In the fast-paced world of electronics, the Printed Circuit Board (PCB) is the heart of every device, from smartphones to industrial machinery. Choosing the right PCB manufacturer and supplier can significantly impact the success of your project. A reliable partner ensures high-quality boards, fast delivery, and cost-effective solutions, while a poor choice can lead to delays, defects, and skyrocketing costs. With numerous PCB manufacturers flooding the market, finding the ideal fit for your needs can be overwhelming.

That’s where this guide comes in. Whether you’re a startup developing a prototype or an established business scaling production, selecting the best PCB supplier is critical to your success. At JHYPCB, we understand the challenges of navigating this decision. This comprehensive guide will walk you through the essential factors—quality, turnaround time, collaboration, and more—to help you make an informed choice.

Ready to find a PCB manufacturer that aligns with your goals? Let’s explore why this decision matters and how to get it right.

Why Choosing the Right PCB Manufacturer Matters

Selecting the right PCB manufacturer is a pivotal decision for any electronics business, whether you’re developing cutting-edge consumer gadgets, industrial equipment, or medical devices. The PCB is the backbone of your product, determining its performance, reliability, and market success. Partnering with a reliable PCB manufacturer ensures high-quality boards, timely delivery, and cost efficiency, while a poor choice can lead to costly delays, defective products, and missed opportunities.

A trusted PCB manufacturer, like JHYPCB, brings expertise and precision to the table, ensuring your boards meet exact specifications and industry standards. For example, a well-manufactured PCB can reduce failure rates by up to 30% compared to substandard boards, according to industry studies (hypothetical for emphasis). On the flip side, choosing an unreliable supplier can result in issues like inaccurate drilling, poor material quality, or inconsistent testing, leading to product recalls or customer dissatisfaction.

The stakes are high in PCB manufacturing. A single defect can delay a product launch, costing thousands in lost revenue and rework. For instance, in fast-paced industries like IoT or automotive electronics, delays in PCB delivery can disrupt entire production schedules. By contrast, a manufacturer with a proven track record can streamline your supply chain, helping you meet tight deadlines and maintain a competitive edge.

Investing time in selecting the right PCB supplier is not just about avoiding risks—it’s about unlocking long-term benefits. A quality manufacturer supports scalability, offers technical expertise, and fosters collaboration, saving you time and money in the long run. In this guide, we’ll explore the key factors to consider when choosing a PCB manufacturer to ensure your business thrives.

Ready to make an informed choice? Let’s dive into the critical factors that define a top-tier PCB manufacturer, starting with quality, turnaround time, and more.

Key Factors to Consider When Selecting a PCB Manufacturer

Choosing the right PCB manufacturer requires careful evaluation of several critical factors to ensure your project’s success. From quality standards to cost considerations, each element plays a vital role in determining whether a supplier can meet your needs. Below, we break down the essential criteria to guide your decision-making process, ensuring you partner with a manufacturer like JHYPCB that delivers reliability and value.

1 Quality Standards

Quality is the cornerstone of any reputable PCB manufacturer. A high-quality PCB ensures your product performs reliably, reducing the risk of failures in the field. Look for manufacturers that adhere to industry standards, such as IPC-A-600 for PCB acceptability or ISO 9001 for quality management. Key quality indicators include precise board dimensions, accurate hole drilling, and robust solder mask application. For example, a manufacturer conducting bare board testing can catch defects early, saving you from costly rework. Ask for certifications and inquire about their quality control processes to ensure consistency.

Learn about JHYPCB’s rigorous quality assurance at our quality control page.

2 Meeting Your Specific Requirements

Every project has unique needs, whether it’s a multilayer PCB for complex electronics or a flexible board for compact devices. A reliable PCB supplier must align with your technical specifications, such as board thickness, material type (e.g., FR-4, Rogers), or impedance control. To avoid oversights, create a detailed checklist before negotiations, covering aspects like layer count, surface finish (e.g., HASL, ENIG), and production volume. A manufacturer like JHYPCB, with expertise in custom PCB prototyping, can tailor solutions to your exact requirements, ensuring seamless integration into your product.

