Table of Contents

Finding a reliable quick turn PCB assembly manufacturer is critical when your project schedule is tight and every day of delay can affect your product launch or customer delivery.

The right partner will help you get high‑quality prototypes and low‑volume builds on time, while the wrong choice can lead to missed deadlines, quality issues and unexpected costs.

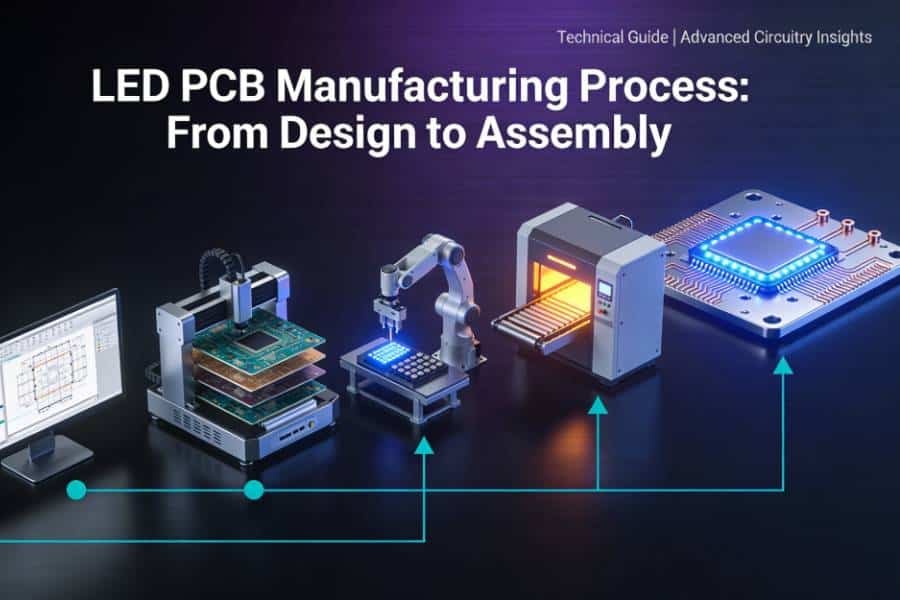

A good quick turn PCB assembly manufacturer does far more than just solder components onto boards.

It combines fast PCB fabrication, efficient component sourcing, professional assembly processes and thorough testing into a single, well‑coordinated service designed for speed and reliability.

What Does a Quick Turn PCB Assembly Manufacturer Do?

A quick turn PCB assembly manufacturer focuses on delivering fully assembled and tested printed circuit boards in significantly shorter lead times than standard production schedules.

Instead of waiting several weeks, you can often receive prototypes or small batches in just a few days, depending on design complexity and component availability.

Typical services provided by a quick turn PCB assembly manufacturer include:

