Table of Contents

High Tg vs. Ordinary Tg PCBs – Why It Matters

In today’s fast-evolving electronics landscape, where 5G networks power seamless connectivity and AI-driven devices demand flawless performance, the choice of PCB material can make or break a project. Imagine a high-speed router failing under heat stress or a satellite circuit warping during operation—issues like these highlight the critical role of PCB material selection. At the heart of this decision lies the Glass Transition Temperature (Tg), a key metric that determines how a PCB performs under thermal and mechanical stress. But what exactly separates High Tg PCBs from their Ordinary Tg counterparts, and why should engineers, designers, and manufacturers care?

The Tg value, or Glass Transition Temperature, marks the point at which a PCB’s resin base shifts from a rigid, glassy state to a softer, rubber-like state. This transition affects the board’s ability to withstand heat, maintain structural integrity, and support high-frequency signals. Ordinary Tg PCBs, typically based on standard FR-4 materials with Tg values around 120-130°C, suffice for everyday electronics like consumer gadgets. However, as industries like telecommunications, automotive, and aerospace push the boundaries with high-frequency signals and extreme environments, High Tg PCBs—with Tg values of 150°C or higher—have emerged as the go-to solution for reliability and performance.

At JHYPCB, we’ve seen firsthand how the right PCB material can transform project outcomes. With our expertise in PCB manufacturing and PCB assembly, including services like SMT, THT, and turnkey solutions, we help clients navigate these choices to meet demanding specifications. This article dives deep into the differences between High Tg and Ordinary Tg PCBs, exploring their unique properties and why High Tg materials are increasingly critical in applications like 5G communication, AI hardware, and multilayer PCB designs. Whether you’re designing a prototype or scaling production, understanding these distinctions will empower you to make informed decisions for your next project.

Ready to explore the world of Tg and its impact on PCB performance? Let’s break down the key differences and discover why High Tg PCBs are shaping the future of electronics. For tailored solutions or expert guidance, reach out to us at sales@pcbjhy.com.

What is an Ordinary Tg PCB?

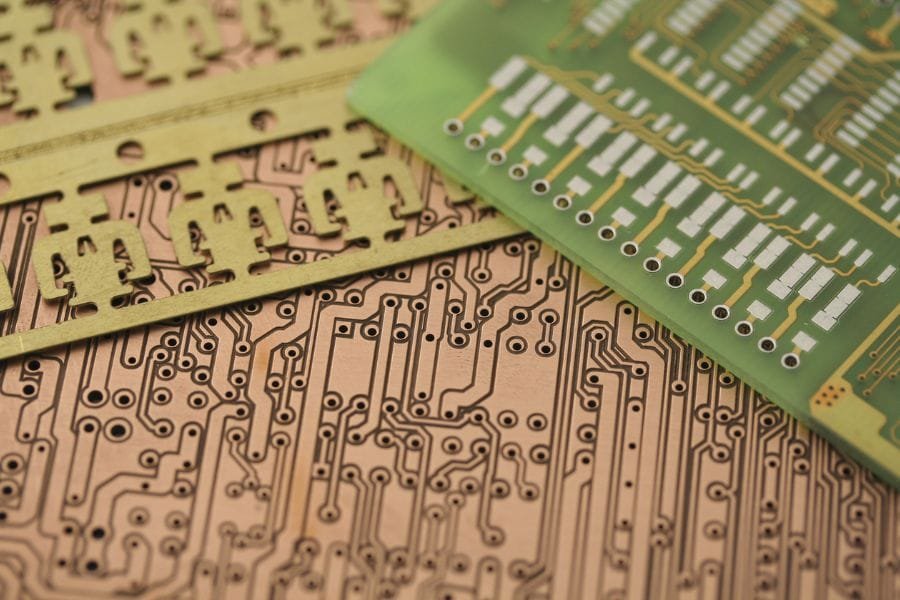

When it comes to Printed Circuit Boards, Ordinary Tg PCBs are the workhorses of the electronics industry, powering countless devices we use daily. Defined by their Glass Transition Temperature (Tg)—typically ranging from 120°C to 130°C—these boards are built using standard FR-4 materials, a composite of woven fiberglass and epoxy resin. Their affordability, versatility, and ease of manufacturing make them a go-to choice for a wide range of applications. But what exactly are Ordinary Tg PCBs, and where do they shine or fall short?

