Table of Contents

Introduction to Dust Control in SMT Production Lines

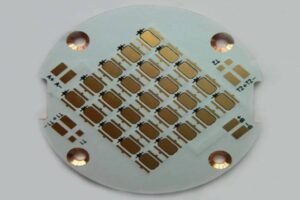

Surface Mount Technology (SMT) production lines are critical for manufacturing high-quality printed circuit board assemblies (PCBAs). However, environmental dust and contaminants like cotton wool, fibers, hair, dandruff, and paper scraps can significantly impact the quality of SMT processes. Unlike the common focus on tiny particles (0.3–0.5 µm), larger contaminants pose a greater threat to solder paste printing, reflow soldering, and component placement. This article explores why dust control is essential, its effects on SMT production, and practical steps to maintain a clean production environment.

Why Dust Control Matters in SMT Manufacturing

Customers demand strict environmental controls in SMT production to ensure consistent quality and reliability. Contaminants can cause defects that compromise the performance of electronic components, especially in fine-pitch or Ball Grid Array (BGA) soldering. Effective dust management not only improves product quality but also extends the lifespan of precision equipment used in SMT lines.

How Dust Affects SMT Production Quality

Dust and contaminants can disrupt various stages of the SMT process, leading to defects and long-term reliability issues. Below are the key impacts:

- Solder Paste Printing Issues: Contaminants on PCB stencils can block apertures, reducing solder paste application and causing insufficient solder joints (lack of tin).

- Reflow Soldering Defects: Dust on PCB panels may lift the stencil, leading to excessive solder paste or creating solder voids, black spots, or poor tin adhesion during reflow. These issues can affect product reliability.

- Short Circuits from Glass Fibers: Glass fibers from PCBs, especially during cutting, can settle between pads, potentially causing solder bridges or creating pathways for electromigration over time.

- Tombstone Effect in Small Components: Contaminants on small chips (e.g., resistors, capacitors, inductors) can exacerbate uneven tensile stress in molten solder, leading to tombstoning.

- Equipment Performance: Dust accumulation on pick-and-place machine nozzles can cause material misplacement or throwing, reducing accuracy. Excessive dust on precision instruments, such as those driven by bearing screws, may also degrade performance and longevity.

While larger solder joints may tolerate some contamination, fine-pitch components, BGAs, or micro-components like 0201 and 01005 are highly sensitive, making dust control critical.

Best Practices for Controlling Dust in SMT Production Lines

To mitigate the risks of dust-related defects, SMT production lines should adopt the following disciplines, aligned with 5S principles (Sort, Set in order, Shine, Standardize, Sustain):

- Avoid Carton Unpacking Near SMT Lines: Carton packaging is a major source of dust and fibers. Prohibit opening cartons in or near the production area. Ideally, separate carton unpacking from the SMT line to minimize contamination.

- Use Anti-Static and Dust-Free Clothing: Operators and engineers should wear anti-static clothing and dust-free caps to prevent cotton batts, fibers, or hair from contaminating the production environment.

- Minimize Glass Fiber Contamination: PCBs contain glass fibers that can disperse during cutting. Perform PCBA cutting away from the SMT line to avoid spreading glass fiber dust and fillers.

- Implement Dust Removal Systems: Use sticky dust pads and door blower devices to reduce external dust brought into the production area.

These measures require minimal investment and can be integrated into routine 5S and discipline management practices.

Dust Control Standards for SMT Production

While SMT production lines don’t typically require cleanroom-level cleanliness, they should aim for a “clean room-like” environment. Focus on controlling falling dust particles larger than 10 µm (e.g., hair is 30–50 µm). As production scales to smaller components like 0201 or 01005, stricter dust control (targeting smaller particles) becomes necessary.

To measure effectiveness, adopt quantifiable industrial standards for dust fall. Regularly assess and tighten specifications based on production needs and capacity. Tools like Solder Paste Inspection (SPI) may not always detect contaminants, so proactive environmental controls are essential.

Conclusion

Controlling dust in SMT production lines is vital for ensuring high-quality PCBAs, especially as components become smaller and more complex. By implementing simple yet effective measures—such as separating carton unpacking, using dust-free clothing, and maintaining 5S discipline—manufacturers can reduce defects, improve reliability, and extend equipment lifespan. For advanced SMT lines producing fine-pitch or micro-components, stricter dust control standards are recommended to meet evolving industry demands.

For more insights on optimizing SMT production, explore our PCBA Insights Blog or contact us for expert guidance on PCB assembly solutions.