Table of Contents

Introduction

Selecting the right PCB material is crucial for ensuring your prototype delivers optimal performance, durability, and cost-efficiency. With materials like FR-4, metal core PCBs, Rogers PCBs, polyimide, and ceramic PCBs available, understanding their properties empowers you to make informed decisions. This comprehensive guide explores the advantages, disadvantages, and ideal applications of these materials, providing insights to streamline your PCB prototyping process. Whether designing for high-frequency, high-power, flexible, or extreme environments, JHYPCB offers expert solutions to bring your vision to life.

Why PCB Material Selection Matters

The choice of PCB material significantly impacts your prototype’s performance, reliability, and cost. Key factors such as electrical properties, thermal management, flexibility, and budget constraints must be considered. By choosing the right material, you can:

- Enhance electrical performance for high-frequency applications.

- Improve heat dissipation for high-power designs.

- Ensure flexibility for compact or wearable devices.

- Guarantee reliability in extreme environments.

- Optimize costs without sacrificing quality.

At JHYPCB, we guide you through material selection to meet your project’s unique requirements.

Common PCB Materials and Their Properties

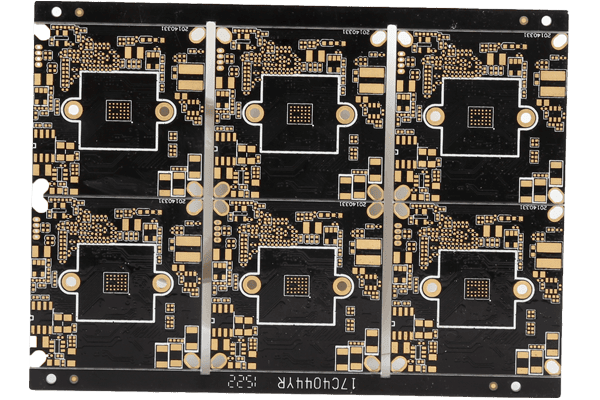

1. FR-4 PCBs

FR-4 is the most widely used PCB material due to its affordability and versatility. Composed of woven fiberglass with an epoxy resin binder, it offers a strong balance of electrical insulation and mechanical strength.

Advantages:

- Cost-effective: Ideal for budget-conscious projects.

- Good electrical insulation: Suitable for standard electronic applications.

- Mechanical strength: Durable for rigid PCB designs.

- Widely available: Supported by most PCB manufacturers, including JHYPCB’s prototyping services.

Disadvantages:

- Limited flexibility: Unsuitable for flexible or rigid-flex PCBs.

- Poor heat dissipation: Less effective for high-power applications requiring thermal management.

Market Insights:

According to a MarketsandMarkets report, the global FR-4 market is projected to reach USD 2.3 billion by 2025, growing at a CAGR of 6.9% from 2020 to 2025, reflecting its widespread adoption.

Best Applications:

- Consumer electronics (e.g., smartphones, laptops).

- General-purpose prototyping.

- Low-to-medium power applications.

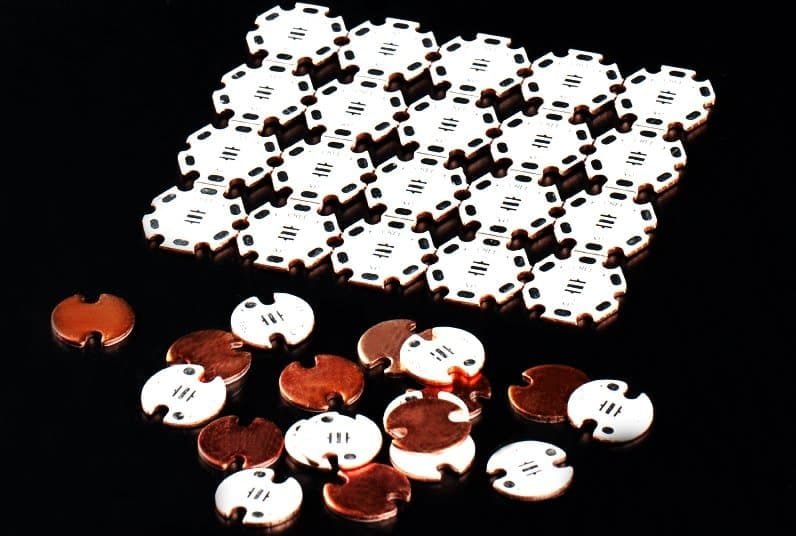

2. Metal Core PCBs (MCPCBs)

Metal core PCBs feature a metal base, typically aluminum or copper, to enhance thermal conductivity. They are designed for applications where heat dissipation is critical.

Advantages:

- Superior heat dissipation: Ideal for high-power applications.

- Durability: Resistant to thermal stress and mechanical wear.

- Compact design: Enables efficient thermal management in smaller form factors.

Disadvantages:

- Higher cost: More expensive than FR-4 due to specialized materials.

- Limited flexibility: Primarily used for rigid applications.

