Table of Contents

Introduction to SPI in SMT Assembly

In the fast-paced world of electronics manufacturing, quality control is paramount. At JHYPCB, we understand that the key to producing high-quality PCBs lies in the details of our SMT assembly process. One crucial step that often goes unnoticed but plays a vital role in ensuring PCB quality is Solder Paste Inspection or SPI.

So, what exactly is SPI in the SMT process? SPI, short for Solder Paste Inspection, is a critical quality control measure used in Surface Mount Technology (SMT) assembly. It’s an automated optical inspection technique that examines the solder paste deposits on a PCB before component placement. This inspection ensures that the right amount of solder paste is applied in the correct locations, setting the foundation for a successful SMT assembly.

The importance of SPI in SMT assembly cannot be overstated. As PCB designs become more complex and component sizes shrink, the margin for error in solder paste application becomes increasingly narrow. Even minor inconsistencies in solder paste volume, position, or shape can lead to significant defects in the final product. This is where SPI shines, acting as a gatekeeper to catch potential issues before they become costly problems.

At JHYPCB, we’ve integrated advanced SPI systems into our SMT assembly lines to enhance our PCB manufacturing quality. By implementing SPI, we’re able to:

- Detect and correct solder paste printing errors early in the production process

- Ensure consistent solder joint quality across all PCBs

- Reduce defects related to insufficient or excess solder paste

- Minimize rework and improve overall production efficiency

SPI technology has evolved significantly over the years, from simple 2D imaging to sophisticated 3D measurement systems. These advancements have made SPI an indispensable tool in modern SMT assembly, capable of measuring solder paste volume, area, height, and position with incredible accuracy.

As we delve deeper into the world of SPI in SMT assembly, you’ll discover how this technology is revolutionizing PCB manufacturing. From its core principles to its impact on production quality, we’ll explore why SPI has become a cornerstone of quality assurance in the electronics industry.

Stay tuned as we unpack the intricacies of the SPI process, its benefits, and how it’s shaping the future of PCB assembly at JHYPCB and beyond. Whether you’re a seasoned engineer or new to the world of PCB manufacturing, understanding SPI is key to appreciating the level of precision and care that goes into every board we produce.

-In-The-SMT-Assembly-Process.jpg)

The SPI Process Explained

At JHYPCB, we believe that understanding the SPI process is crucial for appreciating the quality assurance measures we implement in our SMT assembly line. Let’s dive into the heart of SPI technology and explore how it works to ensure your PCBs meet the highest standards.

Key Components of an SPI System

A typical SPI system consists of several essential components working in harmony:

- Illumination System: High-quality LED lights that provide consistent, even lighting for accurate inspection.

- Camera System: High-resolution cameras capture detailed images of the solder paste deposits.

- Optical System: Lenses and mirrors that focus and direct light for optimal image capture.

- Motion Control System: Precise motors and stages that move the PCB or camera for comprehensive coverage.

- Image Processing Software: Advanced algorithms that analyze the captured images and compare them to predefined standards.

