Table of Contents

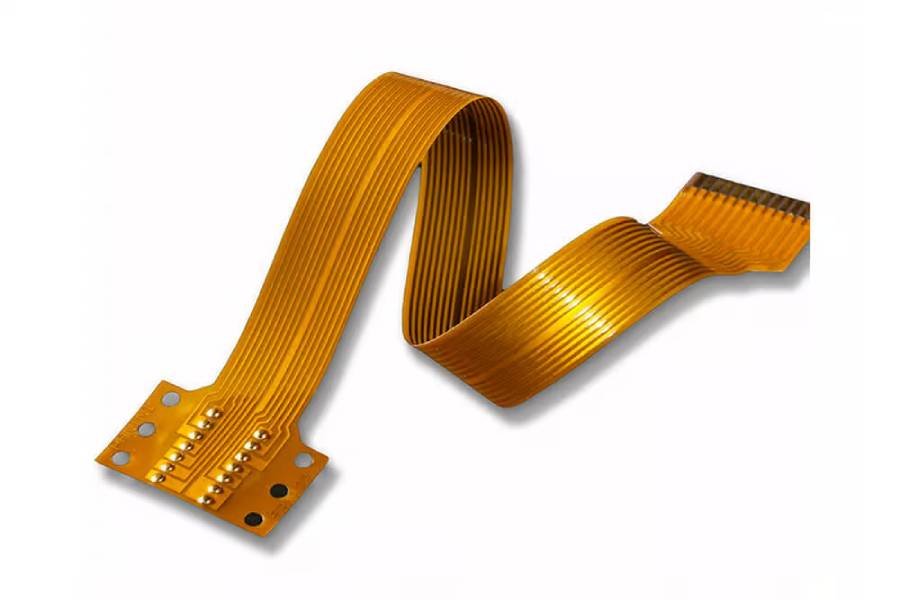

In the fast-evolving electronics and communications industry, flexible printed circuit boards (FPCs) have become indispensable due to their ability to bend, fold, and fit into complex designs. Unlike rigid PCBs, flexible PCBs reduce assembly errors, withstand harsh environments, and handle intricate electronic configurations. At JHYPCB, a trusted PCB manufacturer based in China, we leverage these advantages to deliver top-tier flexible PCB manufacturing and PCB assembly services, including single-sided, double-sided, multilayer, rigid-flex PCBs, SMT, THT, and turnkey solutions. Our expertise also extends to component sourcing and SMT stencil production, ensuring seamless project execution. Contact us at sales@pcbjhy.com for tailored solutions.

A critical material in flexible PCB production is electrolytic copper foil, a cost-effective and reliable conductor that’s gaining prominence in the industry. With years of experience in PCB fabrication, JHYPCB frequently uses electrolytic copper foil to craft high-quality flexible circuits that meet diverse application needs. In this article, we’ll dive into the composition of flexible PCBs, the manufacturing process of electrolytic copper foil, its advantages over rolled annealed foil, and how to choose the right material for your project.

