Aluminum PCB Manufacturing & Assembly Services

Reliable aluminum PCB manufacturer & MCPCB supplier in China, providing fast prototypes and small to medium-volume production for LED lighting, power supply and other high-power electronics.

JHYPCB specializes in aluminum PCB and metal core PCB fabrication, from single-sided aluminum PCBs for LED lamps to complex multilayer aluminum boards for power modules and automotive electronics.

With in-house manufacturing and assembly lines, we can take your aluminum PCB project from Gerber files to fully assembled boards with stable quality, controlled costs and on-time delivery.

- 15+ years of experience in aluminum PCB production and MCPCB fabrication.

- 1–24 layers, 0.8–5.0 mm board thickness, copper up to 10 oz for high current designs.

- Fast prototype lead time from 2–5 days, flexible order quantities from 1 pc to 1000+ pcs.

- RoHS-compliant, ISO-certified manufacturing with full electrical testing and AOI inspection.

Why Choose JHYPCB for Aluminum PCB Manufacturing?

Choosing the right aluminum PCB manufacturer is critical for the thermal performance, reliability and cost of your LED, power supply and high-power electronic products.

With over 15 years of experience in aluminum PCB and MCPCB fabrication, JHYPCB provides consistent quality, flexible manufacturing and responsive technical support for global customers.

Extensive aluminum PCB capabilities

JHYPCB supports 1–24 layer aluminum PCBs and MCPCBs, board thickness from 0.8–5.0 mm, copper weight up to 10 oz, and multiple solder mask colors to meet different design and branding requirements.

Strong thermal performance for high-power designs

We use high-quality aluminum core materials with high thermal conductivity to improve heat dissipation for LED lighting, power modules, automotive electronics and other high-power applications.

Fast prototypes and flexible order quantities

Aluminum PCB prototypes can be delivered in as fast as 2–5 days, and we accept both small prototype runs and medium-volume production so you can move from design validation to mass production smoothly.

One-stop fabrication and assembly service

In addition to aluminum PCB manufacturing, JHYPCB provides SMT and through-hole assembly for LED boards and other aluminum PCB products, including component sourcing, soldering, testing and packaging.

Quality assurance and engineering support

Every aluminum PCB is manufactured under ISO-compliant processes with AOI inspection and electrical testing, and our engineering team can review your Gerber files, stack-up and design rules before production to reduce risks and improve manufacturability.

Send your Gerber files and specifications to sales@pcbjhy.com for a quick DFM review and quotation.

Aluminum PCB Manufacturing Capabilities

JHYPCB provides comprehensive aluminum PCB and MCPCB manufacturing capabilities to support LED lighting, power electronics, automotive and other high-power applications.

From single-piece prototypes to medium-volume production, our factory can handle a wide range of board sizes, layer counts, copper weights and surface finishes for aluminum core PCBs.

| Feature | Capability |

|---|---|

| Quality grade | IPC Class 2 standard production for aluminum PCBs and MCPCBs. |

| Number of layers | 1–24 layers aluminum PCB or hybrid constructions with FR4 and aluminum cores. |

| Order quantity | From 1 prototype board to 1000+ pieces per order, suitable for pilot runs and ongoing production. |

| Build time | Typical lead time from 2–5 days for prototypes and up to 5 weeks for complex or larger-volume jobs. |

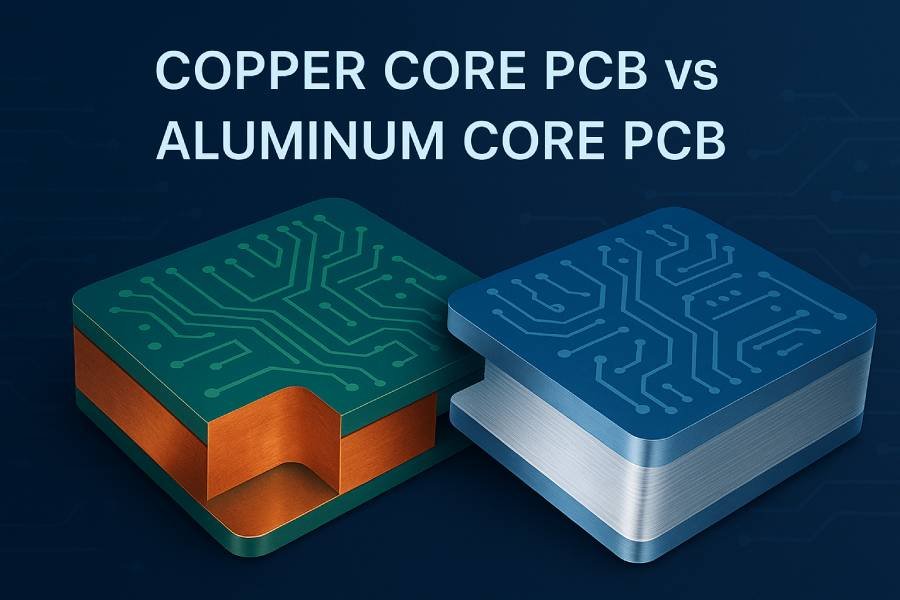

| Base materials | Aluminum core (commonly 1060 series), optional copper core or FR4 coverlay structures depending on thermal and mechanical requirements. |