- Rapid PCB fabrication for prototype and low‑volume orders

- Components sourcing or full turnkey material procurement

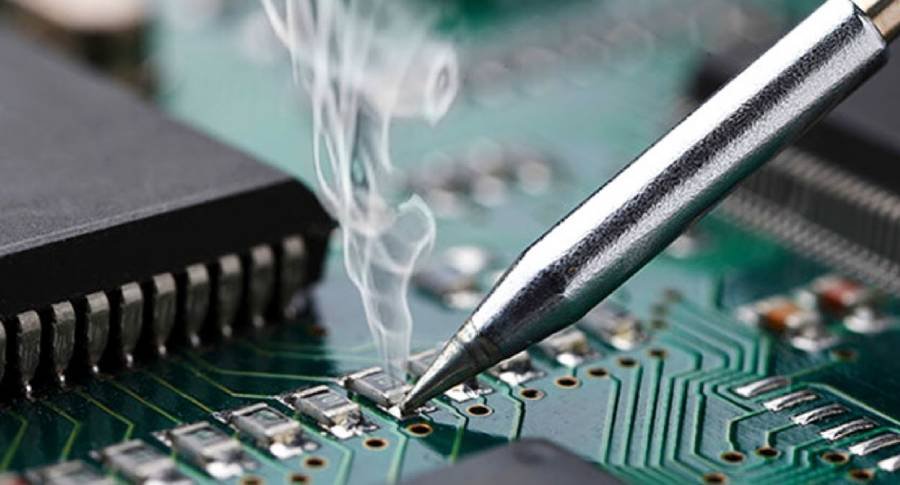

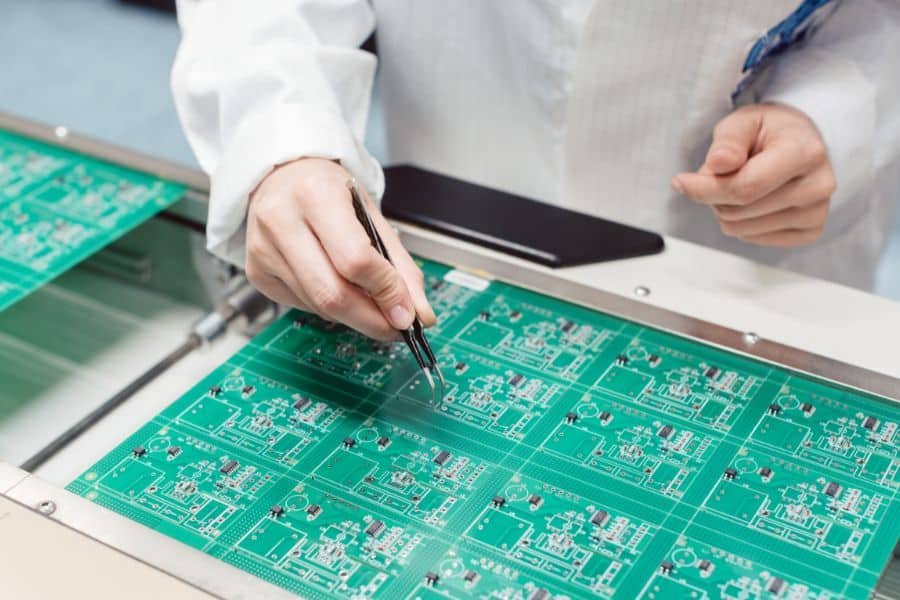

- SMT, through‑hole and mixed‑technology PCB assembly

- Reflow, wave and selective soldering processes

- AOI, X‑ray, ICT and functional testing as required

- Final inspection, packing and shipment to your location

This one‑stop approach is especially valuable when you are iterating designs quickly and need a manufacturer that can handle the entire quick turn PCB assembly process without unnecessary hand‑offs or delays.

When Do You Need a Quick Turn PCB Assembly Manufacturer?

You should consider working with a dedicated quick turn PCB assembly manufacturer whenever speed, flexibility or frequent design changes are key factors in your project.

Some common situations include new product development, pilot runs and time‑critical orders.

Typical use cases include:

- Engineering prototypes and proof‑of‑concept builds:You need quick turn PCB assembly services to validate new designs and demonstrate core functionality.

- Frequent design iterations:Your hardware is evolving rapidly, and you must update layouts and BOMs several times in a short period.

- Pilot and low‑volume production:You require limited quantities for field trials, certifications or initial market launches.

- Urgent or time‑sensitive projects:You must meet strict launch dates, customer commitments, trade shows or urgent repair needs.

In all of these scenarios, choosing the right quick turn PCB assembly manufacturer directly impacts your ability to keep the schedule under control and maintain product quality.

Key Factors When Evaluating Quick Turn PCB Assembly Manufacturers

When comparing potential partners, it helps to use a structured checklist that covers technical capabilities, quality systems, logistics and communication.

1. Lead Time and Schedule Reliability

For quick turn projects, promised lead time and actual on‑time delivery performance are critical.

Ask each quick turn PCB assembly manufacturer about typical lead times for prototypes, small batches and complex designs, and whether they can handle rush orders when your schedule changes unexpectedly.

You should also clarify:

- What factors can affect lead time (layer count, special materials, rare components)

- How they handle component shortages or engineering questions

- Whether they provide realistic delivery dates instead of overly optimistic promises

A manufacturer with proven quick turn PCB assembly services and a strong track record of on‑time delivery is usually a safer choice than one that only occasionally handles expedited work.

