Professional Copper Core PCB Manufacturer

High-Performance Copper Core PCBs for LED and Power Applications

What Is a Copper Core PCB and Why It Matters

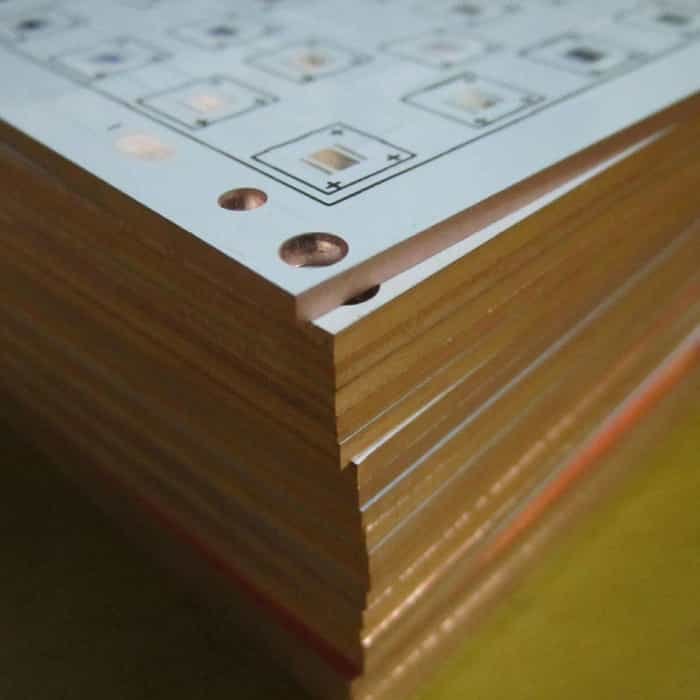

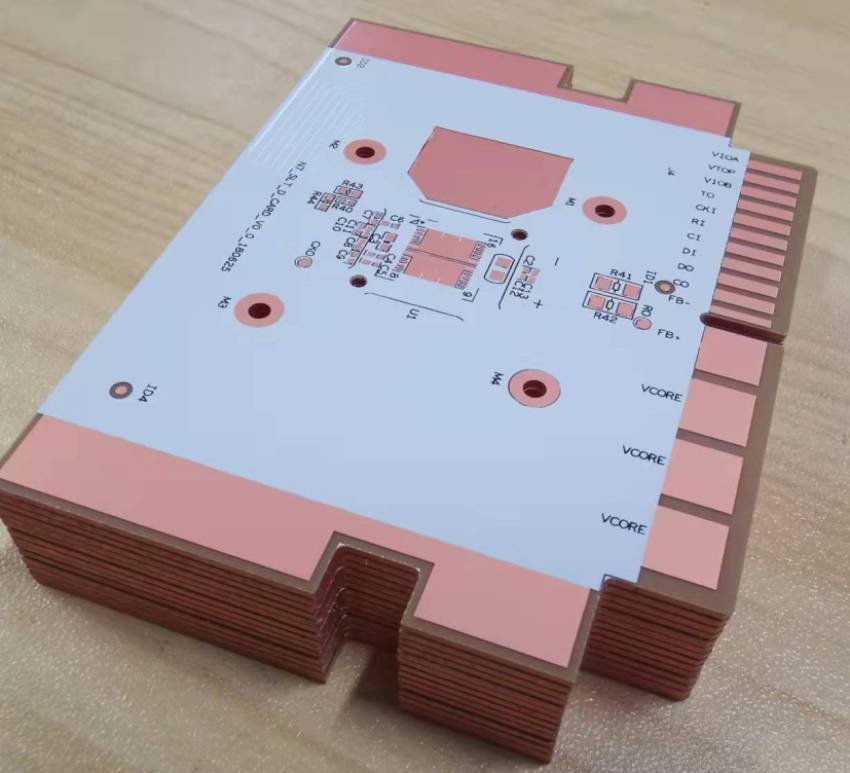

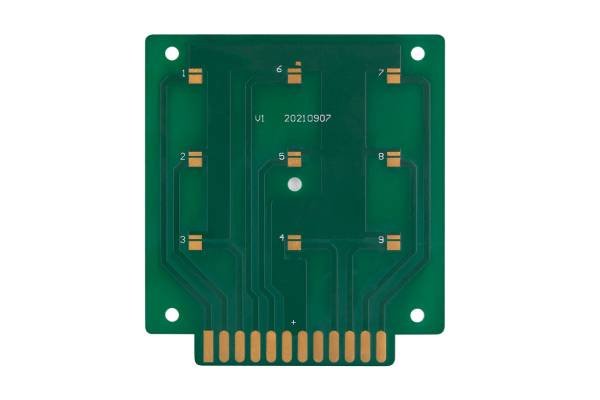

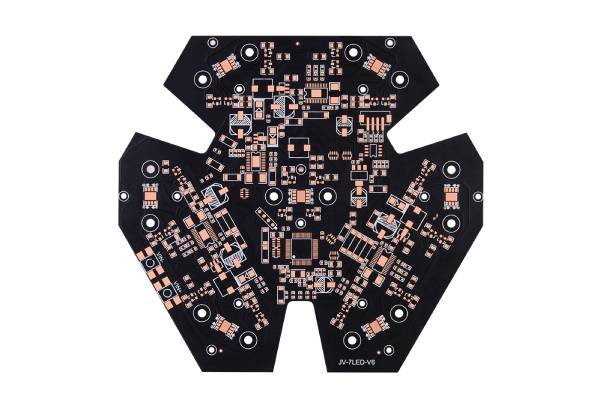

Copper core PCBs, also known as copper-based PCBs, feature a solid copper substrate instead of aluminum or FR4. The copper core acts as an excellent heat conductor, quickly transferring heat away from critical components. This makes them ideal for high-power and high-temperature applications, such as LED modules and power converters.

