Table of Contents

Introduction

In the ever-evolving world of electronics, understanding advanced materials can give you a competitive edge. But what is a single-sided insulated hole aluminum PCB? This innovative circuit board solution stands out for its unique design and thermal efficiency, making it a go-to choice for various high-performance applications. Let’s uncover the essentials of this technology and how it can benefit your projects.

What Are Single-Sided Insulated Hole Aluminum PCBs?

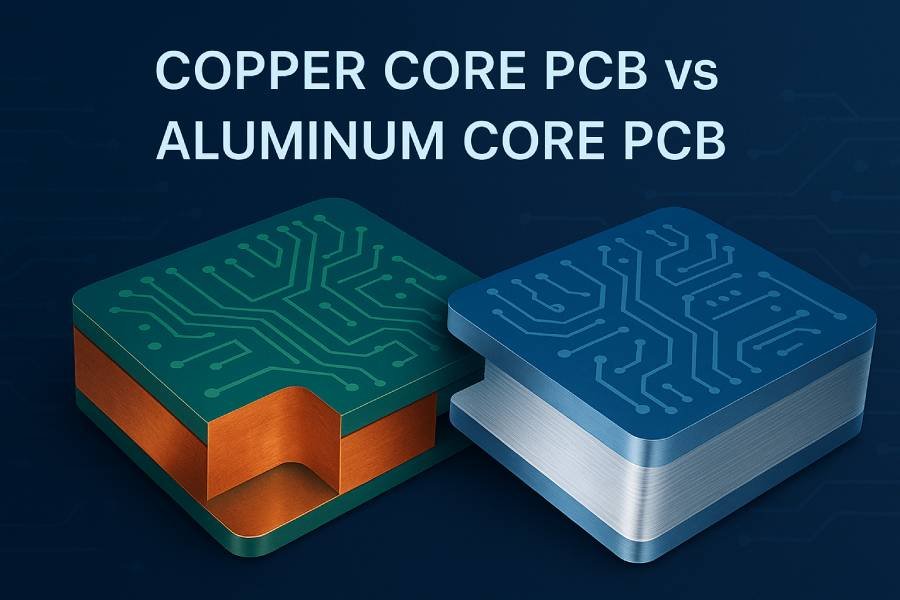

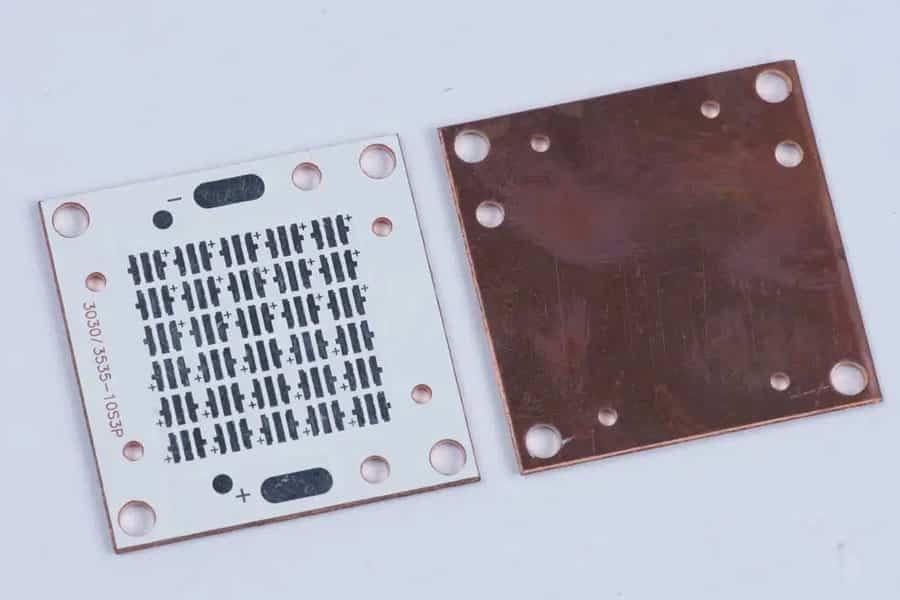

So, what is a single-sided insulated hole aluminum PCB? It’s a specialized aluminum-based circuit board that differs from standard single-sided aluminum PCBs. Constructed with a 5052 aluminum base, a dielectric layer, and a copper foil layer, its key feature is pre-drilled holes filled with epoxy resin. This design allows DIP components to pass through the aluminum while maintaining electrical insulation, with the aluminum core enabling both electrical connections and insulated vias—hence the name “insulated hole aluminum PCB.”

