Table of Contents

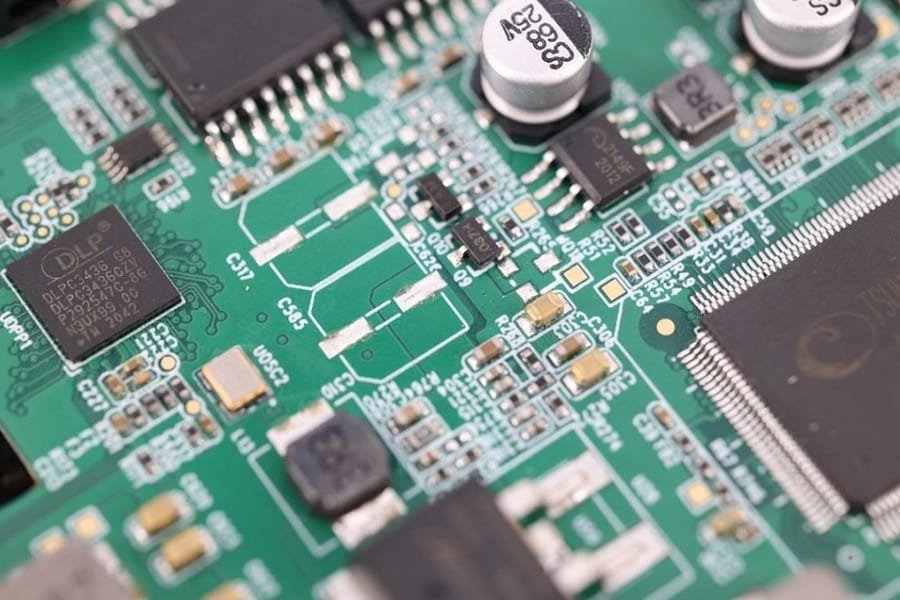

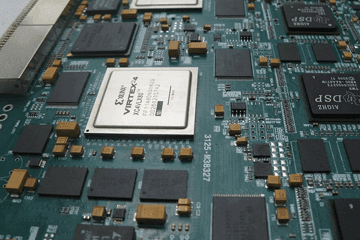

In the fast-paced electronics industry, PCB prototype assembly is the cornerstone of transforming innovative designs into functional products. From IoT devices to automotive systems, a seamless PCB assembly process ensures quality, performance, and speed to market. According to a 2025 industry report, the global PCB market is projected to reach $90 billion, driven by demand for compact, high-performance circuits. At JHYPCB, we combine cutting-edge Surface Mount Technology (SMT) and Thru-Hole Technology (THT) to deliver reliable PCBA prototyping. This comprehensive guide outlines the 8-step PCB prototype assembly process, highlights common pitfalls, and explains why JHYPCB is your trusted partner for PCB assembly services.

Why PCB Prototype Assembly Matters

Prototyping allows engineers to test designs, identify flaws, and optimize performance before mass production. A well-executed PCBA prototyping process minimizes costly rework, accelerates timelines, and ensures your product meets industry standards. However, challenges like component shortages or design errors can derail projects. At JHYPCB, our streamlined process ensures precision and efficiency, saving you time and resources.

SMT vs. THT: Key Technologies

- Surface Mount Technology (SMT): Perfect for compact designs, SMT places tiny components like resistors and ICs (down to 01005 size) directly onto the PCB surface. It’s ideal for high-density, automated assembly in modern electronics like wearables and IoT devices.

