Table of Contents

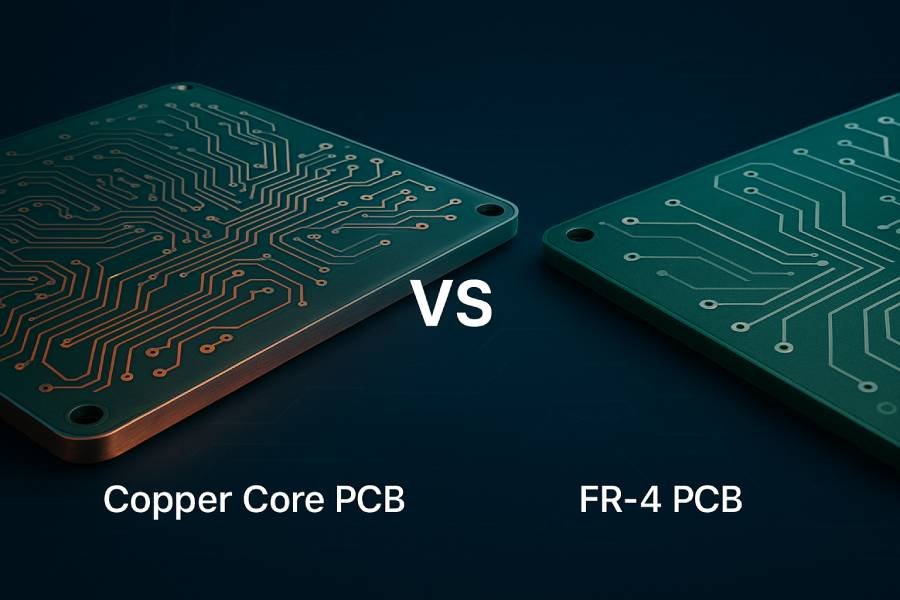

Choosing the right PCB material is crucial for achieving long-lasting performance, optimal heat management, and cost efficiency in electronic devices. While FR-4 PCBs have dominated the industry for decades, the emergence of copper core PCBs is transforming high-power and industrial applications. In this guide, we’ll compare copper core PCBs vs FR-4, discuss their strengths and weaknesses, and show you how to choose the best option for your next project.

What is a Copper Core PCB?