| Board size | Minimum 6 × 6 mm, maximum 610 × 610 mm panel size for aluminum PCBs. |

| Board thickness | Standard thickness range from 0.8 mm to 5.0 mm for aluminum-based PCBs. |

| Copper weight | Finished copper thickness from 0.5 oz up to 10 oz for high-current power designs. |

| Min trace / spacing | Minimum track and spacing down to 4 mil / 4 mil for aluminum PCB circuitry. |

| Solder mask | One or both sides as required by the design, suitable for LED aluminum PCBs and other applications. |

| Solder mask colors | Green, white, blue, black, red and yellow to match LED reflection or branding needs. |

| Silkscreen | Single or double-sided legends printed as per the customer’s Gerber files. |

| Silkscreen colors | White, black or yellow silkscreen available. |

| Surface finishes | HASL, lead-free HASL (RoHS) and ENIG (electroless nickel immersion gold) for reliable solderability and shelf life. |

| Additional options | Countersink holes, screw holes and custom machining for heat sinks and mechanical assembly. |

If you need to confirm whether your aluminum PCB design fits within these capabilities, send your Gerber files and specifications to sales@pcbjhy.com for a quick DFM check and quotation.

Aluminum PCB Types and Services

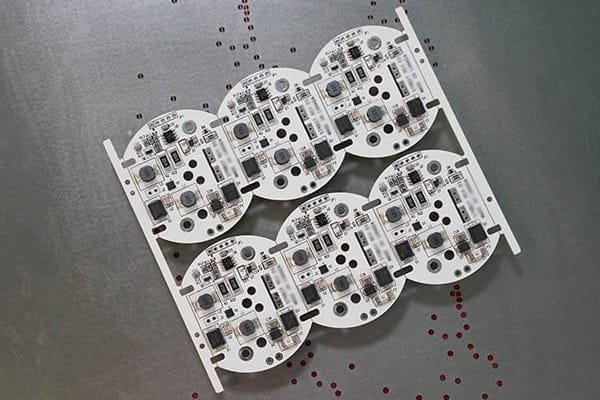

Aluminum PCB Prototype

Rapid aluminum PCB prototype fabrication helps you verify thermal performance, mechanical fit and assembly process before committing to larger volumes.

JHYPCB supports low-quantity aluminum PCB prototypes starting from a single piece, with typical lead times from 2–5 days depending on the board complexity and required surface finish.

Flexible Aluminum PCB

Flexible aluminum PCBs use special structures that allow limited bending or forming while still taking advantage of an aluminum or metal base for thermal management

They are useful in applications where LED boards or power modules must follow curved housings or irregular shapes, such as automotive lighting, decorative lighting and compact devices.

Hybrid Aluminum PCB

Hybrid aluminum PCBs combine FR4 and aluminum cores within the same board or stack-up so that high-power areas can dissipate heat efficiently while low-power circuits remain on standard FR4.

This approach can optimize cost and performance by using aluminum only where it is really needed, for example around power components, MOSFETs, LEDs or regulators.

