Table of Contents

Introduction

In the fast-evolving world of electronics, heat management is a critical challenge. Have you ever wondered what a single-sided aluminum PCB is and why it’s becoming a go-to solution for high-power devices? This innovative circuit board combines durability, efficiency, and excellent thermal performance, making it essential for industries like LED lighting and automotive electronics. Let’s explore what sets it apart and how it can benefit your next project.

What Are Single-Sided Aluminum PCBs?

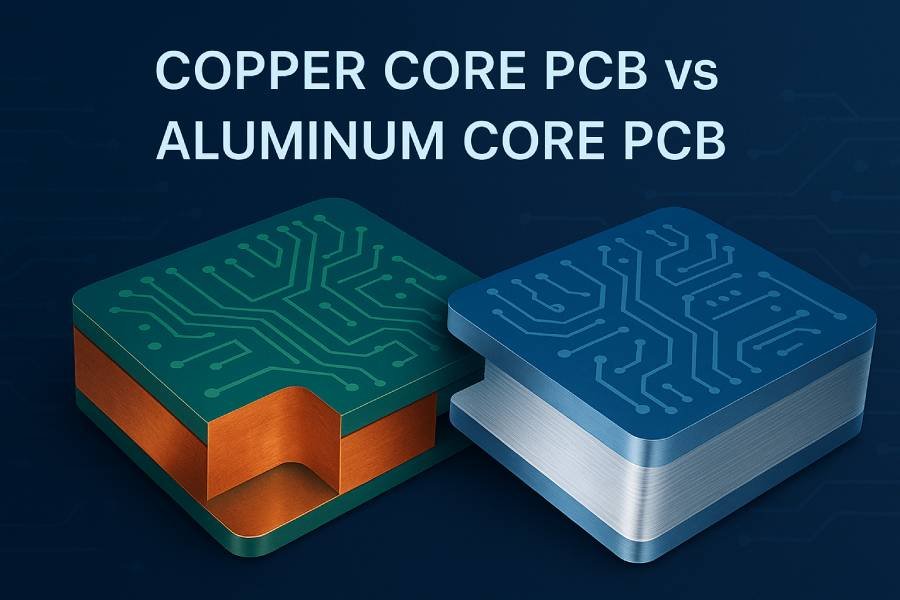

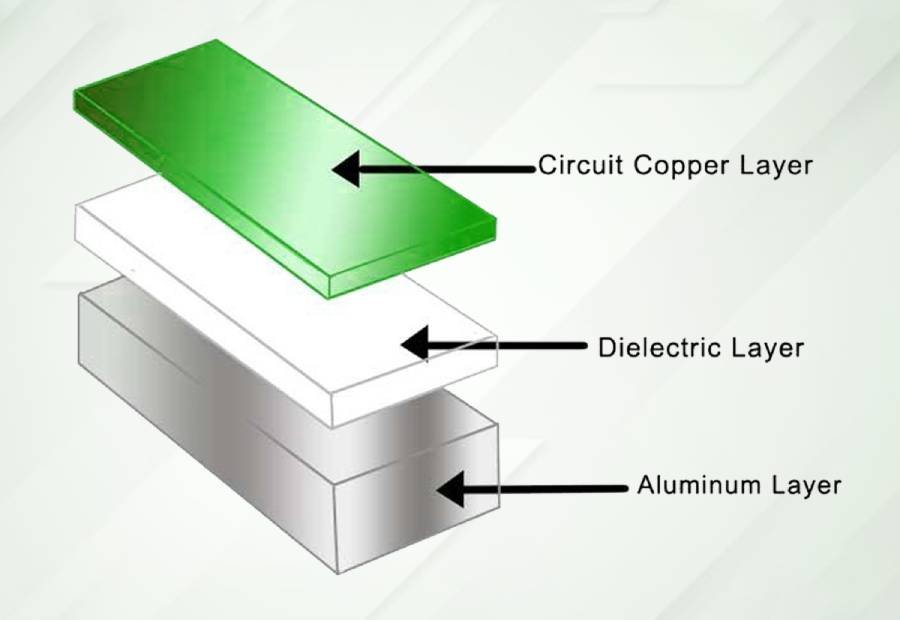

So, what is a single-sided aluminum PCB? At its core, it’s a type of PCB that uses an aluminum base as its foundation, layered with an insulating dielectric and a copper foil for conductivity. Unlike traditional FR4 PCBs made from fiberglass, single-sided aluminum PCBs are designed with heat dissipation in mind. The aluminum base acts as a natural heat sink, while the insulating layer prevents electrical shorts, and the copper layer handles the circuitry—all on one side, with the other side remaining smooth for mounting or thermal adhesive. This design makes it ideal for applications where overheating is a concern, offering a significant upgrade over FR4 in terms of thermal efficiency and mechanical strength.

What sets this PCB apart is its simplicity combined with performance. The single-sided layout means all the circuitry is concentrated on one surface, making it easier to manufacture and cost-effective for projects that don’t require complex multi-layer designs. Compared to FR4 PCBs, which struggle with heat buildup in high-power applications, single-sided aluminum PCBs excel by efficiently transferring