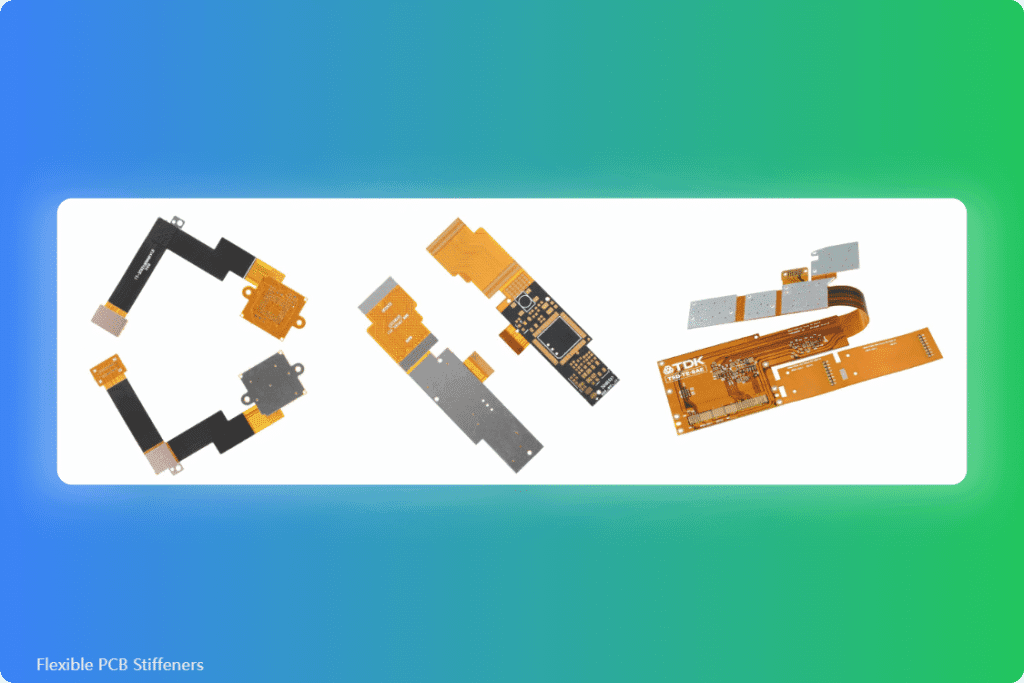

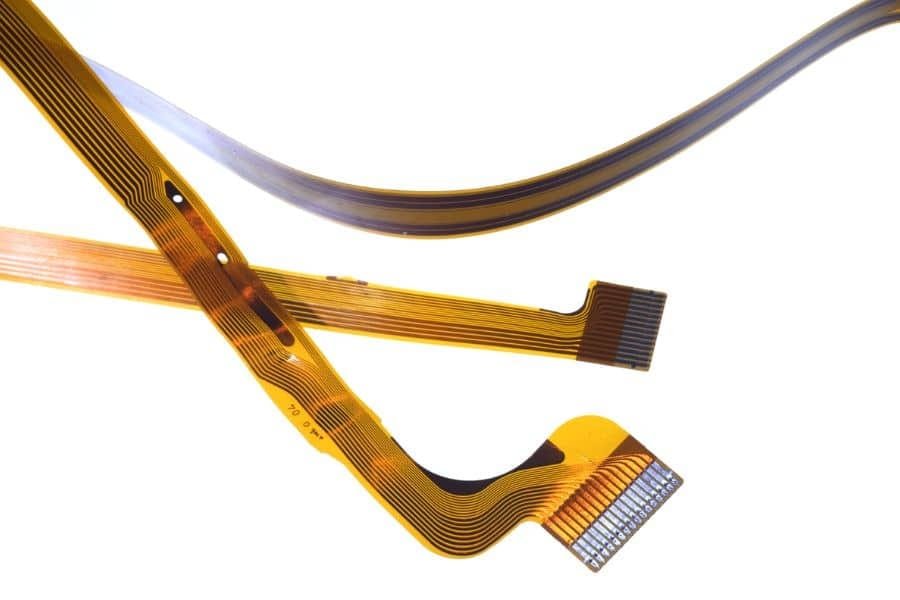

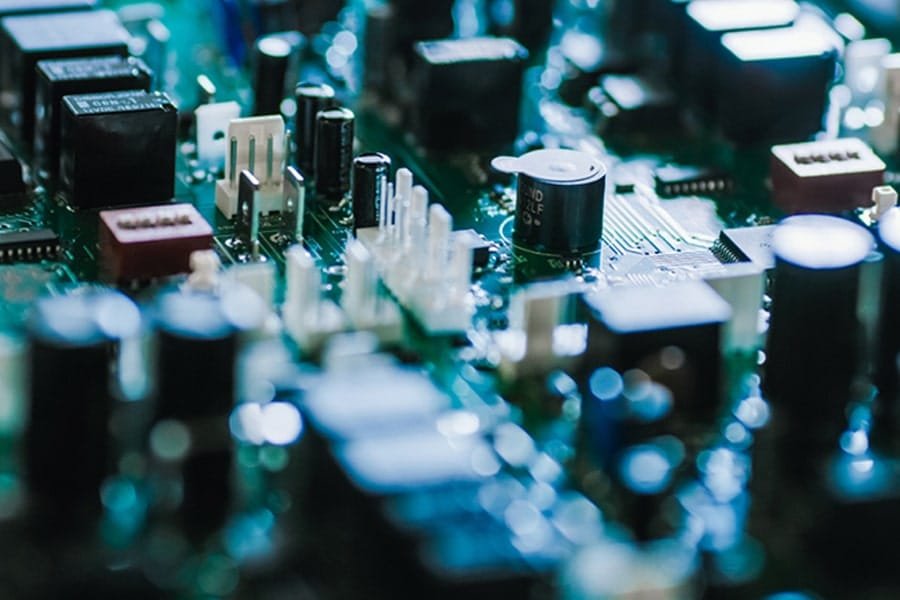

Flexible PCB Stiffeners Guide: Benefits & Uses

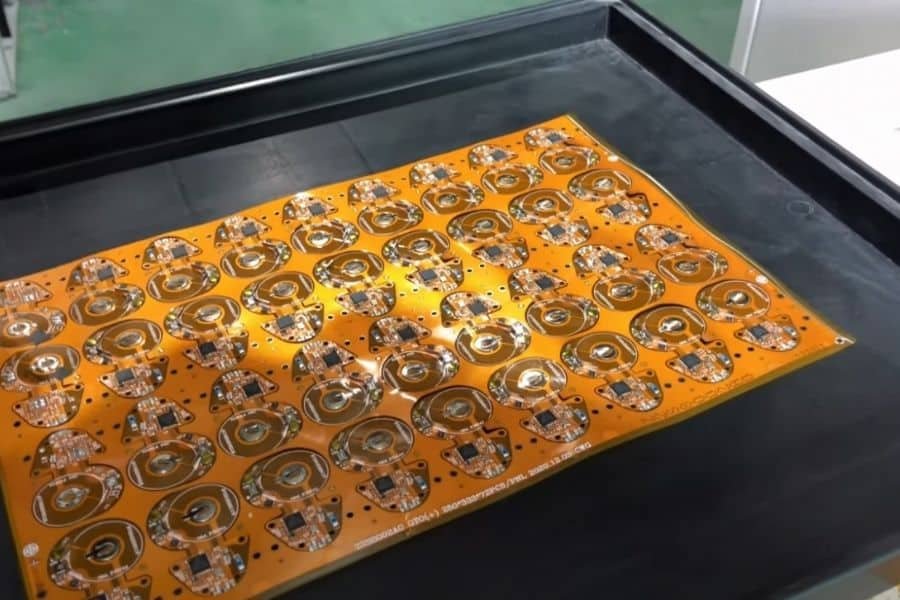