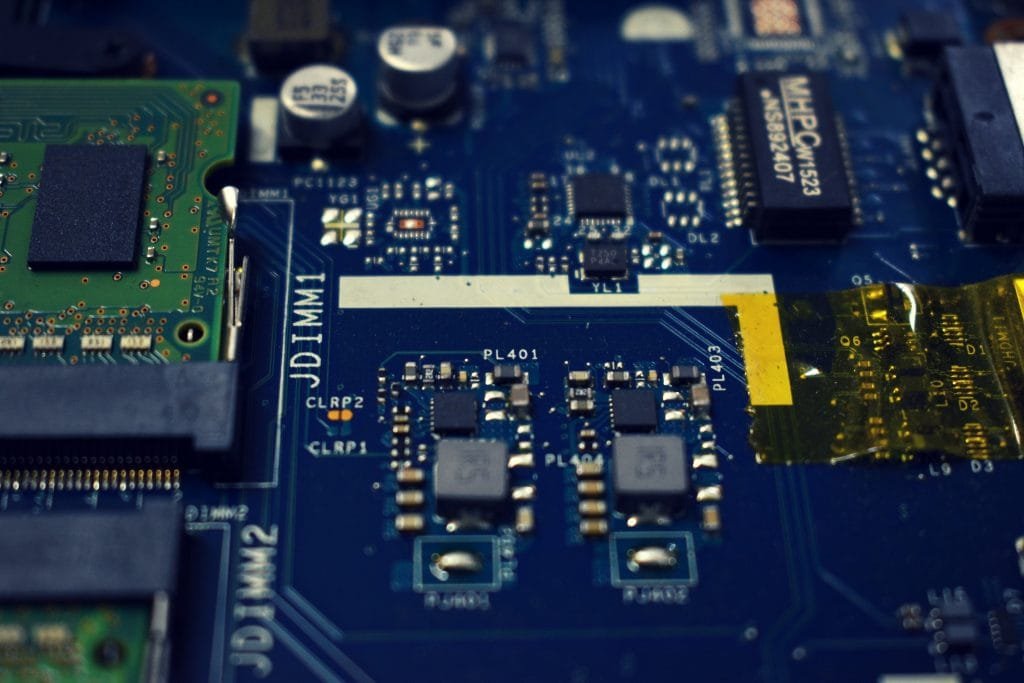

- Thru-Hole Technology (THT): Suited for larger components like capacitors or coils, THT involves inserting leads through PCB holes and soldering them on the opposite side, ensuring durability for high-stress applications like automotive electronics.

The 8-Step PCB Prototype Assembly Process

1. Confirming the PCB Assembly Contract

The PCB prototype assembly journey begins with a detailed contract. You provide critical files—Gerber files, Bill of Materials (BOM), centroid data, and assembly drawings—to outline your project requirements. Clear communication ensures the final PCBA aligns with your vision. At JHYPCB, we discuss delivery timelines and pricing transparently, tailoring solutions to your needs.

Pro Tip: Include detailed notes in your BOM to avoid misinterpretation. For example, specifying component tolerances can prevent sourcing delays.

2. Design for Manufacturability (DFM) Inspection

Before production, our engineers conduct a DFM inspection to catch design issues, such as incorrect component footprints or unmanufacturable layouts. For instance, a misplaced via can cause short circuits, leading to costly rework. We analyze your files and collaborate with you to refine the design, ensuring manufacturability without compromising performance.

Case Study: A recent JHYPCB client avoided a major delay by fixing an oversized component footprint during DFM, saving weeks in production time.

3. Component Procurement

High-quality components are the backbone of PCBA prototyping. Using your BOM, we source parts from trusted global vendors. If a component is unavailable due to supply chain constraints, we propose alternatives after your approval, ensuring compatibility and reliability.

JHYPCB Advantage: Our extensive supplier network enables fast, cost-effective procurement, even for hard-to-find components like 01005 packages.

4. Incoming Material Inspection

Every component undergoes rigorous inspection to verify quality, specifications, and compliance. This step eliminates defective parts, ensuring your PCB assembly performs as expected. At JHYPCB, we use advanced tools to check for counterfeit or substandard components, safeguarding your project’s success.

Why It Matters: A single faulty resistor can cause circuit failure, impacting reliability and performance.