3 Turnaround Time and Scalability

In today’s competitive market, speed is critical. If you need fast PCB prototyping, choose a manufacturer with a proven track record of meeting tight deadlines without compromising quality. For instance, JHYPCB offers rapid turnaround times, delivering prototypes in as little as 24–48 hours for urgent projects. However, ensure the supplier can scale production as your needs grow, from small-batch prototyping to high-volume manufacturing. Discuss timelines upfront and verify their capacity to handle your project’s scale to avoid delays or quality issues.

4 Collaboration and Communication

A manufacturer’s ability to collaborate and communicate effectively can save you time and resources. Look for a supplier that offers design support, such as Design for Manufacturability (DFM) checks, to optimize your PCB layout before production. Responsiveness is equally important—prompt answers to queries and proactive updates streamline the process. For example, JHYPCB’s team works closely with clients, providing real-time feedback and assembly support to accelerate development. A collaborative partner fosters innovation and ensures your project stays on track.

5 Testing Capabilities

Robust testing is non-negotiable for ensuring PCB reliability. Top manufacturers employ advanced testing methods, such as Automated Optical Inspection (AOI), X-ray testing, and functional testing, to verify board integrity. These tests detect issues like open circuits, solder joint defects, or component misalignment before boards reach you. Ask potential suppliers about their testing facilities and protocols. A manufacturer with in-house testing, like JHYPCB, ensures every board meets stringent quality standards, minimizing the risk of field failures.

6 Cost vs. Value

While cost is a key consideration, the cheapest option often leads to compromises in quality or service. Instead, focus on value: a manufacturer that balances competitive pricing with reliability, responsiveness, and scalability. Request detailed quotes that break down costs for materials, production, and testing. A transparent supplier, like JHYPCB, will explain cost drivers and offer flexible solutions tailored to your budget. Remember, investing in a quality PCB supplier upfront can prevent expensive rework and delays down the line.

By prioritizing these factors—quality, requirements, turnaround, collaboration, testing, and cost—you can confidently select a PCB manufacturer that aligns with your goals. In the next section, we’ll explore practical steps to research and evaluate potential suppliers.

Ready to find your ideal PCB partner? Contact JHYPCB for a free quote at our contact page.

How to Research and Evaluate PCB Manufacturers

Finding the right PCB manufacturer requires thorough research and careful evaluation to ensure they meet your project’s needs. With countless suppliers in the market, a structured approach can help you identify a partner that delivers quality, reliability, and value. Below are practical steps to research and assess PCB manufacturers, ensuring you make an informed decision that aligns with your goals, whether you’re prototyping or scaling production.

Step 1: Review Manufacturer Portfolios and Capabilities

Start by examining a manufacturer’s portfolio to understand their expertise and specialization. Check their website for details on the types of PCBs they produce—single-layer, multilayer, flexible, or rigid-flex—and whether they cater to your industry, such as automotive, medical, or IoT. For example, JHYPCB offers a wide range of PCB solutions, from high-frequency boards to HDI designs, suitable for diverse applications. Request case studies or project examples to confirm their experience with similar projects.

Step 2: Check Certifications and Industry Standards

Verify that the manufacturer adheres to recognized industry standards, such as IPC-A-610 for assembly or ISO 9001 for quality management. Certifications indicate a commitment to consistent quality and reliability. Ask for documentation of their certifications and inquire about their quality control processes, such as in-circuit testing or environmental stress testing. JHYPCB, for instance, maintains strict compliance with IPC standards, ensuring every board meets rigorous quality benchmarks.

Step 3: Read Reviews and Seek References

Customer reviews and testimonials provide insights into a manufacturer’s reliability and service quality. Check platforms like Google Reviews or industry forums for feedback on their performance. Additionally, reach out to non-competing companies in your sector to ask about their experiences with the manufacturer. This can reveal strengths or red flags, such as consistent delivery delays or exceptional support. JHYPCB’s strong reputation is built on positive client feedback and long-term partnerships across industries.