Characteristics of Ordinary Tg PCBs

Ordinary Tg PCBs are designed for environments where thermal and mechanical demands are moderate. The Tg value of 120-130°C indicates the temperature at which the board’s resin transitions from a rigid, glassy state to a more flexible, rubber-like state. This transition can affect the board’s dimensional stability and electrical performance. Key features include:

- Material Composition: Standard FR-4, a cost-effective blend of epoxy resin and fiberglass, offering decent mechanical strength and insulation properties.

- Thermal Limits: Suitable for operating temperatures well below their Tg, typically up to 100-110°C, to avoid performance degradation.

- Manufacturing Simplicity: Compatible with standard PCB manufacturing processes, including SMT (Surface-Mount Technology) and THT (Through-Hole Technology), with lower production costs compared to advanced materials.

At JHYPCB, we produce Ordinary Tg PCBs for clients seeking reliable solutions for cost-sensitive projects, leveraging our turnkey PCB assembly and component sourcing services to streamline production.

Common Applications of Ordinary Tg PCBs

Ordinary Tg PCBs are ideal for applications where high temperatures or extreme conditions aren’t a concern. You’ll find them in:

- Consumer Electronics: Smartphones, tablets, and gaming consoles, where operating conditions are stable and heat dissipation is manageable.

- Home Appliances: Microwaves, refrigerators, and air conditioners, which require dependable but not high-performance boards.

- Basic Computing Devices: Desktop PCs, low-end servers, and peripherals that don’t handle high-frequency signals or intense thermal loads.

These applications benefit from the balance of performance and cost that Ordinary Tg PCBs provide, making them a staple in mass-market electronics.

Limitations of Ordinary Tg PCBs

While Ordinary Tg PCBs are reliable for standard use cases, they have notable limitations when pushed beyond their thermal or electrical capabilities:

- Thermal Vulnerability: At temperatures approaching or exceeding their Tg (120-130°C), these boards risk softening, leading to warping, delamination, or cracking. This is particularly problematic during high-temperature processes like lead-free soldering, which can reach 260°C.

- Mechanical Instability: Higher thermal expansion (measured by the Coefficient of Thermal Expansion, or CTE) can cause misalignment in multilayer boards or stress on vias and traces, compromising reliability.

- High-Frequency Performance: Ordinary Tg PCBs struggle in high-frequency applications (e.g., above 1 GHz), where signal loss and dielectric instability become issues, making them unsuitable for advanced technologies like 5G communication or AI hardware.

For engineers working on projects with minimal thermal or frequency demands, Ordinary Tg PCBs remain a practical choice. However, as industries like telecommunications and automotive push for higher performance, these limitations highlight the need for more robust alternatives. Curious about how High Tg PCBs address these challenges? Stay tuned for the next section, or contact JHYPCB at sales@pcbjhy.com to explore our PCB prototype and multilayer PCB solutions tailored to your needs.

What is a High Tg PCB?

As electronic devices evolve to meet the demands of cutting-edge technologies like 5G communication, AI hardware, and automotive electronics, the need for robust, high-performance PCBs has never been greater. Enter High Tg PCBs, engineered to thrive in environments where standard boards falter. Defined by a Glass Transition Temperature (Tg) of 150°C or higher, these advanced boards offer superior thermal and mechanical stability, making them a cornerstone of modern, high-reliability applications. But what exactly sets High Tg PCBs apart, and why are they becoming indispensable in industries pushing the boundaries of innovation?

Defining High Tg PCBs

A High Tg PCB is a type of circuit board designed to withstand elevated temperatures without compromising its structural or electrical integrity. The Tg value—the temperature at which the board’s resin transitions from a rigid, glassy state to a softer, rubber-like state—starts at 150°C, with some advanced materials reaching 170°C or more. Unlike standard FR-4 used in Ordinary Tg PCBs, High Tg boards incorporate specialized resins, such as modified epoxy or polyimide blends, to achieve these higher thresholds. This makes them ideal for applications requiring enhanced durability under thermal stress.

Key Characteristics of High Tg PCBs

High Tg PCBs are tailored for demanding environments, offering a range of properties that elevate their performance:

- Enhanced Thermal Resistance: With a Tg of 150°C or above, these boards maintain rigidity during high-temperature processes like lead-free soldering, which can exceed 260°C, preventing warping or delamination.

