Table of Contents

Introduction

Flexible Printed Circuit Boards (FPCs) are at the heart of modern electronics, enabling innovative designs in compact, high-performance devices like foldable smartphones, wearable medical sensors, and electric vehicle (EV) systems. Known for their lightweight, high-density wiring, and exceptional flexibility, Flexible PCBs are critical for industries embracing 5G, AI, and IoT technologies. Understanding FPC manufacturing terms—such as Coverlay, Polyimide, and Reel to Reel—is essential for engineers, designers, and procurement professionals aiming to create reliable, cutting-edge products. This guide explains key FPC terminology to empower you with the knowledge to navigate the manufacturing process confidently.

Understanding Flexible PCBs

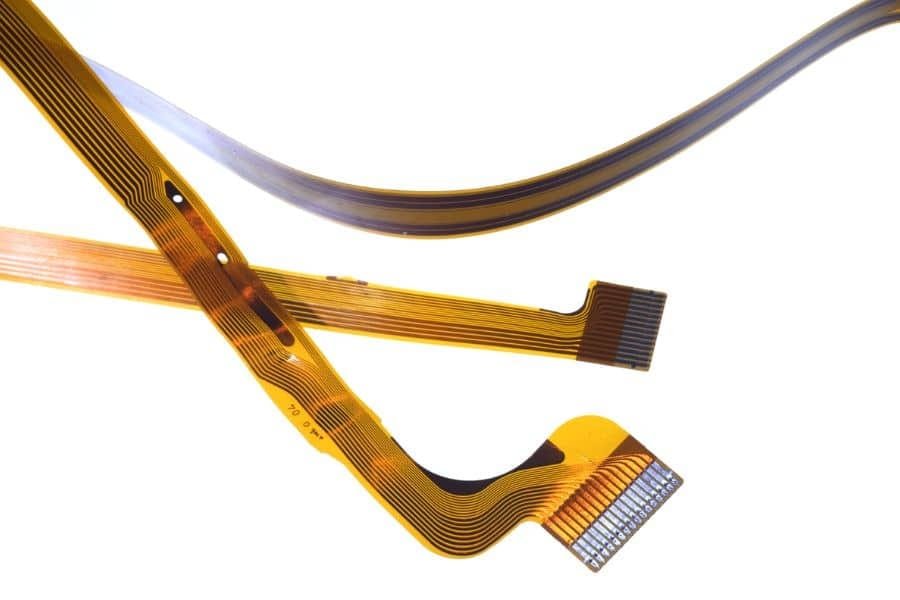

Flexible Printed Circuit Boards (FPCs) are specialized circuit boards designed to bend, twist, and conform to tight spaces, making them ideal for modern electronics requiring compact, lightweight designs. Unlike rigid PCBs, which use stiff materials like FR4, Flexible PCBs leverage substrates such as Polyimide or Polyester, offering unmatched flexibility and high-density wiring. These properties make FPC manufacturing critical for applications like foldable smartphones, wearable medical devices, 5G antennas, and electric vehicle (EV) battery systems. For example, in foldable phones, FPCs with Coverlay and Impedance Control ensure reliable performance during repeated bending.

FPCs excel in dynamic environments, enduring millions of flex cycles without failure, as seen in disk drive heads or medical wearables. Their lightweight nature reduces device weight, while advanced processes like Reel to Reel manufacturing enhance production efficiency. This section introduces key FPC manufacturing terms to help you understand their design and production.

FPC vs. Rigid PCB Comparison

The following chart compares Flexible PCBs and rigid PCBs across key characteristics, highlighting FPC advantages in modern electronics.

FPC Materials

Materials in Flexible PCB manufacturing determine the performance, flexibility, and durability of circuits in applications ranging from foldable smartphones to 5G antennas and electric vehicle (EV) systems. Below are key FPC materials essential for understanding the construction and functionality of Flexible PCBs.

- Acrylic: A polyacrylic resin film commonly used as a Coverlay in Flexible PCBs. Acrylic provides insulation and flexibility, protecting circuits from environmental stress and bending. It is widely used in consumer electronics like wearables and foldable displays.

- Kapton: A Polyimide film developed by DuPont, known for its heat resistance up to 400°C. Kapton is ideal for FPC manufacturing in harsh environments, such as aerospace avionics and EV battery management systems, ensuring thermal and electrical reliability.

