Table of Contents

In today’s fast-paced world of electronics, where we’re surrounded by gadgets that power our daily lives—from smartphones to industrial machinery—it’s easy to overlook the tiny details that make everything tick. But if you’ve ever wondered how signals zip through your devices without a hitch, the answer often lies in something as simple yet crucial as copper foil in PCB manufacturing. As a leading PCB manufacturer based in China, at JHYPCB, we’ve seen firsthand how this material forms the backbone of high-quality circuit boards. In this post, we’ll dive deep into what copper foil is, its types, applications, and why it’s indispensable for PCB fabrication and assembly. Whether you’re a hobbyist tinkering with prototypes or an engineer sourcing components for large-scale production, understanding copper foil can help you make smarter decisions for your projects.

What is Copper Foil in PCBs?

Copper foil is essentially a thin layer of copper that’s electrodeposited onto the base layer of a printed circuit board (PCB). Acting as the conductor, it forms a continuous metal sheet that carries electrical signals across the board. This material is negatively electrolytic, meaning it’s created through an electrolysis process that ensures high purity and uniformity. One of its standout features is its low oxygen content on the surface, which allows it to bond seamlessly with various substrates, including metals and insulating materials.

In PCB manufacturing, copper foil is etched to create intricate circuit patterns after being laminated onto the insulating layer and protected with a solder mask. This process is what turns a blank board into a functional powerhouse. But copper foil isn’t just about conductivity—it’s also a champion in electromagnetic shielding and antistatic protection. By placing conductive copper foil on the substrate surface and grounding it to a metal base, you get excellent continuity and shielding against interference, which is vital in sensitive electronic environments.

At JHYPCB, we specialize in incorporating high-grade copper foil into our PCB prototypes, single-sided, double-sided, and multilayer boards, as well as rigid, flexible, and rigid-flex PCBs. Our expertise ensures that every layer adheres perfectly, minimizing defects and maximizing performance.