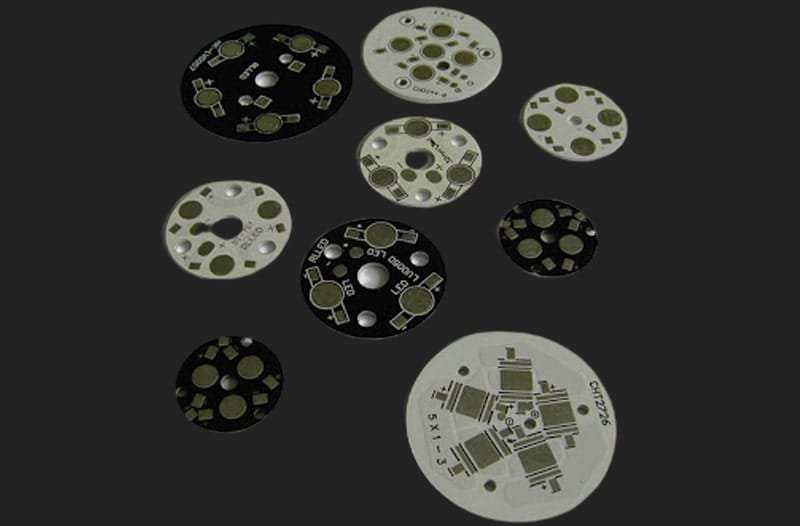

Single-Sided Aluminum PCB

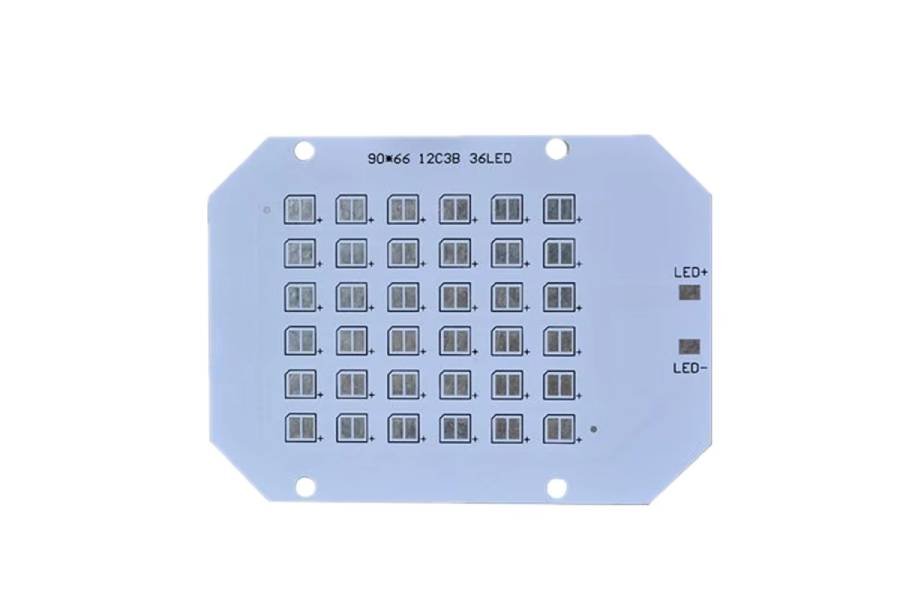

Single-sided aluminum PCBs are widely used in LED lighting and power supply products where components are mounted on one side and heat is transferred directly through the aluminum base.

This structure offers excellent heat dissipation with a relatively simple stack-up, making it a cost-effective choice for many LED lamps, drivers and power modules.

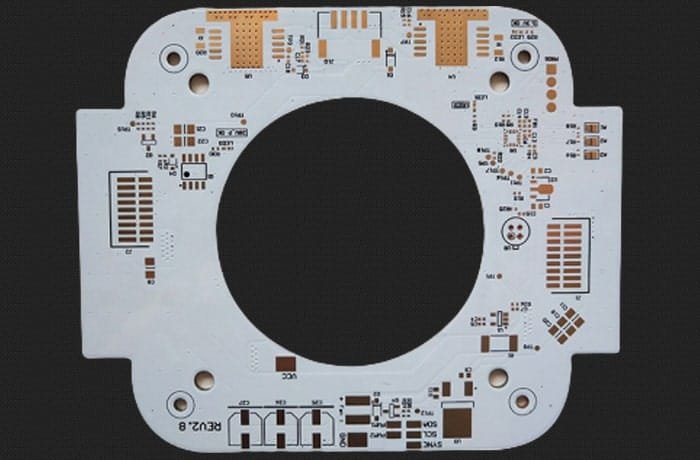

Double-Sided Aluminum PCB

Double-sided aluminum PCBs provide copper circuits on both sides of the dielectric layer, giving more routing flexibility and higher component density than single-sided designs.

They are suitable for more complex LED modules, automotive electronics and power control boards that require additional circuitry while still benefiting from aluminum core heat dissipation.

Multilayer Aluminum PCB

Multilayer aluminum PCBs combine multiple circuit layers with an aluminum or metal core to handle high power, signal integrity and compact layouts in one design.

This type is commonly used in demanding applications such as industrial power supplies, motor control, automotive power modules and telecom equipment where both electrical and thermal performance are critical.