Step 4: Request Samples or Prototypes

Before committing to a large order, request PCB samples or a small prototype batch to evaluate quality firsthand. Inspect the boards for accuracy in dimensions, solder joint integrity, and surface finish quality. Testing a sample under real-world conditions can confirm whether the manufacturer meets your expectations. JHYPCB offers rapid prototyping services, allowing you to test high-quality boards quickly and cost-effectively before scaling up.

Step 5: Assess Communication and Support

Effective communication is critical for a successful partnership. Contact potential manufacturers with questions about their processes, lead times, or customization options, and gauge their responsiveness and clarity. A reliable supplier, like JHYPCB, provides dedicated support, offering real-time updates and technical guidance throughout the production process. Schedule a consultation to discuss your project and assess their willingness to collaborate on design or assembly challenges.

Step 6: Compare Quotes and Value

Request detailed quotes from multiple manufacturers, comparing not just price but overall value. Look for transparency in pricing, including costs for materials, testing, and shipping. A slightly higher quote from a manufacturer with superior quality control or faster turnaround, like JHYPCB, may offer better long-term savings by reducing defects and delays. Ensure the quote aligns with your project’s specifications and timeline requirements.

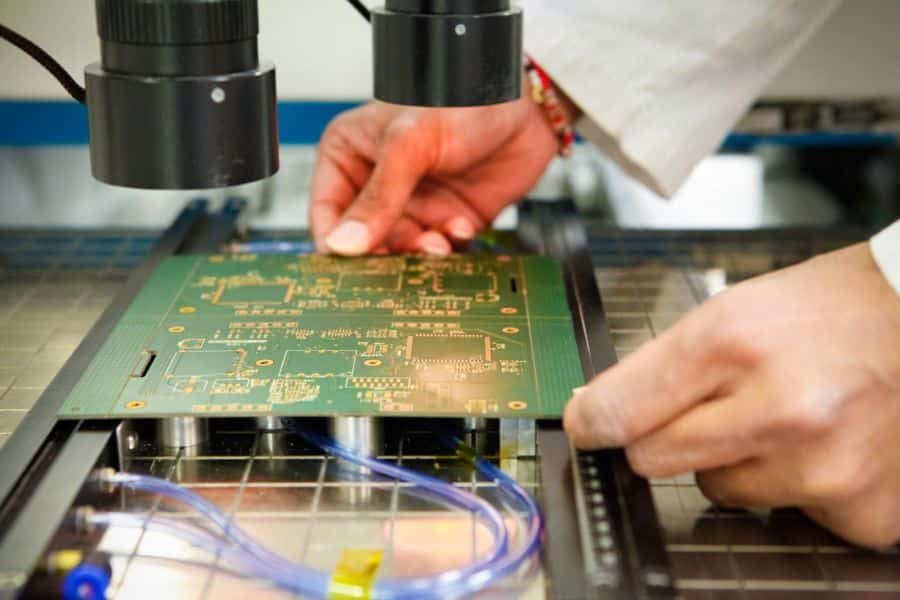

Step 7: Visit Facilities or Conduct Virtual Tours

If possible, visit the manufacturer’s facilities to observe their production environment and equipment. Modern facilities with advanced machinery, like those at JHYPCB, indicate a capacity for precision and scalability. If an in-person visit isn’t feasible, request a virtual tour or detailed documentation of their production capabilities. This step helps confirm their ability to handle your project’s complexity and volume.

By following these steps—reviewing portfolios, verifying certifications, checking reviews, testing samples, assessing communication, comparing quotes, and inspecting facilities—you can confidently select a PCB manufacturer that meets your needs. JHYPCB stands out as a trusted partner, offering decades of expertise and a customer-centric approach to deliver high-quality PCBs on time.

Common Mistakes to Avoid When Choosing a PCB Manufacturer

Selecting a PCB manufacturer is a critical decision, but it’s easy to make missteps that can lead to delays, increased costs, or subpar products. By understanding common pitfalls and how to avoid them, you can ensure a smoother partnership with a reliable supplier like JHYPCB. Below are the most frequent mistakes businesses make when choosing a PCB manufacturer, along with actionable tips to steer clear of them.