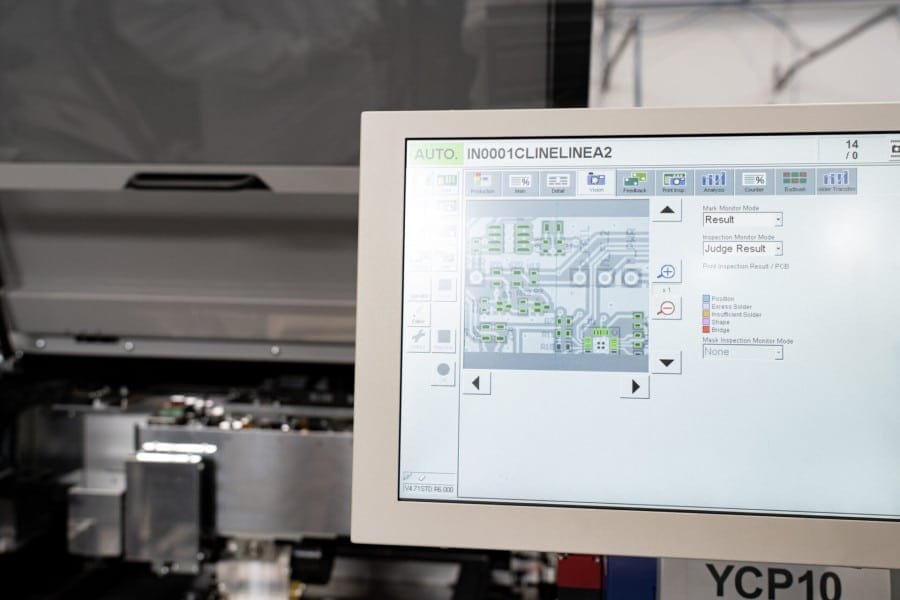

- User Interface: A dashboard that displays results and allows operators to fine-tune inspection parameters.

How SPI Works: 3D Measurement Techniques

Modern SPI systems at JHYPCB utilize sophisticated 3D measurement techniques to provide the most accurate and reliable inspection results. Here’s a step-by-step breakdown of the SPI process:

- PCB Loading: The printed circuit board enters the SPI machine after solder paste application.

- Illumination: The board is illuminated using structured light patterns, typically a series of parallel lines or a grid.

- Image Capture: Multiple high-resolution cameras capture images of the illuminated board from different angles.

- 3D Reconstruction: The system uses the captured images to create a detailed 3D model of the solder paste deposits. This is typically done using one of two methods:

- Phase Shift Profilometry: Analyzes the deformation of projected light patterns.

- Laser Triangulation: Uses laser beams to measure the height of solder paste deposits.

- Measurement and Analysis: The 3D model is analyzed to measure critical parameters such as:

- Solder paste volume

- Area coverage

- Height

- Position (x, y coordinates)

- Shape and contour

- Comparison and Evaluation: These measurements are compared against predetermined specifications and tolerances.

- Defect Detection: Any deviations from the set parameters are flagged as potential defects. Common issues detected include:

- Insufficient solder paste

- Excess solder paste

- Bridging between pads

- Misaligned deposits

- Reporting: The SPI system generates a detailed report of its findings, often including visual representations of the inspected board.

- Feedback Loop: In advanced setups, this data can be fed back to the solder paste printer for real-time adjustments, ensuring consistent quality throughout the production run.

The entire SPI process happens in mere seconds per board, allowing for 100% inspection without slowing down the SMT assembly line. This speed, combined with its accuracy, makes SPI an invaluable tool in our quest for PCB perfection at JHYPCB.

By employing state-of-the-art SPI technology in our SMT assembly process, we’re able to catch and correct solder paste-related issues before they lead to costly defects. This proactive approach not only improves the quality of our PCBs but also enhances overall production efficiency, reducing waste and rework.

As we continue to explore the world of SPI in SMT assembly, you’ll gain a deeper appreciation for the level of precision and care that goes into every PCB we produce at JHYPCB. Stay tuned as we delve into the myriad benefits of implementing SPI in the next section.

Benefits of Implementing SPI

At JHYPCB, we’ve witnessed firsthand the transformative impact of integrating Solder Paste Inspection into our SMT assembly process. The benefits of SPI extend far beyond simple defect detection, influencing every aspect of our PCB manufacturing. Let’s explore the key advantages that make SPI an indispensable part of modern SMT assembly.

1. Improved Quality Control

SPI serves as a critical quality gatekeeper in the early stages of PCB assembly. By inspecting solder paste deposits before component placement, we can:

- Detect and correct printing errors immediately, preventing downstream issues

- Ensure consistent solder paste volume and coverage across all pads

- Maintain precise alignment of solder paste deposits

- Identify trends in solder paste application, allowing for proactive process adjustments

This level of scrutiny results in significantly higher overall PCB quality, meeting and often exceeding our customers’ exacting standards.

2. Reduced Defects and Rework

One of the most significant benefits of SPI in SMT assembly is the dramatic reduction in defects and subsequent rework. By catching issues early, we can:

- Minimize solder-related defects such as shorts, open circuits, and insufficient joints

- Reduce the occurrence of tombstoning, bridging, and other component placement issues

- Decrease the need for post-assembly rework and repairs

- Lower the risk of field failures due to hidden solder joint problems

Our data shows that implementing SPI has led to a substantial decrease in defect rates, with some product lines seeing improvements of up to 50% in first-pass yield.