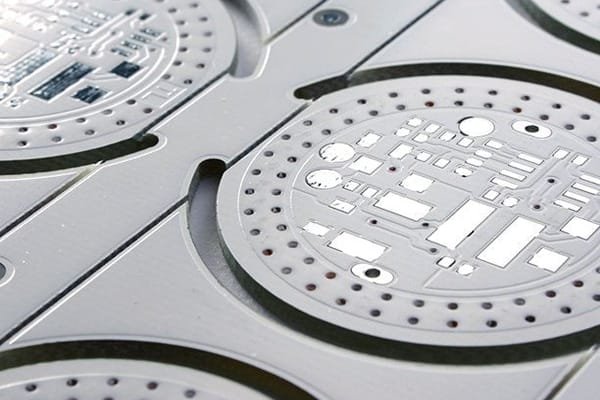

Plating Through-Hole Aluminum PCB

Plating through-hole (PTH) aluminum PCBs use special processing to create plated vias through the dielectric and aluminum structure, allowing more complex interconnection between layers.

JHYPCB can produce PTH aluminum PCBs for designs that need both strong thermal paths and dense routing, such as high-power converters and advanced LED drivers.

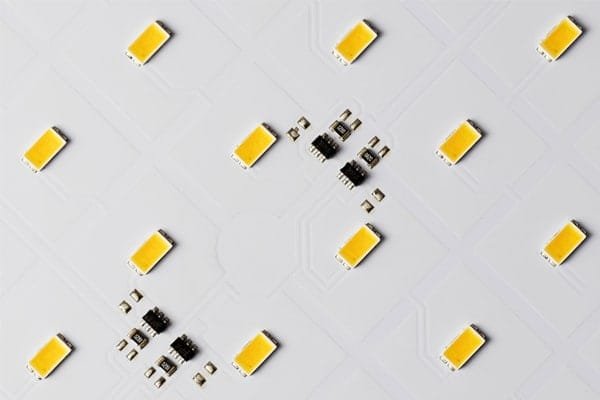

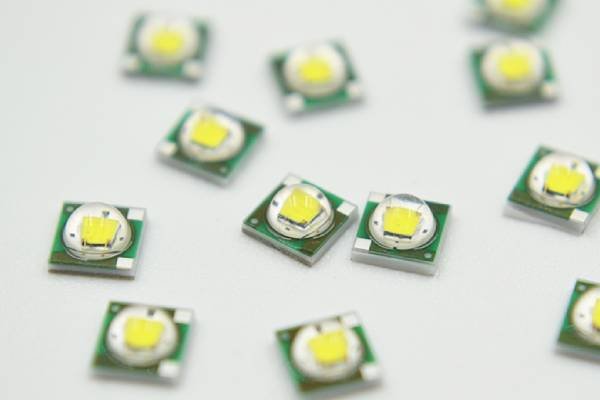

LED Aluminum PCB / MCPCB for LED Lighting

LED aluminum PCBs, also known as LED MCPCBs, are designed specifically to mount high-power LEDs and quickly transfer heat away from the LED junction to the heat sink.

JHYPCB manufactures LED aluminum PCBs for street lights, flood lights, high bay lights, automotive lights, backlighting modules and many other LED lighting products.

If you are not sure which aluminum PCB structure is suitable for your project, share your requirements with our engineers and we will suggest the most appropriate type based on power, size, budget and target lifetime.

Aluminum PCB Assembly Services

In addition to aluminum PCB and MCPCB fabrication, JHYPCB also provides professional aluminum PCB assembly services for LED lighting, power supplies, automotive electronics and other high-power applications.

Our SMT and through-hole assembly lines can handle everything from single-layer LED aluminum boards to complex multilayer aluminum PCBs, helping you reduce suppliers and shorten your time to market.

One-stop aluminum PCB manufacturing and assembly

You can send us your Gerber files, BOM and assembly drawings, and we will deliver ready-to-use assembled aluminum PCBs according to your specifications.

SMT and through-hole assembly capabilities

We also support through-hole and mixed technology assembly for connectors, large electrolytic capacitors, transformers and other components that require strong mechanical support.

Component sourcing and supply chain support

Our centralized material purchasing and inventory management help you reduce procurement workload, control costs and avoid shortages during production.

Quality control and functional testing

For LED aluminum PCBs and power modules, we can also perform functional tests, burn-in and custom testing procedures to verify performance before shipment.

Ready to combine aluminum PCB fabrication with assembly in one order? Contact JHYPCB today or send your Gerber, BOM and assembly files to sales@pcbjhy.com for an integrated quotation.

What Is Aluminum PCB?

An aluminum PCB, also known as an aluminum printed circuit board or aluminum core PCB, is a circuit board that uses an aluminum metal base instead of a traditional FR4 fiberglass base.

By combining a copper circuit layer, a thermally conductive dielectric layer and an aluminum substrate, aluminum PCBs provide much better heat dissipation and mechanical strength than standard FR4 PCBs in high-power applications.