heat away from components. For instance, while FR4 might suffice for low-power devices, aluminum PCBs are the preferred choice when dealing with LEDs or power modules where temperature control is critical. This makes them a smart pick for anyone looking to enhance reliability and longevity in their electronic designs.

Technical Structure and Working Principle

The technical structure of a single-sided aluminum PCB is a masterpiece of engineering, designed to balance heat management and electrical performance. Let’s break it down layer by layer to understand how it works.

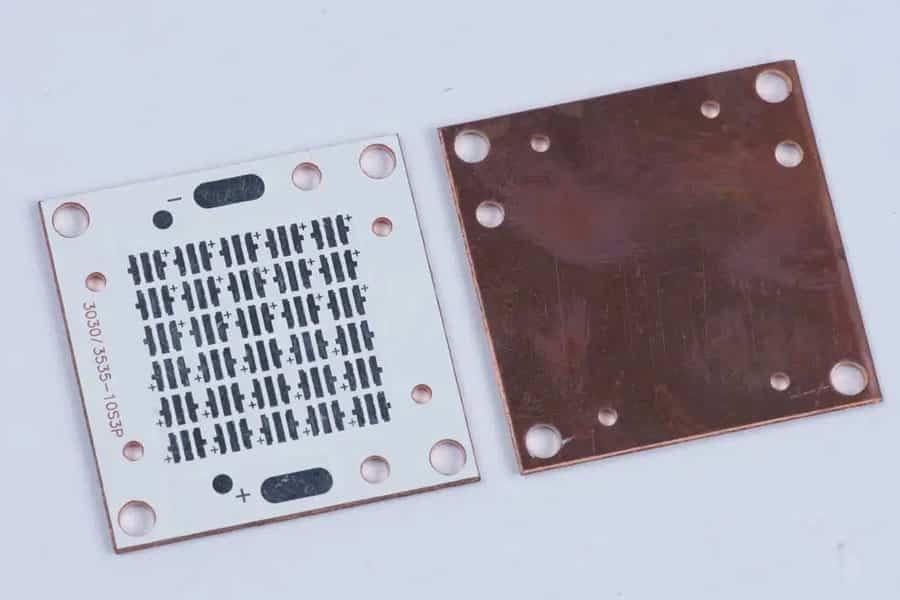

- Copper Foil Layer: This is the topmost layer, typically ranging from 1oz to 4oz in thickness, where the circuit patterns are etched. It conducts electricity with precision, carrying signals and power to the components mounted on the board. The copper’s excellent conductivity ensures minimal energy loss, making it ideal for high-current applications.

- Insulating Dielectric Layer: Sandwiched between the copper and aluminum, this thin layer (often 0.05mm to 0.15mm thick) serves a dual purpose. It provides electrical insulation to prevent short circuits while allowing heat to transfer from the copper layer to the aluminum base. With thermal conductivity ratings typically between 1W/m·K and 12W/m·K, this layer is the key to the PCB’s heat-dissipation prowess.

- Aluminum Base Layer: The foundation of the PCB, this layer is usually made from high-quality aluminum alloys like 5052 or 6061. Acting as a natural heat sink, it absorbs and dissipates heat generated by components, keeping temperatures in check. Its mechanical strength also adds durability, resisting bending or cracking under stress.