Market Insights:

A Grand View Research report notes that the global MCPCB market was valued at USD 1.35 billion in 2020, with a projected CAGR of 6.2% from 2021 to 2028, driven by demand in LED lighting and automotive electronics.

Best Applications:

- LED lighting systems.

- Power electronics (e.g., motor drives, inverters).

- Automotive and aerospace applications.

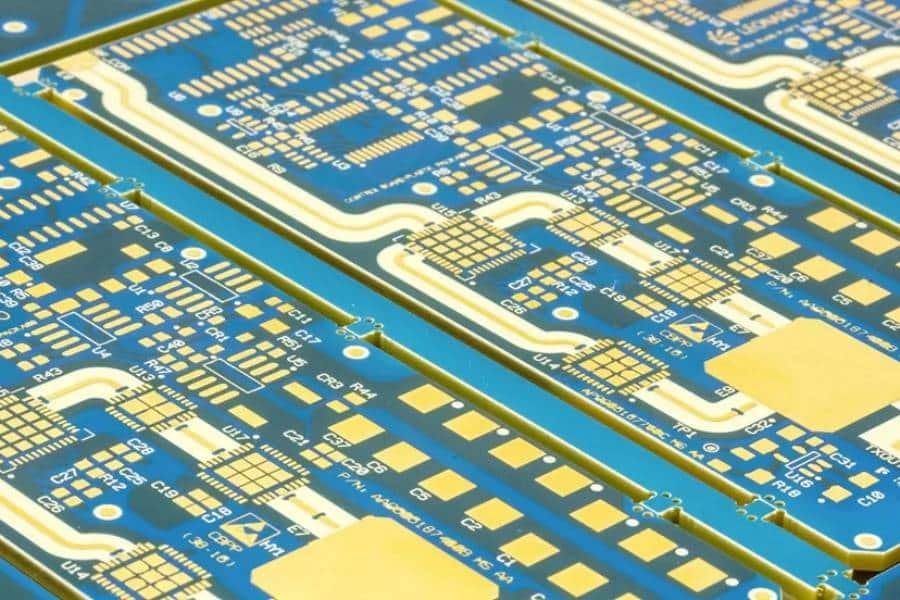

3. Rogers PCBs

Rogers PCBs are high-performance materials designed for high-frequency applications, using advanced laminates for superior electrical properties. Similar materials, like PTFE (Teflon) PCBs, also support microwave and RF applications with low dielectric loss.

Advantages:

- Excellent electrical performance: Low dielectric loss for high-frequency signals.

- Stable dielectric constant: Ensures consistent performance in RF and microwave applications.

- High-frequency support: Ideal for advanced communication systems.

Disadvantages:

- Higher cost: More expensive than FR-4 and MCPCBs.

- Complex manufacturing: Requires specialized expertise, available at JHYPCB’s advanced manufacturing services.

Market Insights:

Per a Transparency Market Research report, the global Rogers PCB market was valued at USD 1.28 billion in 2019, with an expected CAGR of 8.5% from 2020 to 2027, fueled by demand in telecommunications and aerospace.

Best Applications:

- RF and microwave circuits.

- 5G and wireless communication systems.

- Aerospace and defense electronics.

4. Polyimide PCBs

Polyimide PCBs are flexible materials known for their high thermal stability and flexibility, making them ideal for flexible and rigid-flex PCB designs.

Advantages:

High flexibility: Perfect for compact and wearable devices.

Excellent thermal stability: Withstands temperatures up to 260°C.

Lightweight and thin: Ideal for space-constrained designs.

Disadvantages:

Higher cost: More expensive than FR-4.

Complex manufacturing: Supported by JHYPCB’s flexible PCB services.

Market Insights:

The global flexible PCB market was valued at USD 3.1 billion in 2022, with a projected CAGR of 10.6% from 2023 to 2030, per Grand View Research, driven by demand in wearables and aerospace.

Best Applications:

Wearable electronics (e.g., smartwatches, fitness trackers).

Aerospace and military systems.

Flexible displays and medical sensors.

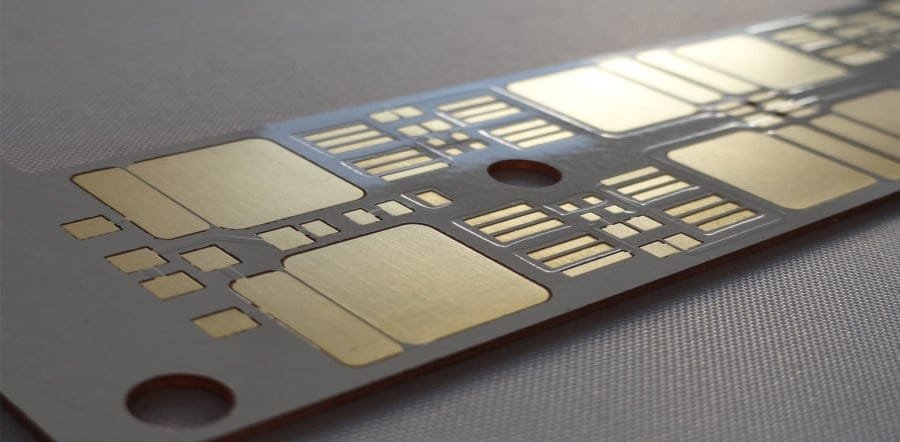

5. Ceramic PCBs

Ceramic PCBs use substrates like alumina or aluminum nitride, offering superior thermal conductivity and electrical insulation for high-reliability applications.