2. Technical and Manufacturing Capabilities

The best quick turn PCB assembly manufacturer for your project is one whose technical capabilities match your design requirements.

Review their published capability tables and discuss any special needs directly with their engineering team before placing an order.

Consider factors such as:

- Supported board types:rigid, flex, rigid‑flex, HDI

- Maximum and recommended layer counts for quick turn builds

- Minimum trace/space and drill sizes they can reliably achieve

- Supported component packages(fine‑pitch ICs, BGAs, QFNs, CSPs, connectors, power devices)

- Available soldering processes and rework options

- Testing and inspection methods suitable for your application

A technically strong quick turn PCB assembly manufacturer can often suggest design improvements or alternative materials that make your boards easier and faster to build.

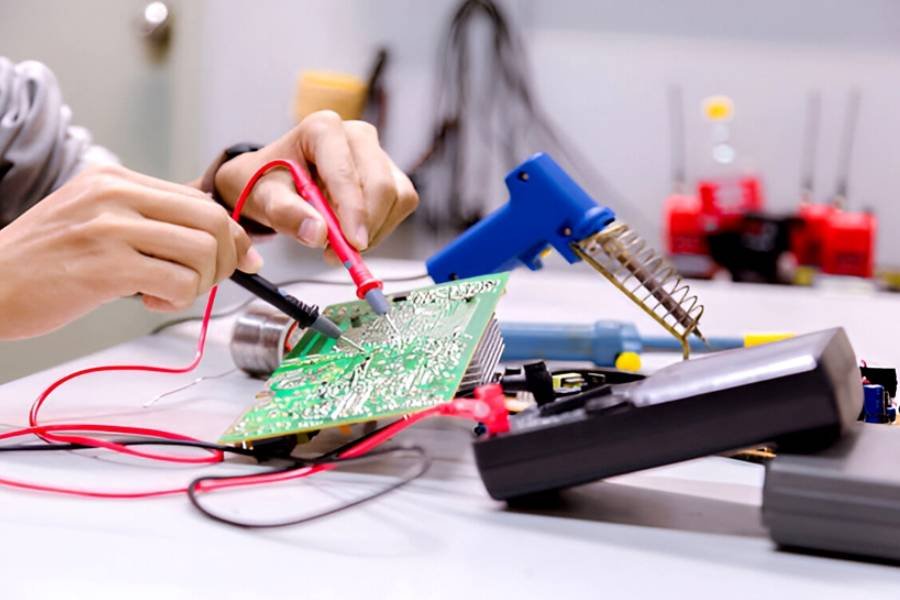

3. Quality Systems and Testing

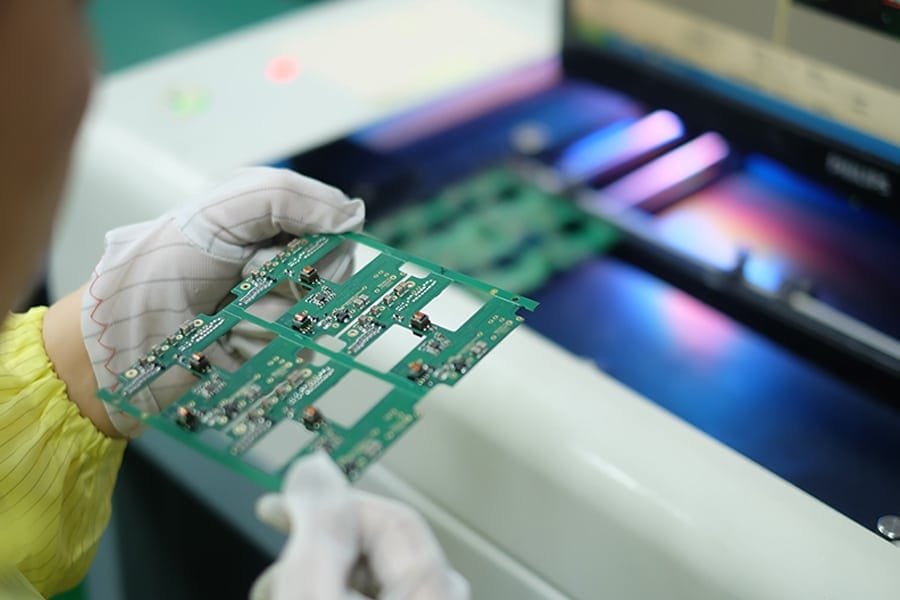

Speed is important, but quick turn PCB assembly should never sacrifice quality.