Compared with standard aluminum PCBs, copper core boards offer higher thermal conductivity, better dimensional stability, and enhanced mechanical strength. They are the go-to solution for engineers who demand reliability and performance under extreme conditions.

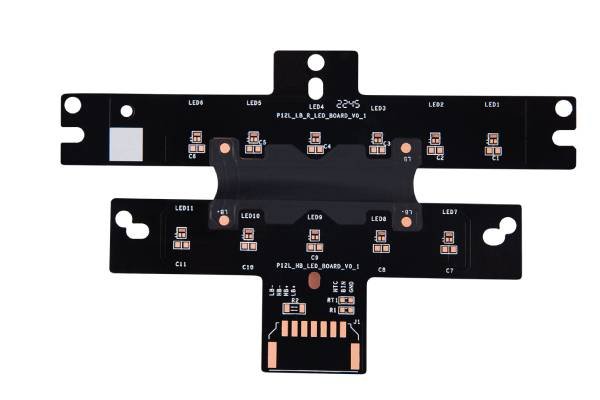

Why Choose Copper Core PCBs for LED Applications

Copper core PCBs are particularly popular in LED lighting systems due to their outstanding heat dissipation and durability. Key benefits include:

Partner with a Leading Copper Core PCB Manufacturer

With years of experience in PCB manufacturing, JHYPCB offers advanced copper core PCB fabrication services tailored for global clients. From prototype to mass production, we ensure consistent quality and fast turnaround times.

Our Copper Core PCB Manufacturing Capabilities

At JHYPCB, we specialize in high-quality copper core PCB manufacturing for LED and high-power applications. Below are our core production capabilities and specifications to ensure performance, stability, and precision in every project.

| Specification | Capability |

|---|---|

| Structure | Single-sided, double-sided, multilayer copper core PCBs |

| Base Materials | Shengyi, Totking, and other copper-based substrates |

| Thermal Conductivity | 1 – 5 W/m·K |

| Maximum Board Size | 1200 × 540 mm |

| Board Thickness | 0.4 – 3.0 mm |

| Copper Core Thickness | 0.5 – 4 oz (up to 140 μm) |

| Min. Trace Width / Spacing | 4/4 mil |

| Drill & Via Capabilities | Plated through holes, blind/buried vias, countersunk holes, Z-axis milling |

| Min. Hole Size | 0.3 mm |

| Surface Finish Options | ENIG, OSP |

| Solder Mask Colors | Green, White, High Reflectivity White, Black, Matte Black |

| Surface Technology | Pedestal technology (chemical etching + plating) |

| Testing & Quality Control | 100% E-test, AOI, cross-section analysis |

| Applications | LED lighting, automotive, power electronics, aerospace, and more |

🔸 Copper Core PCB Materials We Support

| Material Code | Brand | Type | Thermal Conductivity (W/m·K) | Tg (°C) |

|---|---|---|---|---|

| SCR20S | Shengyi | Copper | 2.1 | 160 |

| T511 | Totking | Copper | 3.0 | 100 |

| T512 | Totking | Copper | 4.0 | 100 |

| T512C | Totking | Copper | 5.0 | 130 |

Copper Core PCB Price List and Bulk Order Service

The price of copper core PCBs depends on several factors:

- PCB layer count and copper thickness

- Board size and complexity

- Quantity (prototype or bulk)

- Surface finish and material type

As a low-cost copper core PCB manufacturer in China, we provide flexible pricing for both small and large volume orders. Contact us to get a detailed copper core PCB pricelist tailored to your specifications.

Industries and Applications of Copper Core PCBs

Copper core PCBs are designed for demanding applications that require efficient heat transfer and high reliability. They are widely used in:

- LED lighting and displays

- Automotive power systems

- Power electronics and converters

- Industrial control boards

- Communication and radar modules

LED copper core PCBs are particularly suitable for high-power lighting systems that demand durability and performance.

Why Choose JHYPCB as Your Copper Core PCB Manufacturer

Choosing the right copper core PCB manufacturer is crucial for ensuring long-term performance, cost efficiency, and product reliability. At JHYPCB, we combine technical expertise with advanced manufacturing capabilities to deliver high-quality copper core PCBs that meet your exact requirements.

Strict Quality Control System

Every PCB undergoes 100% electrical testing, AOI inspection, and cross-section analysis to guarantee reliability and compliance with IPC standards.

Global Supply Capability

We ship copper core PCBs to clients worldwide, offering flexible logistics and stable supply chains to support your ongoing production needs.

Frequently Asked Questions About Copper Core PCBs

Copper has much higher thermal conductivity than aluminum, allowing better heat dissipation and stability in high-power circuits.

Prototype orders typically take 5–7 working days, while bulk orders depend on design complexity and quantity.

Yes. We provide competitive pricing for both small and bulk orders, ensuring great value for every customer.

Ready to Start Your Copper Core PCB Project?

Partner with JHYPCB — your trusted copper core PCB manufacturer in China.

Get reliable performance, professional support, and fast worldwide delivery.

Related Metal Core PCB Manufacturing Services

Related Posts

- Choosing the Right Metal Core PCB Manufacturer is Critical to Your Success

- Top PCB Board Manufacturer And Supplier In China

- The Best PCB Manufacturer In China

- Custom Circuit Board Printing

- Custom PCB Manufacturing In China

- Why choose FR4 as the general material of PCB?

- Why is FR4 Used to Make High Tg PCBs?

- What Is FR-4 Material In PCB Fabrication?