliance over time.

By carefully reviewing materials, supply chain management, and component sourcing practices, you can choose an LED PCB manufacturer that not only meets your technical requirements, but also protects your project from supply interruptions, quality fluctuations, and compliance risks in the long run.

Compare Lead Time, Cost and Flexibility

When choosing a reliable LED PCB manufacturer, it is not enough to look at technical capability alone. Lead time, pricing structure, and production flexibility directly affect your time‑to‑market and overall project profitability, especially for fast‑moving LED lighting and electronics markets.

1 Prototype and Mass Production Lead Time

- Ask for typical lead times for bare LED PCB fabrication, LED PCB assembly prototypes, small batches, and mass production, and check whether they can support quick‑turn services when needed.

- Verify if the manufacturer can keep lead times stable during peak seasons, and whether they offer priority or expedited options for urgent aluminum LED PCB or high‑power LED PCB orders.

- Confirm how they handle engineering changes (ECOs) and whether such changes will significantly impact lead time once your project has entered mass production.

2 Cost Structure and Total Cost of Ownership

- Look beyond the unit price of the PCB and consider the full cost structure, including tooling, setup charges, LED PCB assembly costs, testing, packaging, and logistics.

- Evaluate how yield rates, rework rates, and field failure rates might affect your total cost of ownership; a slightly higher unit price from a high‑quality LED PCB manufacturer may still result in lower overall costs.

- Ask for transparent quotations that break down major cost elements, so you can compare different LED PCB factories fairly and identify where cost optimization is truly possible.

3 Pricing Transparency and Long‑Term Stability

- Check whether the manufacturer has clear pricing rules for changes in board size, layer count, copper thickness, or component counts in LED PCB assemblies.

- Ask how often they review pricing and under what conditions prices may increase, for example due to raw material fluctuations or exchange rate changes.

- Evaluate whether they are open to long‑term pricing agreements, volume discounts, or framework contracts that give you better cost visibility for future LED projects.

4 Capacity, Scalability and Production Flexibility

- Confirm current production capacity and how much room the LED PCB manufacturer has to grow with your project, from initial prototypes to high‑volume mass production.

- Ask if they can flexibly switch between different batch sizes, product variants, or LED PCB assembly configurations without excessive setup times or surcharges.

- Check how they schedule production for urgent orders, engineering trial runs, and regular mass production, and whether your orders will receive stable priority as your cooperation deepens.

5 Logistics, Incoterms and Delivery Options

- Understand the available shipping options (express, air, sea) and typical transit times from the factory to your main markets, especially if you work with a China LED PCB manufacturer.

- Clarify Incoterms (such as EXW, FOB, CIF, DAP) and how responsibilities and costs are split for freight, customs clearance, and insurance.

- Ask if they can support consolidated shipments, scheduled deliveries, or shipment directly to your EMS partners or end customers to simplify your supply chain.

By comparing lead time performance, cost structure, and production flexibility in a structured way, you can identify an LED PCB manufacturer that not only meets your technical requirements but also supports your business goals and product roadmap over the long term.

Verify Experience, Case Studies and Market Reputation

Technical capability alone is not enough; a truly reliable LED PCB manufacturer also needs proven experience, successful case studies, and a solid market reputation. Verifying these aspects helps you reduce the risk of hidden quality issues and ensures the supplier can support your LED projects in real‑world conditions.

1 Industry Experience and Application Focus

- Check how many years the manufacturer has been producing LED PCB and LED PCB assembly, and whether LED applications are a major focus rather than a minor side business.

- Ask for details about their experience with different LED markets, such as general lighting, automotive lighting, outdoor and street lighting, LED display modules, signage, and backlight units.

- Verify whether they have experience with aluminum LED PCB, high‑power LED PCB, and metal core PCB (MCPCB) specifically, not just standard FR‑4 boards.

2 Reference Projects and Case Studies

- Request case studies or reference projects similar to your own, including photos, technical highlights, and key challenges solved by the LED PCB manufacturer.

- Ask for examples that demonstrate high reliability, such as projects involving long‑life outdoor lighting, automotive or industrial LED systems where durability and thermal management are critical.

- Look for evidence that the factory can handle the full process, from design support and prototyping to stable mass production of complex LED PCB assemblies.

3 Customer References and Long‑Term Partnerships

- Ask if the manufacturer can provide customer references (where confidentiality allows) so you can understand real‑world performance in areas like quality, delivery, communication, and after‑sales support.