Structure and Design Features

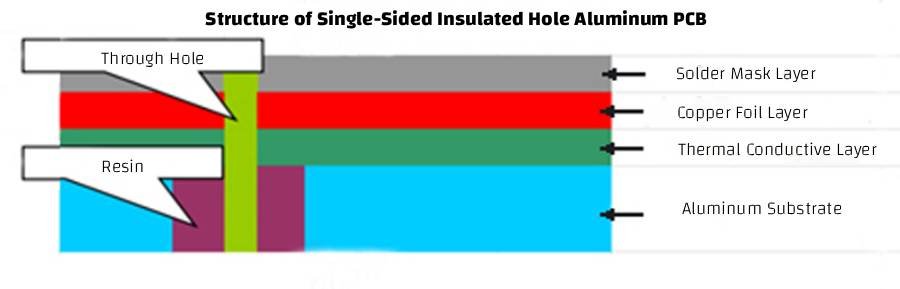

The structure of a single-sided insulated hole aluminum PCB is both simple and ingenious. It includes:

- Aluminum Base (5052): Provides a sturdy foundation with excellent heat dissipation.

- Dielectric Layer: Ensures insulation between the aluminum and copper layers.

- Copper Foil Layer: Conducts electricity with precision.

As shown in the attached diagram, the board features a thin dielectric layer (0.02mm) and a 1oz copper foil with a thermal conductivity of 1W/mK. This layered design, combined with insulated holes, offers a perfect balance of conductivity and insulation, making it ideal for complex assemblies.

Special Manufacturing Techniques

Crafting these PCBs involves unique processes to achieve their distinctive properties:

- Counterboring: Creates precise depressions for specific component placements.

- Controlled Depth Holes/Slots: Ensures accurate depth for insulated vias, enhancing reliability.

These techniques require skilled execution, ensuring the board meets the high standards needed for demanding applications.

Manufacturing Capabilities Overview

Expert PCB manufacturing services offer robust production capabilities for these boards, including:

- Board Thickness: 0.8mm to 3.0mm (tolerance ±10%).

- Copper Foil Thickness: 35μm to 105μm (tolerance ±10%).

- Solder Mask Colors: White, black, red, blue, or green.

- Silkscreen Colors: Black or white.

- Surface Finishes: ENIG, lead-free HASL, leaded HASL, or OSP.

- Shaping Methods: V-CUT, CNC, or die punching.

- Lead Time: Fast delivery in 4-5 days.

- Applications: Automotive LED lights, medical devices, machinery, and DIP packaging.

This versatility ensures the boards are tailored to meet diverse project requirements with efficiency.

Applications and Product Advantages

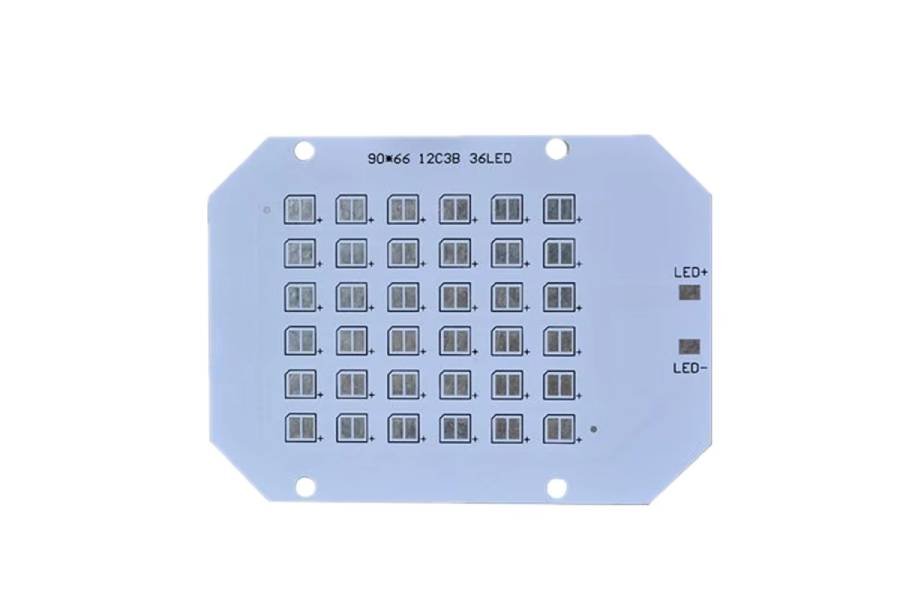

Single-sided insulated hole aluminum PCBs shine in various settings:

- Automotive LED Lights: Enhances brightness and longevity.

- Medical Devices: Supports reliable performance in critical equipment.

- Machinery: Improves efficiency in industrial applications.

- Specialty Lighting: Used in flashlights, stage projectors, and LED streetlights.

Their advantages include a long lifespan for metal components, efficient heat dissipation, stability, and broad applicability, making them a smart choice for modern designs.

Conclusion

Now that you know what a single-sided insulated hole aluminum PCB is, it’s clear they offer a powerful solution for high-performance electronics with their unique insulated hole design and thermal efficiency. Expert PCB manufacturing services can bring these benefits to your projects with precision and speed. Ready to explore more? Contact us at sales@pcbjhy.com for tailored support.