- Low Coefficient of Thermal Expansion (CTE): High Tg materials exhibit minimal expansion when heated, ensuring dimensional stability and reducing stress on vias, traces, and solder joints.

- Superior Mechanical Strength: These boards retain their structural integrity at elevated temperatures, making them less prone to cracking or deformation under mechanical stress.

- Optimized for High-Frequency Applications: High Tg PCBs offer improved dielectric properties, reducing signal loss and supporting stable performance in high-frequency circuits, such as those used in 5G networks or RF applications.

Benefits of High Tg PCBs

The unique properties of High Tg PCBs translate into tangible advantages for manufacturers and engineers:

- Reliability in Harsh Conditions: From automotive engine control units to aerospace systems, High Tg PCBs perform consistently in high-heat and high-vibration environments.

- Compatibility with Advanced Manufacturing: These boards support complex multilayer PCB designs and processes like SMT assembly, ensuring precision and reliability during production.

- Support for Lead-Free Processes: High Tg materials align with RoHS-compliant manufacturing, meeting global environmental standards without sacrificing performance.

Enhanced Signal Integrity: In high-frequency applications, High Tg PCBs minimize dielectric loss and maintain low voltage standing wave ratio (VSWR), critical for technologies like high-speed data transmission.

Where High Tg PCBs Shine

High Tg PCBs are the preferred choice for industries where performance cannot be compromised. You’ll find them in:

- Telecommunications: Supporting 5G infrastructure, base stations, and microwave circuits that demand stable high-frequency performance.

- Automotive Electronics: Powering advanced driver-assistance systems (ADAS) and electric vehicle (EV) components exposed to heat and vibration.

- Aerospace and Defense: Ensuring reliability in satellite systems, radar equipment, and military-grade hardware operating in extreme conditions.

- Industrial Applications: Used in heavy machinery and control systems where thermal cycling is common.

By leveraging advanced materials and engineering, High Tg PCBs provide a robust foundation for next-generation electronics. In the next section, we’ll dive into the specific differences between High Tg and Ordinary Tg PCBs, exploring how these properties translate into real-world performance advantages. Stay tuned to learn which board is right for your project!

Key Differences Between High Tg and Ordinary Tg PCBs

Choosing the right PCB material can significantly impact the performance, reliability, and longevity of your electronic designs. While Ordinary Tg PCBs serve well for standard applications, High Tg PCBs are engineered to meet the rigorous demands of advanced technologies like 5G communication, AI hardware, and automotive electronics. Understanding the differences between these two types of PCBs is crucial for engineers and manufacturers aiming to optimize their projects. This section breaks down the key distinctions across temperature resistance, mechanical strength, thermal stability, high-frequency performance, and other practical considerations, helping you make informed decisions for your next design.

1. Temperature Resistance and Control

The ability to withstand high temperatures during manufacturing and operation is a defining factor for PCBs. Here’s how High Tg and Ordinary Tg PCBs compare:

High Tg PCBs: With a Glass Transition Temperature (Tg) of 150°C or higher, these boards are built to endure elevated temperatures, such as those encountered during lead-free soldering (often exceeding 260°C). The manufacturing process requires precise temperature control, often involving heat treatments above 180°C, to ensure the board retains its rigidity and structural integrity. This makes High Tg PCBs ideal for processes like SMT assembly and multilayer PCB fabrication, where thermal stress is significant.

Ordinary Tg PCBs: Limited to a Tg of 120-130°C, these boards are prone to softening or warping when exposed to temperatures near or above their Tg. Standard soldering processes (e.g., lead-based soldering at ~200°C) are manageable, but lead-free soldering or prolonged heat exposure can cause issues like delamination or trace damage.

Why It Matters: For applications requiring high-temperature reliability, such as automotive engine control units or industrial automation systems, High Tg PCBs prevent performance degradation, while Ordinary Tg PCBs are better suited for low-heat environments like consumer electronics.

2. Mechanical Strength

Mechanical durability under thermal and physical stress is another critical differentiator:

High Tg PCBs: These boards maintain superior mechanical strength at elevated temperatures, resisting deformation, cracking, or breakage. Their robust resin systems, such as modified epoxy or polyimide blends, ensure consistent performance even in high-vibration environments, making them suitable for aerospace and military applications.

