Table of Contents

When requesting a quote from a PCB supplier or ordering a PCB prototype on a manufacturer’s pricing page, you’ll often need to specify or select the Tg value of the PCB board. Different Tg values can impact the final PCB prototype manufacturing costs—essentially, you’re paying for enhanced thermal performance. So, what exactly is the Tg value, and when should you opt for high Tg sheets to ensure reliability?

In the PCB manufacturing industry, the Tg value (Glass Transition Temperature) is the most common metric for classifying FR-4 substrates. Generally, a higher Tg value correlates with greater sheet reliability, especially in demanding applications like high-power electronics or automotive systems.

For instance, Tg135° sheets are ideal for motherboards and consumer electronics, while Tg180° sheets suit CPU boards, DDR3 memory substrates, and IC packaging. At JHYPCB, we’ve seen firsthand how choosing the right Tg can prevent failures in real-world scenarios, drawing from our extensive experience in PCB manufacturing and assembly services.

The role of PCB substrates in printed circuit boards is as crucial as the boards themselves are to electronic devices. Let’s dive deeper into this essential parameter, updated with 2025 insights on emerging trends like advanced thermal management for 5G and EV applications.

Classification of PCB Substrates

PCB substrates can be divided into organic and inorganic types based on their nature.

Organic substrates include multiple layers of paper impregnated with phenolic resin or non-woven/glass cloth layers with epoxy resin, polyimide, cyanate ester, or BT resin. Their purpose varies with the PCB’s required physical characteristics, such as operating temperature, frequency, or mechanical strength.

Inorganic substrates, like ceramics, aluminum, iron, or copper, are primarily for heat dissipation.

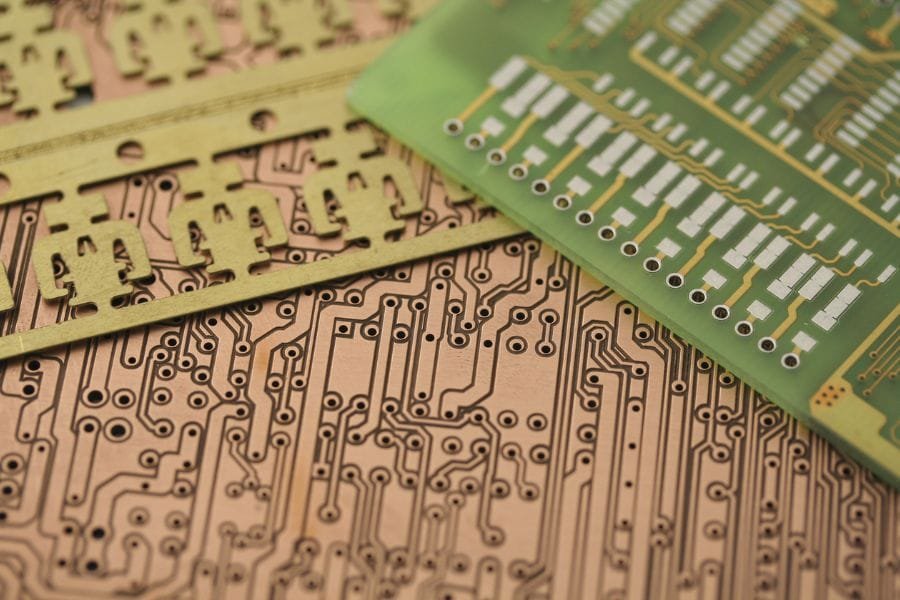

Rigid PCBs typically use organic substrates like FR-4 epoxy glass fiber cloth, with epoxy resin as the adhesive and electronic-grade glass fiber cloth as reinforcement.

Tg is short for Glass Transition Temperature. FR-4 relies on epoxy resin, and Tg is a critical parameter for this material. PCBs must be flame-resistant, softening only at a certain temperature without burning. Thus, Tg is the critical point where the PCB substrate shifts from a solid to an elastic fluid state.

A higher Tg demands more heat during pressing, resulting in a more rigid yet brittle board. This can affect mechanical drilling quality and electrical characteristics in subsequent processes.

Tg represents the highest temperature (°C) at which the PCB base material remains rigid.

PCB substrate Tg is graded as: standard FR-4 at 130°-140°; high-Tg FR-4 over 170°; medium Tg at 150°. PI materials in flexible PCBs can reach 400°.

Below is a table of Tg values for different PCB base materials:

| Base Material | PREPREG | FR2 | CEM1 | CEM3 | FR4 | FR4 High Tg | Teflon | Polyimide |

|---|---|---|---|---|---|---|---|---|

| Tg (°C) | – | 30 | 60/90 | 125 | 135 | 150/170/210 | 160 | >250 |

The Tg value affects PCB dimensional stability. Higher Tg improves temperature resistance, mechanical, and electrical properties—vital for lead-free PCB manufacturing.