3. Cost Savings in the Long Run

While the initial investment in SPI technology may seem significant, the long-term cost savings are substantial:

- Reduced material waste from scrapped boards and components

- Lower labor costs associated with rework and manual inspections

- Decreased warranty claims and returns due to improved product reliability

- Enhanced production efficiency, leading to higher throughput

- Minimized production line downtime caused by major defects

At JHYPCB, we’ve calculated that our SPI systems typically pay for themselves within 12-18 months through these various savings.

4. Enhanced Process Control and Optimization

SPI doesn’t just detect defects; it provides valuable data for continuous process improvement:

- Real-time feedback allows for immediate adjustments to the solder paste printing process

- Trend analysis helps identify recurring issues, guiding preventive maintenance schedules

- Data-driven insights enable fine-tuning of printer parameters for optimal performance

- Improved traceability with detailed inspection records for each PCB

This wealth of data empowers our engineering team to continuously refine our SMT assembly process, pushing the boundaries of what’s possible in PCB manufacturing.

5. Increased Customer Satisfaction

Ultimately, the benefits of SPI translate directly to increased customer satisfaction:

- Higher product quality and reliability

- Faster turnaround times due to reduced rework

- Competitive pricing enabled by improved efficiency

- Enhanced transparency with detailed quality reports

Our commitment to using advanced SPI technology in our SMT assembly process has helped us build lasting relationships with clients who demand nothing but the best in PCB manufacturing.

6. Compliance with Industry Standards

In an era of increasingly stringent quality requirements, SPI helps ensure compliance with various industry standards:

- IPC-A-610 for acceptability of electronic assemblies

- ISO 9001 quality management systems

- Industry-specific standards like automotive (IATF 16949) or medical device (ISO 13485) requirements

By implementing SPI, we at JHYPCB can confidently meet and exceed these standards, opening doors to a wide range of markets and applications for our PCBs.

As we continue to leverage the power of SPI in our SMT assembly process, we’re constantly amazed by the new possibilities it unlocks. The benefits of improved quality, reduced defects, cost savings, and enhanced process control combine to create a powerful competitive advantage for JHYPCB and, by extension, for our valued customers.

SPI Integration in the SMT Assembly Line

At JHYPCB, we pride ourselves on our state-of-the-art SMT assembly process. A crucial element of this process is the seamless integration of SPI into our production line. Let’s explore how we’ve optimized our SPI placement and ensured compatibility with other SMT equipment to achieve maximum efficiency and quality in PCB manufacturing.

1. Placement within the Production Process

The strategic placement of SPI equipment in the SMT assembly line is critical for maximizing its effectiveness. At JHYPCB, we’ve positioned our SPI systems as follows:

- Post-Printing Inspection:

- Immediately after the solder paste printing stage

- Before component placement

- This allows for immediate detection and correction of solder paste-related issues

- Pre-Reflow Inspection (Optional):

- After component placement but before the reflow process

- This secondary inspection can catch any issues that may have occurred during component placement

By placing SPI at these crucial points, we ensure that potential problems are identified and addressed at the earliest possible stage, preventing costly downstream issues.

2. Inline vs. Offline SPI

We utilize both inline and offline SPI systems in our SMT assembly process:

- Inline SPI: Integrated directly into the production line for real-time, 100% inspection

- Advantages: Immediate feedback, no production slowdown, seamless integration

- Used for high-volume production runs

- Offline SPI: Separate from the main production line

- Advantages: More detailed inspection, flexible for different board sizes

- Used for low-volume, high-mix production, and for more in-depth analysis

This dual approach allows us to balance speed and thoroughness, adapting our inspection process to the specific needs of each PCB production run.

