Table of Contents

As devices like smartphones, wearables, and medical equipment demand greater compactness, flexible PCBs have become essential for modern electronics. These bendable circuits enable innovative designs but come with a higher price tag than rigid PCBs. In this article, we explore what flexible PCBs are, their applications, why their costs are elevated, and proven strategies to reduce flexible PCB pricing for cost-effective manufacturing.

What Are Flexible PCBs and How Do They Work?

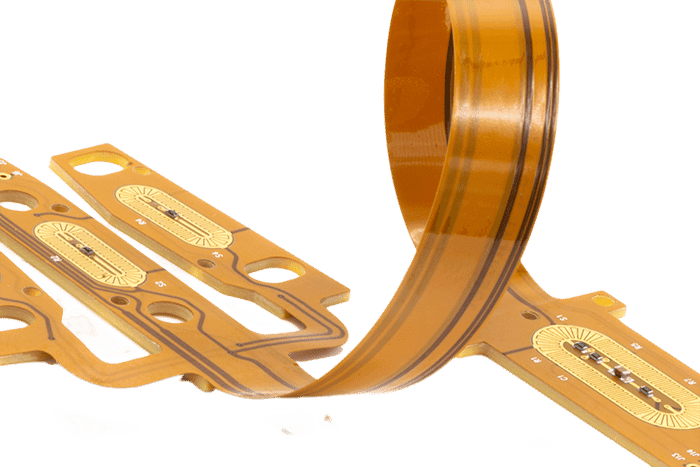

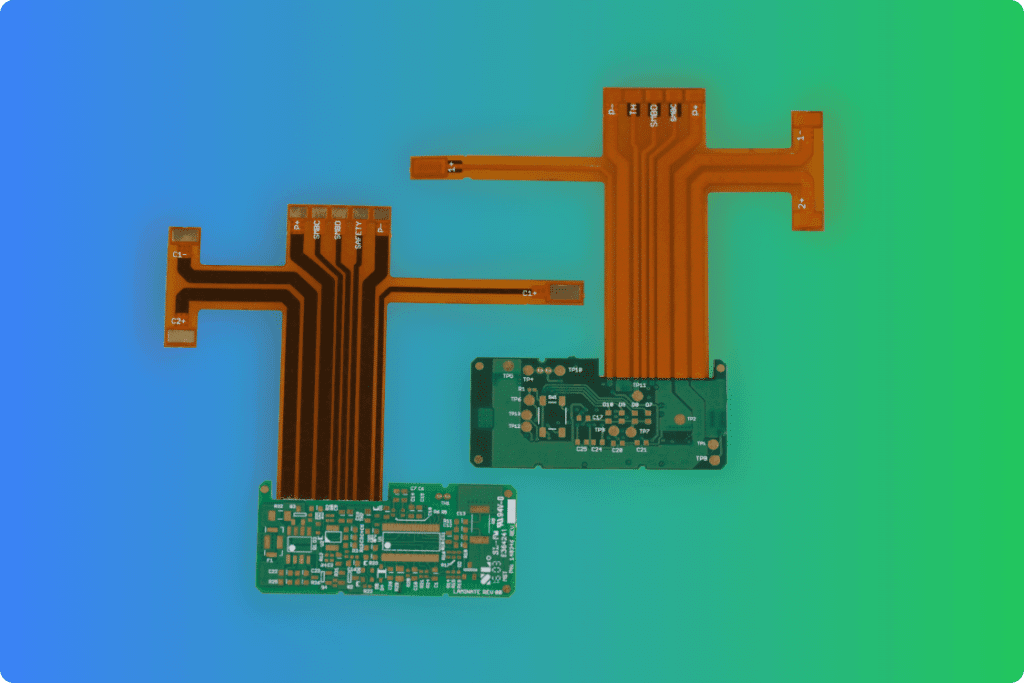

A flexible PCB, also known as a flex circuit, is a printed circuit board made from flexible materials like polyimide or polyester film, allowing it to bend and conform to various shapes. Unlike rigid PCBs, which use a stiff FR-4 substrate, flexible PCBs offer unique adaptability, making them ideal for compact and miniaturized devices.