Look for manufacturers that maintain robust quality management systems and invest in appropriate inspection and test equipment.

Key points to check include:

- Whether they follow recognized quality standards and process controls

- Use of AOI, X‑ray for BGAs, ICT and functional testing where applicable

- Procedures for handling non‑conformances and corrective actions

- Availability of documentation such as inspection reports and test records

A quick turn PCB assembly manufacturer that takes quality seriously will be transparent about its processes and willing to discuss how it ensures consistent results under tight schedules.

4. Component Sourcing and Turnkey Capabilities

For many projects, the ability of a quick turn PCB assembly manufacturer to source components quickly is just as important as PCB fabrication speed.

Ask whether they provide full turnkey quick turn PCB assembly, partial turnkey or consigned material options.

Important questions include:

- Which distributors and channels they use for components

- How they handle obsolete or long lead‑time parts in your BOM

- Whether they can suggest alternative components with similar specifications

- How they manage component traceability and storage conditions

A manufacturer with strong supply chain capabilities can significantly reduce delays and help keep your quick turn PCB assembly schedule on track.

5. Engineering Support and Communication

Good communication is essential when working with a quick turn PCB assembly manufacturer, especially if you are still refining the design.

Look for partners that respond quickly to questions, provide clear feedback and proactively flag potential issues in your files.

Useful signs of strong support include:

- DFM and DFA review for quick turn PCB assembly orders

- Early warnings about risky footprints, spacing or thermal issues

- Clear checklists for required files and data formats

- A dedicated contact person or support team for your projects

The right quick turn PCB assembly manufacturer will act as a technical partner, not just a supplier, helping you avoid problems before they become expensive delays.

6. Pricing Transparency and Total Cost

While quick turn PCB assembly often costs more per unit than standard lead‑time services, good pricing should still be transparent and reasonable.

Ask for itemized quotes that show PCB fabrication, components, assembly, testing and any extra charges so you can compare offers fairly.

When comparing different quick turn PCB assembly manufacturers, consider:

- Not only the unit price, but also the value of shorter lead times

- Whether they charge extra for engineering review, stencils or setup

- The impact of potential delays or quality issues on your project cost

In many cases, paying slightly more for a reliable quick turn PCB assembly manufacturer is cheaper than dealing with late deliveries or repeated rework.

Quick Turn PCB Assembly Manufacturer in Different Regions

Quick turn PCB assembly manufacturers operate in many regions, including North America, Europe and Asia, each with different strengths in cost, logistics and communication.

Understanding these differences helps you choose the best partner for your specific priorities.

In general:

- Local manufacturers(e.g., in the USA or Europe)can offer very fast shipping and easier communication but may have higher unit costs.

- Overseas manufacturers(especially in China)often provide lower prices and strong quick turn capabilities, with slightly longer shipping times but excellent value for many projects.

Many companies use a mix of both:local quick turn PCB manufacturers for urgent, low‑volume needs and China‑based quick turn PCB assembly manufacturers for competitively priced prototypes and pilot runs.

Advantages of Working with a China‑Based Quick Turn PCB Assembly Manufacturer

China has become one of the most important hubs for quick turn PCB assembly due to its mature manufacturing ecosystem, advanced equipment and efficient component supply chains.

For many projects, a China‑based quick turn PCB assembly manufacturer offers an attractive balance of speed, cost and technical capability.

Key advantages often include:

- Competitive pricing for both PCB fabrication and assembly

- Access to high‑speed SMT lines and modern production equipment

- Well‑established relationships with major component distributors

- Experience handling a wide range of designs from global customers

- Scalable capacity from rapid prototypes to larger volumes

For companies willing to manage international logistics and communication, partnering with a quick turn PCB assembly manufacturer in China can significantly reduce overall project cost while maintaining strong performance and reasonable lead times.

