Understanding PCB Assembly Quotes and Orders

Getting a quote and placing an order for PCB assembly can be a complex process involving determining your requirements, obtaining quotes, selecting a supplier, and finalizing the order. This article provides step-by-step guidance to streamline getting quotes and ordering PCB assembly.

We will cover key steps like:

- Clarifying your PCB assembly requirements

- Preparing needed Gerber files and specifications

- Requesting quotes from assembly service providers

- Comparing pricing structures across quotes

- Choosing a reliable supplier

- Confirming order details like payment terms and delivery logistics

Following these critical steps will allow you to get the best PCB assembly quote and pick the optimal service provider to deliver your assembled PCBs. Understanding the quote and order process upfront is essential for a smooth PCB assembly experience.

Table of Contents

Understanding PCB Assembly Quotes

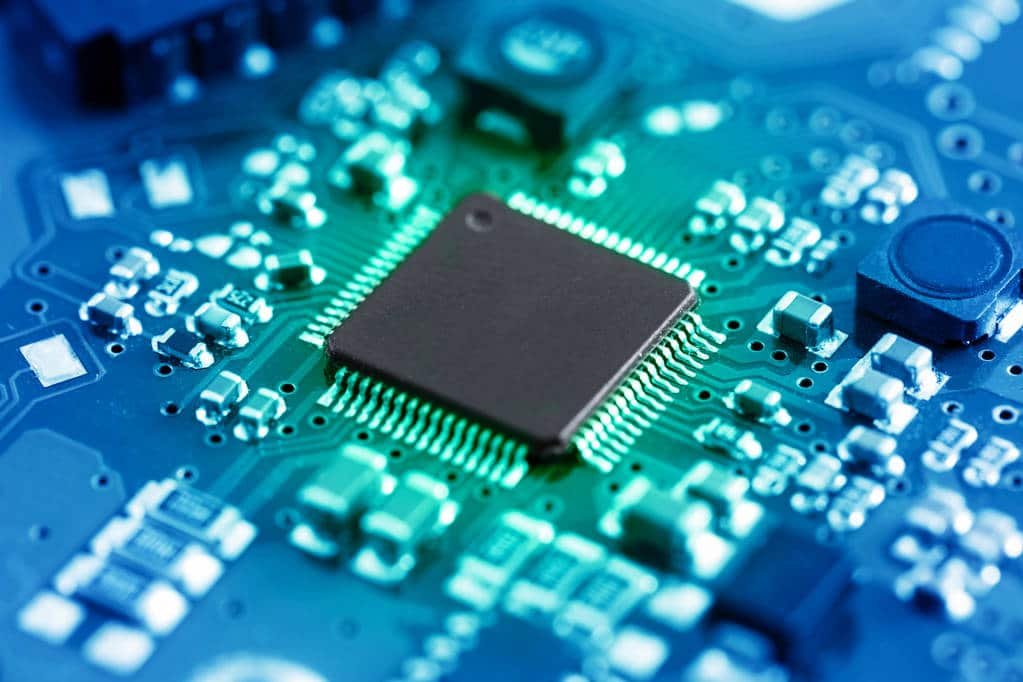

Understanding PCB Assembly quotes is a crucial step in the process of getting your printed circuit board assembled. A PCB Assembly quote is a document that outlines the cost of assembling your PCB, including the cost of labor, components, and any other additional services that may be required.

To understand the quote, it is essential to know the different components that make it up. Typically, a PCB Assembly quote consists of the following:

- Bill of Materials (BOM) – This includes a list of all the components required to assemble your PCB.

- Gerber Files – These files contain your PCB’s design specifications, including the components’ location, routing information, and other necessary details.

- Manufacturing Specifications – This includes information about the manufacturing process, such as the type of soldering used, the number of layers required, and the overall size and shape of the PCB.

- Cost Breakdown – This is a breakdown of all the components and services required for the PCB Assembly.

Getting a PCB Assembly quote can be done by contacting PCB Assembly service providers and providing them with your BOM and Gerber Files. It is important to note that different providers may have different pricing structures, and it is recommended to get quotes from multiple providers to compare prices and services offered.

Ordering PCB Assembly

Ordering PCB Assembly involves several crucial steps to ensure your PCB is assembled correctly and meets your specific requirements. Here are the steps to follow when ordering PCB Assembly:

- Determine your requirements: Before ordering PCB Assembly, you need to determine your requirements, including the number of boards needed, the type of components required, the delivery time, and any other specific requirements you may have.

- Get a quote: Once you have determined your requirements, you can request a PCB Assembly quote from your chosen service provider. As discussed earlier, the quote should include a breakdown of the cost of labor, components, and other services required.

- Review the quote: Review the PCB Assembly quote to ensure it meets your specific requirements and budget. If necessary, you can request changes or clarification from the service provider.

- Place the order: If you are satisfied with the quote, you can order with the service provider. Ensure you provide all the necessary information, including your BOM, Gerber Files, and any other required specifications.

- Payment: PCB Assembly service providers typically require payment upfront before commencing the assembly process. Make sure you understand the payment terms and conditions and arrange payment accordingly.