- Pay attention to whether they have long‑term customers who have cooperated with them for many years, especially in demanding LED markets; this is a strong sign of consistent performance.

- Evaluate whether they are willing to sign NDAs and respect intellectual property, which is essential for building trust in LED product development.

4 Online Presence and Third‑Party Feedback

- Review the manufacturer’s website, technical articles, and documentation to see if they demonstrate deep understanding of LED PCB, aluminum LED PCB, and LED PCB assembly processes.

- Check third‑party platforms, forums, or industry directories for general feedback on the company’s responsiveness, product quality, and reliability.

- Be cautious of factories with very limited information, inconsistent branding, or no traceable history, especially if they offer unusually low prices for complex LED PCB work.

5 Factory Visits, Audits and Trial Orders

- Whenever possible, plan a factory visit or remote audit to verify that their actual production scale, equipment, and process control match what is promised in presentations or quotations.

- Use an initial trial order or pilot run to validate real performance in lead time, quality, communication efficiency, and problem‑solving before committing to large‑volume LED PCB assemblies.

- Observe how the manufacturer handles issues during the trial phase; a reliable LED PCB manufacturer responds quickly, shares root‑cause analysis, and takes corrective actions proactively.

By systematically checking experience, case studies, references, and real customer feedback, you can shortlist LED PCB manufacturers that have already proven themselves in the market, rather than relying only on brochures and price quotes.

Communication, Service and After‑Sales Support

Even the best LED PCB technology can fail to deliver value if communication is slow or after‑sales support is weak. Choosing an LED PCB manufacturer with responsive service and clear processes helps you avoid delays, misunderstandings, and unresolved quality issues over the entire product lifecycle.

1 Responsiveness and Technical Communication

- Evaluate how quickly the supplier responds to your inquiries, RFQs, and engineering questions, both during the quotation phase and after orders are placed.

- Confirm that you have direct access to technical personnel (engineers, project managers) who can discuss aluminum LED PCB designs, stack‑ups, and LED PCB assembly details, not only sales staff.

- Check whether they provide clear written communication on issues such as design feedback, DFM/DFT findings, and schedule changes, instead of vague or inconsistent replies.

2 Project Management and Information Transparency

- Ask if the LED PCB manufacturer assigns a dedicated account or project manager for your key projects, responsible for coordinating engineering, production, and logistics.

- Verify whether they can provide regular status updates for important orders, including PCB fabrication progress, LED PCB assembly stages, testing completion, and shipment schedules.

- Evaluate how they handle engineering changes (ECOs): you should see a structured process with version control, confirmation steps, and clear impact analysis on cost and lead time.

3 Handling Issues and Corrective Actions

- Understand their standard procedure when problems occur, such as delays, quality defects, or shipping damage: who is responsible, how quickly they respond, and how they communicate root‑cause analysis.

- Ask whether they have a formal corrective and preventive action (CAPA) system to document issues, analyze root causes, and implement improvements on future LED PCB and LED PCB assembly runs.

- Check if they are willing to share test data, photos, and analysis reports when failures occur, and whether they can cooperate with your team on joint failure analysis for critical projects.

4 After‑Sales Support and Warranty

- Clarify the warranty terms for LED PCB and assembled LED boards, including coverage scope, warranty period, and conditions under which claims are accepted or excluded.

- Ask how they support you when field failures or returns occur: for example, failure analysis, rework, replacement, or cost‑sharing arrangements for confirmed manufacturing defects.

- Evaluate whether they are prepared to support long‑term spare parts and repeat orders for existing LED PCB designs, especially for products with multi‑year lifecycles.

5 Cultural Fit and Long‑Term Collaboration

- Consider whether the manufacturer’s working style, communication habits, and problem‑solving attitude fit your company culture and expectations.

- Look for signs of a partnership‑oriented mindset: proactive suggestions, openness to process improvement, and willingness to invest time in understanding your LED product roadmap.

- Prefer an LED PCB manufacturer who aims to build a long‑term relationship rather than only chasing one‑time orders, as this usually leads to better support, more stable quality, and more competitive total cost over time.

Practical Checklist and Key Questions to Ask

This chapter turns the previous analysis into a practical checklist you can use when evaluating any LED PCB manufacturer. It is designed to help you quickly compare suppliers and identify which one is the best fit for your LED projects.

10.1 LED PCB Manufacturer Checklist

When you screen or audit a potential partner, systematically review the following points:

- Technical capabilities

- Can they reliably produce aluminum LED PCB, metal core PCB (MCPCB), and high‑power LED PCB for your application?