3. Compatibility with Other SMT Equipment

Ensuring smooth integration and compatibility between SPI and other SMT equipment is crucial for maintaining production efficiency. At JHYPCB, we’ve taken several steps to achieve this:

- Data Integration:

- Our SPI systems are connected to our Manufacturing Execution System (MES)

- This allows for real-time data sharing and process control

- Feedback Loops:

- SPI data is fed back to the solder paste printer for automatic adjustments

- This closed-loop system ensures consistent solder paste application

- Conveyor Synchronization:

- SPI conveyor speeds are matched with other inline equipment

- This prevents bottlenecks and ensures smooth board transfer

- Software Compatibility:

- We use SPI software that is compatible with our pick-and-place machines and reflow ovens

- This enables seamless communication between different stages of the SMT process

- Standardized Board Handling:

- Our SPI systems use the same board handling mechanisms as other equipment in the line

- This minimizes the risk of board damage during transfers

4. Line Balancing with SPI

Integrating SPI into the SMT assembly line requires careful consideration of production flow. We’ve implemented the following strategies to maintain line balance:

- Cycle Time Matching:

- SPI inspection times are optimized to match the cycle times of other processes

- This prevents the SPI stage from becoming a bottleneck

- Parallel Processing:

- For high-volume production, we use multiple SPI machines in parallel

- This allows us to maintain high throughput without compromising inspection quality

- Buffer Systems:

- We’ve implemented smart buffer systems before and after the SPI stage

- These buffers help smooth out any temporary fluctuations in processing times

- Flexible Routing:

- Our production line layout allows for flexible board routing

- Boards can bypass the SPI stage if necessary, based on product requirements or line conditions

5. Training and Maintenance

Successful SPI integration isn’t just about hardware and software – it’s also about people. At JHYPCB, we invest heavily in:

- Operator Training:

- Comprehensive training programs for SPI system operation and data interpretation

- Regular refresher courses to keep our team up-to-date with the latest SPI technologies

- Maintenance Schedules:

- Regular preventive maintenance to ensure SPI system accuracy and reliability

- Quick response protocols for any SPI-related issues to minimize downtime

- Continuous Improvement:

- Regular review of SPI data and performance metrics

- Ongoing optimization of SPI parameters based on production feedback

By carefully considering all these aspects of SPI integration, we at JHYPCB have created a smooth, efficient SMT assembly process that consistently produces high-quality PCBs. Our thoughtful integration of SPI technology allows us to maintain strict quality control without sacrificing productivity, ensuring that we can meet the diverse needs of our clients in the ever-evolving world of electronics manufacturing.

Key Parameters Measured by SPI

At JHYPCB, our commitment to quality in PCB manufacturing is reflected in the meticulous attention we pay to every aspect of the SMT assembly process. The SPI stage is crucial in this regard, as it allows us to measure and control critical parameters that directly impact the quality of the final product. Let’s explore the key parameters that our SPI systems measure and why they’re so important in ensuring top-notch PCB assembly.

1. Solder Paste Volume

One of the most critical parameters measured by SPI is solder paste volume. This measurement is essential because:

- Correct volume ensures proper solder joint formation

- Too little paste can lead to weak or open connections

- Excess paste can cause bridging between adjacent pads

Our SPI systems use advanced 3D measurement techniques to accurately calculate the volume of each solder paste deposit. We typically aim for a volume tolerance of ±30% from the nominal value, though this can vary based on specific product requirements.

2. Area Coverage

Area coverage refers to the extent to which solder paste covers the pad. This parameter is crucial because:

- Insufficient coverage can result in poor electrical and mechanical connections

- Excessive coverage might lead to solder bridging or component misalignment

Our SPI systems measure the area of each solder paste deposit and compare it to the expected pad area. We generally target an area coverage of 80-100% for optimal results.

3. Height and Shape

The height and shape of solder paste deposits are vital parameters that our SPI systems measure with high precision. These measurements are important because:

- Consistent height ensures uniform solder joints across the board

- Proper shape indicates correct stencil design and printing process

We typically look for a height tolerance of ±50% from the nominal value. The shape of the deposit should be a smooth, well-defined mound without any signs of smearing or inconsistencies.

4. Alignment (X, Y, and θ)

Accurate alignment of solder paste deposits is crucial for successful component placement. Our SPI systems measure:

- X and Y positions: Ensure the paste is centered on the pad

- θ (theta): Measures any rotational misalignment

We typically aim for alignment tolerances within ±50% of the pad width or 50 μm, whichever is greater. This precision ensures that components will be correctly placed and soldered.