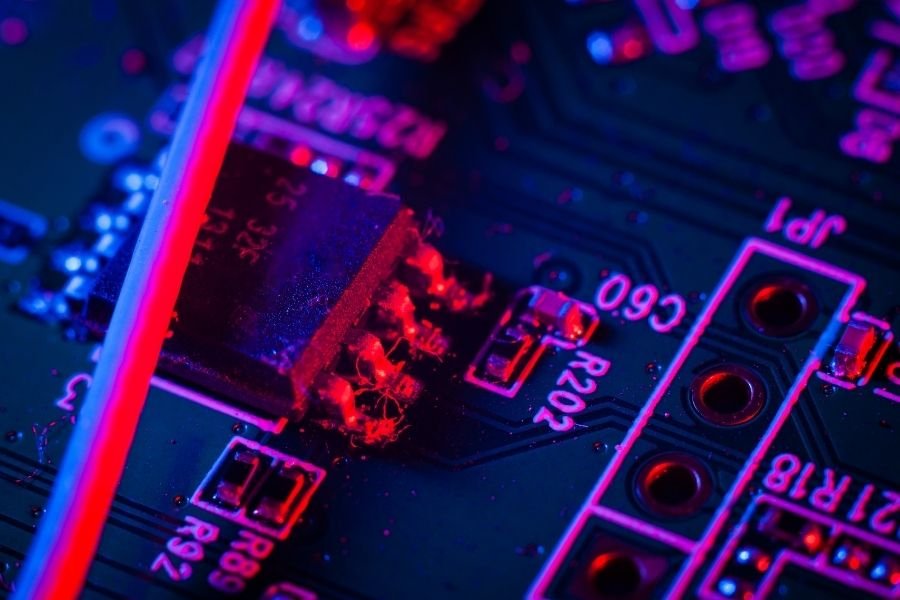

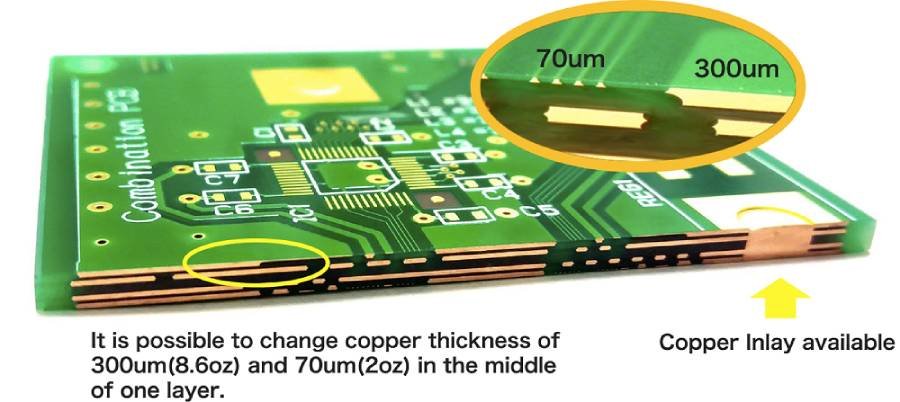

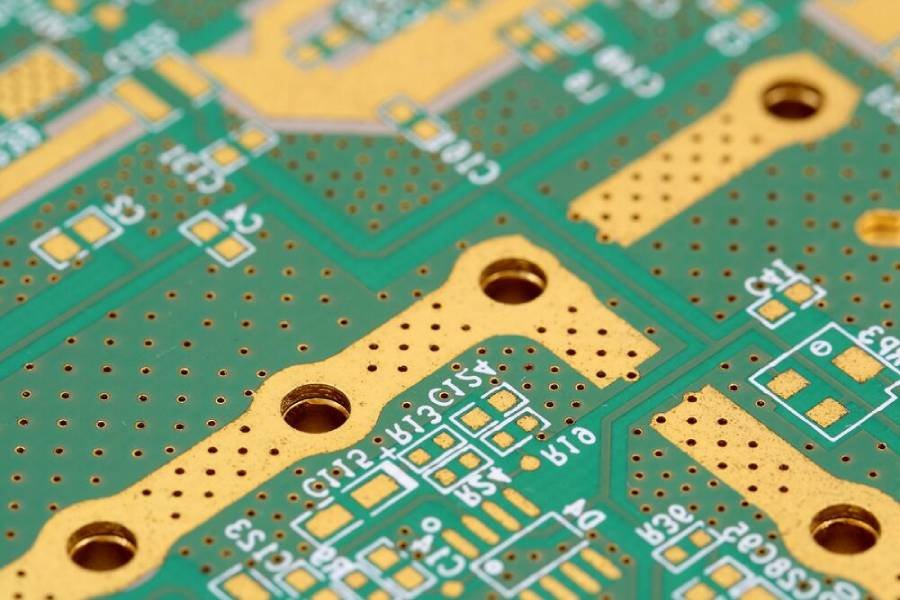

Detailed view of electrolytic copper foil thickness in PCB manufacturing, highlighting 70um and 300um layers on a printed circuit board for optimal conductivity and signal flow.

Types of Copper Foil Used in PCBs

Not all copper foils are created equal, and choosing the right type depends on your project’s needs. Here’s a breakdown of the common varieties:

- Self-Adhesive Copper Foil: This comes with a built-in adhesive backing, making it easy to apply for quick repairs or custom shielding. It’s popular in DIY projects or for adding extra protection against EMI (electromagnetic interference).

- Single-Sided Copper Foil: As the name suggests, copper is applied to only one side of the substrate. Ideal for simpler circuits where cost-efficiency is key, this type is often used in basic consumer electronics.

- Double-Sided Copper Foil: Copper on both sides allows for more complex designs with interconnections between layers. It’s a staple in multilayer PCBs, enabling denser component placement and better signal integrity.

These types can be further customized based on thickness and purity. Electronic-grade copper foil, for instance, boasts a purity of 99.7% and thicknesses ranging from 5μm to 105μm. This high purity is what makes it a go-to material for the rapidly evolving electronics industry.