Ordinary Tg PCBs: While adequate for standard conditions, these boards lose rigidity when temperatures approach their Tg, increasing the risk of mechanical failure. For example, multilayer boards may experience via cracking or layer separation under thermal cycling.

Data Point: High Tg PCBs typically exhibit a flexural modulus of 20-25 GPa compared to 15-20 GPa for Ordinary Tg PCBs, providing better resistance to bending and stress.

3. Thermal Stability

Thermal stability encompasses how well a PCB maintains its dimensions and performance under heat:

High Tg PCBs: These boards feature a lower Coefficient of Thermal Expansion (CTE), typically 50-70 ppm/°C, minimizing dimensional changes during thermal cycling. They also boast low moisture absorption (often <0.5%) and high resistance to thermal shock, ensuring reliability in harsh conditions like satellite systems or high-power RF circuits.

Ordinary Tg PCBs: With a higher CTE (80-100 ppm/°C), these boards are more susceptible to expansion and contraction, which can stress solder joints, vias, and traces. Their higher moisture absorption (up to 1-2%) can lead to swelling or delamination in humid environments.

Why It Matters: High Tg PCBs’ superior thermal stability reduces the risk of circuit failure in applications like 5G base stations, where consistent performance under fluctuating temperatures is critical.

4. High-Frequency Performance

As modern electronics push into higher frequency bands, PCB materials must support reliable signal transmission:

High Tg PCBs: Designed for high-frequency applications, these boards offer lower dielectric loss and a smaller Voltage Standing Wave Ratio (VSWR), ensuring minimal signal degradation. Their stable dielectric properties make them ideal for GHz-range signals in 5G networks, microwave circuits, and high-speed data transmission.

Ordinary Tg PCBs: These boards struggle with signal integrity above 1 GHz, exhibiting higher dielectric loss and signal delay. This limits their use in advanced applications requiring low-loss signal paths.

Example: In a 5G antenna module, a High Tg PCB can maintain signal clarity at 3.5 GHz or higher, while an Ordinary Tg PCB may introduce unacceptable losses, affecting performance.

5. Other Factors: Cost, Availability, and Environmental Impact

Beyond performance, practical considerations like cost and environmental compliance also play a role:

Cost: High Tg PCBs are more expensive due to specialized materials (e.g., high-performance resins) and stricter manufacturing requirements. Ordinary Tg PCBs, using standard FR-4, are more cost-effective for budget-conscious projects.

Availability: Ordinary Tg PCBs are widely available and easier to source, while High Tg materials may require specialized suppliers or longer lead times.

Environmental Compliance: High Tg PCBs are often designed to meet RoHS and low-halogen standards, aligning with global environmental regulations. Ordinary Tg PCBs also comply but may not offer the same level of eco-friendly material options for advanced applications.

Comparison Table:

Feature | High Tg PCB (Tg ≥ 150°C) | Ordinary Tg PCB (Tg 120-130°C) |

|---|---|---|

Temperature Resistance | Handles >260°C soldering, no warping | Limited to ~200°C, risks delamination |

Mechanical Strength | High rigidity, resists cracking | Softer under heat, prone to failure |

Thermal Stability (CTE) | 50-70 ppm/°C, low moisture absorption | 80-100 ppm/°C, higher moisture uptake |

High-Frequency Performance | Low dielectric loss, supports GHz signals | Higher signal loss, limited to <1 GHz |

Cost | Higher due to advanced materials | Cost-effective for standard applications |

Why These Differences Matter

The distinctions between High Tg and Ordinary Tg PCBs directly impact their suitability for specific applications. For projects involving high-speed data, multilayer designs, or extreme environments, High Tg PCBs offer unmatched reliability. Conversely, Ordinary Tg PCBs remain a practical choice for simpler, cost-sensitive applications like consumer gadgets. In the next section, we’ll explore the specific advantages of High Tg PCBs in real-world applications, from 5G infrastructure to automotive systems, to help you decide which material best fits your project’s needs.

Advantages of High Tg PCBs in Real-World Applications

As industries like 5G telecommunications, automotive electronics, and aerospace engineering push the boundaries of performance, High Tg PCBs have become a critical enabler of reliable, high-efficiency electronics. With a Glass Transition Temperature (Tg) of 150°C or higher, these advanced circuit boards offer unique advantages that make them indispensable in demanding applications. From supporting high-frequency signals to ensuring durability in complex manufacturing processes, High Tg PCBs deliver unmatched performance where Ordinary Tg PCBs often fall short. This section explores the key advantages of High Tg PCBs in real-world scenarios, highlighting why they’re the preferred choice for cutting-edge technologies.