5. PCB Assembly Production

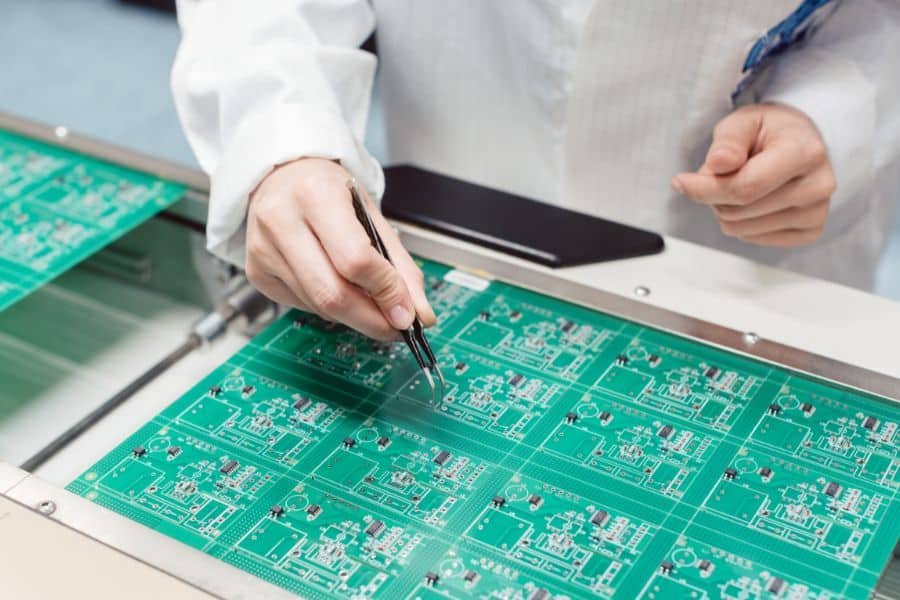

Production transforms your design into a functional PCBA:

- PCB Fabrication: The bare board is manufactured based on your Gerber files.

- Solder Paste Application: A stencil applies solder paste to precise locations.

- Component Placement: Automated pick-and-place machines position components with pinpoint accuracy, supporting ultra-small packages like 01005.

- Reflow Soldering: The board passes through a reflow oven, bonding components securely.

- THT Assembly (if applicable): Larger components are inserted and soldered manually or via wave soldering for robust connections.

Trend Insight: The rise of 5G and IoT has boosted demand for SMT assembly, enabling compact, high-performance designs.

6. PCBA Inspection

Quality assurance is critical. We employ multiple inspection methods:

- Manual Inspection: Detects visible defects like misaligned components.

- Automated Optical Inspection (AOI): Identifies soldering issues or placement errors.

- X-Ray Inspection: Reveals hidden defects, such as solder joint voids.

Case Study: For a medical device project, JHYPCB’s AOI caught a solder bridge, preventing a potential field failure.

7. PCBA Testing

Testing ensures your PCBA meets performance expectations. We conduct:

- Flying Probe Test: Verifies electrical connectivity for prototypes.

- In-Circuit Test (ICT): Checks for shorts, opens, and component functionality (ideal for complex boards).

- Functional Test: Simulates real-world conditions to confirm performance.

- Reliability Test: Assesses durability under stress, such as temperature cycling.

Pro Tip: Specify test protocols in your contract to align with project requirements, such as functional testing for IoT applications.

8. Packaging and After-Sales Support

Proper packaging protects your PCBA during shipping, using anti-static materials to prevent damage from moisture or electrostatic discharge. At JHYPCB, our commitment extends beyond delivery. Our after-sales team provides ongoing support, from troubleshooting to reordering components, ensuring your project succeeds.

JHYPCB Advantage: Our dedicated support team is available 24/7 to address any post-delivery issues.

How to Reduce PCB Prototype Assembly Costs

Cost optimization is a top priority for PCBA prototyping. Here are practical strategies:

- Simplify Design: Reduce PCB layers or use standard sizes to lower fabrication costs.

- Choose Standard Components: Opt for widely available parts to avoid premium pricing.

- Plan for Scale: Order prototypes in small batches to secure bulk discounts on components.

- Leverage DFM: Early design reviews can eliminate costly rework, such as fixing incorrect footprints.

At JHYPCB, we provide cost-effective PCB assembly services, balancing quality and affordability. For example, we helped a startup reduce costs by 20% by optimizing their PCB layout during DFM.