5. Bridging and Separation

Our SPI systems also check for potential bridging between adjacent pads and ensure proper separation. This is crucial because:

- Bridging can cause short circuits

- Insufficient separation can lead to solder beading during reflow

The system measures the distance between solder paste deposits and flags any instances where this distance falls below the specified threshold.

6. Consistency Across the Board

While individual measurements are important, consistency across the entire PCB is equally crucial. Our SPI systems analyze:

- Pad-to-pad variations

- Board-to-board variations in a production run

This allows us to identify any systematic issues in our solder paste printing process and make necessary adjustments.

7. Advanced Measurements

In addition to these basic parameters, our state-of-the-art SPI systems at JHYPCB can perform more advanced measurements:

- Surface Roughness: Indicates the quality of paste mixing and printing

- Paste Spread: Measures how much the paste has spread after printing

- Volumetric Transfer Efficiency: Compares actual deposited volume to theoretical stencil volume

These advanced measurements provide deeper insights into our solder paste printing process, allowing for even finer control and optimization.

8. Customized Inspection Criteria

At JHYPCB, we understand that different PCB designs and applications may require different inspection criteria. Our SPI systems allow for customized measurement parameters based on:

- Pad size and shape

- Component type (e.g., fine-pitch BGAs vs. larger discrete components)

- Customer-specific requirements

This flexibility ensures that our inspection process is always aligned with the specific needs of each PCB we manufacture.

9. Data Analysis and Reporting

While measuring these parameters is crucial, equally important is how we analyze and act on this data. Our SPI systems provide:

- Real-time data visualization

- Trend analysis tools

- Comprehensive inspection reports

This allows our engineers to quickly identify and address any issues, ensuring consistent quality across our entire production run.

By meticulously measuring and controlling these key parameters through our advanced SPI systems, we at JHYPCB can guarantee the highest quality in our PCB assembly process. This attention to detail is what sets us apart in the competitive world of PCB manufacturing, allowing us to meet and exceed the expectations of even our most demanding clients.

SPI Technology Advancements

At JHYPCB, we pride ourselves on staying at the cutting edge of PCB manufacturing technology. The field of SPI has seen remarkable advancements in recent years, and we’ve been quick to adopt these innovations to enhance our SMT assembly process. Let’s explore some of the key technological advancements in SPI and how they’re revolutionizing PCB quality control.

1. 2D vs 3D SPI Systems

One of the most significant advancements in SPI technology has been the shift from 2D to 3D inspection systems:

2D SPI Systems:

- Use traditional image processing techniques

- Measure area coverage and alignment

- Limited in their ability to measure volume and height accurately

3D SPI Systems:

- Utilize advanced optical techniques for three-dimensional measurements

- Provide accurate data on paste volume, height, and shape

- Offer superior defect detection capabilities

At JHYPCB, we’ve transitioned to state-of-the-art 3D SPI systems across our production lines. This upgrade has dramatically improved our ability to detect and prevent solder paste-related defects, resulting in higher quality PCBs and improved customer satisfaction.

2. AI and Machine Learning in Modern SPI

Artificial Intelligence (AI) and Machine Learning (ML) are revolutionizing SPI technology, and we’re harnessing these advancements at JHYPCB:

- Intelligent Defect Classification:

- AI algorithms can categorize defects more accurately than traditional rule-based systems

- This leads to fewer false positives and more precise quality control

- Predictive Maintenance:

- ML models analyze SPI data to predict potential equipment failures

- This allows us to schedule maintenance proactively, minimizing unexpected downtime

- Process Optimization:

- AI-powered systems can suggest optimal SPI parameters based on historical data

- This results in continuous improvement of our inspection process

- Adaptive Thresholds:

- ML algorithms can dynamically adjust inspection thresholds based on process variations

- This ensures consistent quality even with changing production conditions

By integrating AI and ML into our SPI systems, we’ve significantly enhanced our defect detection capabilities and overall process efficiency.

3. High-Speed Inspection Technologies

As PCB designs become more complex and production volumes increase, the need for faster inspection speeds has never been greater. Recent advancements include:

- Multi-projector Systems:

- Use multiple light projectors to capture 3D data simultaneously

- Dramatically increase inspection speed without compromising accuracy

- High-speed Cameras:

- Latest-generation cameras capture high-resolution images at incredible speeds

- Allow for 100% inspection even in high-volume production environments

- Parallel Processing:

- Advanced computing architectures process multiple areas of the PCB simultaneously

- Significantly reduce overall inspection time

At JHYPCB, we’ve implemented these high-speed technologies to ensure that our SPI process keeps pace with our high-volume production capabilities, without sacrificing accuracy or quality.