1. Superior Performance in High-Frequency Applications

In an era dominated by 5G networks, high-speed data transmission, and RF/microwave circuits, maintaining signal integrity at high frequencies is non-negotiable. High Tg PCBs excel in these environments due to their optimized dielectric properties:

- Low Dielectric Loss: High Tg materials minimize signal attenuation, ensuring clear and reliable transmission in GHz-range frequencies (e.g., 3.5 GHz or higher for 5G applications).

- Reduced Voltage Standing Wave Ratio (VSWR): Lower VSWR translates to better signal quality, critical for applications like 5G base stations, satellite communications, and radar systems.

- Stable Signal Propagation: Unlike Ordinary Tg PCBs, which suffer from signal delays and losses above 1 GHz, High Tg PCBs maintain consistent performance, making them ideal for AI hardware and IoT devices handling massive data throughput.

Real-World Example: In a 5G antenna module, a High Tg PCB ensures minimal signal degradation, enabling faster data rates and reliable connectivity in urban networks, where Ordinary Tg PCBs would struggle to keep up.

2. Enhanced Reliability in Complex Manufacturing Processes

High Tg PCBs are designed to withstand the rigors of advanced PCB manufacturing and assembly processes, offering superior adaptability and reliability:

- Support for Multilayer Designs: High Tg PCBs maintain structural integrity during the high-temperature lamination of multilayer PCBs, reducing the risk of layer separation or warping. This is crucial for compact, high-density designs in automotive ADAS (Advanced Driver-Assistance Systems) or medical devices.

- Compatibility with Lead-Free Soldering: With soldering temperatures often exceeding 260°C in SMT (Surface-Mount Technology) and THT (Through-Hole Technology) processes, High Tg PCBs resist softening or damage, ensuring precise component placement and strong solder joints.

- Improved Processing Stability: Their low Coefficient of Thermal Expansion (CTE) minimizes dimensional changes during thermal cycling, enhancing compatibility with intricate stack-up designs and overlay graphics.

Real-World Example: In turnkey PCB assembly for a high-performance server, High Tg PCBs enable reliable production of 12-layer boards, maintaining alignment and stability through multiple reflow cycles, where Ordinary Tg PCBs might deform.

3. Environmental Compliance and Sustainability

As global regulations like RoHS (Restriction of Hazardous Substances) and low-halogen standards tighten, High Tg PCBs align with modern environmental expectations:

- Lead-Free Compatibility: High Tg materials are engineered to support lead-free soldering processes, reducing the environmental impact of PCB production without compromising performance.

- Low-Halogen Options: Many High Tg PCBs incorporate low-halogen resins, minimizing harmful emissions during manufacturing and disposal, making them a sustainable choice for green electronics.

- Durability for Longevity: Their robust thermal and mechanical properties extend the lifespan of electronic devices, reducing waste in applications like industrial control systems or renewable energy equipment.

Real-World Example: In solar inverter systems, High Tg PCBs meet stringent environmental standards while withstanding outdoor thermal cycling, ensuring long-term reliability and eco-friendly operation.

4. Versatility Across Demanding Industries

High Tg PCBs shine in applications where thermal, mechanical, or electrical challenges are paramount:

- Automotive Electronics: From electric vehicle (EV) battery management systems to engine control units, High Tg PCBs handle high temperatures and vibrations, ensuring safety and performance.

- Aerospace and Defense: In satellite systems and military-grade radar, High Tg PCBs deliver reliability under extreme thermal and mechanical stress.

- Telecommunications: High Tg PCBs power 5G infrastructure, supporting high-frequency signals and thermal stability in densely packed base stations.

- Industrial Applications: In heavy machinery or high-power LED lighting, High Tg PCBs resist thermal shock and maintain performance in harsh environments.

Case Study: A leading aerospace manufacturer used High Tg PCBs in a satellite communication module, achieving zero failures over 10,000 thermal cycles, compared to Ordinary Tg PCBs, which showed delamination after 2,000 cycles.