Why JHYPCB Is a Reliable Quick Turn PCB Assembly Manufacturer in China

JHYPCB is a China‑based quick turn PCB assembly manufacturer focused on helping global customers turn ideas into working hardware quickly and reliably.

By combining PCB fabrication, components sourcing and PCB assembly services under one roof, JHYPCB offers a convenient one‑stop solution for prototypes and low‑volume builds.

As a quick turn PCB assembly manufacturer in China, JHYPCB aims to provide:

- Fast, predictable lead times for many prototype and small‑batch projects

- Flexible order quantities suitable for engineering builds and pilot runs

- Support for SMT, through‑hole and mixed‑technology assembly

- Appropriate testing and inspection options for different applications

- Responsive communication and practical engineering advice for each project

If you are looking for a quick turn PCB assembly manufacturer that can balance speed, quality and cost, working with a China‑based partner like JHYPCB can be an effective way to support your development schedule.

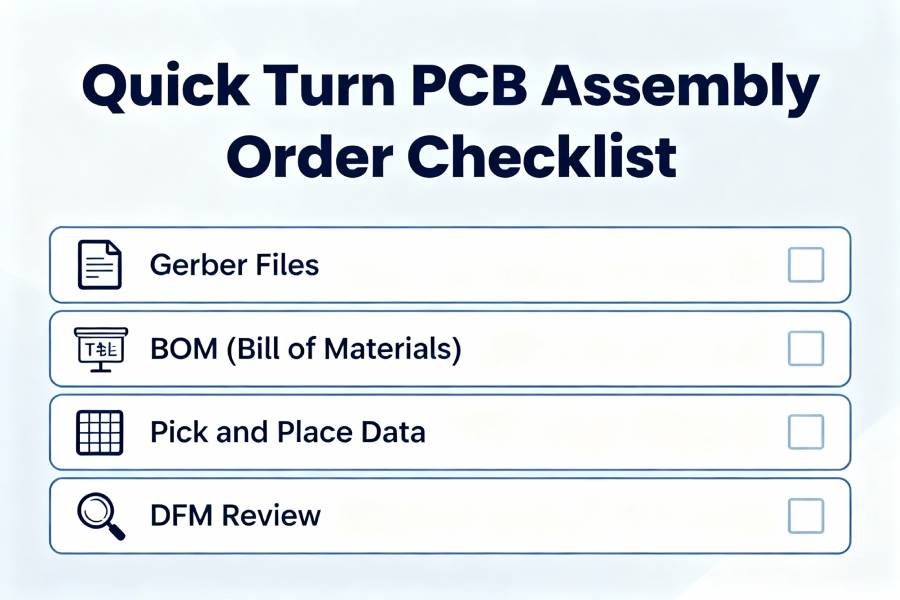

Checklist Before You Place a Quick Turn PCB Assembly Order

Before you send files to any quick turn PCB assembly manufacturer, it helps to prepare a simple checklist to avoid delays and misunderstandings.

Make sure you have:

- Complete Gerber and drill files that match your latest design revision

- A clear, structured BOM with manufacturer part numbers and alternatives where possible

- Pick‑and‑place/centroid data and assembly drawings with polarity and orientation details

- Defined test requirements or acceptance criteria for your boards

- Realistic expectations for lead time, considering design complexity and components availability

Using this checklist makes it easier for your quick turn PCB assembly manufacturer to start work immediately and deliver reliable boards on time.

Final Thoughts: Choosing the Best Quick Turn PCB Assembly Manufacturer for Your Projects

Choosing the right quick turn PCB assembly manufacturer is ultimately about finding a partner that matches your technical needs, schedule and budget.

By carefully evaluating lead times, capabilities, quality systems, component sourcing, communication and pricing, you can select a manufacturer that supports your product roadmap instead of slowing it down.

For many companies, partnering with a China‑based quick turn PCB assembly manufacturer such as JHYPCB provides a strong combination of speed, cost effectiveness and technical support for prototypes and low‑volume production.

With the right quick turn PCB assembly manufacturer at your side, your hardware development process becomes faster, more predictable and more competitive in demanding markets.