4. Advanced Lighting Techniques

Lighting plays a crucial role in SPI accuracy, and recent advancements have led to significant improvements:

- Multi-spectrum Lighting:

- Combines different light wavelengths for enhanced defect detection

- Particularly useful for inspecting challenging solder paste formulations

- Programmable Lighting Patterns:

- Allows for optimized illumination based on PCB design and solder paste characteristics

- Improves inspection accuracy for a wide range of pad geometries

- High-intensity LED Arrays:

- Provide consistent, flicker-free illumination

- Enhance image quality and measurement accuracy

These advanced lighting techniques enable our SPI systems to perform accurate inspections across a diverse range of PCB designs and solder paste types.

5. Integration with Industry 4.0

The latest SPI systems are designed to seamlessly integrate with Industry 4.0 principles:

- IoT Connectivity:

- SPI machines can communicate with other equipment in real-time

- Enables data-driven decision making across the entire production line

- Cloud-based Data Analytics:

- SPI data can be stored and analyzed in the cloud

- Facilitates big data analysis for long-term process improvement

- Digital Twin Technology:

- Creates a virtual replica of the SPI process

- Allows for offline optimization and scenario testing

At JHYPCB, we’re leveraging these Industry 4.0 capabilities to create a more connected, intelligent, and efficient SMT assembly process.

6. Miniaturization and Fine-pitch Capabilities

As electronic components continue to shrink, SPI technology has evolved to meet the challenge:

- Ultra-high Resolution Optics:

- Capable of inspecting solder paste deposits on pads as small as 01005 (0.4mm x 0.2mm)

- Ensures quality control even for the most demanding miniaturized designs

- Advanced Image Processing:

- Employs sophisticated algorithms to accurately measure tiny solder paste deposits

- Provides reliable inspection for fine-pitch and ultra-fine-pitch components

These advancements allow us at JHYPCB to confidently manufacture and inspect even the most complex and miniaturized PCB designs.

By staying at the forefront of these technological advancements in SPI, JHYPCB ensures that we can meet the evolving needs of the electronics industry. Our investment in cutting-edge SPI technology translates directly to higher quality PCBs, increased production efficiency, and ultimately, greater value for our customers.

Interpreting SPI Data

At JHYPCB, we believe that the true power of Solder Paste Inspection lies not just in collecting data, but in interpreting and acting upon it effectively. Our advanced SPI systems generate a wealth of information, and our expertise lies in transforming this data into actionable insights that drive continuous improvement in our PCB manufacturing process.

1. Understanding Inspection Reports

SPI inspection reports are comprehensive documents that provide detailed information about the solder paste printing process. At JHYPCB, we train our operators and engineers to quickly and accurately interpret these reports:

- Summary Statistics:

- Overall pass/fail rate

- Average values for key parameters (volume, area, height, alignment)

- Standard deviations to assess process consistency

- Detailed Pad-level Data:

- Individual measurements for each pad on the PCB

- Color-coded visualizations to quickly identify out-of-spec deposits

- Trend Analysis:

- Charts showing parameter variations across the board

- Board-to-board comparisons within a production run

- Defect Maps:

- Visual representations of the PCB showing the location of potential defects

- Categorization of defects by type (insufficient paste, bridging, misalignment, etc.)

By thoroughly understanding these reports, our team can quickly identify issues and take corrective actions, ensuring consistent quality in our PCB production.

2. Common Defects Detected by SPI

Our SPI systems are adept at detecting a wide range of solder paste-related defects. Some of the most common issues we look for include:

- Insufficient Solder Paste:

- Characterized by low volume or area coverage

- Can lead to weak or open solder joints

- Excess Solder Paste:

- Identified by high volume measurements

- May cause solder bridging or component misalignment

- Bridging:

- Detected when solder paste connects adjacent pads

- Can result in short circuits if not corrected

- Misalignment:

- Identified by off-center paste deposits

- May lead to component placement issues

- Smearing:

- Characterized by elongated or irregular paste deposits

- Often indicates issues with the stencil or printing process

- Paste Height Variations:

- Detected when paste height is inconsistent across the board

- Can lead to uneven solder joints

By promptly identifying and addressing these defects, we at JHYPCB can prevent downstream issues and ensure high-quality PCB assembly.