- Do their process limits (minimum trace/space, via size, copper thickness, panel size) match your current and future designs?

- LED PCB assembly and testing

- Do they offer in‑house LED PCB assembly with suitable SMT equipment, reflow profiles, and inspection (AOI, X‑ray, functional test)?

- Can they support required tests such as 100% electrical test, lighting test, and, if needed, reliability or aging tests?

- Quality system and certifications

- Are they certified to relevant standards (for example ISO 9001) and compliant with RoHS/REACH or other required regulations?

- Do they have documented procedures, traceability, and a clear approach to corrective and preventive actions?

- Engineering, DFM/DFT and support

- Is there a professional engineering team providing DFM/DFT review and proactive suggestions for LED PCB designs?

- Do they handle design files, revisions, and ECOs with robust version control and clear communication?

- Materials, sourcing and supply chain

- Which materials and brands are used for aluminum cores, laminates, solder mask, and LEDs, and are they traceable and documented?

- Do they have stable component sourcing channels and backup options for critical parts?

- Lead time, cost and flexibility

- Are prototype and mass‑production lead times clear and realistic, including options for quick‑turn orders?

- Is the pricing structure transparent, and can they scale flexibly from small batches to high‑volume LED PCB assemblies?

- Experience and reputation

- Do they have case studies or references for similar LED applications in your target market?

- Is there evidence of long‑term partnerships with other customers and a positive reputation in terms of quality and service?

- Communication and after‑sales

- How fast and clearly do they respond to technical questions and project updates?

- Are after‑sales processes (warranty, failure analysis, replacement) clearly defined and reasonable?

10.2 Key Questions to Ask Your LED PCB Manufacturer

Use these questions during RFQ, technical discussions, or factory audits to get deeper insight:

- Capabilities and process

- “What are your standard and maximum capabilities for aluminum LED PCB and metal core PCB (thickness, copper weight, panel size, thermal conductivity)?”

- “Which types of LED packages and assembly processes do you handle most frequently?”

- Quality and testing

- “Which quality certifications do you hold, and what kind of in‑process and final tests do you routinely perform for LED PCB assemblies?”

- “Can you share typical yield rates or defect data for similar LED projects?”

- Engineering and design support

- “Do you provide formal DFM/DFT reviews, and can you show examples of reports or improvements you suggested for other LED customers?”

- “How do you manage design revisions and ECOs to avoid production using outdated files?”

- Materials and sourcing

- “Which material and LED brands do you typically use, and can you work with our specified AVL or preferred components?”

- “How do you ensure traceability and compliance (RoHS, REACH, UL where applicable) for all materials and components?”

- Lead time and logistics

- “What are your standard lead times for prototypes and mass production, and what options exist for expedited orders?”

- “Which shipping methods and Incoterms do you usually work with for international customers?”

- Service and long‑term cooperation

- “How do you handle quality issues or field failures, and what is your typical response and resolution time?”

- “How do you support customers over the long term when products require stable supply for many years?”

By using this checklist and these targeted questions, you can compare LED PCB manufacturers in a structured way, quickly identify red flags, and focus your time and resources on those suppliers most likely to become reliable, long‑term partners for your LED products.

Conclusion: Building a Long‑Term Partnership

Choosing a reliable LED PCB manufacturer is not just a one‑time sourcing decision; it is the foundation of a long‑term technical and supply chain partnership that directly shapes the performance, reliability, and competitiveness of your LED products. A strong partner can help you optimize aluminum LED PCB designs, improve LED PCB assembly yields, shorten time‑to‑market, and reduce total cost of ownership over the entire product lifecycle.

When making your final decision, look beyond the lowest unit price and consider the complete picture: manufacturing capabilities, quality systems, engineering support (DFM/DFT), material and component sourcing, lead time and flexibility, proven experience, communication efficiency, and after‑sales service. A manufacturer that consistently performs well in all these areas is far more likely to support your long‑term roadmap, handle product upgrades smoothly, and protect your brand reputation in demanding LED markets.

By using the structured approach and practical checklist outlined in this guide, you can confidently evaluate and compare different LED PCB manufacturers and identify the one that best fits your technical requirements, business goals, and growth plans. In the end, the right LED PCB manufacturer is not just a supplier, but a strategic partner that helps you deliver safer, more efficient, and more reliable LED lighting and electronic solutions to your customers worldwide.