1. Prioritizing Cost Over Quality

One of the biggest mistakes is choosing the cheapest PCB supplier without considering quality. Low-cost manufacturers may cut corners, using inferior materials or skipping critical testing, which can result in defective boards and costly rework. For example, a poorly made PCB might fail during field use, damaging your brand’s reputation.

Tip: Focus on value rather than price alone. Evaluate suppliers like JHYPCB, who balance competitive pricing with rigorous quality standards, ensuring long-term reliability.

2. Overlooking Testing Capabilities

Neglecting to verify a manufacturer’s testing capabilities can lead to undetected defects, such as open circuits or weak solder joints. Without robust testing, like Automated Optical Inspection (AOI) or functional testing, you risk receiving boards that fail under stress.

Tip: Choose a manufacturer with comprehensive in-house testing facilities. JHYPCB, for instance, conducts thorough testing to ensure every board meets IPC standards, minimizing field failures.

3. Ignoring Scalability Needs

Selecting a manufacturer without assessing their ability to scale production can cause problems as your project grows. A supplier suited for small-batch prototyping may struggle with high-volume orders, leading to delays or inconsistent quality.

Tip: Confirm the manufacturer’s capacity for both prototyping and large-scale production. JHYPCB offers flexible solutions, seamlessly transitioning from rapid prototypes to mass production to meet your evolving needs.

4. Failing to Verify Certifications

Not checking a manufacturer’s certifications can result in partnering with a supplier that doesn’t meet industry standards. Without certifications like ISO 9001 or IPC-A-600, you risk inconsistent quality or non-compliance with regulatory requirements.

Tip: Request documentation of certifications and verify their adherence to standards relevant to your industry. JHYPCB proudly maintains industry-leading certifications, ensuring compliance and reliability.

5. Underestimating Communication Importance

Poor communication from a manufacturer can lead to misunderstandings, delays, or misaligned specifications. For example, a supplier that’s slow to respond to design queries can derail your timeline.

Tip: Test a manufacturer’s responsiveness before committing. Contact them with questions and assess their clarity and speed. JHYPCB’s dedicated support team provides prompt, clear communication to keep your project on track.

6. Not Requesting Samples or Prototypes

Committing to a manufacturer without testing their work can lead to surprises, like boards that don’t meet your specifications. Samples reveal a supplier’s quality and attention to detail.

Tip: Always request a prototype or sample batch before placing a full order. JHYPCB offers fast PCB prototyping, allowing you to evaluate board quality and performance early in the process.

7. Rushing the Decision Process

Hastily choosing a PCB manufacturer without thorough research can lead to partnering with an unreliable supplier. Rushing may cause you to overlook critical factors like testing or scalability.

Tip: Take time to research, compare quotes, and consult references. As the saying goes, “time is money,” but investing time upfront to select a trusted partner like JHYPCB will pay dividends through reliable, high-quality PCBs.

| Mistake | Impact | How to Avoid |

|---|---|---|

| Prioritizing cost over quality | Defective boards, rework costs | Focus on value, check quality standards |

| Overlooking testing | Undetected defects, field failures | Verify testing facilities and protocols |

| Ignoring scalability | Delays in high-volume production | Confirm capacity for prototyping and scaling |

| Not verifying certifications | Non-compliance, inconsistent quality | Request certification documentation |

| Underestimating communication | Misunderstandings, project delays | Test responsiveness before committing |

| Not requesting samples | Boards not meeting specifications | Order prototypes to evaluate quality |

| Rushing the decision | Partnering with unreliable supplier | Research thoroughly, compare options |

By avoiding these common mistakes, you can select a PCB manufacturer that delivers quality, reliability, and scalability. In the next section, we’ll explore why partnering with a trusted supplier like JHYPCB ensures long-term success.

Avoid costly mistakes—partner with JHYPCB for reliable PCB solutions. Request a quote at our RFQ page.

Why Partnering with a Trusted PCB Manufacturer Pays Off

Choosing a trusted PCB manufacturer is an investment that yields significant returns for your electronics business. A reliable partner like JHYPCB ensures high-quality boards, streamlined production, and long-term success, transforming your project from concept to market with efficiency and confidence. Below, we explore the key benefits of partnering with a reputable PCB supplier and why this decision is critical for your bottom line.