Definition and common names

Aluminum PCBs are often referred to as metal core PCBs (MCPCBs), insulated metal substrate (IMS) boards, aluminum substrate PCBs, aluminum clad PCBs or LED aluminum PCBs.

All of these terms describe PCBs that use an aluminum or metal base to improve thermal conductivity and manage the heat generated by power devices and LEDs.

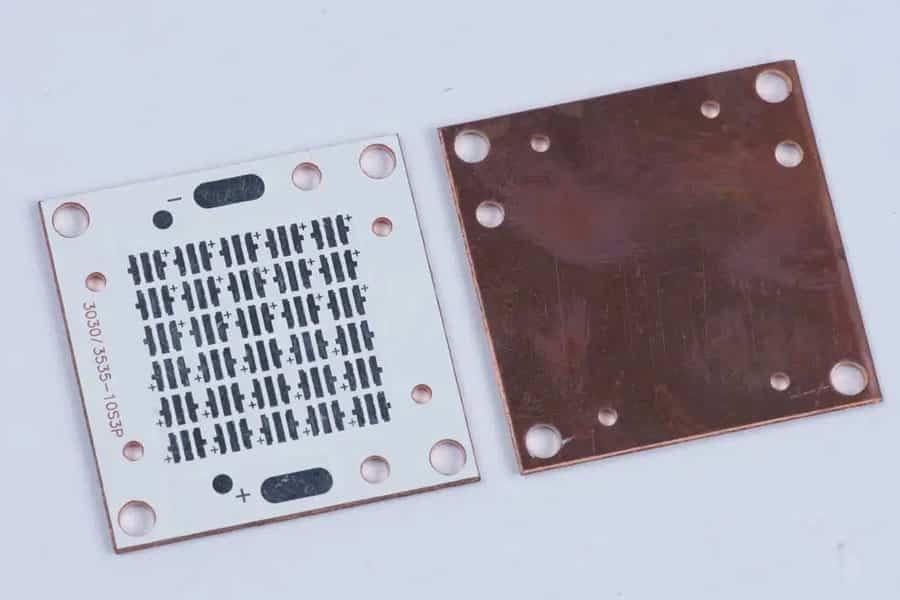

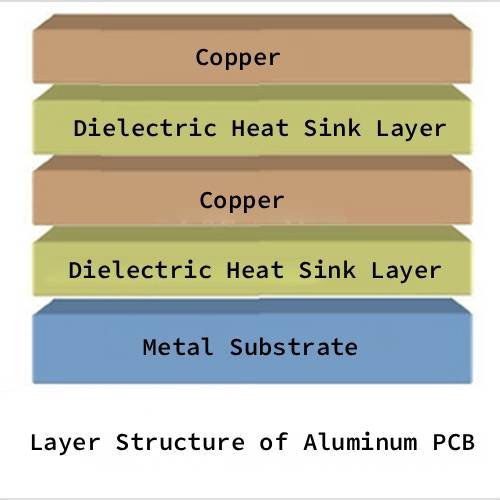

Basic structure of an aluminum PCB

A typical aluminum PCB consists of three main layers: a copper circuit layer, a thermally conductive but electrically insulating dielectric layer, and an aluminum base layer.

In many designs there is also an optional protective film or membrane on the aluminum surface to prevent scratches and corrosion during handling and assembly.

Aluminum PCB Stack-Up and Working Principle

The performance of an aluminum PCB mainly comes from its special stack-up, which combines a standard copper circuit layer with a thermally conductive dielectric and an aluminum metal base.

This structure creates a direct thermal path from heat-generating components to the aluminum substrate and then to an external heat sink or device housing.

Aluminum PCB structure and layers

- Copper circuit layer: The top copper layer forms the electrical circuits and pads for components, just like on FR4 PCBs, and can be manufactured in different copper weights depending on current requirements.

- Thermally conductive dielectric layer: This thin insulating layer sits between the copper and the aluminum base, providing electrical insulation while transferring heat from the copper to the aluminum substrate.

- Aluminum base layer: The aluminum substrate gives the PCB mechanical strength and high thermal conductivity, helping to spread and dissipate heat across a larger area.

- Optional aluminum base membrane: A protective film can be applied to the back side of the aluminum to reduce scratches, oxidation and corrosion during handling and assembly.