PCB Prototype Assembly in Key Industries

PCB prototype assembly serves diverse industries, each with unique requirements:

- Medical Devices: Precision is critical for devices like pacemakers. JHYPCB’s SMT assembly supports high-density designs for compact medical electronics.

- Automotive: THT ensures durability for components exposed to vibration, such as engine control units.

- IoT: Lightweight, small-footprint PCBs enable innovative wearables and smart devices.

Case Study: JHYPCB delivered a high-density PCBA for an IoT sensor, meeting strict size and power constraints within a 5-day turnaround.

Common Challenges and Solutions

- Design Errors: Collaborate during DFM to catch issues like incorrect via placement.

- Component Shortages: Maintain an updated BOM and approve alternative parts early.

- Testing Gaps: Specify comprehensive test protocols, such as functional testing for specific applications.

- Delayed Delivery: Partner with a supplier like JHYPCB, known for fast PCB assembly services in China.

How to Choose the Right PCBA Supplier

Selecting the right supplier for PCB prototype assembly can make or break your project. Here’s how to choose a reliable PCBA supplier:

- Evaluate Technical Expertise: Ensure the supplier supports both SMT and THT and can handle complex designs, like 01005 components.

- Check Quality Certifications: Look for ISO 9001 or IPC standards compliance to guarantee consistent quality.

- Assess Turnaround Time: Fast delivery is critical for prototyping. JHYPCB offers prototypes in as little as 3-5 days.

- Verify Supply Chain Strength: A robust global network ensures component availability, even during shortages.

- Prioritize Communication: Choose a supplier with responsive support. JHYPCB’s 24/7 team ensures seamless collaboration.

- Review Case Studies: Check the supplier’s track record in your industry, such as medical or automotive applications.

- Compare Costs: Balance affordability with quality. JHYPCB provides transparent pricing and cost-saving DFM insights.

JHYPCB Advantage: As a leading provider of ** PCB assembly services in China**, we combine advanced technology, rigorous quality control, and dedicated support to deliver exceptional results.

Why Choose JHYPCB for PCB Assembly Services?

JHYPCB stands out as a leader in PCB prototype assembly:

- Advanced Technology: Expertise in SMT and THT for diverse applications.

- Fast Turnaround: Prototypes delivered in as little as 3-5 days.

- Rigorous Quality Control: Comprehensive inspections and testing ensure reliability.

- Global Reach: Trusted PCB assembly services in China, with a worldwide supplier network.

Ready to kickstart your PCB prototype assembly project? Contact JHYPCB for a free quote.

FAQs

What is the difference between SMT and THT?

SMT assembly is ideal for compact, automated designs, while THT assembly suits larger, durable components for high-stress applications.

How long does PCB prototype assembly take?

Turnaround varies by complexity, but JHYPCB delivers standard prototypes in 3-5 days, thanks to our efficient PCB assembly services.

How can I reduce PCB prototype assembly costs?

Simplify designs, use standard components, and leverage DFM to minimize rework. JHYPCB offers cost-effective solutions tailored to your needs.

What files are needed for PCB prototype assembly?

You’ll need Gerber files, BOM, centroid data, and assembly drawings to ensure accurate production.

How do I choose a PCB assembly supplier?

Look for technical expertise, quality certifications, fast turnaround, and strong communication. JHYPCB excels in all areas, making us a top choice for PCB assembly services in China.

What are common mistakes in PCB assembly?

Incomplete BOMs, incorrect footprints, or skipping DFM checks can lead to delays. Partner with JHYPCB to avoid these pitfalls.

Related Reading

- Electronic PCB Assembly Process and Flow Chart

- How to Select the Right Low-volume PCB Assembly Manufacturer?

- Materials Used in Surface Mount Technology

- Selective Wave Soldering Guidelines

- 5 kinds of circuit board assembly welding production process

- SMT PCB Assembly Manufacturing Process Introduces

- The Two Typical SMT Reflow Soldering Temperature Curve Modes

- How to Solder On Flex PCB?

- One-Stop Solution: The Advantages of Turnkey PCB Manufacturing and Assembly