- Polyimide (PI): A high-performance substrate for Flexible PCBs, offering exceptional thermal and electrical resistance. Polyimide withstands extreme temperatures, making it vital for FPC for 5G antennas and AI-driven medical devices where reliability is critical.

- Polyester Films: Also known as PET films (e.g., DuPont’s Mylar), these provide strong dielectric properties for Flexible PCBs. Used as protective layers or substrates, Polyester Films are common in membrane switches and compact electronics like calculators.

- Copper Foil: The conductive layer in Flexible PCBs, typically made from electrodeposited or rolled annealed copper. Copper Foil enables high-density wiring and is essential for signal transmission in applications like IoT devices and automotive electronics.

- Adhesive Materials: Heat-cured adhesives, such as epoxy or acrylic-based bonding layers, join copper foil to substrates like Polyimide in FPC manufacturing. These materials ensure structural integrity during bending and environmental exposure.

- Liquid Crystal Polymer (LCP): An advanced substrate for Flexible PCBs, valued for its low dielectric loss and high-frequency performance. LCP is increasingly used in FPC for 5G and high-speed communication devices due to its superior electrical properties.

These materials enable Flexible PCBs to meet the demands of modern electronics, from compact wearables to high-frequency 5G systems.

FPC Design Features

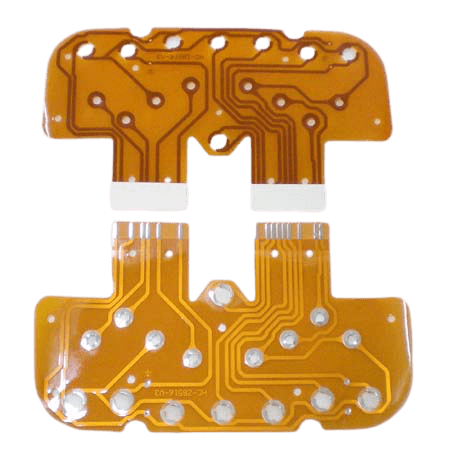

The design of Flexible PCBs incorporates unique features that enable flexibility, durability, and functionality in compact electronics like foldable smartphones, medical wearables, and 5G devices. These features distinguish FPC manufacturing from rigid PCB design, ensuring performance under bending and dynamic conditions. Below are key design features essential for understanding FPC designs.

- Access Hole: A feature in Flexible PCBs that exposes solder joints or pads for external connections. Access Holes are created by removing sections of the Coverlay, allowing component welding in applications like wearable sensors and automotive displays.

- Anchoring Spurs: Finger-like extensions added to solder pads on single-sided Flexible PCBs to enhance adhesion. Anchoring Spurs reduce the risk of pads lifting during bending, ensuring reliability in dynamic applications like foldable phone hinges.

- Coverlay: A soft acrylic or Polyimide layer applied to Flexible PCBs to protect circuits from environmental stress and bending. Unlike rigid PCB solder masks, Coverlay in FPC provides flexibility and durability, critical for devices like smartwatches and medical implants.

- Stiffener: A rigid material, such as FR4 or Polyimide, added to specific areas of Flexible PCBs to provide mechanical support. Stiffeners are commonly used in connector regions of FPCs for applications like 5G antennas, ensuring stability during assembly and use.

These design features enable Flexible PCBs to adapt to complex shapes and dynamic environments, making them indispensable for modern electronics.

FPC Manufacturing Processes

The manufacturing processes for Flexible PCBs are critical to achieving the flexibility, reliability, and performance required in modern electronics, such as 5G communication devices, electric vehicle (EV) systems, and AI-driven wearables. These processes involve specialized techniques to ensure FPC manufacturing meets stringent industry standards for high-density wiring and dynamic applications. Below are key processes that define the production of Flexible PCBs.

- Bonding Layer: A heat-cured adhesive, typically epoxy or acrylic-based, used to join copper foil to substrates like Polyimide or Polyester in Flexible PCBs. The Bonding Layer ensures structural integrity during bending and exposure to environmental stressors like heat and humidity. For example, in foldable smartphones, the Bonding Layer maintains circuit stability across millions of flex cycles.

- Reel to Reel: A continuous manufacturing process for Flexible PCBs that uses reels to automate high-volume production. Reel to Reel PCB manufacturing involves feeding a flexible substrate through processing stations for patterning, etching, and lamination, reducing labor costs and improving efficiency. This process is widely used for producing FPCs for IoT sensors and automotive electronics.