Flexible PCBs function similarly to rigid PCBs, with conductive tracks and components, but their bendability enables use in tight spaces. For example, they are critical in devices like smartphones, where circuits must wrap around components, or in medical devices like smart catheters, which require intricate flexibility. According to IPC’s 2024 PCB Market Report, the global flexible PCB market was valued at $18.36 billion in 2024, with a projected CAGR of 13.7% through 2030, driven by demand for lightweight, compact electronics.

Where Are Flexible PCBs Used?

Flexible PCBs shine in applications where rigid PCBs fall short. Their ability to bend and fit into small, irregular spaces makes them indispensable in:

- Consumer Electronics: Smartphones, smartwatches, and headphones rely on flexible PCBs for compact designs.

- Automotive Systems: Flex circuits enable complex wiring in car dashboards and sensors.

- Medical Devices: Hearing aids and minimally invasive tools use flexible PCBs for precision and flexibility.

- Aerospace: Lightweight and durable, flex PCBs are used in satellites and avionics.

Flexible PCBs also serve as interconnectors, linking multiple circuits with flexible pathways, and are often combined with rigid boards to create rigid-flex PCBs, overcoming limitations of both types. For more on rigid-flex designs, check our guide on Understanding Rigid-Flex PCBs.

Why Is Flexible PCB Cost Higher?

The flexible PCB cost is typically 5-10 times higher than rigid PCBs due to several key factors:

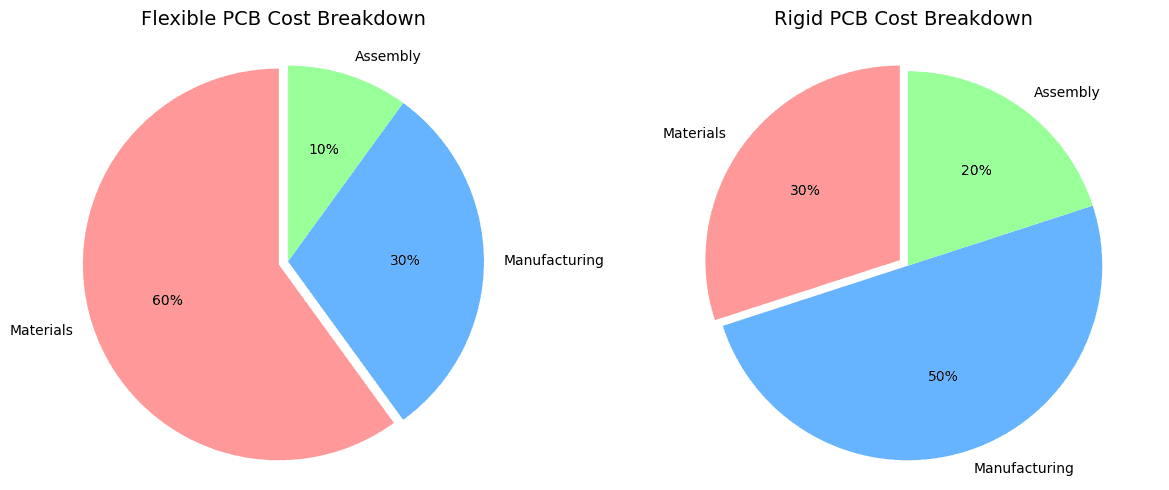

Premium Materials

Flexible PCBs use costly substrates like polyimide, which can cost 5-10 times more than the FR-4 used in rigid PCBs. Polyimide’s durability and heat resistance justify its price but significantly drive up flex PCB pricing.

Complex Manufacturing

The manufacturing process for flexible PCBs is intricate, requiring precise lamination and bonding under controlled temperature and pressure. Mishandling can compromise flexibility or reliability, increasing production costs.