Why These Advantages Matter

The superior performance of High Tg PCBs in high-frequency applications, complex manufacturing, and environmentally conscious designs makes them a game-changer for industries pushing technological boundaries. Whether you’re developing a 5G-enabled IoT device or a rugged industrial controller, High Tg PCBs provide the reliability and efficiency needed to succeed. In the next section, we’ll explore when to choose High Tg over Ordinary Tg PCBs, offering practical guidance to align material selection with your project’s goals.

When to Choose High Tg Over Ordinary Tg PCBs

Selecting the right PCB material is a pivotal decision that can determine the success of your electronic project. While Ordinary Tg PCBs are cost-effective and reliable for standard applications, High Tg PCBs offer enhanced performance for demanding environments. Knowing when to opt for High Tg over Ordinary Tg PCBs depends on understanding your project’s specific needs, from operating conditions to performance requirements and budget constraints. This section provides practical guidance to help engineers, designers, and manufacturers make informed choices, ensuring optimal performance and reliability for their applications.

1. High-Temperature Operating Environments

If your project involves exposure to elevated temperatures, High Tg PCBs are often the better choice:

Why Choose High Tg? With a Glass Transition Temperature (Tg) of 150°C or higher, High Tg PCBs maintain structural integrity during high-temperature processes like lead-free soldering (exceeding 260°C) or in operating environments with sustained heat. They resist warping, delamination, and softening, unlike Ordinary Tg PCBs (Tg 120-130°C), which may fail under similar conditions.

Relevant Applications:

Automotive electronics, such as engine control units or EV battery management systems, where temperatures can exceed 100°C.

Industrial equipment, like motor drives or high-power LED lighting, exposed to thermal cycling.

Aerospace systems, including avionics or satellite modules, operating in extreme thermal conditions.

When Ordinary Tg Suffices: For consumer electronics like smartphones, TVs, or home appliances, where operating temperatures rarely exceed 80°C, Ordinary Tg PCBs provide sufficient reliability at a lower cost.

Example: A designer developing a solar inverter for outdoor use would choose a High Tg PCB to withstand prolonged heat exposure, while a low-power IoT sensor for indoor use might work fine with an Ordinary Tg PCB.

2. High-Frequency and High-Speed Signal Requirements

For projects involving high-frequency signals or high-speed data transmission, High Tg PCBs are the preferred option:

Why Choose High Tg? High Tg PCBs offer superior dielectric properties, reducing dielectric loss and Voltage Standing Wave Ratio (VSWR), which ensures stable signal integrity at frequencies above 1 GHz. This is critical for applications like 5G infrastructure, RF circuits, or AI-driven hardware. Ordinary Tg PCBs, with higher signal loss, are less effective in these scenarios.

Relevant Applications:

Telecommunications, such as 5G base stations or microwave antennas, requiring low signal attenuation.

High-speed computing, including servers or data centers handling rapid data transfer.

Medical devices, like MRI scanners, where precise signal transmission is essential.

When Ordinary Tg Suffices: For low-frequency applications, such as basic audio circuits or simple microcontrollers operating below 1 GHz, Ordinary Tg PCBs are adequate and more budget-friendly.

Example: A 5G router designer would select a High Tg PCB to ensure reliable signal performance at 3.5 GHz, while a basic USB peripheral could use an Ordinary Tg PCB without issue.

3. Complex Manufacturing and Multilayer Designs

Projects requiring intricate manufacturing processes or multilayer PCB designs benefit significantly from High Tg PCBs:

Why Choose High Tg? The low Coefficient of Thermal Expansion (CTE) and high thermal stability of High Tg PCBs ensure dimensional stability during high-temperature processes like lamination, drilling, and SMT assembly. This reduces risks like via cracking or layer misalignment in multilayer boards (e.g., 8+ layers). Ordinary Tg PCBs are more prone to thermal expansion issues, compromising reliability in complex designs.

Relevant Applications:

High-density electronics, such as compact servers or IoT gateways, requiring multilayer configurations.

Advanced PCB assembly, including turnkey solutions with precise component placement.

Prototyping for high-reliability products, where consistent performance is critical.

When Ordinary Tg Suffices: For single- or double-layer boards in simple designs, like basic consumer gadgets, Ordinary Tg PCBs are easier to manufacture and more cost-effective.

Example: A 12-layer PCB for a telecommunications switch would benefit from a High Tg PCB to maintain alignment during lamination, while a single-layer board for a remote control could use an Ordinary Tg PCB.