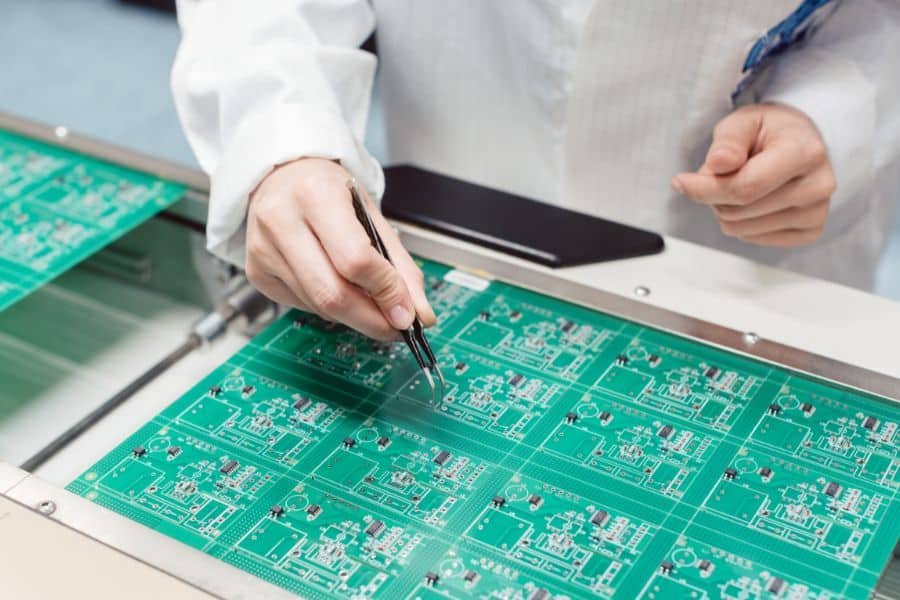

- Quality control: Once the PCB Assembly is complete, it is essential to conduct quality control to ensure that the PCB meets your requirements and specifications. This involves checking for defects, ensuring that all components are correctly installed, and conducting necessary testing.

- Delivery: The service provider will deliver the assembled PCB to your preferred location once the quality control is complete.

Factors to consider before ordering PCB Assembly

Before ordering PCB Assembly, there are several important factors that you should consider to ensure that the process runs smoothly and that the final product meets your requirements. Here are some of the critical factors to keep in mind:

- The complexity of the design: The complexity of your PCB design can significantly impact the cost and timeline of the assembly process. More complex designs may require specialized equipment or techniques, increasing the cost and the time needed for assembly.

- Components availability: It is essential to ensure all the required components are available and can be easily sourced. If any components are out of stock or have a long lead time, this can delay the assembly process.

- Assembly requirements: Different PCB Assembly service providers may have different assembly requirements. It is important to ensure that the chosen provider can accommodate your requirements, such as soldering techniques, inspection methods, or testing requirements.

- Volume of the order: The volume of the order can significantly impact the cost and timeline of the assembly process. Larger volumes may require longer lead times and additional testing and quality control procedures.

- Budget: It is important to consider your budget when ordering PCB Assembly. Different providers may offer different pricing structures, and obtaining quotes from multiple providers is important to ensure that you get the best value for your budget.

- Service provider reputation: Choosing a reputable PCB Assembly service provider is essential. Look for providers with a track record of delivering high-quality products, excellent customer service, and timely delivery.

- Confirm delivery time: Confirm the delivery time of your PCB Assembly order with your provider. Ensure the delivery time aligns with your requirements and any potential delays or issues are addressed before finalizing the quote.

Tips for a Successful PCB Assembly Order

Ordering PCB Assembly can be a complex process, and there are several tips that you can follow to ensure a successful outcome. Here are some key tips to keep in mind:

- Communication with PCB Assembly provider: Effective communication with your PCB Assembly provider is crucial to ensure your requirements are met and any issues are addressed promptly. It is important to provide clear and detailed instructions, ask questions if anything is unclear, and respond promptly to requests for information or feedback.

- Reviewing the design before ordering: Before placing your PCB Assembly order, it is essential to review your design thoroughly. This can help identify any potential issues or areas requiring additional attention during the assembly process. Make sure to review your design carefully, and if possible, have a second set of eyes review it as well.

- Quality control during PCB Assembly: Quality control is essential in ensuring that your PCB is assembled correctly and meets your requirements. You should work with your PCB Assembly provider to develop a quality control plan, including regular inspections, testing, and other necessary procedures. Be sure to communicate your quality control requirements clearly to your provider.

- Testing and validation: Once the PCB Assembly is complete, it is important to conduct thorough testing and validation to ensure that it meets your requirements. This can include functional testing, environmental testing, and any other specific testing requirements that you may have. Work with your PCB Assembly provider to develop a testing plan that covers all necessary aspects of the assembly.

- Flexibility: It is essential to remain flexible throughout the PCB Assembly process. Issues may arise, and changes may be required, so it is important to be open to discussing and implementing changes as needed to ensure a successful outcome.

Following these tips can increase the likelihood of a successful PCB Assembly order. Effective communication with your provider, reviewing the design before ordering, quality control during assembly, testing, and validation, and remaining flexible are all key factors in achieving a successful outcome.

Conclusion

In summary, ordering PCB Assembly can be a complex process, but following some key steps can ensure a successful outcome. Before ordering PCB Assembly, it is important to consider your design requirements, the components required, delivery time, and quality control procedures. Effective communication with your PCB Assembly provider is crucial, as is reviewing your design before ordering and conducting thorough testing and validation. When finalizing your PCB Assembly quote, review the quote carefully, confirm component availability and delivery time, negotiate pricing if necessary, and confirm payment terms. By following these tips, you can increase the likelihood of a successful PCB Assembly order that meets your requirements and expectations.

JHYPCB is a professional and reliable turnkey PCB assembly service provider. Our experienced team is dedicated to providing high-quality and reliable PCB assembly services to meet your unique requirements. We use state-of-the-art technology and follow rigorous quality control procedures to ensure that your PCB assembly is completed to your satisfaction. Contact us today to learn more about our services and how we can help bring your PCB assembly project to life. Let JHYPCB be your partner in success.