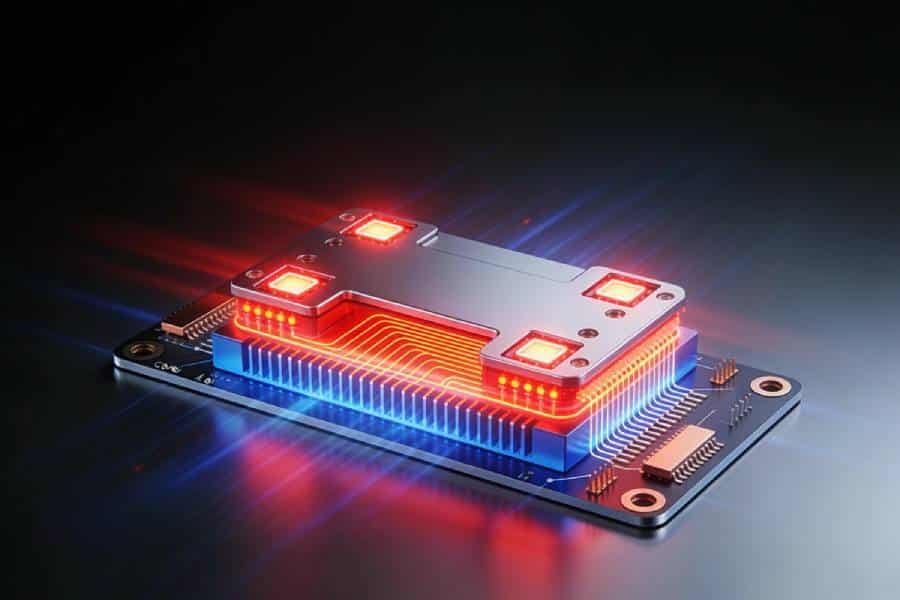

How aluminum PCBs work in thermal management

During operation, heat generated by LEDs, power devices or other components flows from their solder pads into the copper circuit layer and then through the thermally conductive dielectric into the aluminum base.

The aluminum substrate quickly spreads this heat and, when combined with a heat sink, housing or chassis, helps keep junction temperatures lower, increase reliability and extend the lifetime of the final product.

Aluminum PCB Performance, Advantages and Limitations

Aluminum PCBs are widely used in high-power and high-heat applications because they combine good electrical performance with excellent thermal conductivity and mechanical strength.

Compared with standard FR4 PCBs, aluminum core boards can transfer heat much more efficiently, helping designers reduce component temperatures, improve reliability and increase power density.

Key performance characteristics of aluminum PCBs

The core performance of an aluminum PCB comes from its thermally conductive dielectric and aluminum base, which significantly reduce thermal resistance between heat sources and the heat sink.

For example, a typical 1.5 mm FR4 PCB can have a thermal resistance around 20–22 °C/W, while a 1.5 mm aluminum PCB with a proper dielectric layer can achieve a thermal resistance in the range of about 1–2 °C/W.

Aluminum PCBs also show good dimensional stability, with relatively small dimensional changes over a wide temperature range compared with many other materials.

Because the thermal expansion coefficient of aluminum is close to that of copper, aluminum PCBs can better handle the stresses caused by temperature cycling than many other substrate options.

Main advantages of aluminum core PCBs

Typical limitations and design considerations

Aluminum PCB Applications

Because of their excellent thermal performance and mechanical strength, aluminum PCBs and MCPCBs are widely used in LED lighting, power electronics, automotive, industrial and other high-power fields.

They are especially suitable for designs where a large amount of heat must be transferred away from components while keeping the board compact and cost-effective.

LED lighting and illumination

Power supplies and power converters

The aluminum core helps spread and dissipate heat from MOSFETs, diodes, transformers and other power components, allowing higher power density and more reliable operation.

Automotive lighting and electronics

Their good thermal conductivity, mechanical strength and resistance to vibration make them suitable for harsh automotive and transportation environments.

Industrial control and power equipment

Aluminum PCBs help these systems maintain performance under continuous operation and high ambient temperatures, reducing downtime and maintenance costs.

Telecom and networking equipment

In these applications, aluminum core boards help dissipate the heat generated by high-frequency and high-power devices while keeping the assemblies compact and reliable.

Computer, audio and consumer electronics

Aluminum PCBs support compact layouts and higher power densities while keeping critical components within safe temperature limits in these consumer and professional devices.

Aluminum PCB

Manufacturing Process

Aluminum PCBs follow a dedicated manufacturing process that is similar to FR4 PCB production but includes special steps for handling the aluminum base and thermally conductive dielectric.

Understanding the main process steps helps designers optimize their stack-up, copper thickness and design rules for better manufacturability and performance.