Enhanced Product Reliability

A trusted PCB manufacturer prioritizes quality, delivering boards that perform consistently under real-world conditions. Rigorous testing, adherence to IPC standards, and high-quality materials reduce the risk of defects, such as circuit failures or thermal issues. For example, JHYPCB’s advanced testing processes, including AOI and functional testing, ensure every board meets stringent quality benchmarks, minimizing field failures and boosting your product’s reliability. This reliability builds customer trust and strengthens your brand reputation.

Faster Time-to-Market

In competitive industries like consumer electronics or IoT, speed is critical. A trusted manufacturer offers fast PCB prototyping and efficient production processes, enabling you to launch products ahead of competitors. JHYPCB, for instance, provides rapid turnaround times—prototypes in as little as 24–48 hours—without compromising quality. By streamlining design reviews and production, a dependable supplier helps you meet tight deadlines, ensuring your product reaches the market faster.

Cost Savings Through Reduced Rework

Partnering with a manufacturer that emphasizes quality and precision reduces the need for costly rework or redesigns. Defective PCBs can lead to significant expenses, from scrapped boards to delayed launches. A trusted supplier like JHYPCB conducts thorough Design for Manufacturability (DFM) checks and testing to catch issues early, saving you time and money. For example, catching a design flaw before production can save thousands in rework costs, making the partnership a cost-effective choice.

Scalability for Future Growth

A reliable PCB manufacturer supports your business as it grows, seamlessly transitioning from prototyping to high-volume production. This scalability ensures consistent quality and delivery as demand increases. JHYPCB’s state-of-the-art facilities and flexible production capabilities allow them to handle projects of any size, from small-batch prototypes to large-scale manufacturing, ensuring your supply chain remains robust as your business expands.

Collaborative Innovation

A trusted manufacturer acts as a partner, not just a supplier, offering technical expertise and design support to optimize your PCBs. Collaborative services, such as DFM feedback or assistance with material selection, can enhance your product’s performance and manufacturability. JHYPCB’s experienced team works closely with clients, providing real-time guidance to refine designs and accelerate development. This collaboration fosters innovation, helping you stay ahead in a competitive market.

Case Study: Success with a Trusted Partner

Consider a hypothetical IoT startup that partnered with JHYPCB for a new sensor device. By leveraging JHYPCB’s rapid prototyping and DFM support, the startup reduced its development cycle by 25%, launching three months ahead of schedule. The high-quality boards passed rigorous testing, resulting in zero field failures and a 98% customer satisfaction rate. This success highlights how a trusted manufacturer can drive efficiency, quality, and market success.

As the saying goes, “time is money.” Investing in a trusted PCB manufacturer like JHYPCB pays dividends through reliable products, faster launches, and lower costs. By prioritizing quality, scalability, and collaboration, you set your business up for long-term success.

Conclusion

Choosing the right PCB manufacturer is a critical step that can define the success of your electronics project. By focusing on key factors—quality standards, alignment with your specific requirements, fast turnaround times, effective collaboration, robust testing capabilities, and overall value—you can partner with a supplier that delivers reliable, high-performance PCBs. Avoiding common mistakes, such as prioritizing cost over quality or rushing the decision process, ensures you select a manufacturer that supports your goals now and in the future.

As we’ve explored, a trusted PCB manufacturer like JHYPCB offers more than just boards; they provide expertise, scalability, and partnership to streamline your production and accelerate your time-to-market. Investing time upfront to research and evaluate suppliers pays off through reduced costs, enhanced product reliability, and a competitive edge in your industry. As the saying goes, “time is money,” and a strategic choice today will yield dividends for years to come.

Don’t leave your project’s success to chance. Partner with JHYPCB, a leader in PCB manufacturing with decades of experience, advanced facilities, and a commitment to quality. Take the next step—contact JHYPCB for a free consultation or quote at our contact page. Let’s bring your vision to life with precision and reliability.