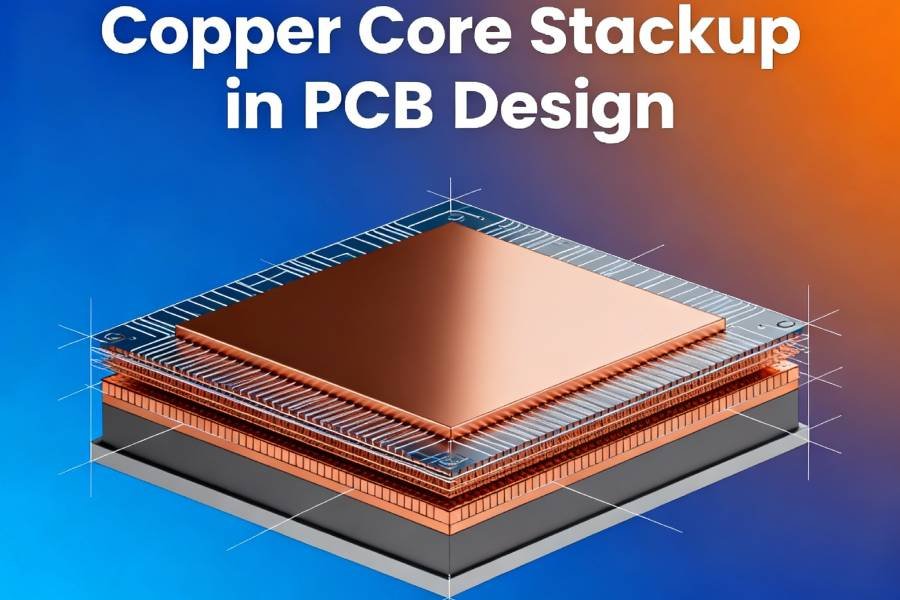

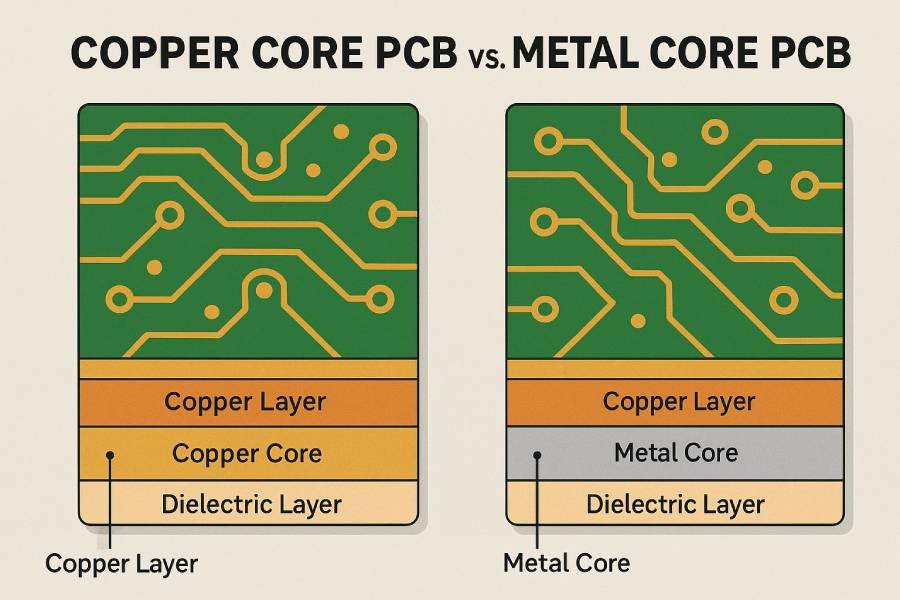

A copper core PCB uses a thick copper plate as its base, sandwiched between an insulating layer and circuit traces. This design provides unmatched thermal conductivity—often required for components handling large currents or generating significant heat.

Benefits of Copper Core PCBs:

- Excellent heat dissipation

- Robust mechanical stability

- Highly resistant to vibration and thermal stress

Want to dive deeper into copper core PCB structure, manufacturing processes, and real-world advantages? Check out our guide: What is Copper Core PCB? Comprehensive Overview, Advantages & Industry Insights.

What is FR-4 PCB?

FR-4 PCBs are built on layers of woven fiberglass with epoxy resin, known for good insulation, mechanical strength, and affordability. This material is the backbone of most consumer electronics due to its reliability and wide manufacturing compatibility.

Benefits of FR-4 PCBs:

- Cost-effective for general use

- Flexible for complex multi-layer designs

- Widely available and understood within the industry

Key Differences Between Copper Core and FR-4 PCB

- Thermal Conductivity & Heat Dissipation

Copper core PCBs have thermal conductivities exceeding 380W/m·K, protecting sensitive components from overheating. In contrast, FR-4 substrates offer modest thermal handling (approx. 0.3W/m·K), which can be insufficient for power projects, requiring extra heat sinks or custom cooling layouts.

- Mechanical Strength & Reliability

Copper-based boards excel in mechanical stability, resisting warping and vibration damage—essential for industrial equipment and automotive electronics. FR-4 boards, while strong, tend to be less resilient when exposed to extreme mechanical or thermal stress.

- Design Flexibility & Layer Count

FR-4’s construction allows for intricate, multi-layer, high-density circuit layouts. Copper core PCBs, due to their solid metal base, offer less flexibility in stacking layers but are unbeatable for single- or double-sided thermal performance.

- Cost & Availability

FR-4 is generally cheaper and more accessible for mass production. Copper core PCBs come with a higher material cost, offset by reduced thermal management requirements and longer device lifespans.