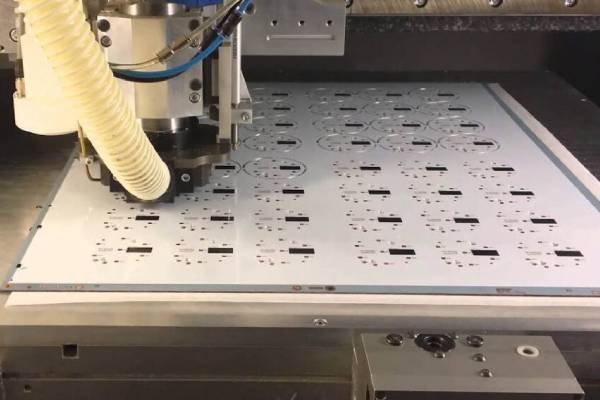

Material preparation and cutting

Production starts with selecting the correct aluminum base material, dielectric and copper thickness according to the design requirements and target thermal performance.

The aluminum-clad panels are then cut to the required production panel size to fit the manufacturing line and equipment.

Drilling and hole preparation

Holes for mounting, screws and any required plated or non-plated holes are drilled in the aluminum PCB panels using CNC drilling machines. For designs that require plating through holes, extra processing is needed to ensure reliable insulation and metallization around the aluminum core.

Circuit imaging and etching

A photoresist layer is applied to the copper surface and exposed with the circuit pattern using phototools or laser imaging equipment.After development, unwanted copper is removed by chemical etching, leaving only the designed traces, pads and copper areas on the aluminum PCB.

Solder mask and silkscreen printing

A solder mask layer is coated on the board to protect copper areas and define the solderable pads for components. Silkscreen printing is then used to add component outlines, reference designators, polarity marks and logos to the aluminum PCB surface.

Surface finish

Surface finish is applied to the exposed copper pads to protect them from oxidation and ensure good solderability during assembly. Common finishes for aluminum PCBs include HASL, lead-free HASL and ENIG, depending on the application, assembly process and cost considerations.

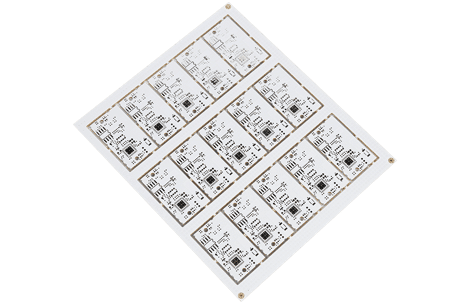

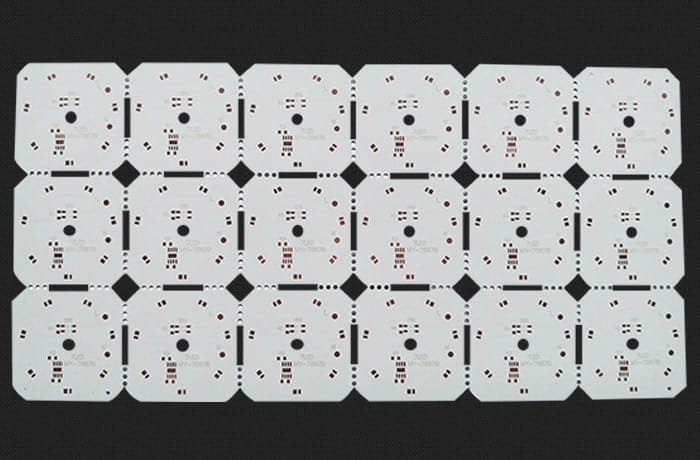

Profiling, V-cut and routing

After the surface finish, the aluminum PCB panels are profiled to the final board outline by routing, punching or a combination of both. V-cuts or breakaway tabs can be added to allow multiple aluminum PCBs to be panelized for assembly and then easily separated after assembly.

Electrical test and final inspection

Finished aluminum PCBs are electrically tested to verify connectivity and detect short circuits or open circuits before shipment. Visual inspection and AOI are also used to check solder mask, silkscreen, hole quality and board edges so that only qualified aluminum PCBs are delivered to customers.

Aluminum PCB vs FR4 PCB

Aluminum PCBs and FR4 PCBs use very different base materials, so their thermal performance, cost and suitable applications are also different.

Understanding the key differences helps you decide when to choose a metal core aluminum PCB instead of a standard FR4 board.Aluminum PCBs and FR4 PCBs use very different base materials, so their thermal performance, cost and suitable applications are also different.

Understanding the key differences helps you decide when to choose a metal core aluminum PCB instead of a standard FR4 board.