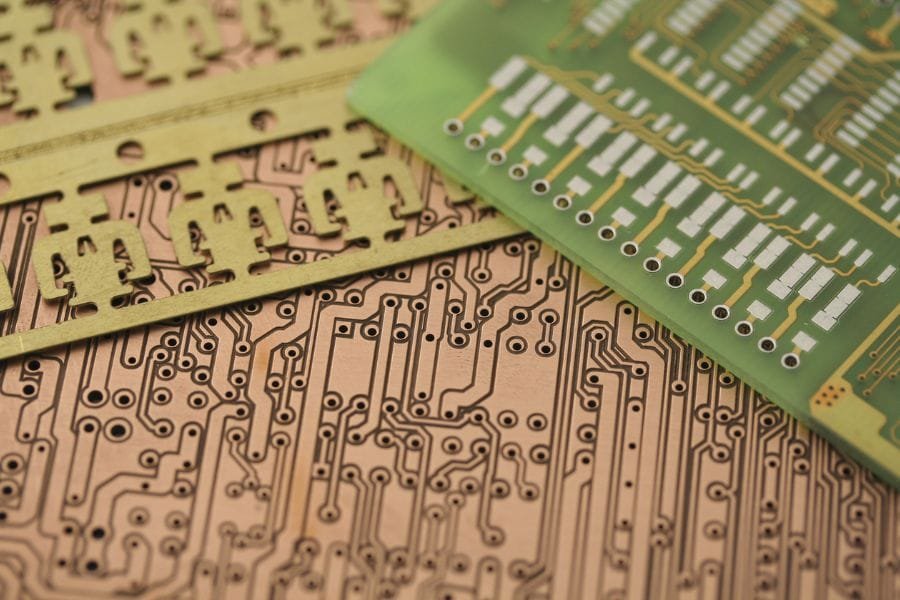

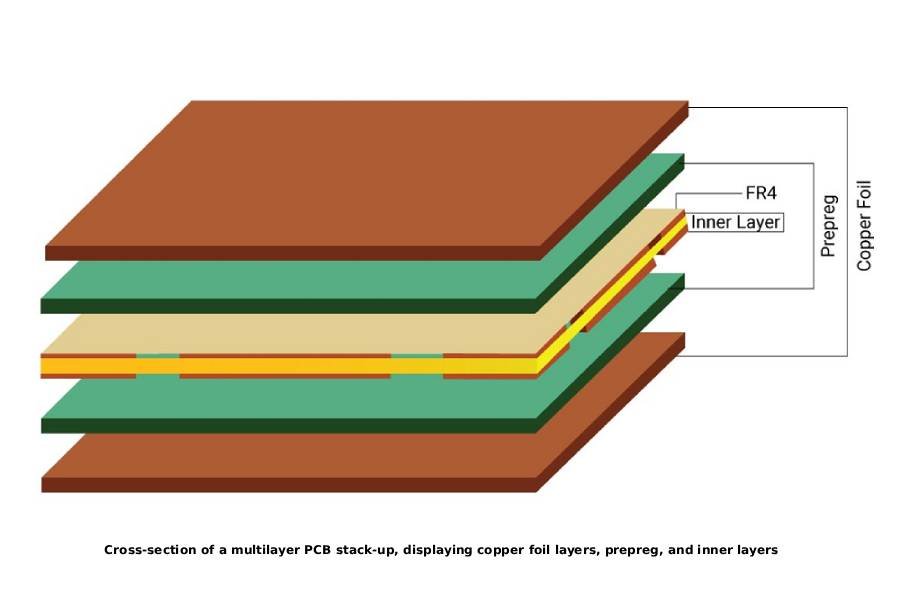

Cross-section of a multilayer PCB stack-up, displaying copper foil layers, prepreg, and inner layers.

Applications of Copper Foil in Electronics

The demand for copper foil is skyrocketing as electronic devices become more sophisticated. It’s a foundational material in the information industry, supporting everything from industrial calculators and communication equipment to QA devices, lithium-ion batteries, TVs, VCRs, CD players, copiers, telephones, air conditioners, and automotive electronic parts.

Think about it: How many electronic devices did you use today? Chances are, quite a few. These gadgets rely on non-conductive substrates etched with copper pathways to connect components and allow signals to flow. Without PCBs—and by extension, without quality copper foil—no electrical device could function properly. From household appliances to heavy-duty industrial gear, PCBs provide the mechanical support and electrical connectivity that keep our world running.

In our PCB assembly services at JHYPCB, we use premium copper foil in SMT (Surface Mount Technology), THT (Through-Hole Technology), and mixed-technology assemblies. We also offer turnkey PCB assembly, component sourcing, and SMT stencils, ensuring that your boards are built with materials that stand up to real-world demands. For example, in lithium-ion batteries, copper foil’s conductivity helps optimize energy transfer, while in automotive electronics, its durability ensures reliability under harsh conditions.

Why Copper Foil Matters for PCB Quality

Copper foil isn’t just a conductor—it’s the unsung hero that ensures your PCBs are reliable, efficient, and long-lasting. Its ability to form strong bonds with insulating layers reduces the risk of delamination, while its shielding properties protect against noise and static that could fry sensitive components. As the electronics market grows, so does the need for high-purity, versatile copper foils that can handle thinner profiles without sacrificing strength.

At JHYPCB, we’re committed to using top-tier copper foils in all our manufacturing processes. This dedication to quality is why our clients trust us for everything from prototypes to full-scale production. If you’re dealing with issues like signal loss or EMI in your designs, upgrading your copper foil specs could be the game-changer you need.

Final Thoughts

Copper foil might seem like a small piece of the PCB puzzle, but its impact on performance, reliability, and innovation is massive. As we continue to push the boundaries of electronics, materials like this will only become more critical. If you’re ready to elevate your PCB projects with expert manufacturing and assembly services, reach out to us at JHYPCB. Our team is here to help with custom solutions tailored to your needs—whether it’s rigid-flex PCBs, component sourcing, or full turnkey assembly.

Contact us today at sales@pcbjhy.com to discuss how we can bring your ideas to life. Let’s build something amazing together!