So, how does it all work together? The magic lies in the synergy of these layers. When a component like an LED or power transistor generates heat, the copper foil layer conducts it to the dielectric layer. This layer efficiently transfers the heat to the aluminum base, which then disperses it into the surrounding environment or a connected heat sink. Meanwhile, the insulating layer ensures that no electrical current leaks between the copper and aluminum, maintaining circuit integrity. This combination makes single-sided aluminum PCBs a reliable choice for applications where both thermal management and electrical isolation are critical, such as in high-power LED lighting or automotive electronics.

Performance Advantages

Single-sided aluminum PCBs stand out for their impressive performance characteristics, making them a top choice for demanding applications. Let’s explore what makes them so effective.

- Superior Heat Dissipation: One of the standout features is their exceptional ability to manage heat. With thermal conductivity ranging from 1W/m·K to 12W/m·K, these PCBs can reduce thermal resistance to as low as 0.1°C·in²/W—far better than the 2.0-2.5°C·in²/W of traditional FR4 boards. This means they can handle high-power devices like LEDs or power amplifiers without overheating, extending component life and improving efficiency.

- Robust Mechanical Strength: The aluminum base provides excellent durability, resisting bending, twisting, and impact better than fiberglass-based PCBs. This makes them ideal for rugged environments, such as automotive or industrial settings, where reliability is non-negotiable.

- Electromagnetic Shielding: The metal core offers natural electromagnetic interference (EMI) shielding, reducing noise and protecting sensitive circuits. This is a game-changer for applications like audio systems or communication devices where signal clarity is critical.

- Dimensional Stability: These PCBs maintain their shape even under thermal stress. With a low coefficient of thermal expansion (around 22ppm/°C for aluminum), they experience minimal size changes—typically less than 2.5% from 30°C to 150°C—ensuring consistent performance over time.

- Cost-Effective Power Density: By efficiently dissipating heat, single-sided aluminum PCBs allow for higher power densities in a compact design. This not only boosts performance but also reduces the need for additional cooling solutions, saving costs in the long run.

For anyone designing high-performance electronics, these advantages translate to longer-lasting products and fewer failures. Whether it’s keeping an LED streetlight bright for years or ensuring a power module runs smoothly, the performance edge of single-sided aluminum PCBs is hard to beat.

Manufacturing Process and Techniques

Creating a single-sided aluminum PCB involves a meticulous process that blends precision engineering with advanced materials. Here’s a look at how these boards come to life.

The journey begins with material selection. High-quality aluminum alloys, such as 5052 or 6061, are chosen for their excellent thermal conductivity and mechanical strength. A dielectric layer, typically a thin polymer with thermal conductivity between 1W/m·K and 12W/m·K, is selected to ensure effective heat transfer while maintaining insulation. The copper foil, often ranging from 1oz to 4oz in thickness, is prepared for circuit patterning.

Next comes lamination. The aluminum base, dielectric layer, and copper foil are stacked and bonded together using high-temperature and high-pressure lamination. This step ensures a strong, uniform bond that can withstand thermal cycling without delamination.