3. Data-Driven Process Improvement

At JHYPCB, we don’t just use SPI data for defect detection; we leverage it for continuous process improvement:

- Statistical Process Control (SPC):

- We use SPI data to generate control charts

- This helps us identify process shifts or trends before they lead to defects

- Root Cause Analysis:

- When issues are detected, we dive deep into the data to identify underlying causes

- This might involve analyzing correlations between defects and specific process parameters

- Optimization of Printing Parameters:

- SPI data guides us in fine-tuning stencil design, printer settings, and paste formulation

- We use this information to optimize our process for different PCB designs

- Predictive Maintenance:

- By analyzing long-term trends in SPI data, we can predict when equipment might need maintenance

- This proactive approach helps us minimize unexpected downtime

4. Real-time Monitoring and Feedback

Our advanced SPI systems at JHYPCB provide real-time data, allowing for immediate process adjustments:

- Closed-loop Feedback:

- SPI data is fed back to the solder paste printer in real-time

- This allows for automatic adjustments to maintain optimal paste deposition

- Operator Alerts:

- The system can notify operators immediately when it detects a trend towards out-of-spec conditions

- This enables quick interventions to prevent defects

- Dynamic Threshold Adjustment:

- Based on SPI data, the system can automatically adjust inspection thresholds

- This ensures our quality standards remain consistent even as process conditions change

5. Machine Learning for Enhanced Interpretation

At JHYPCB, we’re leveraging machine learning to take our SPI data interpretation to the next level:

- Pattern Recognition:

- ML algorithms can identify subtle patterns in SPI data that might escape human notice

- This helps us predict and prevent potential quality issues

- Anomaly Detection:

- AI-powered systems can flag unusual data points or trends

- This allows us to investigate and address potential issues proactively

- Automated Root Cause Analysis:

- ML models can analyze complex interactions between multiple parameters

- This helps us quickly identify the root causes of defects

6. Comprehensive Reporting and Traceability

Our SPI data interpretation process at JHYPCB culminates in comprehensive reporting:

- Production Run Reports:

- Detailed summaries of SPI results for each production run

- Includes trend analysis and comparisons to historical data

- Quality Assurance Documentation:

- SPI data forms a crucial part of our quality assurance records

- This supports our commitment to transparency and traceability

- Customer Reports:

- We can provide detailed SPI data to customers upon request

- This demonstrates our commitment to quality and builds trust with our clients

By mastering the art and science of SPI data interpretation, we at JHYPCB ensure that every insight gleaned from our inspection process translates into tangible improvements in our PCB manufacturing. This data-driven approach allows us to consistently deliver high-quality PCBs that meet and exceed our customers’ expectations.

Best Practices for Effective SPI Implementation

At JHYPCB, we’ve developed a set of best practices to ensure our SPI process is as effective as possible:

- Optimizing SPI Settings:

- Regular calibration of SPI equipment

- Customizing inspection parameters for each PCB design

- Balancing sensitivity and false-positive rates

- Integration with MES:

- Connecting SPI data to our Manufacturing Execution System

- Enabling real-time process control and traceability

- Operator Training:

- Comprehensive training programs on SPI operation and data interpretation

- Regular refresher courses to stay updated with latest technologies

- Maintenance Schedule:

- Implementing preventive maintenance routines

- Regular cleaning of optical components to ensure accuracy

- Continuous Improvement:

- Regular review of SPI data to identify areas for process enhancement

- Encouraging feedback from operators and engineers

SPI's Role in Industry 4.0 and Smart Manufacturing

SPI is a crucial component in our journey towards Industry 4.0 at JHYPCB:

- Data Collection and Analysis:

- SPI generates vast amounts of data for big data analytics

- Enables predictive quality control and process optimization

- Internet of Things (IoT) Integration:

- SPI machines connected to our factory-wide network

- Real-time data sharing across different production stages

- Artificial Intelligence and Machine Learning:

- AI-powered defect classification and prediction

- Machine learning algorithms for continuous process improvement

- Digital Twin Technology:

- Creating virtual models of our SPI process

- Allows for offline optimization and scenario testing

- Integration with MES and Other Factory Systems:

- Seamless data flow between SPI and other production systems

- Enables holistic view of the entire manufacturing process

Case Study: SPI Implementation at JHYPCB

Here’s a real-world example of how we’ve leveraged SPI to improve our PCB manufacturing:

Challenge: We were experiencing higher-than-desired defect rates on a complex, high-density PCB design for a critical customer.

Solution:

- Implemented advanced 3D SPI system

- Customized inspection parameters for the specific board design

- Integrated SPI data with our solder paste printer for closed-loop control

Results:

- 40% reduction in solder paste-related defects

- 25% decrease in overall production time

- Improved customer satisfaction and repeat orders

Lessons Learned:

- Importance of customizing SPI parameters for each product

- Value of closed-loop control in maintaining process stability

- Need for ongoing operator training to maximize SPI effectiveness

Future Trends in SPI Technology

At JHYPCB, we’re always looking ahead. Here are some trends we’re watching in SPI technology:

- AI-Driven Autonomous Inspection:

- Self-learning systems that can adapt to new PCB designs without human intervention

- AI-powered defect prediction and prevention

- Augmented Reality Integration:

- AR overlays for real-time visualization of SPI data on actual PCBs

- Enhanced operator guidance for defect resolution

- Nano-scale Inspection Capabilities:

- SPI systems capable of inspecting ever-smaller solder paste deposits

- Supporting the trend towards further miniaturization in electronics

- Multi-process Inspection Integration:

- Combined SPI and Automated Optical Inspection (AOI) systems

- Holistic quality control covering solder paste, component placement, and solder joints

- Cloud-based SPI Data Analytics:

- Global data sharing and analysis across multiple production sites

- Advanced predictive modeling using aggregated data from multiple sources

Conclusion

SPI has become an indispensable tool in modern PCB manufacturing, and at JHYPCB, we’ve embraced this technology to its fullest potential. By leveraging advanced SPI systems, we’ve been able to:

- Dramatically improve our PCB quality and consistency

- Reduce defects and rework, leading to cost savings

- Enhance our process control and optimization capabilities

- Stay at the forefront of Industry 4.0 and smart manufacturing trends

Our commitment to SPI technology reflects our larger commitment to quality, efficiency, and customer satisfaction. As we look to the future, we’re excited about the continued evolution of SPI technology and its potential to further revolutionize PCB manufacturing.

At JHYPCB, we’re not just keeping pace with these advancements – we’re helping to drive them. Our investment in cutting-edge SPI technology, coupled with our expertise in its implementation and data interpretation, allows us to deliver PCBs of unparalleled quality to our customers.

Whether you’re looking for high-volume production or complex, high-density PCB designs, our advanced SPI capabilities ensure that we can meet and exceed your expectations. Trust JHYPCB to be your partner in navigating the ever-evolving landscape of PCB manufacturing, where quality is not just inspected, but built into every step of our process.

Related Reading

- Top 10 Factors to Consider When Choosing a PCB Assembly Company

- One-Stop Solution: The Advantages of Turnkey PCB Manufacturing and Assembly

- PCB Assembly Cost: A Comprehensive Guide for Cost-Effective PCB Manufacturing

- 3 Special Reminders for Printed Circuit Board Assembly (PCBA)

- What is Lead-Free Solder Paste (Pb-Free) in PCB Assembly?

- Choosing the Right PCB Assembly Manufacturer for Your Needs

- What Is Prototype PCB Assembly?

- The Advantages and Disadvantages of Surface Mount Technology (SMT)

- Materials Used in Surface Mount Technology

- SMT PCB Assembly Manufacturing Process Introduces

- The Two Typical SMT Reflow Soldering Temperature Curve Modes

- 30 Common SMT PCB Assembly Defects

- Reflow Soldering VS. Wave Soldering: What’s the difference?

- What is the difference between SMT and SMD?

- The Main PCB Assembly Process Steps