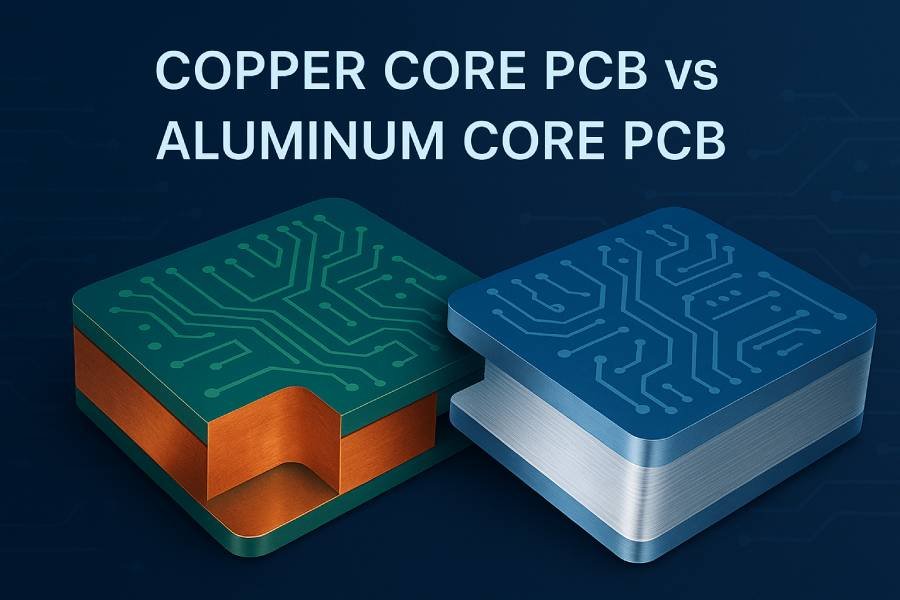

Considering aluminum core PCBs? Discover the differences in our post: Copper Core vs Aluminum Core PCBs: Key Differences, Pros & Cons, and How to Choose (2025 Guide).