The Core Components of Flexible PCBs and the Importance of Conductors

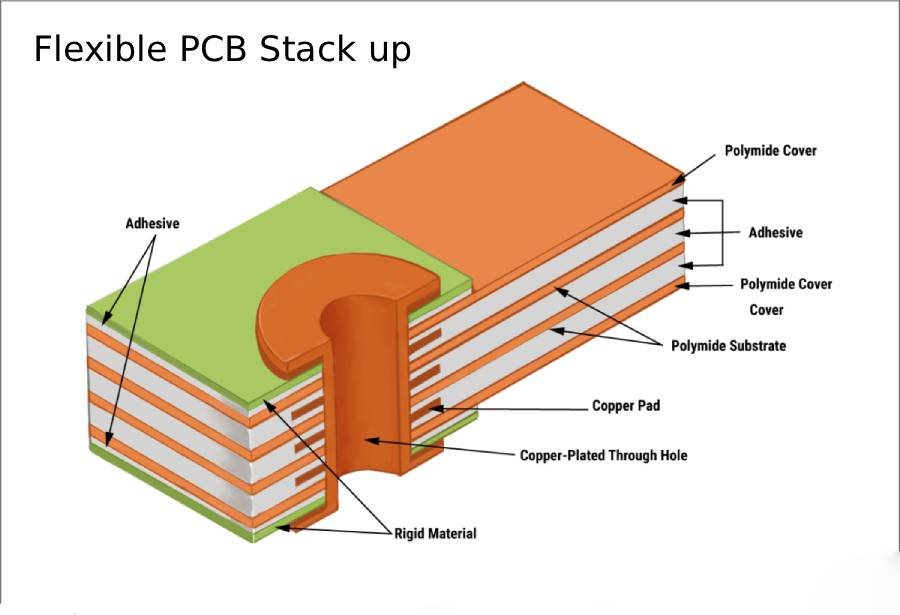

A flexible PCB consists of three primary components: conductors, adhesives, and insulators. These materials are strategically arranged to ensure current flows as designed and integrates with other electronic components. Common adhesives include epoxy resin, acrylic, or pressure-sensitive adhesives (PSA), while insulators typically use polyester or polyamide for electrical isolation and mechanical strength.

The conductor, however, is the heart of the circuit, directly impacting its conductivity and durability. While materials like silver, carbon, or aluminum are occasionally used, copper foil reigns supreme due to its superior conductivity, flexibility, and corrosion resistance. In flexible PCB manufacturing, copper foil is produced in two ways: rolled annealed copper foil or electrolytic copper foil. At JHYPCB, we carefully select the appropriate foil based on project requirements to ensure optimal performance.

Imagine designing a wearable device or an automotive system where the PCB must endure repeated bending without failing. The choice of copper foil becomes critical. Let’s explore how electrolytic copper foil is made and why it’s a go-to choice.

How Electrolytic Copper Foil is Manufactured

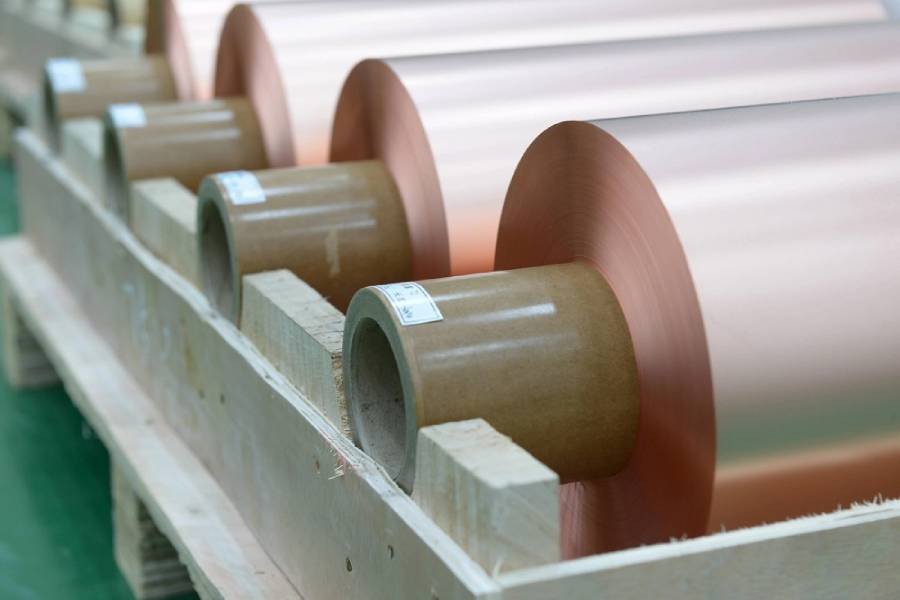

The production of electrolytic copper foil is a fascinating process rooted in electrochemistry. It begins with a copper sulfate solution, often mixed with additives to fine-tune the foil’s properties. This solution is passed through an electrolytic cell, where an electric current causes copper ions to deposit onto a cathode surface, forming a thin copper film.

The thickness of the foil is controlled by the speed of the cathode drum—faster rotation attracts more copper deposits, resulting in thicker foil. This allows manufacturers to produce foils ranging from a few microns to thicker specifications. Post-production, the foil undergoes treatments to enhance its performance:

- Bonding treatment: Improves adhesion to the adhesive layer.

- Heat resistance treatment: Ensures durability during high-temperature PCB manufacturing.

- Stability treatment: Prevents oxidation during storage or use.