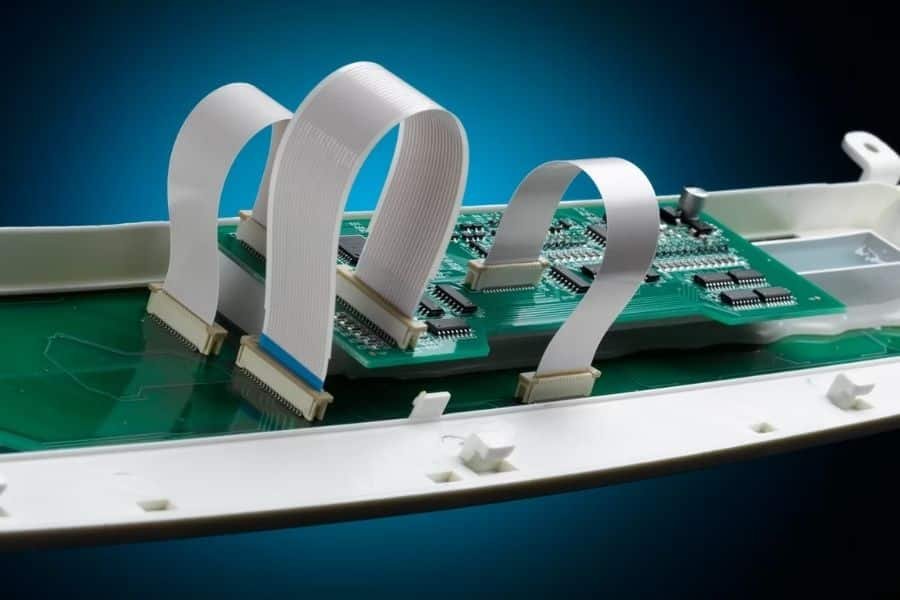

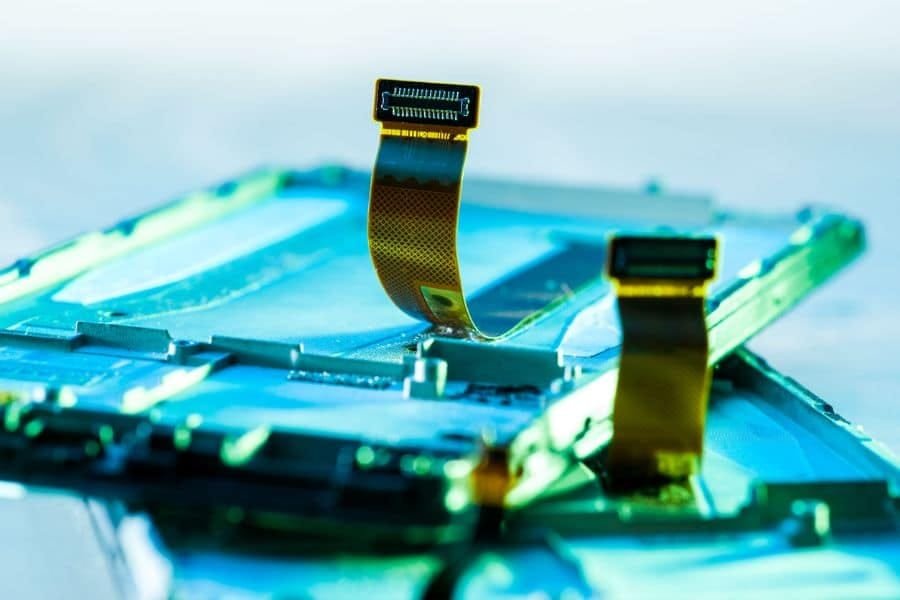

Flexible PCB stiffeners enhance durability and performance in modern electronics. This guide from JHYPCB explores their benefits, materials like FR4 and polyimide, and applications in 5G, medical, and aerospace designs. Learn how to choose the right stiffener thickness, avoid common mistakes, and optimize your flexible PCB with expert insights. Discover more today!