Design and Assembly Factors

Additional cost drivers include the number of layers, copper thickness, track spacing, drilling, stiffeners, gold fingers, and surface finishes. Each adds complexity and expense to the flex circuit design.

Visualizing Cost Drivers

As illustrated, material costs dominate flexible PCB pricing, unlike rigid PCBs, where manufacturing is the primary expense.

Comparing Flex vs. Rigid PCB Pricing: A Detailed Breakdown

To illustrate the cost disparity, consider these examples from IPC’s 2024 PCB Cost Analysis Report:

- A 4-layer 6″x4″ rigid FR-4 PCB costs ~$30 per square inch at low volumes.

- An equivalent flexible polyimide PCB ranges from $150 to $300+ per square inch, depending on quantity and features like stiffeners.

- For larger 12″x18″ 8-layer boards, a rigid PCB costs ~$150, while a flex version starts at $1,500 and can exceed $3,000 for low volumes with custom options.

These differences stem from material costs and manufacturing complexity, making cheap flexible PCBs a challenge without strategic design.

How to Reduce Flexible PCB Costs in 2025

Reducing flexible PCB manufacturing costs requires optimizing key cost drivers. Here are proven strategies to achieve low-cost flexible PCBs:

Minimize the Number of Layers

Each additional layer increases material (copper, adhesive) and manufacturing complexity. Reducing layers by 1-2 can cut costs by up to 20%. Use design software like Altium Designer to simulate layer reduction while maintaining functionality. For tips, see our Top 10 PCB Design Tips.

Order in Bulk

Manufacturers offer discounts for high-volume orders. Before bulk production, create prototypes to perfect your flex circuit design, avoiding costly revisions. Prototyping services are available at PCBElec.com.

Simplify Drilling and Vias

Drilling increases manufacturing complexity. Minimize vias and simplify track layouts to reduce production time and costs.

Use Rigid-Flex Where Possible

If only certain parts of the PCB need flexibility, opt for a rigid-flex PCB. This hybrid approach uses cheaper rigid sections where flexibility isn’t required, balancing cost and performance.

Evaluate Alternative Materials

While polyimide is standard, polyester films can be a cost-effective alternative for less demanding applications. Discuss options with your manufacturer to weigh trade-offs.

Ready to Optimize Your Flexible PCB Costs?

By applying these strategies, you can significantly lower flexible PCB pricing without sacrificing quality. Contact our team at PCBElec.com for a free consultation or download our Flexible PCB Design Guide to start saving today.

Frequently Asked Questions

How can I reduce flexible PCB costs?

Reduce costs by minimizing layers, ordering in bulk, simplifying drilling, using rigid-flex PCBs where possible, and exploring alternative materials like polyester.

Why are flexible PCBs so expensive?

Flexible PCBs cost more due to premium materials (e.g., polyimide), complex manufacturing processes, and additional design features like stiffeners and gold fingers.

Related Posts

- What Is Flexible PCB Coverlay (FPC Cover Layer)?

- The Manufacturing Process Of Double-sided Flexible PCB Coverlay

- What Are The Advantages And Applications Of Rigid-Flex PCBs?

- Rigid PCB vs Flex PCB: What Is The Difference?

- What Are Flexible PCB Stiffeners?

- How to Solder On Flex PCB?

- 16 Factors Affecting The Cost And Price of Flexible PCB

- Development and Applications of FPC Flexible PCB

- Flexible Printed Circuit For Today’s Packaging

- Knowledge of Flexible PCB Manufacturing Process Steps

- Custom Flex PCB:Tailored Solutions for Your Applications

- Introduction to Semi-Flex PCBs: Bridging Rigid and Flex PCBs

- Flexible PCB Manufacturing: A Guide to Fabrication and Assembly

- How to Select the Right Flexible PCB Manufacturer for Your Product: A 6-Step Guide

- Layer Stackup in Rigid-Flex PCB

- What Are The Types of Flexible Circuit Boards?

- Top Applications of Flexible Printed Circuit Boards in 2024