Application Scenarios

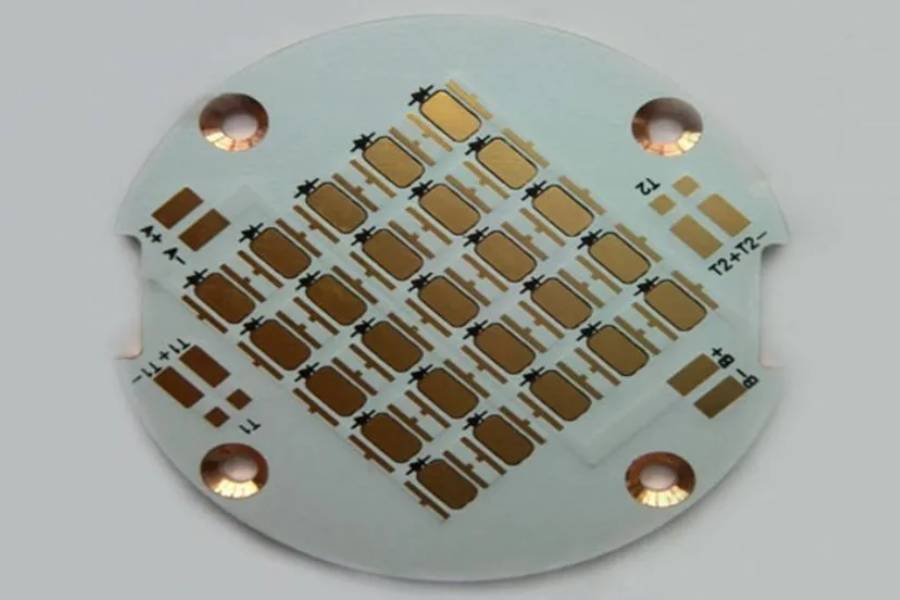

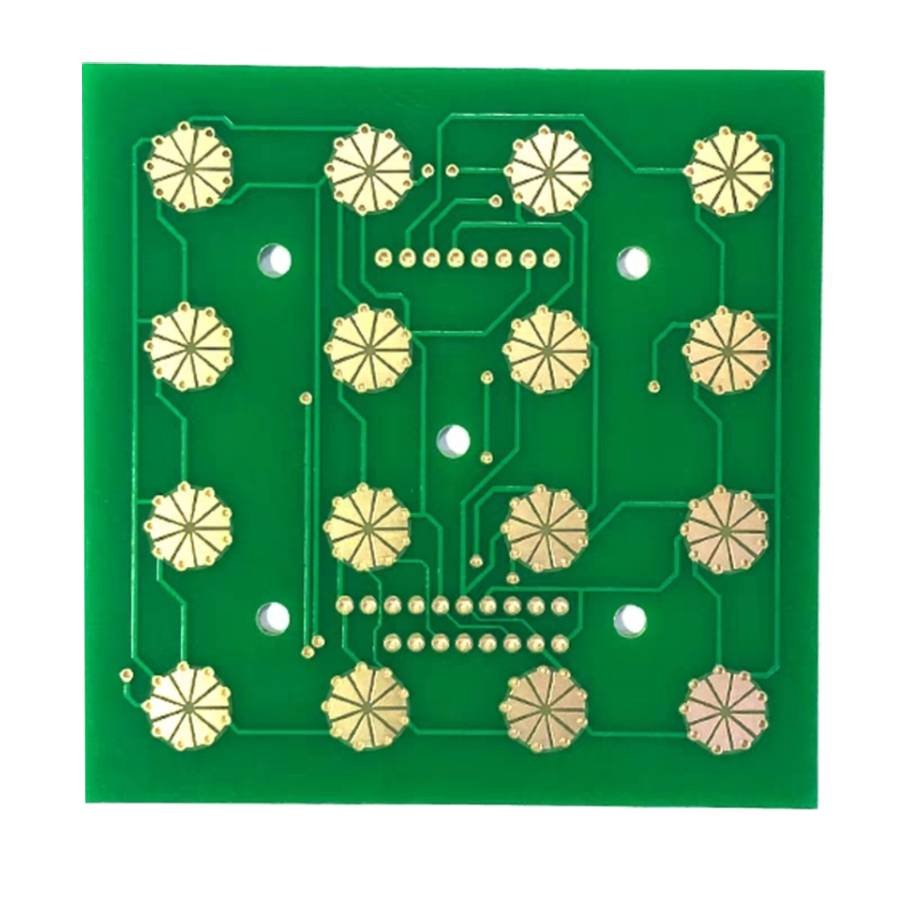

Copper core PCBs are the go-to choice for LED lighting, power modules, automotive electronics, and renewable energy applications—anywhere heat dissipation is paramount and reliability non-negotiable. FR-4 PCBs remain best for consumer devices, IoT sensors, smartphones, and computers, where cost and miniaturization matter most.

Looking for the best copper core designs for high-power LEDs? See: 6 Types of Copper Core PCBs for High-Power LEDs: Ultimate Guide from JHYPCB Manufacturer.

Pros and Cons

Copper Core PCB

Pros: Excellent thermal performance, strong mechanical properties, longer lifespan, reduced need for extra cooling hardware

Cons: Higher cost, limited multi-layer design flexibility, heavier than FR-4

FR-4 PCB

Pros: Cost-effective, supports versatile complex circuitry, lightweight, mature supply chain

Cons: Poor thermal conductivity, less suited to harsh environments

How to Choose: Decision Factors

Power and thermal requirements: If your design involves high-power or heat-sensitive components, copper core PCBs should be your default.

Budget and volume: For high-volume consumer electronics, FR-4 offers proven performance at lower cost.

Longevity/reliability: Industrial or automotive devices demand copper core’s superior durability.

Design complexity: Multi-layer, high-density circuits lean towards FR-4—unless thermal management cannot be compromised.

FAQs on Copper Core vs FR-4 PCB

How do I know which PCB material is best for my project?

Assess your device’s expected power output, operating environment, and lifetime. Use copper core for heat-critical, industrial settings; FR-4 for standard, mass-market products.

Are copper core PCBs always more expensive?

Yes, but total system costs may be reduced thanks to minimized cooling needs and improved reliability.

Can copper core PCBs replace FR-4 in all scenarios?

Not always—choose based on thermal, mechanical, and design needs.

Conclusion

Both copper core and FR-4 PCBs have vital roles in modern electronics. Your material choice should reflect your device’s performance requirements, operating conditions, and budget. Use the decision checklist above—and make sure to consult our related guides for a deeper understanding.