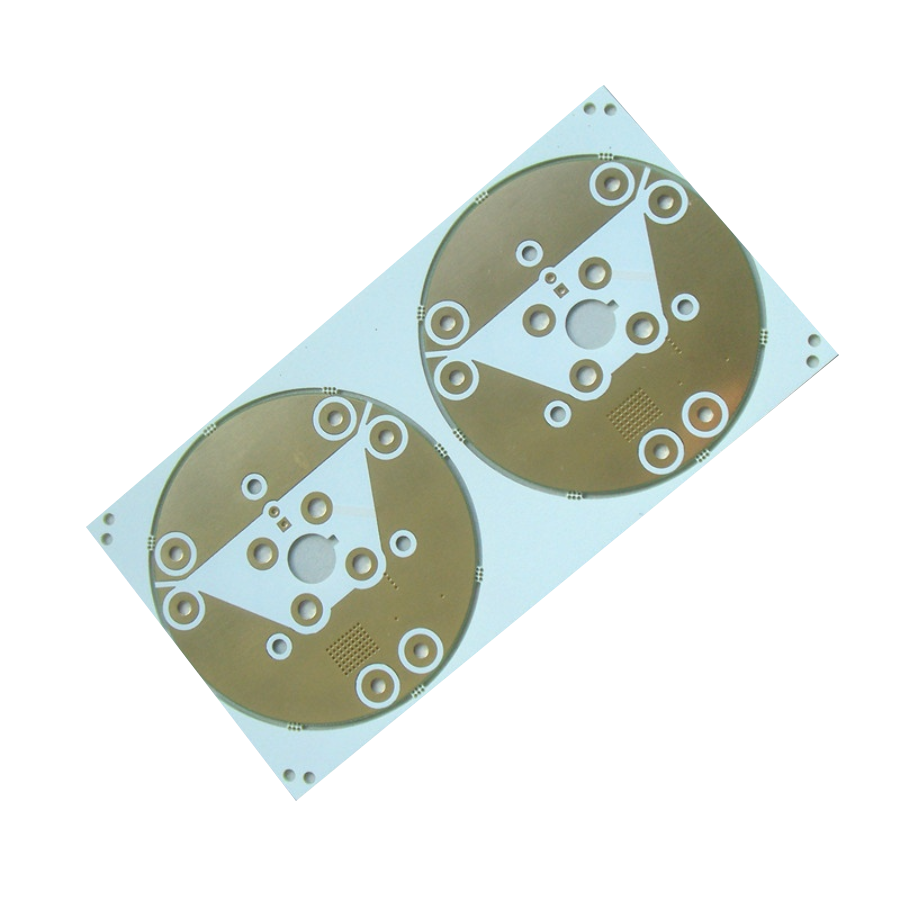

The circuit patterning phase follows, where the copper layer is coated with a photoresist, exposed to UV light through a mask, and etched to create the desired circuit design. This process requires precision to meet the exact specifications of the project.

Surface finishing is crucial for durability and solderability. Options include lead-free HASL, ENIG (with gold thickness from 0.5µ” to 3.0µ”), or OSP, each tailored to the application’s needs. The board is then shaped using techniques like CNC routing, V-cut scoring, or laser cutting to achieve the final dimensions.

Finally, quality testing ensures reliability. Techniques such as AOI (Automated Optical Inspection), electrical testing, and thermal stress tests verify that each PCB meets industry standards. With lead times as short as 2-3 days for standard orders, this streamlined process delivers custom solutions efficiently.

For designers, understanding this process highlights the flexibility of single-sided aluminum PCBs, allowing tailored designs that meet specific thermal and electrical demands.

Wide-Ranging Applications

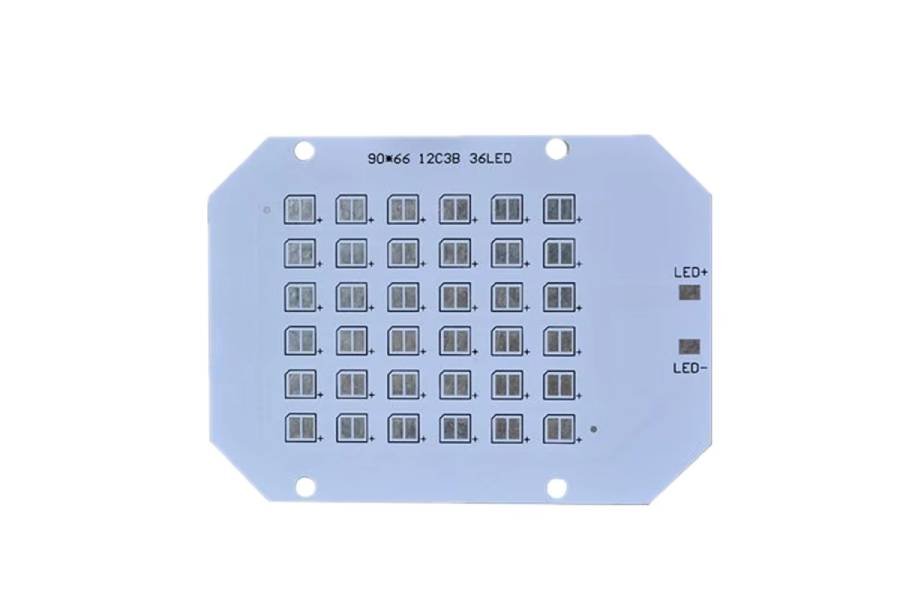

Single-sided aluminum PCBs are versatile workhorses, finding their place in a variety of industries where heat management and durability are paramount. Let’s explore where they shine.