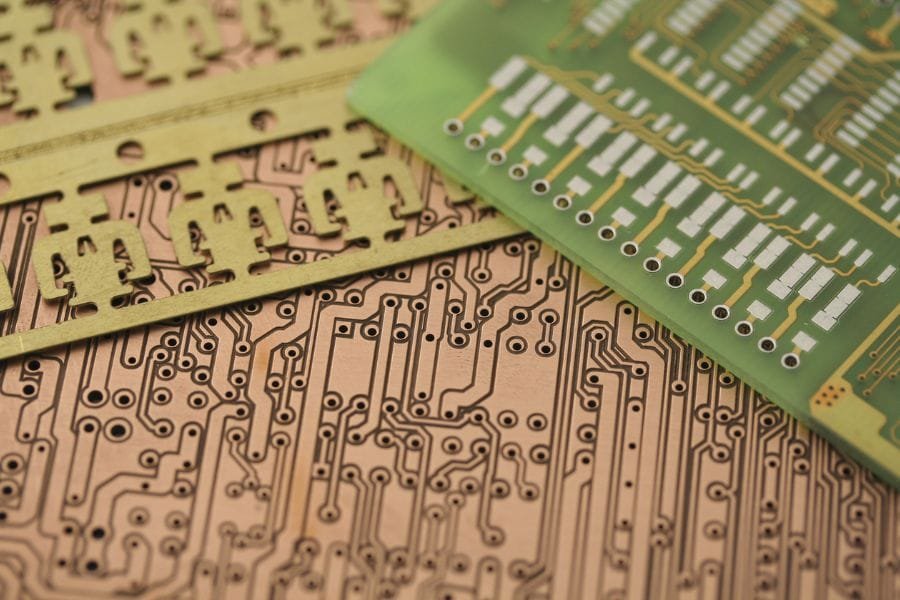

In contrast, rolled annealed copper foil is made by heating and rolling copper sheets, creating a smoother surface with enhanced ductility and flexibility. While this method excels in certain applications, the simplicity of electrolysis makes electrolytic copper foil more cost-effective, a key reason it’s widely used in JHYPCB’s flexible PCB production lines.

Electrolytic vs. Rolled Annealed Copper Foil: Which is Right for Your Flexible PCB?

The structural differences between electrolytic and rolled annealed copper foil directly influence their performance. Rolled annealed foil has a horizontal crystal structure at room temperature, transforming into a lamellar structure under high pressure and heat. This results in a smoother surface, higher conductivity, and better suitability for fine-line circuits and applications requiring extreme flexibility, such as foldable smartphones or medical devices.

Electrolytic copper foil, on the other hand, maintains a columnar crystal structure regardless of temperature or pressure. While its surface is slightly rougher, it still offers excellent conductivity and ductility. Its biggest advantage? Cost-efficiency—electrolytic foil is typically 20-30% cheaper than rolled annealed foil due to the simpler manufacturing process. However, it may not be ideal for ultra-fine circuits (due to potential signal loss from surface roughness) and has slightly lower flex endurance.

So, how do you choose? For high-precision, ultra-flexible applications like rigid-flex PCBs, rolled annealed foil may be the better choice. But for cost-sensitive projects, such as consumer electronics or high-volume production, electrolytic copper foil shines. At JHYPCB, our engineers analyze your project’s needs—layer count, thickness, or environmental demands—to recommend the best material. Our PCB assembly services, including SMT stencil and component sourcing, ensure seamless integration.

For example, we recently produced flexible PCBs for a client’s smart wristband using electrolytic copper foil. The result? Cost savings without compromising signal integrity, leading to excellent market feedback.

Why Electrolytic Copper Foil Matters in Flexible PCBs

In conclusion, electrolytic copper foil is a cost-effective, reliable conductor that makes flexible PCBs lighter, thinner, and more durable. From smartphones to aerospace systems, this material supports cutting-edge applications across industries. At JHYPCB, we’re committed to delivering end-to-end solutions, from single-sided and multilayer flexible PCB manufacturing to comprehensive PCB assembly services like turnkey solutions and SMT stencils.

Have questions about using electrolytic copper foil in your flexible PCB project or need a custom quote? Reach out to our sales team at sales@pcbjhy.com. We’ll provide expert guidance and prototypes to help you create high-performance electronic designs that stand out in a competitive market.