High Tg materials offer:

- High-temperature resistance

- Long delamination durability (for safety)

- Low thermal expansion

- Excellent PTH reliability

- Good mechanical properties

- High thermal stress resistance

- Improved stability: Boosts heat, chemical, moisture resistance, and device stability

- Handles high power density: Ideal for thermal management in high-heat devices

- Enables larger PCBs to reduce heating while meeting design needs

- Suited for multilayer and HDI PCBs: Ensures reliability amid dense circuits and heat dissipation

The Glassy Substance Transformation

The glassy substance shifts reversibly between glassy and high elastic states.

Glass State: Below Tg, the resin is hard and solid. Deformation under force is reversible.

High Elastic State: Above Tg, molecular chains move, making the resin elastomer-like with reversible deformation.

Above Tg, the material softens but returns to rigidity when cooled below Tg, unless decomposed.

Td (thermal decomposition temperature) is when resin decomposes, losing 5% mass—critical for multilayer PCBs, as resin loss affects dielectric properties and impedance.

Lead-free soldering (240-270°C) demands higher Td than tin-lead (210-245°C). For example:

- Conventional FR4 (KB-6160): Tg 135°C, Td 305°C

- Lead-free FR4 (KB-6168LE): Tg 185°C, Td 359°C

Conventional Td works for tin-lead but risks 1.5-3% resin loss in lead-free, potentially causing delamination or voids. Thus, consider Td alongside Tg for lead-free processes.

Material performance differs above/below Tg, but the shift is gradual.

The Effect of Thermal Expansion

Thermal expansion affects PCBs during SMT, changing BGA pad pitch and causing micro-cracks in traces/pads. These may pass initial tests but fail under thermal cycling.

What is CTE?: Coefficient of Thermal Expansion includes X/Y and Z-axis.

Z-axis CTE impacts reliability, distorting plated holes.

X/Y-axis CTE is key for SMT, CSP, and lead-free assembly.

What is Td value?

Is the Higher the Tg Value of the PCB Substrate, the Better?

Not always. Higher Tg delays expansion onset, but overall expansion depends on material type and CTE. Some low Tg substrates expand less than high Tg ones due to resin or fillers.

Low-end FR-4 with Tg 140°C may have higher Td than Tg 170°C versions. Prioritize high Td for lead-free; premium FR-4 balances both.

High Tg substrates are more brittle, affecting drilling efficiency.

As assembly density rises, vias narrow, demanding higher materials—many manufacturers charge extra for high Tg.

Tg=155 costs ~20% more than Tg=135. High Tg needs new drills and longer pressing (150 vs. 110 minutes).

Higher Tg enhances heat/moisture/chemical resistance and stability.

For lead-free assembly, evaluate Tg, Td, CTE, and water absorption holistically.

High Tg PCBs offer better stability:

- High heat resistance: Reduces warpage in welding/thermal shock.

- Low CTE: Minimizes copper fractures in holes, especially in 8+ layer boards.

- Better chemical resistance.

High TG supports high-density tech like SMT/CMT, essential for small apertures, fine wiring, and thinning in electronics.

2025 Trends: Advancements in High Tg Materials and Applications

In 2025, high Tg PCB materials are evolving rapidly, driven by demands in automotive ADAS, 5G infrastructure, and high-power AI servers. According to market reports, the global high-Tg PCB market is projected to grow from $10.5 billion in 2023 to $18.2 billion by 2030, fueled by innovations in thermal management.

Key advancements include:

- Enhanced FR-4 Variants: High-Tg FR-4 (170-180°C) now integrates low-moisture absorption and improved dielectric strength, ideal for EV batteries and high-frequency applications.

- Integration with Thermal Vias and Cooling Tech: Combining high Tg with advanced thermal vias reduces heat in compact designs, as seen in emerging 3D-printed PCBs.

- Sustainability Focus: New eco-friendly high Tg resins minimize environmental impact while maintaining performance.

- Applications in Emerging Tech: From wearable flex PCBs to multilayer HDI for ADAS, high Tg ensures reliability under extreme conditions.

At JHYPCB, we’re incorporating these trends into our rigid, flexible, and rigid-flex PCB manufacturing, helping clients like automotive engineers achieve optimal thermal stability.

Elevate Your PCB Projects with the Right Tg Choice

Tg value is pivotal for PCB thermal resilience, reliability, and cost. By selecting appropriately—considering operating temps, lead-free needs, and 2025 trends—you can avoid failures and optimize performance.

Consult JHYPCB for custom Tg selections in prototypes, multilayer boards, or turnkey assembly. Our expertise ensures high-reliability PCBs tailored to your needs.

High-Tg PCB substrate data download

- date sheet S1170G-High Tg Halogen Free Material

- date sheet S1000-2B-Low CTE High Tg Material

- Date Sheet for High-Tg and High Thermal Reliability Laminate and Prepreg-TU768

- date sheet ITEQ-IT-180A-Low CTE High Tg Material

Parameters of Common high Tg PCB base material

| Material | TG (DSC, °C) | Td (Wt, °C) | CTE-z (ppm/°C) | Td260 (min) | Td288 (min) |

| S1141 (FR4) | 175 | 300 | 55 | 8 | / |

| S1000-2M (FR4) | 180 | 345 | 45 | 60 | 20 |

| IT180 | 180 | 345 | 45 | 60 | 20 |

| Rogers 4350B | 280 | 390 | 50 | / | / |