In LED lighting, these PCBs are a game-changer. Their superior heat dissipation keeps high-power LEDs, like those in streetlights or grow lights, cool and efficient, extending their lifespan by up to 50% compared to traditional boards. This makes them a top choice for outdoor lighting, automotive headlights, and even underwater fixtures.

The automotive sector benefits too, especially in components like engine control units and LED taillights. The robust aluminum base withstands vibrations and temperature swings, ensuring reliable performance in harsh conditions, while the EMI shielding reduces interference in sensitive electronics.

Power electronics rely on these PCBs for applications such as power supplies and inverters. Their ability to handle high current densities without overheating allows for compact, high-efficiency designs, a critical factor in modern energy systems.

In audio and communication devices, the electromagnetic shielding properties minimize noise, delivering clear sound in speakers or stable signals in telecom equipment. This makes them ideal for professional audio systems or 5G infrastructure components.

Even renewable energy taps into their potential, with solar panel inverters and battery management systems using aluminum PCBs to manage heat and improve energy conversion efficiency.

By solving real-world challenges like overheating and signal interference, single-sided aluminum PCBs empower engineers to push the boundaries of innovation across these diverse fields.

Market Trends and Future Development

The landscape of single-sided aluminum PCBs is evolving rapidly, driven by emerging technologies and growing industry demands. Let’s dive into the trends shaping their future.

As of 2025, the rise of 5G technology is fueling demand for efficient thermal management solutions. Single-sided aluminum PCBs are increasingly vital in 5G base stations and devices, where high-frequency components generate significant heat. Their ability to dissipate heat while maintaining compact designs aligns perfectly with this trend.

The electric vehicle (EV) market is another key driver. With EV adoption soaring, these PCBs are finding new roles in battery management systems and power inverters, where reliable heat dissipation enhances battery life and performance. Experts predict a 30% increase in aluminum PCB use in EVs over the next five years.

Sustainability is also influencing the industry. Manufacturers are exploring eco-friendly materials and processes for aluminum PCBs, such as lead-free finishes and recyclable alloys, to meet global green manufacturing standards. This shift is attracting environmentally conscious companies across sectors.

Looking ahead, the development of flexible aluminum PCBs promises to expand their applications into wearable electronics and foldable devices. Combined with advancements in high thermal conductivity dielectrics (up to 15W/m·K), the future holds even greater potential for innovation in power-dense and portable technologies.

These trends highlight a bright future for single-sided aluminum PCBs, positioning them as a cornerstone of next-generation electronics as of September 2025.

Frequently Asked Questions

Single-sided aluminum PCBs spark curiosity, especially for those new to the technology. Here are answers to some common questions to help you get started.

- What types of projects are single-sided aluminum PCBs best suited for? They excel in high-power applications like LED lighting, automotive electronics, and power supplies where heat dissipation is critical. If your project involves components that run hot, this PCB is a perfect fit.

- How do they compare to multi-layer aluminum PCBs in terms of cost? Single-sided versions are generally more cost-effective due to their simpler design and manufacturing process. Multi-layer PCBs offer greater complexity but come with higher costs and longer lead times, making single-sided options ideal for budget-conscious projects.

- Can they handle high temperatures? Yes, with a thermal conductivity up to 12W/m·K and the ability to operate reliably up to 150°C or more, they’re designed to thrive in demanding thermal environments, far surpassing traditional FR4 boards.

- How long does it take to get a custom order? Depending on specifications, lead times can be as short as 2-3 days for standard designs, though complex orders may take a week or more. It’s best to consult with a manufacturer for an accurate timeline.

These insights can guide your decision-making, ensuring you choose the right solution for your needs as of September 2025.