- Impedance Control: A design and manufacturing technique that manages the electrical resistance of Flexible PCB circuits to ensure signal integrity, particularly in high-frequency applications like FPC for 5G antennas and AI-driven medical devices. Impedance Control in FPC involves precise control of trace width, dielectric thickness, and material properties to minimize signal loss.

- Via: Conductive holes that connect multiple layers in Flexible PCBs, enabling complex, high-density circuit designs. Vias in FPCs, such as microvias or plated-through holes, support multilayer configurations in compact devices like smartwatches and EV control units.

These processes enable Flexible PCBs to meet the demands of advanced applications, from high-frequency 5G systems to dynamic wearables.

FPC Applications

Flexible PCBs are integral to a wide range of modern electronics, enabling innovative designs in devices that require flexibility, compact size, and durability. From foldable smartphones to medical wearables and electric vehicle (EV) systems, FPC applications drive advancements in industries embracing 5G, AI, and IoT technologies. Below are key terms related to the applications of Flexible PCBs.

- Dynamic Flex: Flexible PCBs designed for continuous bending, known as Dynamic Flex, are built to withstand millions of flex cycles without failure. These FPCs are critical in applications like disk drive read/write heads, foldable smartphones, and FPC for wearables such as fitness trackers.

- Membrane Switch: A touch-based interface using Flexible PCBs with printed conductive inks, typically silver paste, on a Polyester or Polyimide substrate. Membrane Switches are widely used in compact electronics like remote controls, handheld calculators, and medical device keypads.

These FPC applications showcase the versatility of Flexible PCBs in enabling compact, dynamic, and user-friendly electronics.

Frequently Asked Questions

Understanding Flexible PCB terminology is key to designing and manufacturing advanced electronics. Below are answers to common questions about FPC manufacturing, materials, design, and applications.

What is the difference between a Flexible PCB and a rigid PCB?

Why is Polyimide used in FPC manufacturing?

Polyimide, such as DuPont’s Kapton, is a preferred substrate in FPC manufacturing due to its high thermal resistance (up to 400°C) and excellent electrical insulation. It ensures reliability in FPC for electric vehicles and FPC for 5G antennas.

How does Coverlay protect Flexible PCBs?

What is Impedance Control in FPC design?

Impedance Control in FPC manages electrical resistance to ensure signal integrity in high-speed circuits, such as FPC for 5G devices and AI-driven sensors, minimizing signal loss.

How are Flexible PCBs used in modern electronics?

Flexible PCBs enable compact designs in FPC for AI devices, FPC for electric vehicles, and foldable displays. Dynamic Flex supports wearables, while Membrane Switches provide responsive interfaces.

Conclusion and Further Learning

Mastering Flexible PCB terminology is essential for designing and manufacturing cutting-edge electronics that power compact, dynamic, and high-performance devices. From advanced materials like Polyimide and Liquid Crystal Polymer (LCP) to design features such as Coverlay and Stiffener, these concepts enable FPC manufacturing to meet the demands of modern applications. Manufacturing processes like Reel to Reel and Impedance Control ensure precision in high-frequency systems, such as FPC for 5G antennas and AI-driven wearables. Applications like Dynamic Flex and Membrane Switch highlight the versatility of Flexible PCBs in foldable smartphones, electric vehicle (EV) control units, and IoT devices.

Understanding these FPC manufacturing terms empowers engineers and designers to create innovative solutions for 5G, AI, and EV technologies driving the electronics industry in 2025 and beyond.

Related PCB and PCBA Fabrication Services

- Fast Turn Prototype PCB Service

- Low-Cost PCB Prototype Fabrication

- Rigid-flex PCB Manufacturing Service

- Fast Prototype PCB Assembly Service

- SMT PCB Assembly

- LED PCB Assembly

- Multilayer PCB Manufacturing Service

Advanced Learning:

- Knowledge of Plating on Flexible Circuit Board Surface

- Knowledge of Flexible Printed Circuit Board Processing Technology

- Five factors that FPC PCB designers should know about impedance control

- 6 Tips For Looking For A PCB Prototype Manufacturer

- How to Choose the Right PCB Manufacturer and Supplier

- Knowledge of Flexible PCB Manufacturing Process Steps