Advantages:

Excellent thermal conductivity: Ideal for heat-intensive designs.

High electrical insulation: Suitable for high-voltage applications.

Reliable in extreme environments: Performs well under harsh conditions.

Disadvantages:

High cost: More expensive than other materials.

Brittle: Limited mechanical flexibility.

Market Insights:

The ceramic PCB market is expected to grow at a CAGR of 6.8% from 2023 to 2030, per IndustryARC, driven by automotive and aerospace demand.

Best Applications:

High-power RF modules.

Aerospace and defense electronics.

Medical imaging equipment.

How to Choose the Right PCB Material

Selecting the right PCB material depends on your project’s specific requirements. Consider these factors:

- Application Type:

- High-frequency designs: Opt for Rogers or PTFE PCBs.

- High-power applications: Choose metal core or ceramic PCBs.

- Flexible designs: Select polyimide PCBs.

- General-purpose or budget-conscious projects: Use FR-4.

- Thermal Requirements:

- For heat-intensive applications, prioritize MCPCBs or ceramic PCBs for superior thermal conductivity.

- For standard applications, FR-4 may suffice.

- Flexibility Needs:

- Flexible or rigid-flex PCBs require polyimide materials, supported by JHYPCB’s flexible PCB services.

- Rigid applications can use FR-4, MCPCBs, or ceramic PCBs.

- Budget Constraints:

- FR-4 is the most cost-effective, while Rogers, polyimide, and ceramic PCBs are pricier but offer specialized performance.

- Balance cost and performance based on project goals.

- Manufacturing Capabilities:

- Ensure your PCB manufacturer supports your chosen material. JHYPCB offers expertise in FR-4, MCPCBs, Rogers, polyimide, ceramic PCBs, and more.

Ready to start your PCB prototype? Contact JHYPCB for a free quote tailored to your material needs!

FAQs About PCB Material Selection

What is the most cost-effective PCB material?

FR-4 is the most cost-effective due to its affordability, availability, and versatility for general-purpose applications.

When should I use a metal core PCB?

Use metal core PCBs for high-power applications like LED lighting or automotive electronics where heat dissipation is critical.

Are Rogers PCBs worth the cost?

Rogers PCBs are ideal for high-frequency applications like RF and 5G systems, offering superior electrical performance that justifies their cost.

What are polyimide PCBs used for?

Polyimide PCBs are used in flexible applications, such as wearable electronics, aerospace systems, and medical sensors, due to their flexibility and thermal stability.

When should I choose a ceramic PCB?

Choose ceramic PCBs for high-thermal, high-voltage, or extreme-environment applications, such as aerospace, defense, or medical imaging.

Can I use FR-4 for flexible PCBs?

No, FR-4 is rigid and unsuitable for flexible PCBs. Consider polyimide-based materials for flexibility.

How do I choose a PCB manufacturer?

Select a manufacturer like JHYPCB with expertise in your chosen material, fast turnaround, and reliable support.

Conclusion

Choosing the right PCB material is pivotal to your prototype’s success. FR-4 offers affordability for standard applications, metal core PCBs excel in heat dissipation for high-power designs, Rogers PCBs provide unmatched performance for high-frequency projects, polyimide PCBs enable flexibility for wearables and compact devices, and ceramic PCBs ensure reliability in extreme environments. By evaluating your project’s requirements—application type, thermal needs, flexibility, and budget—you can make an informed decision.

At JHYPCB, we’re committed to helping you select the best material and deliver high-quality PCB prototypes. Get started today with our expert prototyping services and bring your ideas to life!

Need help choosing the right PCB material? Request a consultation with JHYPCB or explore our PCB manufacturing services for tailored solutions.

Related Posts

- A Comprehensive Comparison: Aluminum and FR4 PCBs

- Custom PCB Fabrication in China – Prototyping & Mass Production

- Worry-Free Custom PCB Manufacturing – JHYPCB, The Preferred Choice for American Customers

- Expedited PCB Services – Quick Turnaround for Your Urgent Needs

- Rapid PCB Prototyping and Production – The Keys to Accelerating Your Product Launch

- JHYPCB: The Best Prototype PCB Manufacturer for Your Needs

- Aluminum PCB Prototype: The Ultimate Guide for Engineers and Designers

- Shenzhen – The Global Hub for High-Quality PCB Assembly Manufacturing

- What Is Rogers Material PCB?

- Why is FR4 Used to Make High Tg PCBs?

- Why choose FR4 as the general material of PCB?

- Choosing the Right Metal Core PCB Manufacturer is Critical to Your Success