4. Budget and Cost Considerations

Cost is a critical factor in material selection, and understanding trade-offs is key:

Why Choose High Tg? While High Tg PCBs are more expensive due to advanced materials (e.g., modified epoxy or polyimide blends) and stricter manufacturing requirements, their enhanced performance justifies the investment for high-stakes projects. They reduce long-term costs by minimizing failures and extending product lifespan in demanding applications.

When Ordinary Tg Suffices: For budget-sensitive projects with minimal thermal or performance demands, Ordinary Tg PCBs offer a cost-effective solution without sacrificing reliability in standard conditions.

Balancing Act: Consider the total cost of ownership. For PCB prototypes or low-volume production, High Tg PCBs may be overkill if Ordinary Tg meets the requirements. However, for high-volume or mission-critical applications, the upfront cost of High Tg PCBs can prevent costly failures.

Example: A military-grade radar system warrants the higher cost of High Tg PCBs for reliability, while a mass-produced toy circuit board can rely on Ordinary Tg PCBs to keep costs low.

5. Environmental and Regulatory Requirements

Compliance with environmental standards can also influence your choice:

Why Choose High Tg? High Tg PCBs are designed to support RoHS-compliant, lead-free processes and often incorporate low-halogen materials, aligning with global environmental regulations. Their durability also contributes to longer product lifespans, reducing electronic waste.

When Ordinary Tg Suffices: Ordinary Tg PCBs also meet RoHS standards but may not offer the same range of eco-friendly material options or durability in harsh conditions.

Consideration: If your project targets markets with strict environmental regulations, High Tg PCBs provide a future-proof solution.

Example: A renewable energy controller for a wind turbine would benefit from a High Tg PCB’s environmental compliance and longevity, while a basic appliance circuit might not require such advanced features.

Making the Right Choice

Choosing between High Tg and Ordinary Tg PCBs comes down to balancing performance, reliability, and cost against your project’s specific needs. High Tg PCBs are the go-to choice for high-temperature environments, high-frequency applications, complex multilayer designs, or projects requiring strict environmental compliance. However, for simpler, cost-sensitive applications like consumer electronics, Ordinary Tg PCBs remain a reliable and economical option. In the final section, we’ll wrap up with a comprehensive comparison and actionable insights to guide your PCB material selection.

Choosing the Right PCB for Your Future-Ready Projects

In the fast-paced world of electronics, where innovations like 5G networks, AI-driven systems, and automotive advancements are redefining possibilities, selecting the right PCB material is more critical than ever. High Tg PCBs, with their Glass Transition Temperature (Tg) of 150°C or higher, offer unmatched thermal stability, mechanical strength, and high-frequency performance, making them the go-to choice for demanding applications. In contrast, Ordinary Tg PCBs, with Tg values of 120-130°C, provide a cost-effective solution for standard electronics where thermal and performance requirements are less stringent. Understanding the differences between these materials empowers engineers and manufacturers to align their choices with project goals, ensuring reliability, efficiency, and long-term success.

Throughout this article, we’ve explored how High Tg PCBs excel in high-temperature environments, high-frequency applications, and complex multilayer designs, delivering benefits like low dielectric loss, reduced thermal expansion, and RoHS-compliant sustainability. Ordinary Tg PCBs, while reliable for consumer gadgets and low-power devices, fall short in scenarios requiring robust performance under heat or high-speed signal demands. By evaluating factors like operating conditions, frequency needs, manufacturing complexity, and budget, you can make informed decisions about which PCB material best suits your project.

As technologies like IoT, electric vehicles, and aerospace systems continue to evolve, the demand for High Tg PCBs is set to grow, driven by their ability to meet the challenges of next-generation electronics. Whether you’re developing a 5G base station, prototyping a multilayer PCB, or designing a rugged industrial controller, choosing the right material can make all the difference.

At JHYPCB, we specialize in delivering high-quality PCB manufacturing and assembly services, including High Tg PCB prototypes, SMT and THT assembly, and turnkey solutions. Our expertise ensures your projects meet the highest standards of performance and reliability. Ready to take your design to the next level? Contact us at sales@pcbjhy.com for custom quotes, expert guidance, or to explore our comprehensive component sourcing and multilayer PCB fabrication services. Let’s build the future of electronics together!