Key differences between aluminum PCB and FR4 PCB

Comparison table

| Aspect | Aluminum PCB | FR4 PCB |

|---|---|---|

| Base material | Aluminum metal core with thermally conductive dielectric and copper circuit layer. | Fiberglass-reinforced epoxy (FR4) with copper circuit layers on one or both sides. |

| Thermal conductivity | Much higher overall thermal conductivity due to aluminum base and thermal dielectric, suitable for high-power and high-heat applications. | Low thermal conductivity; heat spreads more slowly, so extra heat sinks or thermal vias are often required in high-power designs. |

| Heat dissipation | Excellent heat dissipation; heat is quickly transferred from components to the aluminum core and then to a heat sink or housing. | Limited heat dissipation; relies mainly on copper thickness, copper area and additional thermal design techniques. |

| Typical applications | LED lighting, power supplies, motor drivers, RF power modules, automotive lighting and other high-power electronics. | General consumer electronics, digital circuits, low-to-medium power devices, computers, communication and control boards. |

| Mechanical strength | Strong metal base with good rigidity and resistance to vibration; suitable for harsh or high-vibration environments. | Good rigidity but less robust than thick aluminum in terms of impact resistance; can be made flexible or rigid-flex with other materials. |

| Layer count | Most common as single-layer or simple double-layer; multilayer and PTH aluminum PCBs are possible but more complex and expensive. | Very flexible layer count from single-layer to high-layer-count multilayer and HDI structures at comparatively lower cost. |

| Cost | More expensive than standard FR4 PCBs due to aluminum base and specialized processing, but cheaper than many other metal core or ceramic options. | Generally lower cost and widely available; ideal for large volumes of standard electronic products. |

| Design considerations | Requires attention to dielectric thickness, thermal conductivity, creepage distances and mounting to heat sinks or housings. | Requires standard PCB design rules; extra measures needed for thermal management in high-power areas. |

In short, aluminum PCBs are preferred when thermal management and mechanical robustness are critical, especially in LED and power electronics, while FR4 PCBs remain the mainstream choice for general electronic circuitry and complex multilayer designs.

Aluminum PCB FAQs

For standard single-sided or simple double-sided aluminum PCB prototypes, the typical lead time is about 2–5 working days after file confirmation and payment.

More complex multilayer aluminum PCBs or large quantities may require additional production time depending on the stack-up, copper thickness and surface finish.

Common design rules include minimum trace and spacing around 4 mil / 4 mil, appropriate pad sizes and hole diameters according to the finished copper thickness and plating.

You should also consider dielectric thickness, clearance to the board edge and mounting holes, and avoid placing critical traces too close to areas where screws or heat sinks will apply mechanical stress.

Aluminum PCB dielectric materials are available with different thermal conductivity values, typically in the range of about 1.0 W/m·K to 3.0 W/m·K or higher for special high-performance materials.

Higher thermal conductivity dielectrics improve heat transfer from the copper layer to the aluminum base but may be more expensive than standard materials.

JHYPCB can manufacture aluminum PCBs starting from a single prototype board, so there is effectively no strict minimum order quantity for standard aluminum PCB fabrication.

For mass production, the recommended order quantity can be optimized based on panel utilization, material usage and logistics to help you reduce cost per unit.

Yes, JHYPCB provides turnkey assembly services for LED aluminum PCBs, including aluminum PCB fabrication, component sourcing, SMT assembly, testing and packaging.

You can send your Gerber files, BOM and assembly drawings, and we will deliver fully assembled LED boards ready for integration into your lighting products.

The price of an aluminum PCB mainly depends on the board size, thickness, copper weight, dielectric thermal conductivity, layer count, surface finish and order quantity.

Additional factors such as special machining, plating through holes in aluminum, tight tolerances and special testing requirements can also affect the final cost.

Aluminum PCBs can be reworked, but the strong heat dissipation of the aluminum base means that higher soldering temperatures and proper tools are needed to avoid damaging components or pads.

It is recommended to use controlled rework stations and follow appropriate profiles, especially for LED and sensitive semiconductor devices.

Aluminum PCBs should be stored in a dry, clean environment, preferably in moisture-barrier bags with desiccant if they will not be assembled soon after delivery.

During handling, avoid scratching the aluminum base and keep the boards away from corrosive environments to maintain good surface condition for assembly.

Ready to Start Your Aluminum PCB Project?

Choosing the right aluminum PCB manufacturer is key to achieving reliable thermal performance, stable quality and competitive costs for your LED and power electronics.

With years of experience in aluminum PCB fabrication and assembly, JHYPCB can support you from early prototypes to ongoing production for a wide range of applications.

Ready to move your aluminum PCB design into production? Share your Gerber files, BOM and requirements with our engineering team and receive a fast, detailed quotation and technical feedback.

You Can Also Email Your Files to sales@pcbjhy.com